Pipe ea tšepe e se nang seam isphaephe ea tšepe e entsoeng ka tšepe e chitja e nang le liphahlo tse se nang moroko o cheselitsoeng holim'a metsi.

Karolelano: Ho ea ka sebōpeho sa karolo, pipe ea tšepe e se nang seamless e arotsoe ka mefuta e 'meli: e pota-potileng le e bōpehileng.

Lerako la botenya ba lebotabophahamo: 0.25-200 limilimithara.

Sebaka sa bopharabophahamo: 4-900 limilimithara.

Mokhoa oa tlhahiso: Tlhahiso ea phala ea tšepe e se nang seamed haholo-holo e amohela mokhoa oa ho taka o chesang kapa o batang.

Melemo: matla a khatello a betere, sebopeho se ts'oanang, matla a phahameng, le ho pota-pota ho molemo.

Mefokolo: litšenyehelo tse phahameng le likhetho tsa boholo bo fokolang

Lisebelisoa: Haholo-holo e sebelisoa e le peipi ea ho cheka petroleum geological, petrochemical cracking pipe, boiler pipe, bearing pipe, hammoho le peipi ea tšepe e nepahetseng haholo bakeng sa koloi, terekere le lifofane.

Likonopo tsa ho Tsamaisa

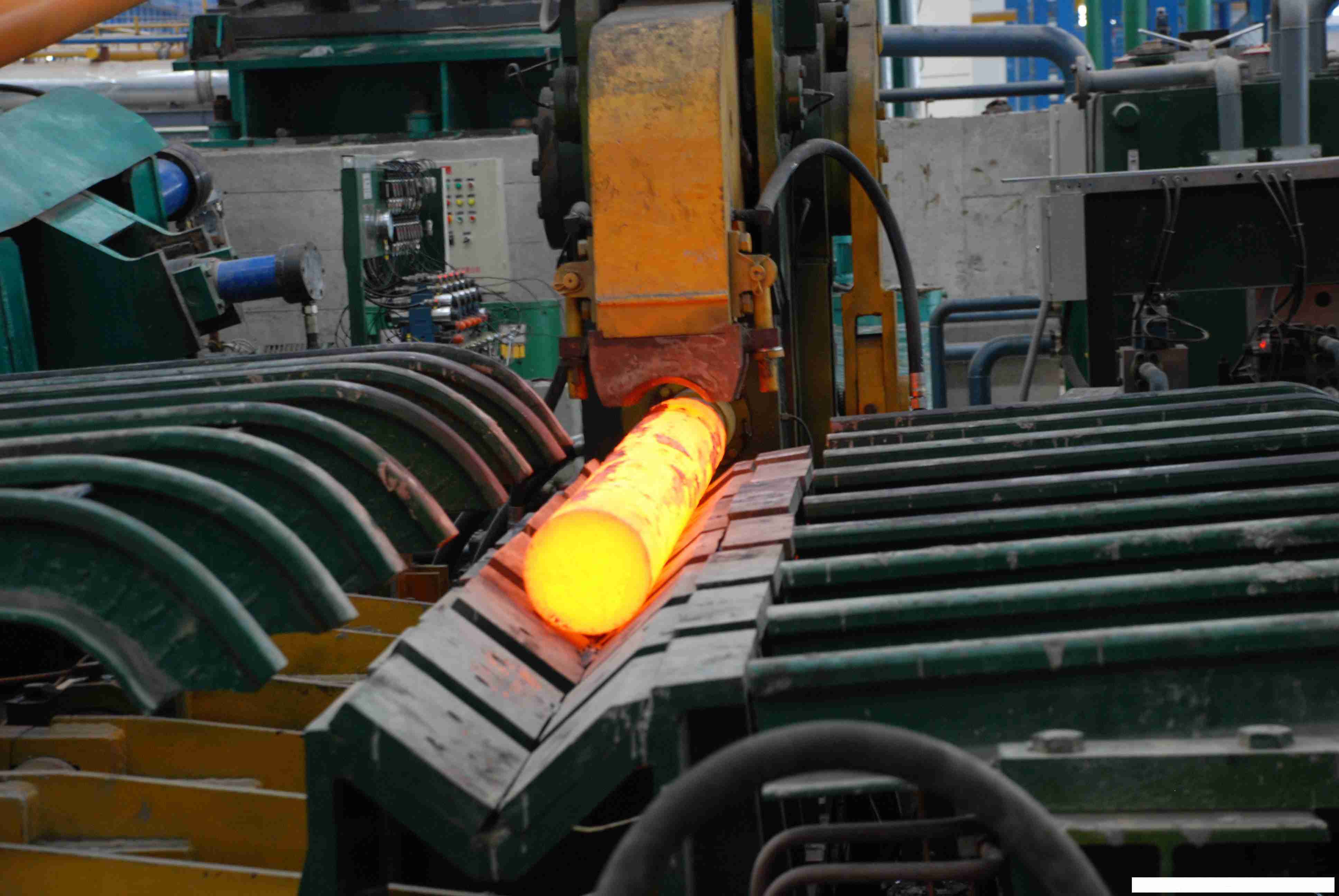

ts'ebetso ea tlhahiso ea mocheso o chesang

Tokiso ea thepa e tala→ Ho futhumatsa → Ho hloekisoa → Ho thetheha → Ho lelefatsa → Ho fokotsa boholo → Ho fokotsa boholo le lebota → Phekolo ea mocheso → Tokiso e otlolohileng → Ho hlahloba le ho etsa liteko → Ho Seha le ho Phetha Sehlahisoa → Kalafo e thibelang ho bola

Tokisetso ea lintho tse tala: Li-billet li hloka ho hloekisoa holimo ho tlosa li-oxide kapa litšila tse ling pele li etsoa.

