Pipe ea tšepe ea mofuta oa Ee etsoa ho latelaASTM A53'me e hlahisoa ho sebelisoa Motlakase-Resistance-Welding (ERW) ts'ebetso.

Peipi ena e sebelisoa haholo bakeng sa lits'ebetso tsa mochini le khatello empa hape e loketse ho sebelisoa e le liphaephe tse akaretsang bakeng sa ho tsamaisa mouoane, metsi, khase le moea.

Mefuta ea liphaephe ea ASTM A53

Ho na le mefuta e meraro:Mofuta oa F, Mofuta oa E, le Mofuta oa S.

Har'a bona, pipe ea tšepe ea Mofuta oa E e etsoa ke ts'ebetso ea ERW.

Haeba u batla ho tseba haholoanyane kaASTM A53, o ka tobetsa mona.

Karolelano ea Kereiti

Mofuta oa E o na le limaraka tse peli: Kereiti ea A leSehlopha sa B.

Boholo Range

Boholo ba mefuta eaASYM A53 ke DN 6-650.

Lethathamo la tlhahiso eaMofuta oa E ke DN 20-650 DN.

Liphaephe tse ka tlaase ho DN 20 li nyenyane haholo bakeng sa Mofuta oa E. Ka mabaka a theknoloji ha ho na mokhoa oa ho li hlahisa, kahoo Mofuta oa S, e lengmokhoa oa ho etsa seamless, e sebelisoa hangata.

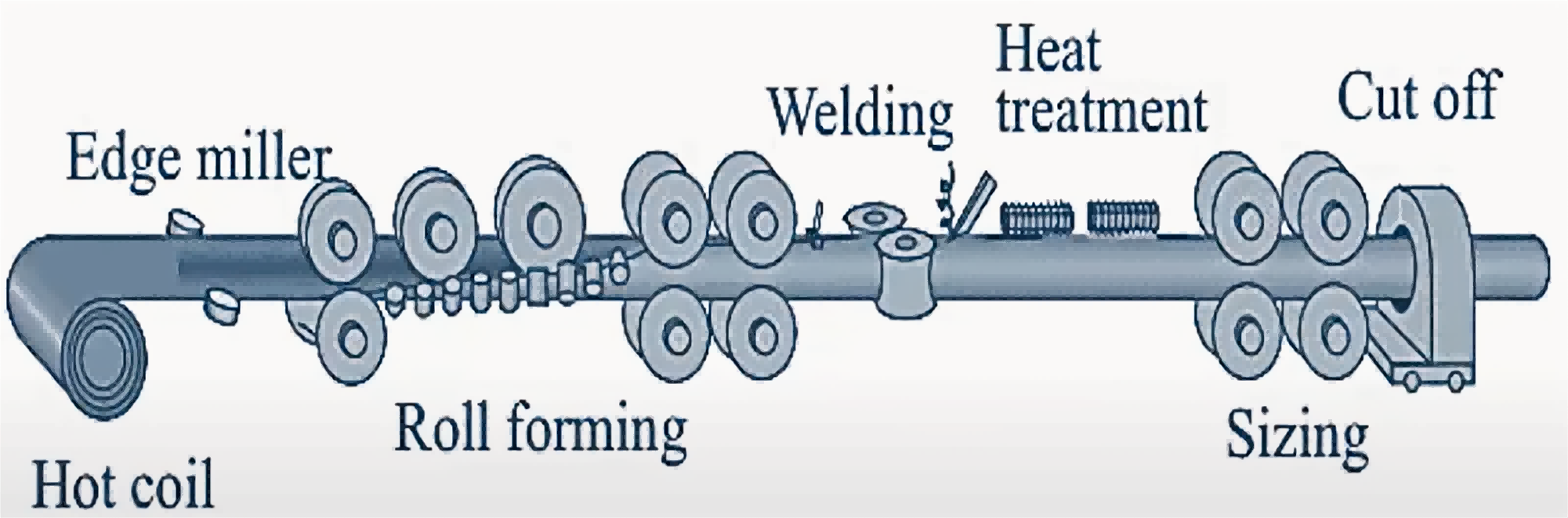

Mokhoa oa Tlhahiso bakeng sa ASTM A53 Mofuta oa E

Ts'ebetso ea tlhahiso e kenyelletsa ho etsa li-coil tsa tšepe ka lirolo, litšepe tsa welding ka ho futhumatsa ka ho hanyetsa, li-welds tsa deburring, le boholo le ho otlolla ho etsa li-tubes.

