Botop Steel SupplyPipa Baja ERWtiGR.B,X42,X46,GR.1,GR.2,S355J0H,S275JRH,SGP,jsb

| Gaya | Standar | Kelas | Pamakéan |

| Pipa Baja ERW | API 5L PSL1 & PSL2 | GR.B,X42,X46,X52,X60,X65,X70, jsb | Angkutan minyak sareng gas |

| ASTM A53 | GR.A ,GR.B | ||

| ASTM A252 | GR.1, GR.2, GR.3 | Pikeun Struktur (Piling) | |

| BS EN10210 | S275JRH, S275J0H, S355J0H, S355J2H, jsb | ||

| BS EN10219 | S275JRH, S275J0H, S355J0H, S355J2H, jsb | ||

| JIS G3452 | SGP, jsb | Angkutan tina Cairan tekanan rendah | |

| JIS G3454 | STPG370, STPG410, jsb | Angkutan tina Cairan tekanan luhur | |

| JIS G3456 | STPG370, STPG410, STPG480, jsb | Pipa baja suhu luhur |

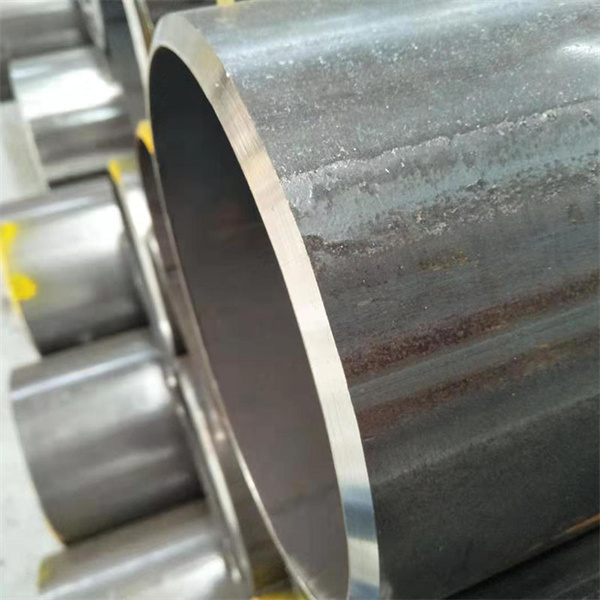

Pipa Tungtung Beveling

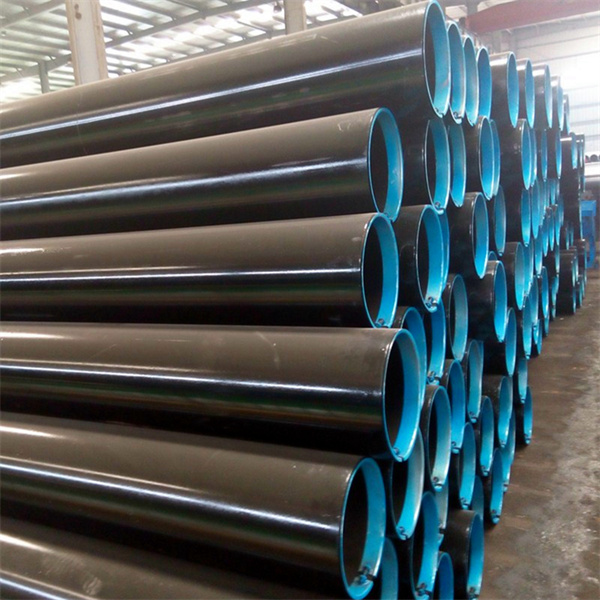

Hideung Lukisan kalawan nyirian

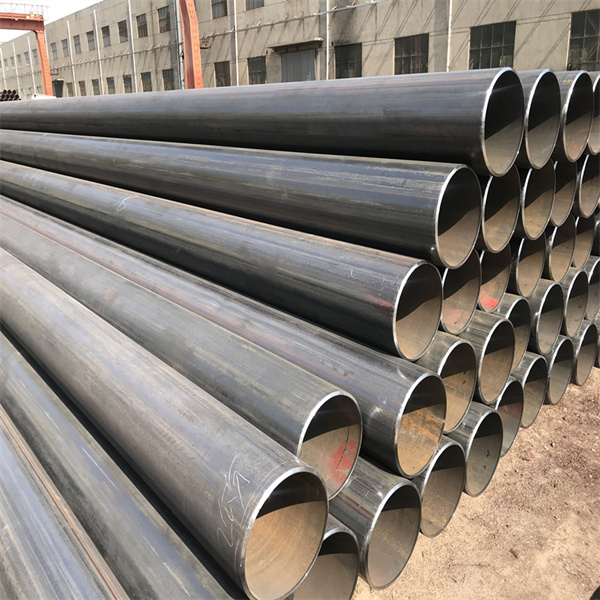

Bundling sareng Sling

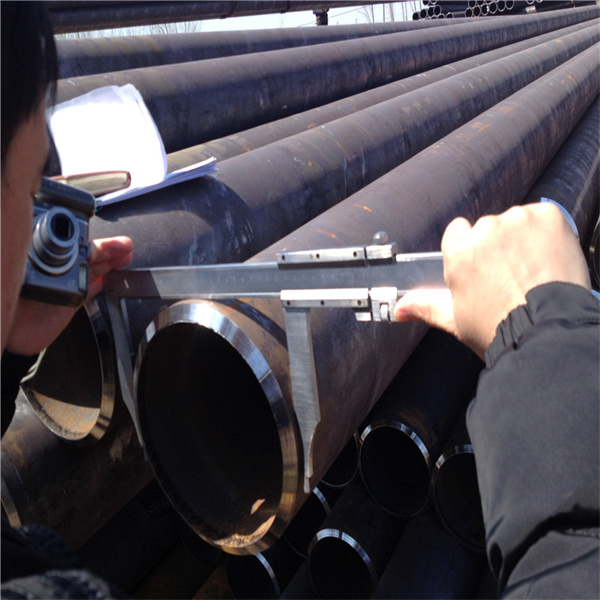

Out Diaméter Inspection

Inspeksi Ketebalan Tembok

Tungtung Inspeksi

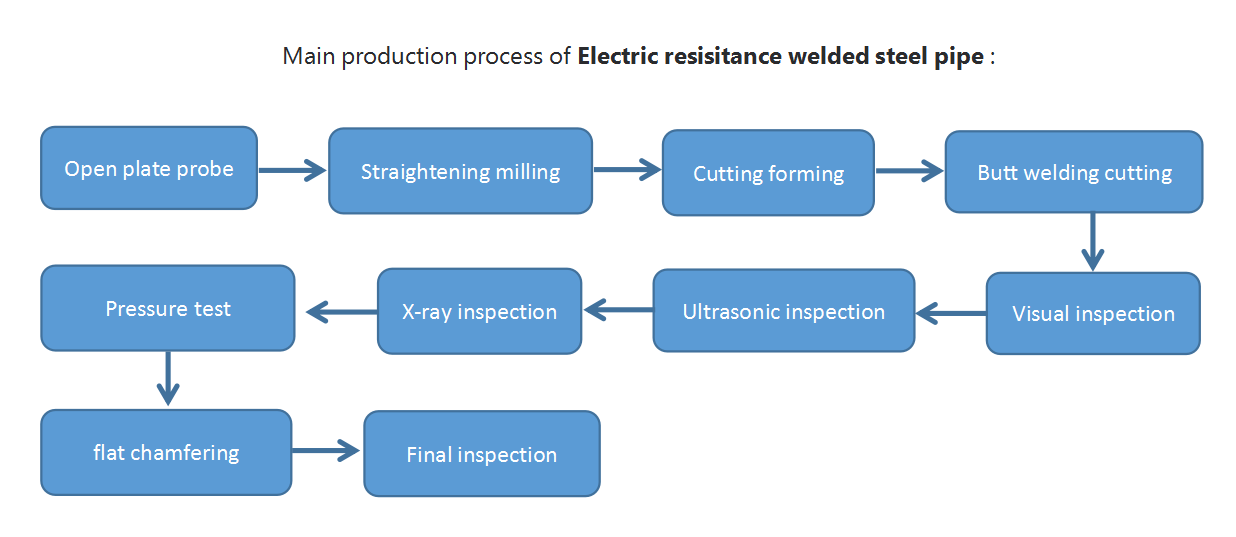

