ASTM A672ke phala ea tšepe e entsoeng ka poleiti ea boleng ba sekepe sa khatello,Motlakase-Fusion-Welded (EFW)bakeng sa tšebeletso ea khatello e phahameng ka mocheso o itekanetseng.

Likonopo tsa ho Tsamaisa

Sehlopha sa Sehlopha sa ASTM A672

Sehlopha sa ASTM A672

ASTM A672 boholo Range

Litlhokomelo tsa Welding

Kalafo ea Mocheso

Likaroloana tsa Lik'hemik'hale

Tension Test

Transverse-Guided-Weld-Bend Tests

Teko ea Khatello

Tlhahlobo ea Radiographic

Mamello ea maemo bakeng sa ASTM A672

ASTM A672 Ponahalo

Mefokolo le Tokiso

Ho tšoaea ASTM A672

Tšebeliso ea pipi ea tšepe ea ASTM A672

Lihlahisoa tsa rona tse Amanang

Sehlopha sa Sehlopha sa ASTM A672

E khethiloe ho latela mofuta oa poleiti e sebelisetsoang ho etsa li-tubes tsa tšepe.

Limaraka tse fapaneng li emela likarolo tse fapaneng tsa lik'hemik'hale le thepa ea mochini bakeng sa maemo a fapaneng a khatello le mocheso.

| Phaephe Kereiti | Mofuta oa tšepe | Tlhaloso ea ASTM | |

| Che. | Kereiti | ||

| A 45 | khabone e hlakileng | A285 / A285M | A |

| A50 | khabone e hlakileng | A285 / A285M | B |

| A 55 | khabone e hlakileng | A285 / A285M | C |

| B 60 | khabone e hlakileng, e bolailoeng | A515 / A515M | 60 |

| B 65 | khabone e hlakileng, e bolailoeng | A515 / A515M | 65 |

| B70 | khabone e hlakileng, e bolailoeng | A515 / A515M | 70 |

| C 55 | khabone e hlabang, e bolailoeng, lijo-thollo tse ntle | A516 / A516M | 55 |

| C 60 | khabone e hlabang, e bolailoeng, lijo-thollo tse ntle | A516 / A516M | 60 |

| C 65 | khabone e hlabang, e bolailoeng, lijo-thollo tse ntle | A516 / A516M | 65 |

| C 70 | khabone e hlabang, e bolailoeng, lijo-thollo tse ntle | A516 / A516M | 70 |

| D 70 | manganese-silicon, e tloaelehileng | A537 / A537M | 1 |

| D 80 | manganese-silicon, Q&TA | A537 / A537M | 2 |

| H 75 | manganese-molybdenum, e tloaelehileng | A302 / A302M | A |

| H80 | manganese-molybdenum, e tloaelehileng | A302 / A302M | B, C, kapa D |

| J 80 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-1B |

| J 90 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-2B |

| J 100 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-3B |

| L 65 | molybdenum | A204 / A204M | A |

| L 70 | molybdenum | A204 / A204M | B |

| L 75 | molybdenum | A204 / A204M | C |

| N 75 | manganese-silicon | A299 / A299M | A |

AQ&T = ho tima le ho halefa.

ВKereiti efe kapa efe e ka fanoa.

Qalong re ka tseba hore na mofuta oa phala ea tšepe ke ofe ka litlhaku tsa sehlopha.

Mephato e qalang ka litlhaku A, B, le C hangata e bontšaphala ea tšepe ea carbon.

Mephato e qalang ka ditlhaku D, H, J, L, le N e bontshaphala ea tšepe ea motsoako.