Litšobotsi tsa ASTM A53 Mofuta oa Pipe ea tšepe ea E

E na le litšepe tse peli tsa longitudinal butt kahare le kantle.Lithako tsa lipoleiti tsa tšepe li cheselitsoe ka hare le ka ntle ho phala nakong ea ts'ebetso ea tlhahiso ho netefatsa matla le ho tiisa.

Li-welds tse ka hare le tsa ka ntle ha li bonahale.Li-welds tse ka hare le tse ka ntle li hloekisoa ho fihlela bophahamo bo lekanang le bo holimo ba phala nakong ea tlhahiso, e leng se tlatsetsang ponahalong ea kakaretso le thepa ea hydrodynamic ea phala.

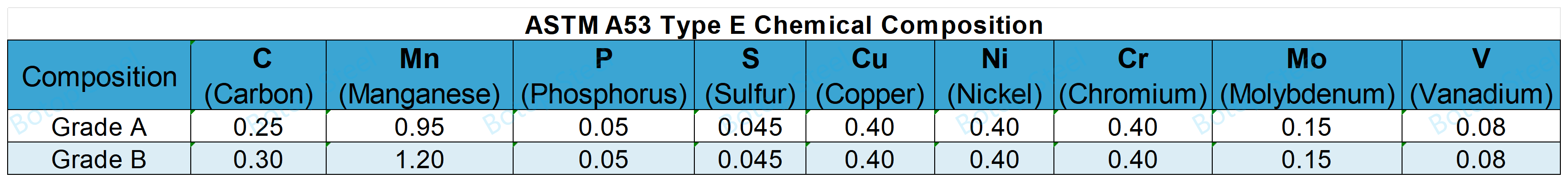

Likarolo tsa lik'hemik'hale tsa mofuta oa ASTM A53 E

Bakeng sa phokotso e 'ngoe le e 'ngoe ea 0.01% ka tlase ho boholo ba carbon e boletsoeng, keketseho ea 0.06 % ea manganese ka holimo ho palo e boletsoeng e tla lumelloa ho fihla ho 1.65%.

Cu, Ni, Cr, Mo, le V, ke likarolo tse hlano hammoho ha li fete 1.00%.

ASTM A53 Mofuta oa E Mechanical Properties

Tension Test

Resistance welded pipes DN ≥ 200 e tla lekoa ho sebelisoa mehlala e 'meli e pota-potileng, e' ngoe ka mose ho weld 'me e 'ngoe e shebane le weld.

| Lenane | karohano | Kereiti A | Sehlopha sa B |

| Matla a tsitsitseng, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Ho hlahisa matla, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Elongation ho 50 mm (2 in) | Hlokomela | A, B | A, B |

Hlokomela A: Bonyane bo bolelele ho 2 ho[50 mm] e tla ba bo laolwang ke equation e latelang:

e = 625000 [1940] A0.2/U0.9

e = bolelele bo tlase ho 2 ho kapa 50 mm ka liphesente, e pota-potiloe ho liperesente tse haufi

A = ka tlase ho 0.75 in2[500 limilimithara2] le karolo e ka holimo-limo ea mohlala oa teko ea tsitsipano, e baloang ho sebelisoa bophara bo boletsoeng ka ntle ba phala, kapa bophara bo itekanetseng ba mohlala oa teko ea tsitsipano le botenya ba lebota bo boletsoeng ba phala, ka boleng bo baliloeng bo pota-potiloe ho 0.01 e haufi.2 [1 limilimithara2].

U=botlaaseng bo boletsoe ba matla a tlase, psi [MPa].