Ho futhumatsa: Billet e kenngoa ka sebōping sa ho futhumatsa ho futhumatsa mocheso o loketseng, oo hangata o leng ka holimo ho 1200 ℃.

Ho phunya: Billet e futhumetseng e kenngoa mochine o phunyeletsang, o o phunyeletsang ho etsa sekoti se sekoti.

Ho thetheha: Ka mor'a ho phunya, billet e kena leloaleng le kolobisang. Billet e feta ka lipara tse ngata tsa meqolo e tsoelang pele ho fokotsa bophara ba ka ntle le ho eketsa bolelele ba billet.

Elongation: Billet e tsoela pele ho otlolloa ka mokhoa oa elongator ho fihlela litlhaloso tse nepahetseng haholoanyane.

Ho fokotsa boholo le lebota: Ho fokotsa boholo le lerako la billet ka mochine oa boholo ho finyella boholo bo khethehileng ba ho qetela le botenya ba lerako.

Phekolo ea mocheso: phala e hloka phekolo ea mocheso ho lokisa mokhatlo oa eona oa tšepe le ho ntlafatsa thepa ea mochine oa thepa, ho kenyelletsa le mekhoa ea ho tloaeleha le ea annealing.

Tokiso ya ho otloloha: Pipe e lokisoa ka mochine o otlolohileng ho netefatsa ho otloloha ha phala.

Tlhahlobo le tlhahlobo: Litlhahlobo le liteko tse fapaneng li etsoa phala ea tšepe e se nang seam e phethiloeng, joalo ka hydrotest, tlhahlobo ea ultrasonic, tlhahlobo ea eddy hajoale, jj.

Ho Seha le ho Phetha Tlhahlobo ea Lihlahisoa: Seha li-tubes ka bolelele bo boletsoeng ho latela litlhoko tsa moreki 'me u etse tlhahlobo ea ho qetela ea pono le ea boholo.