Sehlopha sa ASTM A672

Li-tubes li arotsoe ho ea ka mofuta oa phekolo ea mocheso eo ba e fumanang nakong ea ts'ebetso ea tlhahiso le hore na li hlahlojoa ka radiographical le khatello ea khatello kapa che.

| Sehlopha | Phekolo ea mocheso ka phala | Radiografia, sheba lintlha: | Teko ea khatello, bona molaetsa: |

| 10 | ha ho letho | ha ho letho | ha ho letho |

| 11 | ha ho letho | 9 | ha ho letho |

| 12 | ha ho letho | 9 | 8.3 |

| 13 | ha ho letho | ha ho letho | 8.3 |

| 20 | khatello ea maikutlo e imolohile, sheba 5.3.1 | ha ho letho | ha ho letho |

| 21 | khatello ea maikutlo e imolohile, sheba 5.3.1 | 9 | ha ho letho |

| 22 | khatello ea maikutlo e imolohile, sheba 5.3.1 | 9 | 8.3 |

| 23 | khatello ea maikutlo e imolohile, sheba 5.3.1 | ha ho letho | 8.3 |

| 30 | e tloaelehileng, sheba 5.3.2 | ha ho letho | ha ho letho |

| 31 | e tloaelehileng, sheba 5.3.2 | 9 | ha ho letho |

| 32 | e tloaelehileng, sheba 5.3.2 | 9 | 8.3 |

| 33 | e tloaelehileng, sheba 5.3.2 | ha ho letho | 8.3 |

| 40 | e tloaelehileng le e halefileng, bona 5.3.3 | ha ho letho | ha ho letho |

| 41 | e tloaelehileng le e halefileng, bona 5.3.3 | 9 | ha ho letho |

| 42 | e tloaelehileng le e halefileng, bona 5.3.3 | 9 | 8.3 |

| 43 | e tloaelehileng le e halefileng, bona 5.3.3 | ha ho letho | 8.3 |

| 50 | ho tingoa le ho halefa, sheba 5.3.4 | ha ho letho | ha ho letho |

| 51 | ho tingoa le ho halefa, sheba 5.3.4 | 9 | ha ho letho |

| 52 | ho tingoa le ho halefa, sheba 5.3.4 | 9 | 8.3 |

| 53 | ho tingoa le ho halefa, sheba 5.3.4 | ha ho letho | 8.3 |

Tlhokomelo e khethehileng e lokela ho lefshoa mocheso oa tšebeletso o lebeletsoeng ha ho khethoa sehlopha se loketseng sa thepa.Sheba lintlha tsa ASTM A20/A20M.

ASTM A672 boholo Range

Maemo a boholo a khothaletsoang:DN≥400mm[16 in] le WT≤75mm[3 in].

Bakeng sa boholo bo bong ba pipe, hafeela e finyella litlhoko tse ling tsa tlhaloso ena, e ka boela ea sebelisoa.

Litlhokomelo tsa Welding

Li-seams li lokela ho ba li-welded tse peli, tse kenang ka ho feletseng.

Li-welds li tla etsoa ka letsoho kapa ka boiketsetso ka ts'ebetso ea motlakase e kenyelletsang ho beoa ha tšepe ea ho tlatsa.

Li-welds li ka hlahlojoa ho sebelisoa radiography 'me li lokela ho latela lipehelo tse Karolong ea VII UW-51 ea ASME Boiler le Khoutu ea Sekepe sa Khatello.

Bophahamo ba weld ha boa lokela ho feta 3 mm [1/8 in].