Hlokomela B: Sheba Lethathamo la X4.1 kapa Lethathamo la X4.2, ho sa tsotellehe hore na ho sebetsa eng, bakeng sa bonyane ba boleng ba ho lelefatsa bo hlokehang bakeng sa metsoako e fapa-fapaneng ea mohlala oa teko ea khatello ea maikutlo le matla a fokolang a boletsoeng.

Bend Test

Bakeng sa pipe, DN ≤50, bolelele bo lekaneng ba phala bo tla khona ho kobeha serame ka 90 ° ho pota-pota mandrel ea cylindrical, eo bophara ba eona e leng makhetlo a leshome le metso e 'meli ho feta bophara bo boletsoeng ka ntle ba phala, ntle le ho hlahisa mapetsong leha e le afe le ntle le ho bula weld.

Pipe e matla ka makhetlo a mabeli ho feta DN 32 ha ea lokela ho etsoa teko ea ho koba.

"Double-extra-strong", eo hangata e bitsoang XXSke phala e nang le botenya ba lebota bo matlafalitsoeng ka ho khetheha, bo sebelisoang hangata lits'ebetsong tsa indasteri ho mamella likhatello tse phahameng le maemo a thata. Botenya ba lerako la phala ena bo matla haholo ho feta phala e tloaelehileng, kahoo e fana ka matla a mangata le ho tšoarella hamolemo.

Teko e bataletseng

Teko ea ho batalla e tla etsoa ka phala e cheselitsoeng holim'a DN 50 ka boima bo fetang bo matla (XS) kapa bo bobebe.

Mokhoa o latelang oa liteko o sebetsa ho Mofuta oa E, Mephato A le B.

Nakong ea khatello e bataletseng, weld e lokela ho behoa ho 0 ° kapa 90 ° ho ea moeling oa tataiso ea matla, ho itšetlehile ka litlhoko tse khethehileng.

Mohato oa 1: Lekola ductility ea weld. Ha hoa lokela ho ba le mapetsong kapa ho phunyeha ka har'a libaka tse ka hare kapa tse ka ntle tsa weld ho fihlela sebaka se pakeng tsa lipoleiti tse bataletseng se ka tlase ho tse peli ho tse tharo tsa bophara bo ka ntle ba phala.

Mohato oa 2: Tsoela pele ho tobetsa flat le teko bakeng sa ductility sebakeng se ka ntle ho weld. Ha hoa lokela ho ba le mapetsong kapa maqheka ka hare kapa ka ntle holim'a phala ka ntle ho weld ho fihlela sebaka se pakeng tsa lipoleiti tse bataletseng se ka tlase ho karolo ea boraro ea bophara bo ka ntle ba phala, empa e se ka tlase ho makhetlo a mahlano ho feta lebota la phala.

Mohato oa 3: Lekola botšepehi ba thepa ka ho tsoela pele ho hatella fatše ho fihlela mohlala oa teko o robeha kapa marako a liphaephe a kopana. Sena se sebelisetsoa ho lekola lisebelisoa bakeng sa mathata a joalo ka likarolo tse petsohileng, ho hloka botsitso, kapa li-welds tse sa felletseng.

Teko ea Hydrostatic

Teko ea hydrostatic e tla sebelisoa, ntle le ho lutla ka seam ea weld kapa 'mele oa phala.

Peipi e sa fellang e tla lekoa ka metsi ho latela khatello e fanoeng ho Lethathamo la X2.2,

phaephe e kholehileng le e kopantsoeng e tla lekoa ka hydrostatically ho khatello e sebetsang e fanoeng ho Lethathamo la X2.3.

Bakeng sa liphaephe tsa tšepe tse nang le DN ≤ 80, khatello ea teko e ke ke ea feta 17.2MPa;

Bakeng sa liphaephe tsa tšepe tse nang le DN ~80, khatello ea teko e ke ke ea feta 19.3MPa;

Teko ea Motlakase e sa Senyeheng

Bakeng sa liphaephe tsa Mofuta oa E le Mofuta oa F Sehlopha sa B DN ≥ 50, li-welds li tlameha ho etsoa liteko tsa motlakase tse sa senyeheng.