Kalafo e thibelang ho bola: Haeba ho hlokahala, phala ea tšepe e se nang moroalo e tlotsoa ka oli e thibelang ho bola kapa liphekolo tse ling tse thibelang ho bola, tse kang galvanized;3LPE, FBE joalo-joalo.

Ts'ebetso ea tlhahiso ea serame

Ho lokisa peipi ea billet→Kalafo ea ho tlotsa →Ho kha le ho tlotsa→Mohaho o batang→Kalafo ea mocheso→Tokiso e otlolohileng→Ho hlahloba le ho etsa liteko→Ho Seha le ho Phetha Sehlahisoa→Kalafo e thibelang kutu

Ho lokisoa ha pipe ea billet: Khetho ea phala e loketseng e chesang e kentsoeng e se nang seamless joalo ka lisebelisoa tse tala, ke hore, pipe ea pele ea billet.

Anealing kalafo: E le ho felisa khatello ea kelello e hlahisoang nakong ea ts'ebetso e chesang ea liphaephe tsa billet, hangata liphaephe tsa billet li hloka ho kenngoa.

Pickling le Lubrication: Kamora ho kolobisoa, li-tubes li hloka ho tšeloa ho tlosa letlalo le nang le oxidized le mafome. Ka mor'a moo, ho tšeloa ntho e tlotsang holim'a tube ho fokotsa khohlano le ho roala nakong ea ho toroea ho batang.

Motsoako o batang: Pipe ea billet e behoa mochine o batang oa ho taka 'me o otlolloa ka lefu, mokhoa o fokotsang bophara ba phala hammoho le ho ntlafatsa ho qeta holimo le ho nepahala ha dimensional.

Ka mor'a moo, phekolo ea mocheso le mekhoa e meng ea tlhahiso e tšoana le ho chesa ho chesa, 'me e ke ke ea phetoa mona.

Mokhoa oa ho khetholla pakeng tsa phala ea tšepe e chesang le e batang e huloang ka seamless, u ka tsepamisa maikutlo ho lintlha tse latelang tse bonolo:

| Lenane | ho bidika ho chesang | ho tola mohatsela |

| Ponahalo | Bokaholimo bo makukuno 'me bo ka ba le letlalo le nang le oxidized le likoli tse ngata joalo ka mengoapo, li-pockmarks, le li-indentations. | Qetello e ntle ea bokaholimo, hangata e boreleli ebile e khanya ho feta peipi ea tšepe e halikiloeng |

| Bophara ba Kantle(OD) | OD≥33.9 | OD<33.9 |

| Botenya ba Lerako | 2.5-200 limilimithara | 0.25-12 limilimithara |

| Mamello | E na le botenya bo sa lekaneng ba lebota le ovalization | Botenya ba lebota bo ka ntle bo lekanang le bophara bo nang le mamello e nyane |

| Litheko | Theko e tlaase bakeng sa maemo a tšoanang | Theko e phahameng bakeng sa maemo a tšoanang |

Litekanyetso tsa ts'ebetsong ea lipeipi tsa tšepe tse se nang moeli

Melao ea Machaba

ISO 3183: Lipeipi tsa tšepe bakeng sa indasteri ea oli le khase

American Standard

ASTM A106: Seamless carbon tšepe pipe bakeng sa tšebeletso ea mocheso o phahameng

ASTM A53: Pipe ea tšepe e entsoeng ka seamless le e cheselitsoeng e ntšo le e kentsoeng ka Chelete

API 5L: Pipe ea mela bakeng sa ho tsamaisa oli, khase le metsi

API 5CT: Khase ea seliba sa oli le li-tubing

ASTM A335: Li-tubes tsa tšepe tse se nang seamless le liphaephe bakeng sa ts'ebeletso e phahameng ea mocheso

ASTM A312 : Li-tubes le liphaephe tsa tšepe tse se nang sekoli, tse cheselitsoeng le tse boima.