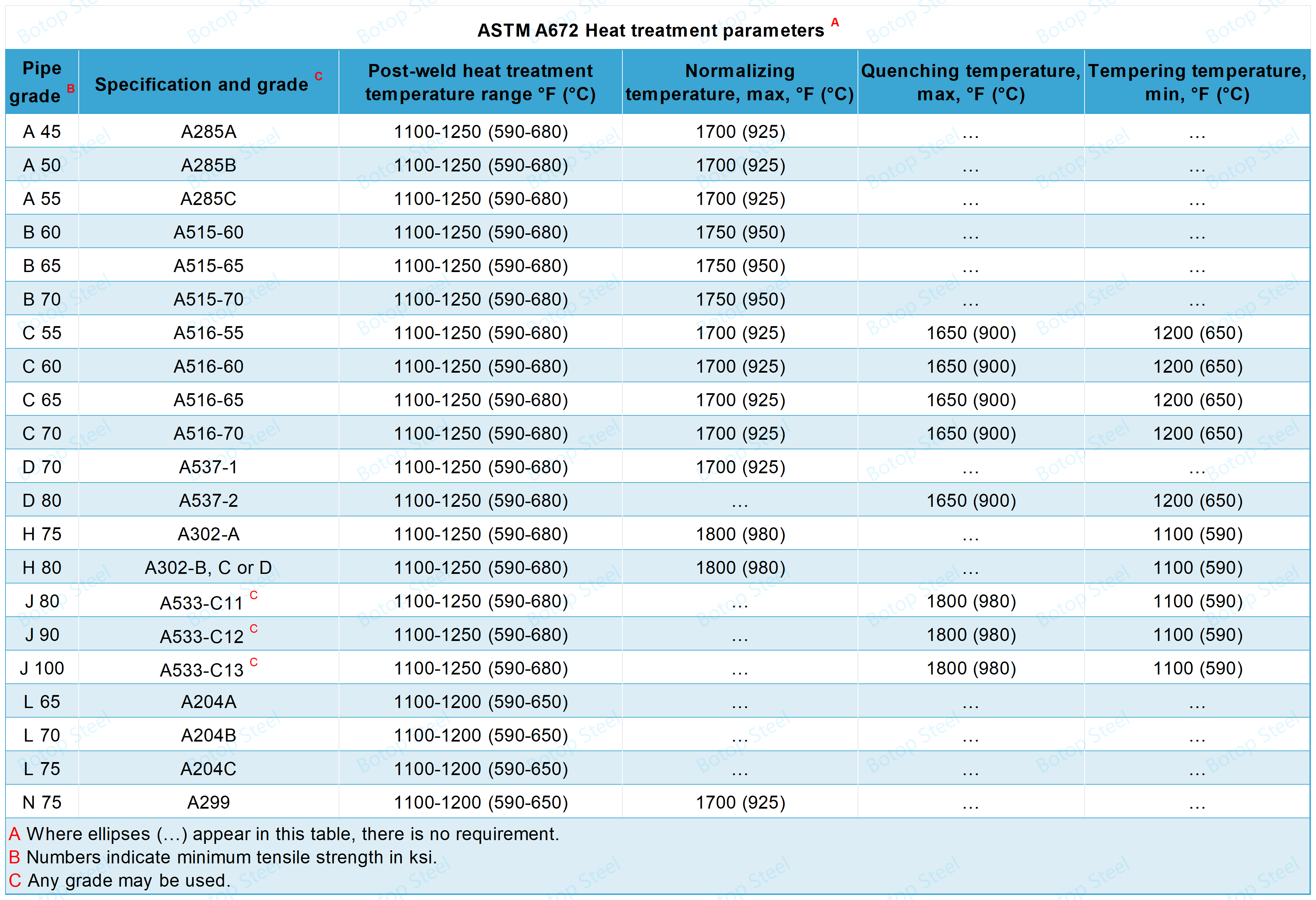

Kalafo ea Mocheso

Lihlopha tsohle ntle le 10, 11, 12, le 13 li tla phekoloa mocheso ka sebōping se laoloang ho ± 25 ° F [± 15 ° C]:

Litlelase 20, 21, 22, le 23

Pipe e lokela ho futhumatsoa ka mokhoa o ts'oanang ka har'a mocheso oa mocheso oa phekolo ea mocheso o bontšitsoeng ho Lethathamo la 2 bakeng sa bonyane ba 1 h/in.[0.4 h/cm] ea botenya kapa bakeng sa 1 h, ho sa tsotellehe hore na ke efe e kholoanyane.

Litlelase 30, 31, 32, le 33

Pipe e tla futhumatsoa ka mokhoa o ts'oanang ho mocheso sebakeng sa austenitizing 'me e se ke ea feta mocheso o tloaelehileng o tloaelehileng o bontšitsoeng ho Lethathamo la 2' me ka mor'a moo e pholile moeeng mocheso oa kamore.

Litlelase 40, 41, 42, le 43

Pipe e tla ba e tloaelehileng.

Phaephe e tla futhumatsoa hape ho mocheso oa mocheso o bontšitsoeng ho Lethathamo la 2 e le bonyane 'me e tšoarelle mocheso oa bonyane ba 0.5 h/in.[0.2 h/cm] ea botenya kapa bakeng sa1/2h, leha e le efe e kholoanyane, le moea o pholileng.

