phala ea tšepe ea JIS G 3444ke sebopeho carbon tšepe pipe e entsoeng ka seamless kapa welded tshebetso, haholo-holo sebelisoa ka boenjiniere ba sechaba le kaho.

Likonopo tsa ho Tsamaisa

Boholo Range

Karolelano ea Kereiti

Mekhoa ea Tlhahiso ea JIS G 3444

Mofuta oa ho qetela oa Tube

Sebopeho sa lik'hemik'hale tsa JIS G 3444

Thepa ea Mechini ea JIS G 3444

Bophahamo ba ho hanyetsa

Bend Test

Liteko Tse Ling

Pipe Weight Tafole ea JIS G 3444

Mamello ea Dimensional ea JIS G 3444

Ponahalo

Ho tshwaya

JIS G 3444 Kopo

Maemo a Amanang

Melemo ea Rōna

Boholo Range

Sepheo se akaretsang Bophara ba ka ntle: 21.7-1016.0mm;

Liqubu tsa motheo le liqubu bakeng sa khatello ea mobu OD: ka tlase ho 318.5mm.

Karolelano ea Kereiti

Li-tubes li arotsoe ka lihlopha tse 5.

STK 290,Setšoantšo sa STK400, STK 490, STK 500, STK 540.

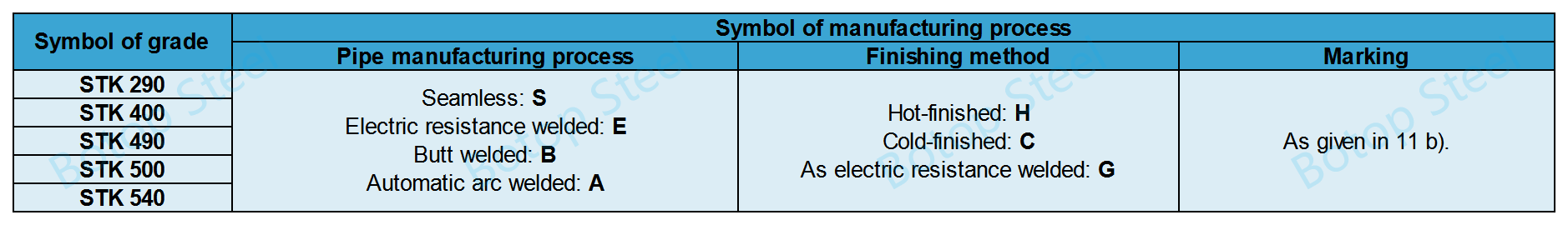

Mekhoa ea Tlhahiso ea JIS G 3444

Li-tubes li tla etsoa ka motsoako oa mokhoa oa ho etsa li-tubes le mokhoa oa ho qetela o bontšitsoeng.

Li-tubes li ka phekoloa hantle ka mocheso haeba li lakatsa.

Haeba Moreki a batla, phala e ka etsoa ka letlapa la tšepe le koahetsoeng kapa tšepe e koahetsoeng. Tabeng ena, mofuta oa ho roala le boleng ba ho roala li tla lumellana le litlhoko tsa JIS G 3444, Sehlomathiso A.

Mefuta ea ho roala e ka sebelisoang ke hot-dip zinki coating, electrolytic zinc coating, hot-dip aluminium coating, hot-dip zinc-5% aluminium alloy coating, hot-dip 55% aluminium-zinc alloy coating, kapa hot-dip zinc-aluminium-magnesium alloy coating.

Mofuta oa ho qetela oa Tube

Liphaephe tsa tšepe li tla ba sephara.

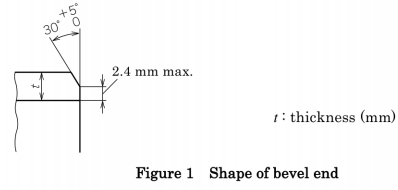

Haeba phala e hlokeha hore e sebetsanoe qetellong ea beveled, angle ea bevel ke 30-35 °, bophara ba bevel ea bohale ba pipe ea tšepe: ke max 2.4mm.