Melao ea Europe

EN 10210: Li-tubes le liphaephe tsa tšepe tse se nang seamless le tse cheselitsoeng bakeng sa meaho e chesang e entsoeng

TS EN 10216 Li-tubes tsa tšepe tse se nang seam le liphaephe (bakeng sa lits'ebetso tsa khatello)

TS EN 10297 Li-tubes tsa tšepe tse chitja tse se nang seam le liphaephe bakeng sa merero ea mochini le e akaretsang

DIN 2448: Litekanyo le boleng ba li-tubes tsa tšepe tse se nang moeli

DIN 17175: Li-tubes tsa tšepe tse sa keneleng mocheso

TS EN 10216-2 Li-tubes tsa tšepe tse se nang alloy le alloy (lisebelisoa tsa khatello)

TS EN 10255 Li-tubes tsa tšepe tse se nang alloy le liphaephe bakeng sa likhokahano tse cheselitsoeng le tse khoele

Melao ea Majapane

JIS G3454: Lipeipi tsa tšepe tsa carbon bakeng sa liphaephe tsa khatello

JIS G3455 : Lipeipi tsa tšepe tsa carbon bakeng sa litšebeletso tse phahameng tsa khatello

JIS G3461 : Liphaephe tsa tšepe tsa carbon bakeng sa li-boilers le li-heaters tsa mocheso

JIS G3463: Boiler le li-tubes tsa mocheso oa tšepe ea tšepe e sa hloekang

Serussia Standard

GOST 8732-78: Li-tubes le liphaephe tsa tšepe tse chesang tse sa koalehang ho latela maemo a Serussia

Melao ea Australia

AS/NZS 1163 : Tekanyetso bakeng sa Mehaho ea Mehaho ea Mehaho le Lipeipi tse koahelang liphaephe tse chitja, tse lisekoere le tse khutlonnetsepa le lihlahisoa tsa liphaephe.

AS 1074: Lipeipi tsa tšepe le lisebelisoa tsa metsi, khase le lipeipi tsa moea.

Taolo ea boleng ba phala ea tšepe e se nang moeli

1. Tlhahlobo ea Pono le Bophara: Ho hlahloba boleng ba bokaholimo, ho kenyeletsoa le likoli tse kang mapetsong, mengoapo, mafome le ho bola, le ho nepahala ha litekanyo, ho kenyeletsoa bolelele, bophara, le botenya ba lebota.

2. Tlhahlobo ea Sebopeho sa Lik'hemik'hale: Etsa bonnete ba hore lik'hemik'hale tsa tšepe tsa tšepe li finyella litlhoko tse tloaelehileng ka tlhahlobo ea spectral le mekhoa e meng.

3. Teko ea thepa ea 'mele: ho kenyelletsa matla a tsitsitseng, matla a tlhahiso, bolelele, tlhahlobo ea boima, joalo-joalo ho netefatsa thepa ea mochini.

4. Teko e sa senyeheng (NDT):

Teko ea Ultrasonic (UT): bakeng sa mefokolo ea ka hare, joalo ka li-inclusions le mapetsong.

-Tlhahlobo ea Magnetic particle (MT): e sebelisoa haholo ho fumana likoli joalo ka mapetsong le haufi le bokaholimo ba phala ea tšepe.

-Teko ea radiographic (RT): e lemoha mefokolo ea kahare ka X-ray kapa γ-ray, e loketseng ho bona liphoso tse kahare ho manonyeletso a cheselitsoeng le 'mele ea liphaephe.

Tlhahlobo ea hajoale ea Eddy (ET): e loketse ho bona mefokolo ea bokaholimo le bokaholimo ba bokaholimo, e sebelisoang haholo bakeng sa lisebelisoa tse nang le marako a masesaane.

Teko ea 5.Hydrostatic: Ka ho tlatsa pipe ea tšepe ka metsi le ho sebelisa khatello e itseng, e hlahlojoa bakeng sa ho lutla ho netefatsa matla a eona a ho jara khatello.