Lihlopha tsa 50, 51, 52, le 53

Pipe e lokela ho futhumatsoa ka mokhoa o ts'oanang ho ea ho mocheso ka har'a mefuta e mengata ea li-austenitizing le e sa feteng mocheso o phahameng oa ho tima o bontšitsoeng ho Lethathamo la 2.

Ka mor'a moo, tima ka metsi kapa oli.Ka mor'a ho tima, phala e tla tsosolosoa ho mocheso o fokolang oa mocheso o bontšitsoeng ho Lethathamo la 2 ebe o tšoaroa ka nako eo.

mocheso oa bonyane ba 0,5 h/inch ea botenya kapa 0,5 h, ho sa tsotellehe hore na o moholoanyane, le o pholileng moeeng.

Likaroloana tsa Lik'hemik'hale

E tla ba boikarabelo ba moetsi ho hlahloba sebopeho sa lik'hemik'hale tsa poleiti le li-welds bakeng sa ho lumellana le litlhoko tsa poleiti bakeng sa thepa e laetsoeng le mokhoa oa ho tjheseletsa oa ho kenya tšepe ea weld, ka ho latellana.

Tension Test

Khafetsa ea liteko: mohlala o le mong ka lotho.

Mokhoa oa Teko: Mehlala ea liteko e tla etsoa ho latela QW-150 Karolong ea IX ea ASME Boiler le Code Vessel Pressure.Mehlala e tla lekoa ka mocheso oa kamore ho latela Mekhoa ea Teko le Tlhaloso ea A370.

Ho ekelletsa bakeng sa Mephato ea Dxx, Hxx, Jxx, le Nxx ho Lihlopheng tsa 3x, 4x, le 5x transverse tensile properties tsa base plate, li tla khethoa ka mehlala e khaotsoeng ho tloha phala e hloekisitsoeng mocheso.

Litlhoko tsa sephetho: Thepa e feto-fetohang ea lenonyeletso le cheselitsoeng e tla kopana le litlhoko tse fokolang bakeng sa matla a ho qetela a matla a poleiti e boletsoeng.

Transverse-Guided-Weld-Bend Tests

Palo ea Liteko: Khafetsa ea liteko: hang ka beche, mehlala e 'meli

Mokhoa oa teko: Litlhoko tsa tlhahlobo tsa Mekhoa ea Teko le Litlhaloso A370, serapa sa A2.5.1.7 se tla fihleloa.

Bakeng sa botenya ba lebota ho feta3/ 8ka hare. [10 limilimithara] empa ka tlase ho3/4in. [19 mm] Litlhahlobo tsa mahlakoreng a mahlakoreng li ka etsoa ho e-na le liteko tsa sefahleho le metso.

Bakeng sa botenya ba marako3/4ho. [19 limilimithara] le ka holim'a lisampole ka bobeli li tla etsoa tlhahlobo ea lehlakore.

Litlhoko tsa sephetho: Teko ea bend e tla amoheleha haeba ho se na mapetsong kapa likoli tse ling tse fetang1/8ka. [3 limilimithara] ka tsela efe kapa efe ba teng ka tšepe weld kapa pakeng tsa tjheseletsa le tšepe botlaaseng ka mor'a ho kobeha.

Mapetso a hlahang mathōkong a mohlala nakong ea teko, 'me a ka tlaase ho1/4in. [6 limilimithara] e lekantsoeng ka tsela efe kapa efe e ke ke ea nkoa.

Teko ea Khatello

Phaephe ea lihlopha tsa X2 le X3 e tla lekoa ho latela Specification A530/A530M, Litlhoko tsa Teko ea Hydrostatic.

Tlhahlobo ea Radiographic

Bolelele bo felletseng ba weld ka 'ngoe ea Sehlopha sa X1 le X2 bo tla hlahlojoa ka radiographic ho latela le ho fihlela litlhoko tsa ASME Boiler le Pressure Vessel Code, Karolo ea VIII, Serapa sa UW-51.

Tlhahlobo ea radiographic e ka etsoa pele ho phekolo ea mocheso.