Teko ea motlakase e sa senyeheng e tla etsoa ho latela Specifications E213, E273, E309 kapa E570.

Haeba tlhahlobo ea motlakase e sa senyeheng e entsoe, phala e tla tšoauoa "NDE".

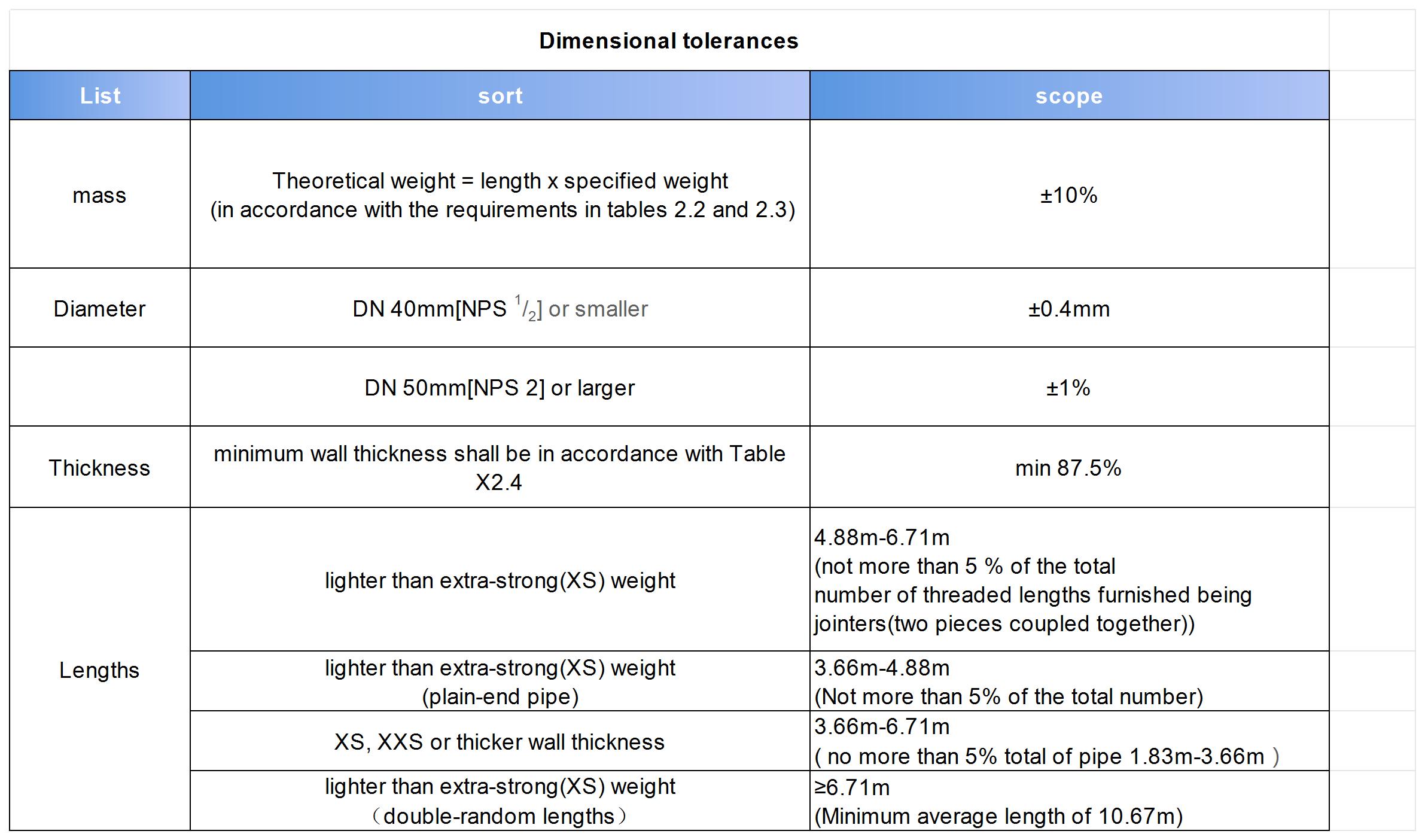

ASTM A53 Dimensional Tolerances

Lithapa tsa Boima ba Pipe le Litlhophiso tsa Pipe

Melemo ea ASTM A53 Mofuta oa E Pipe

Resistance welding ke mokhoa o batlang o le theko e tlase, o etsang hore li-tubes tsa Mofuta oa E e be tse theko e tlase ho hlahisoa le tse loketseng tlhahiso ea bongata.