Teko ea 6.Impact: Haholo-holo bakeng sa lits'ebetso tse nang le mocheso o tlase kapa litlhoko tse ling tse ikhethang, tlhahlobo ea phello e lekola ho tiea ha thepa ha e ka ba le tšusumetso ea tšohanyetso.

7.Metallographic analysis: E hlahloba microstructure ea thepa ho etsa bonnete ba hore mokhatlo oa tšepe oa pipe ea tšepe e se nang moeli o finyella litlhoko.

Litlhokomelo bakeng sa ho reka phala ea tšepe e se nang seamless

Litaba tsa mantlha:

- Hlakisa litlhaloso: etsa bonnete ba hore u fana ka litlhaloso tse nepahetseng tsa boholo bo kang bophara ba bokantle, botenya ba lebota, bolelele, joalo-joalo.

-Khetha thepa: Khetha boemo bo nepahetseng ba tšepe le thepa ho latela tikoloho ea ts'ebeliso, joalo ka tšepe ea khabone, tšepe ea alloy, tšepe e sa hloekang, jj.

- Litekanyetso le litifikeiti: Hlalosa litekanyetso tse lokelang ho lateloa (mohlala, ASTM, API, DIN, joalo-joalo) le litifikeiti tsa boleng tse hlokahalang kapa litlaleho tsa liteko.

-Bongata: Fana ka bongata bo nepahetseng, ho nahanoa ka tšenyo e ka bang teng le litlhoko tse ling.

Litaba tsa tlatsetso:

- Phekolo ea holim'a metsi: ho itšetlehile ka litlhoko tsa kopo, etsa qeto ea hore na pipe ea tšepe e hloka ho phekoloa ka holim'a metsi, joalo ka galvanized kapa penta.

- Phekolo ea ho qetela: Bontša hore na lipheletso tsa liphaephe li hloka phekolo e khethehileng, joalo ka qetello e bataletseng, e beveled, e kopantsoeng, joalo-joalo.

—Tlhaloso ea tšebeliso: Fana ka tikoloho le tšebeliso ea phala ea tšepe e le hore mofani oa thepa a ka khothaletsa lihlahisoa tse loketseng.

- Litlhoko tsa ho paka: Hlalosa litlhoko tse khethehileng tsa ho paka ho netefatsa polokeho nakong ea lipalangoang.

- Nako ea thomello: Netefatsa letsatsi la thomello ea odara ho etsa bonnete ba hore e kopana le kemiso ea projeke ea hau.

- Lipehelo tsa theko: Buisana le ho phethela lipehelo tsa theko, ho kenyelletsa le litšenyehelo tsa ho tsamaisa thepa, lekhetho, joalo-joalo.

-Kamora thekiso: utloisisa litšebeletso tsa morekisi ka mor'a thekiso, joalo ka hore na litaba tsa boleng li sebetsoa joang.

-Ts'ehetso ea Theknoloji: Netefatsa boteng ba ts'ehetso ea tekheniki, haholo bakeng sa lits'ebetso tse ikhethileng kapa lits'ebetso.

Mabapi le rona

Botop Steel ke moetsi le morekisi ea hloahloa oa Seamless Steel Pipe ea China. Ka lilemo tse fetang 16 tsa nalane, re boloka lithane tse fetang 8,000 tsa liphaephe tse seamless setokong khoeli le khoeli. Haeba u batla ho tseba haholoanyane ka lihlahisoa tsa rona tsa lipeipi tsa tšepe, u ka ikopanya le rona ho u fa lihlahisoa le litšebeletso tsa boleng bo phahameng!

li-tag: phala ea tšepe e se nang moeli; seamless tšepe pipe e bolelang; maemo; Bafani, bahlahisi, fektheri, Stockist, lik'hamphani, wholesale, reka, theko, quotation, bongata, for sale, cost.

Nako ea poso: Apr-04-2024