Mamello ea maemo bakeng sa ASTM A672

| Lipapali | Boleng ba ho Mamella | Hlokomela |

| Kantle Diameter | ±0.5% | E ipapisitse le tekanyo ea circumferential |

| Kantle ho Roundness | 1%. | Phapang lipakeng tsa bophara bo boholo le bo nyane ba kantle |

| Ho tsamaisana | 1/8 in. [3 limilimithara] | Ho sebelisa ntlha e otlolohileng ea limithara tse 10 e behiloeng e le hore mahlakore ka bobeli a kopane le phala |

| Botenya | 0.01 in. [0.3 limilimithara] | Botenya ba lebota bo tlase ho feta botenya bo boletsoeng |

| Bolelele | 0-+0.5in [0-+13mm] | dipheletso tse sa sebetsaneng |

ASTM A672 Ponahalo

Peipi e felileng e ke ke ea e-ba le mefokolo e kotsi 'me e tla ba le qetello e kang ea mosebetsi.

Litlhokahalo tse ts'oanang le tse boletsoeng ASTM A20/A20M bakeng sa pheletso ea lipoleiti tsa tšepe.

Mefokolo le Tokiso

Boikemisetso ba Bofokoli

Tekanyetso ea ASTM A672 ha e hlalose maemo a amohelehang a bofokoli le litekanyetso tsa qeto ea liphaephe mme hangata e bua ka maemo a nepahetseng a boenjiniere le mekhoa ea indasteri.

Litšitiso tse ka hare: Litšitiso tse ka hare li ka kenyelletsa porosity, slag, inclusions, joalo-joalo.

Mefokolo ea kantle: Litšitiso tsa kantle li ka kenyelletsa mapetsong, makhopho, mengoallo, jj.

Ho tlosoa ka ho Regrinding

Litšitiso tse ka holim'a metsi li ka tlosoa ka ho sila ka ho fetelletseng kapa ka mochini o nang le botenya bo setseng bo sa feteng 0.3 mm ka tlase ho botenya bo tloaelehileng.

The regrind depression e lokela ho kopanngoa ka mokhoa o ts'oanang sebakeng se potolohileng.

Ho lokisa Welding

Litšitiso li tla tlosoa ka mokhoa o loketseng oa ho itšeha kapa oa ho chesoa ka mocheso le ho lokisoa ho lokisa likoti tse cheselitsoeng.

le ho hlahlojwa ka radioologically ho ya ka ASME Boiler and Pressure Vessel Code, Karolo VIII, Serapa sa UW-51.

Bolelele bo felletseng ba phala e lokisitsoeng bo tla phekoloa ka mocheso ka mor'a ho lokisoa ho latela litlhoko tse boletsoeng tsa liphaephe.

Ho tšoaea ASTM A672

Letšoao le na le tse latelang:

Sesupo sa moetsi, joalo ka lets'oao la khoebo kapa logo.

Tlhaloso ea phala (boholo, botenya ba lerako, joalo-joalo).

Boemo ba thepa kapa mofuta oa phala.Mohlala: C60-22 (khutsufatso ea kereiti: C60 le sehlopha sa 22).

Tekanyetso ea tlhahiso ea phala ke ASTM A672.

Letsatsi la tlhahiso kapa nomoro ea lotho ea tlhahiso.

Tšebeliso ea pipi ea tšepe ea ASTM A672

Indastering ea matla a motlakase, ASTM A672 Electric Welded Steel Pipe hangata e sebelisoa ho fetisa mouoane litsing tsa boiler.

Indastering ea lik'hemik'hale, phala ea tšepe e cheselitsoeng ea ASTM A672 hangata e sebelisoa ho tsamaisa lik'hemik'hale tse fapaneng, litharollo tsa asiti le alkali, le mecha e meng ea litaba.

Indastering ea oli le khase, phala ea tšepe e cheselitsoeng ea ASTM A672 hangata e sebelisoa ho tsamaisa oli e tala, khase ea tlhaho le maro a mang kapa likhase.

Re moetsi oa liphaephe tsa tšepe tsa tšepe tsa boleng bo holimo tse cheselitsoeng le mofani oa thepa ea tsoang Chaena, hape re na le setoko sa liphaephe tsa tšepe tse se nang seam, tse u fang mefuta e mengata ea tharollo ea lipeipi tsa tšepe!

Tags: ASTM a672, efw, peipi ea tšepe ea carbon, kereiti.

Nako ea poso: Apr-23-2024