Ts'ebetso ea ho tjheseletsa tjheseletsa e potlakile mme e ka hlahiswa nako le nako, e leng se eketsang tlhahiso le ho fokotsa dinako tsa loto.

Ka lebaka la thepa ea eona e ntle ea mechine le ho hanyetsa ho bola, mofuta ona oa pipe o sebelisoa haholo mefuteng e sa tšoaneng ea ho tsamaisa maro a kang metsi, khase le mouoane.

Li-welds li ka etsoa hore li se ke tsa bonahala ka ho phekoloa hantle ha li-welds, tse sa ntlafatse ponahalo ea phala feela empa hape li ka fokotsa ho hanyetsa ho phalla ha mokelikeli ho bakoang ke li-welds..

Likopo tsa ASTM A53 Type E Steel Pipe

Tšebeliso ea sebopeho: Ha ho hahoa, pipe ea tšepe ea mofuta oa A53 E sebelisoa e le likarolo tsa mohaho tse kang litšehetso tsa mohaho le tsamaiso ea truss.

Pipe ea metsi: E sebelisoa lits'ebetsong tsa phepelo ea metsi bakeng sa meaho, ho kenyeletsoa le lisebelisoa tsa ho fafatsa mollo.

Sistimi ea mouoane: Litsing tsa indasteri, pipe ena ea tšepe e atisa ho sebelisoa mekhoeng ea ho fana ka mouoane, haholo-holo lits'ebetsong tse tlaase.

Phetiso ea khase: E sebelisoa bakeng sa ho tsamaisa likhase tsa tlhaho kapa tse ling, haholo-holo tsamaisong ea phepelo ea khase ea masepala le ea bolulo.

Limela tsa lik'hemik'hale: bakeng sa ho tsamaisa mouoane o nang le khatello e tlase, metsi le lik'hemik'hale tse ling.

Liloala tsa pampiri le tsoekere: ho fetisa thepa e tala le lihlahisoa tse felileng, hammoho le ho lahla litšila tsa ts'ebetso.

Lisebelisoa tsa ho futhumatsa le ho pholisa: E sebelisoa haholo bakeng sa liphaephe tse futhumatsang, moea le moea o futhumatsang moea (HVAC).

Phekolo ea metsi a litšila: Bakeng sa ho tsamaisa metsi a litšila kapa metsi a hloekisitsoeng.

Mekhoa ea ho nosetsa: Lipeipi tsa metsi tse sebelisetsoang ho nosetsa mobu oa temo.

Morafo: E sebelisetsoa ho tsamaisa metsi le khase merafong.

Lihlahisoa tsa rona tse Amanang

Ho tloha ha e thehoa ka 2014, Botop Steel e fetohile mofani ea ka sehloohong oa phala ea carbon steel Northern China, e tsejoang ka tšebeletso e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse feletseng.

Khampani e fana ka mefuta e fapaneng ea liphaephe tsa tšepe tsa carbon le lihlahisoa tse amanang le tsona,

ho kenyelletsa le seamless, ERW, LSAW, le phala ea tšepe ea SSAW, hammoho le lethathamo le felletseng la lipeipi le li-flanges.

Lihlahisoa tsa eona tse ikhethang li boetse li kenyelletsa li-alloys tsa boemo bo holimo le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho fihlela litlhoko tsa merero e fapaneng ea lipeipi.

Tags: ASTM a53, mofuta e, grade a, grade b, erw.

Nako ea poso: May-12-2024