Résistansi listrik dilas (Metoda manufaktur nyaéta las résistansi listrik atanapi las butt. Metodeu bérés tiasa panas-rengse atanapi tiis-réngsé.

Toleransi OD sareng WT

| Divisi | Toleransi dina OD | Toleransi dina WT | |

| Pipa Baja ERW | 10.5mm≤D≤48.6mm | ± 0,5 mm | -12,5% + Teu dieusian |

| D = 60,5 mm | ± 0,5 mm | ||

| D = 76,3 mm | ± 0,7 mm | ||

| 89.1mm≤D≤139.8mm | ± 0,8 mm | ||

| D = 165,2 mm | ± 0,8 mm | ||

| D = 190,7 mm | ± 0,9 mm | ||

| D = 216,3 mm | ± 1,0 mm | ||

| D = 241,8 mm | ± 1,2 mm | ||

| D = 267,4 mm | ± 1,3 mm | ||

| D = 318,5 mm | ± 1,5 mm | ||

| 355.6mm≤D≤508.0mm | - | ||

| Pipa Astm A252 ERW | Pipa ERW buleud |

| Pipa Astm A53 B ERW | ERW dilas Steel pipe |

| ERW Steel Pipe Tihang | ERW Hideung Steel pipe |

| Hampang Steel ERW Pipa | Pipa Baja Karbon ERW |

ASTM A53 Gr.A & Gr. B Karbon ERW Steel pipe Pikeun Suhu High

EN10210 S355J2H STRUKTURAL ERW pipa baja

JIS G3454 Karbon ERW Steel Pipa tekenan Service

JIS G3452 Karbon ERW Steel Pipa Pikeun Piping Biasa

EN10219 S275J0H S275J2H / S275JRH STRUKTURAL ERW Pipa Tihang Baja