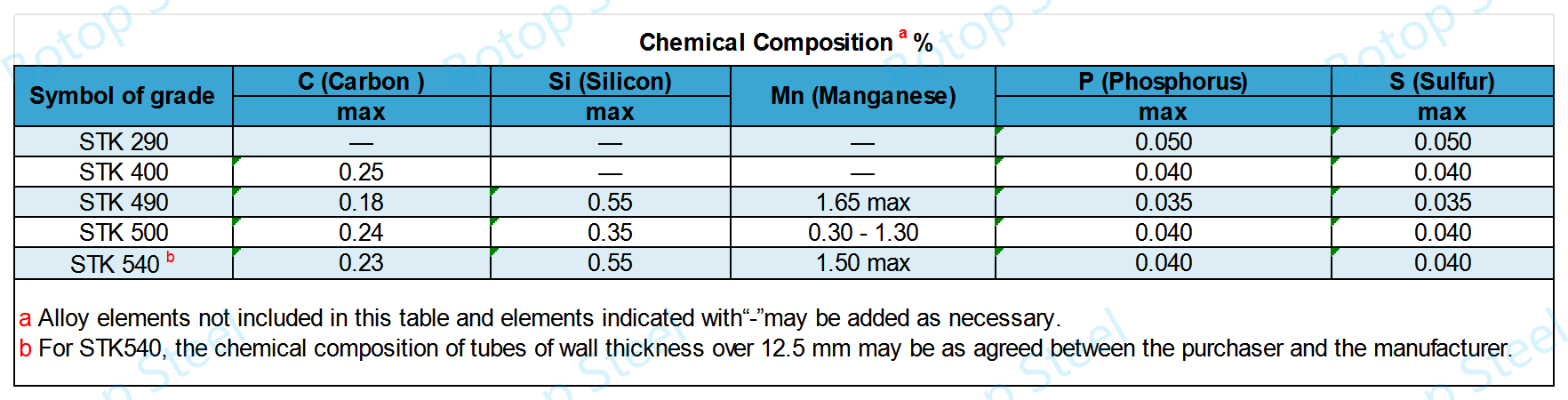

Sebopeho sa lik'hemik'hale tsa JIS G 3444

Mekhoa ea ho hlahloba mocheso e tla lumellana le litlhoko tsa JIS G 0320.

Mokhoa oa ho hlahloba sehlahisoa o tla lumellana le litlhoko tsa JIS G 0321.

Thepa ea Mechini ea JIS G 3444

Litlhoko tse akaretsang tsa liteko tsa mochini li tla tsamaellana le Karolo ea 7 le 9 ea JIS G 0404.

Leha ho le joalo, mokhoa oa lisampole oa liteko tsa mochini o tla lumellana le litlhoko tsa lipehelo tsa Sehlopha sa A ho Karolo ea 7.6 ea JIS G 0404.

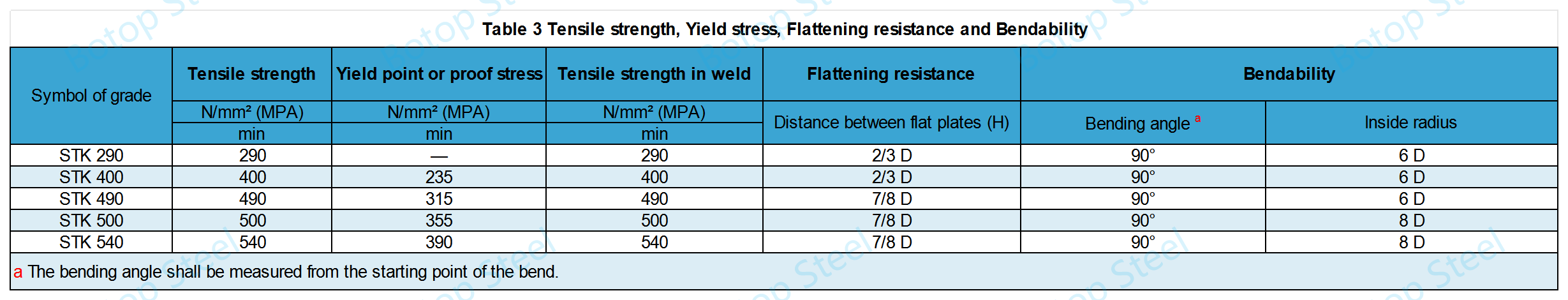

Matla a Tensile le Ntlha ea Kotulo kapa Khatello ea Bopaki

Matla a tsitsitseng le ntlha ea ho kotuloa kapa khatello ea bopaki hammoho le matla a ho tiea ho weld li tla khotsofatsa litekanyetso tse boletsoeng ho Lethathamo la 3.

Matla a thata a weld a sebetsa ho li-tubes tse otlolohileng tsa arc welded.

Matla a weld a tšoana le a hlokahalang bakeng sa 'mele oa phala. Karolo e cheselitsoeng hangata ke sehokelo se fokolang sebopehong, ka hona ho ba le matla a ts'oana ho tiisa ho ts'epahala ha sebopeho se cheselitsoeng.

Letlapa la 3 le boetse le na le litlhoko tsa sebaka sa ho hanyetsa ha Flattening le litlhoko tsa bend angle le bend radius qetellong ea bendability.

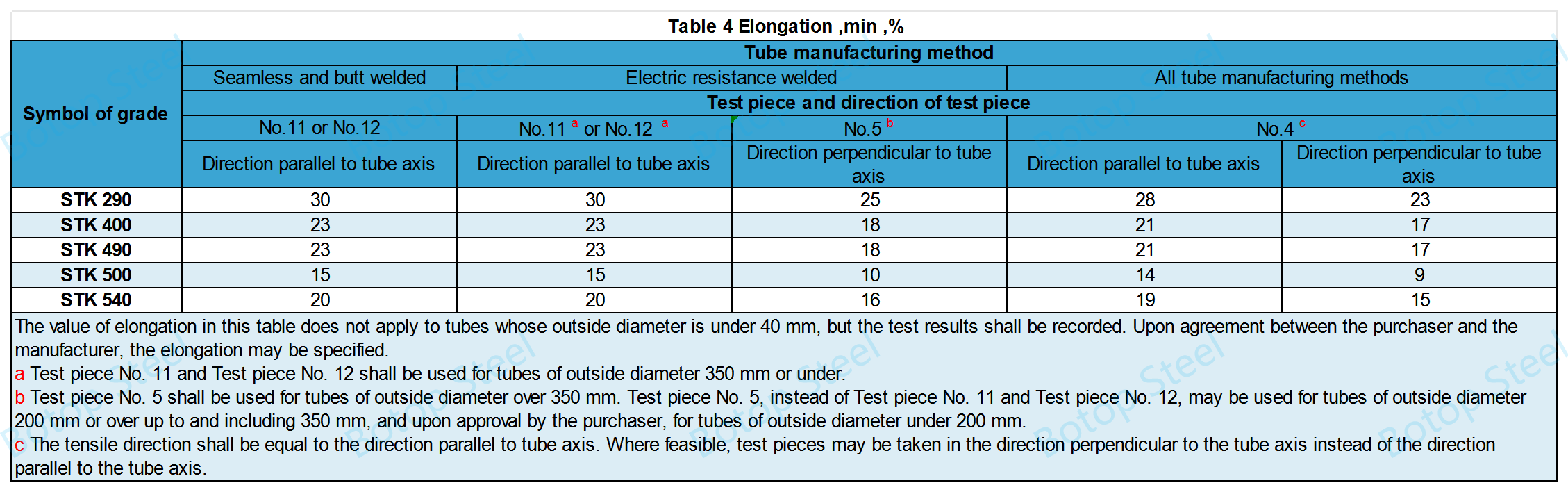

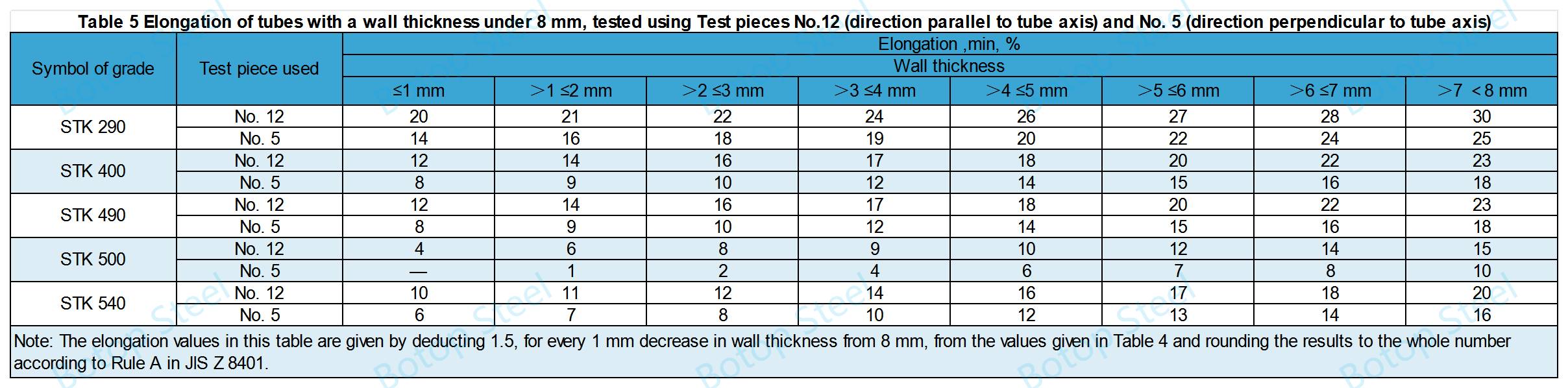

Elongation

Elongation e tsamaellanang le mokhoa oa ho etsa li-tube e bonts'itsoe ho Lethathamo la 4.

Leha ho le joalo, ha teko ea tensile e etsoa ho Test Piece No. 12 kapa Test Piece No.5 e nkiloeng ho tube e ka tlas'a 8 mm ka botenya ba lebota, bolelele bo tla ba ho latela Lethathamo la 5.

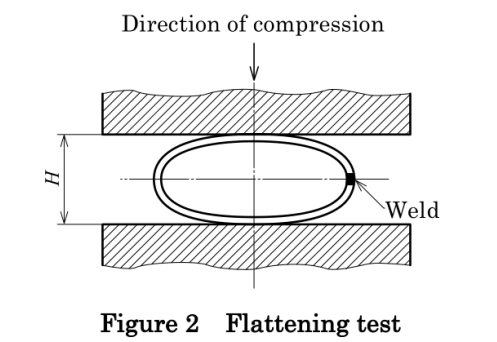

Bophahamo ba ho hanyetsa

Beha sengoathoana sa teko ka mocheso o tloaelehileng (5 ° C ho ea ho 35 ° C) pakeng tsa lipoleiti tse peli tse bataletseng le compress ho batalatsa ho fihlela sebaka se pakeng tsa lipoleiti H e ba e lekanang kapa e nyenyane ho feta boleng bo boletsoeng ho Lethathamo la 3, ebe u hlahloba mapetsong a sengoathoana sa teko.

Beha litšepe tsa ho hanyetsa welded tšepe phala le butt welded tšepe phala e le hore mola pakeng tsa bohareng ba phala le tjheseletsa ke perpendicular ho tataiso ea compression.

Bend Test

Koba sengoathoana sa teko ho pota-pota silindara ka mocheso o tloaelehileng (5 °C ho 35 °C) ka lehlakoreng le kobehang eseng ka tlase ho tekanyo e fokolang ea ho kobeha e boletsoeng ho Lethathamo la 3, le ka radius e ka hare e seng ho feta boholo ba radius e ka hare e boletsoeng ho Lethathamo la 3, 'me u hlahlobe sengoathoana sa teko bakeng sa mapetsong.

Bakeng sa ho lekola mochini oa tšepe o entsoeng ka tšepe o entsoeng ka tšepe le tube ea tšepe e entsoeng ka butt-welded, beha sekhechana sa teko e le hore weld e be 90 °C ho tloha sebakeng se ka ntle sa ho kobeha.

Liteko Tse Ling

Liteko tsa Hydrostatic, liteko tse sa senyeheng tsa li-welds, kapa liteko tse ling li tla lumellanoa esale pele mabapi le litlhoko tse amehang.

Pipe Weight Tafole ea JIS G 3444

Mokhoa oa ho bala boima ba phala ea tšepe

W=0.02466 t (Dt)

W: boima ba yuniti ea tube (kg/m)

t: botenya ba lebota la tube (mm)

D: bophara ba ka ntle ba tube (mm)

0.02466: unit conversion factor bakeng sa ho fumana W

Foromo e ipapisitse le taba ea hore boima ba tšepe ke 7.85 g/cm³.

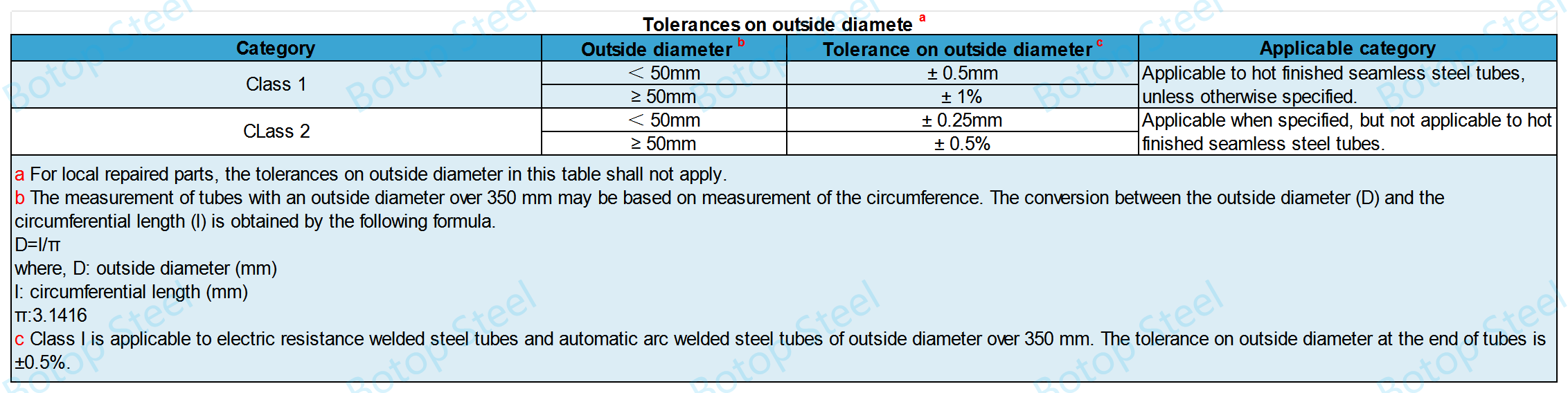

Mamello ea Dimensional ea JIS G 3444

Mamello ea Kantle ea Diameter

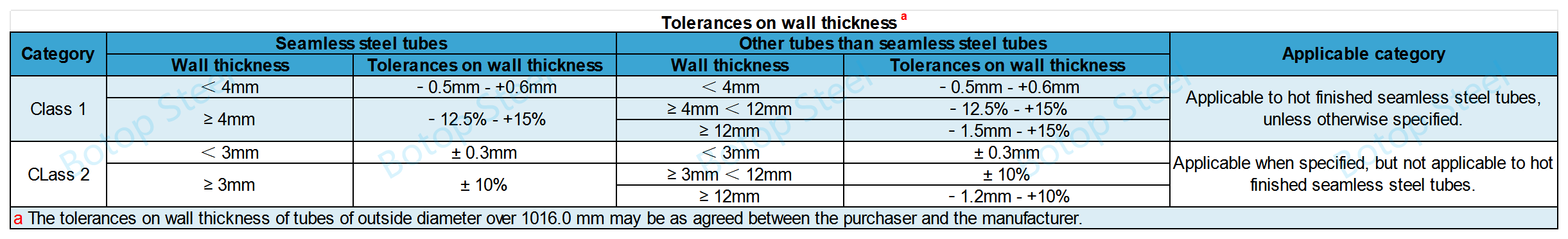

Mamello ea Botenya ba Lerako

Bolelele Mamello

Mamello ea bolelele ba phala ea tšepe, mamello e mpe ke zero, mamello e ntle ha e hlokehe ka ho hlaka, moreki le moetsi ho etsa qeto ka tumellano e kopanetsoeng.

Ponahalo

Libaka tse ka hare le tse ka ntle tsa phala ea tšepe li tla ba tse boreleli 'me li se na likoli tse sa rateheng ho li sebelisa.

Liaparo tse thibelang ho bola tse kang li-zinc tse nang le lisebelisoa tse ngata, li-epoxy, lipente tsa pente, joalo-joalo li ka sebelisoa ho ea ka ntle kapa ka hare.

Ho tshwaya

Pipe e 'ngoe le e' ngoe ea tšepe e tla ngoloa ka boitsebiso bo latelang.

a)Letšoao la mophato.

b) Letšoao la mokhoa oa ho etsa.Letšoao la mokhoa oa tlhahiso e tla ba ka tsela e latelang. Mothalo o ka nkeloa sebaka ke letho.

1) Tube ea tšepe e se nang seamless e chesang e chesang: -SH

2) tube ea tšepe e se nang seamless e felileng ka serame: -SC

3) E le ho hanyetsa motlakase welded tšepe tube: -EG

4) Mocheso o felileng oa ho hanyetsa motlakase o entsoeng ka tšepe o entsoeng ka tšepe: -EH

5) Mohatsela o felileng oa ho hanyetsa motlakase o cheselitsoeng ka tšepe: -EC

6) Li-tubes tsa tšepe tsa butt-welded -B

7) Automatic arc welded steel tubes -A

c) Litekanyo.Botenya ba kantle le botenya ba lebota bo tla tšoauoa.

d) Lebitso kapa khutsufatso ea moetsi.

Ha ho le thata ho tšoaea tšupu hobane bophara ba eona bo ka ntle bo le bonyenyane kapa ha moreki a kōpa joalo, ho ka ’na ha fanoa ka letšoao mokotleng o mong le o mong oa liphaephe ka mokhoa o loketseng.

Mekhoa e joalo ka tšebeliso ea li-label, joalo-joalo.

JIS G 3444 Kopo

Li sebelisetsoa boenjiniere ba sechaba le meaho joalo ka litora tsa tšepe, li-scaffoldings, liqubu tsa maoto, liqubu tsa motheo, le liqubu bakeng sa khatello ea lefatse.

Maemo a Amanang

JIS G 3452: E hlakisa liphaephe tsa tšepe tsa carbon bakeng sa merero e akaretsang (e fapaneng le merero ea meralo mme e tsepamisitsoe haholoanyane ho tsamaisang metsi kapa likhase).

JIS G3454: E hlalosa litekanyetso tsa liphaephe tsa tšepe tsa carbon bakeng sa liphaephe tsa khatello.

ASTM A500: e koahela li-tubes tse entsoeng ka tšepe tse entsoeng ka mokhoa o batang le tse se nang seamless 'me li tšoana le JIS G 3444 ho tse ling tsa litlhoko tsa eona.

EN 10219: E koahela likarolo tse nang le likoti tse cheselitsoeng ka mokhoa o batang bakeng sa merero ea meralo, ho kenyeletsoa liprofaele tse chitja, tse lisekoere le tse khutlonnetsepa.

Melemo ea Rōna

Ho tloha ha e thehoa ka 2014, Botop Steel e fetohile mofani ea ka sehloohong oa phala ea carbon steel Northern China, e tsejoang ka tšebeletso e babatsehang, lihlahisoa tsa boleng bo phahameng, le litharollo tse feletseng.

Khampani e fana ka mefuta e sa tšoaneng ea liphaephe tsa tšepe ea carbon le lihlahisoa tse amanang le tsona, tse kenyelletsang seamless, ERW, LSAW, le phala ea tšepe ea SSAW, hammoho le lethathamo le feletseng la liphaephe le li-flanges.

Lihlahisoa tsa eona tse khethehileng li boetse li kenyelletsa li-alloys tsa boemo bo phahameng le litšepe tse sa hloekang tsa austenitic, tse etselitsoeng ho finyella litlhoko tsa merero e fapaneng ea liphaephe.

Tags: jis g 3444, peipi ea tšepe ea carbon, stk, tube ea tšepe, phala ea sebopeho.

Nako ea poso: May-10-2024