JIS G 3454nyaéta standar industri Jepang pikeun pipa baja karbon pikeun sistem tekanan kalayan suhu operasi maksimum 350 ° C. Standar ngawengku dua sasmita:STPG 370jeungSTPG 410. Ieu lumaku pikeun lalawanan listrik dilas (RW) atanapi pipa seamless kalayan diaméter nominal 10,5 mm nepi ka 660,4 mm (ie 6A mun 650A, atawa 1/8B mun 26B).

JIS G 3454 Pipa baja kedah diproduksi nganggo kombinasi metode manufaktur pipa baja sareng metode finishing anu cocog dina tabel di handap ieu.

| Lambang kelas | Simbol tina prosés manufaktur | ||

| Prosés manufaktur pipa | Métode finishing | Klasifikasi séng-palapis | |

| STPG370 STPG410 | Leres: S Résistansi listrik dilas: E | Panas-réngsé: H Bérés tiis: C Salaku lalawanan listrik dilas: G | Pipa hideung: pipa henteu dibéré palapis séng Pipa bodas: pipa dibéré séng-palapis |

Sacara husus, aya lima métode manufaktur:

SH: Hot-réngsé pipa baja seamless;

SC: Pipa baja seamless tiis-réngsé;

EH: Hot-réngsé lalawanan listrik dilas pipe baja;

EC: Tiis-réngsé lalawanan listrik dilas pipe baja;

EG: Résistansi listrik dilas pipa baja lian ti panas-rengse tur tiis-réngsé leuwih.

Baja Botopmangrupikeun produsén sareng supplier pipa baja karbon dilas kualitas luhur ti China, ogé salaku stokis pipa baja mulus. Upami Anjeun gaduh kaperluan naon, mangga ngarasa Luncat ngahubungan kami sarta kami bakal nyadiakeun Anjeun sareng rojongan teknis profésional gratis.

| Lambang kelas | C | Si | Mn | P | S |

| max | max | — | max | max | |

| STPG 370 | 0,25% | 0,35% | 0,30-0,90% | 0,040% | 0,040% |

| STPG 410 | 0,30% | 0,35% | 0,30-1,00% | 0,040% | 0,040% |

Ngidinan nambahkeun elemen alloying séjén.

Kakuatan Tensile, Titik Ngahasilkeun atanapi Stress Buktina, sareng Manjang

| Lambang tina kelas | Kakuatan regangan | titik ngahasilkeun atawa stress buktina | Elongation mnt,% | |||

| Sapotong tés tensile | ||||||

| No.11 atawa No.12 | No.5 | No.4 | ||||

| N/mm² (MPA) | N/mm² (MPA) | Arah uji tensile | ||||

| min | min | Sajajar jeung sumbu pipe | Jejeg sumbu pipa | Sajajar jeung sumbu pipe | Jejeg sumbu pipa | |

| STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Tes Flattening

Nalika jarak antara dua pelat ngahontal jarak anu ditangtukeun H, moal aya cacad atanapi retakan dina permukaan pipa baja.

Pikeun tabung baja seamless: H = (1+e)t/(e + t/D);

Pikeun pipa baja ERW: H = 1/3 D (pikeun weld) atanapi H = 2/3 D (pikeun porsi tanpa weld);

H: jarak antara pelat flattening (mm);

е: konstan didefinisikeun individual pikeun tiap kelas pipa, 0,08 pikeun STPG 370, 0,07 pikeun STPG 410;

t: ketebalan témbok pipa (mm);

D: diaméterna luar pipa (mm);

Tes Flattening tiasa dianggo pikeun pipa baja kalayan diaméter nominal langkung ageung tibatan 40A (48.6mm).

Bendability

Bendability manglaku ka pipa kalayan diaméter nominal 40 A (48,6) atawa leuwih leutik.

Pipa kudu dibengkokkeun 90 ° dina radius 6 kali diaméter luar na. Tembok pipa kedah bébas tina cacad atanapi retakan.

Unggal pipa baja kedah ngalaman uji tekanan hidrostatik atanapi uji non-destructive.

Uji Hidrostatik

Pertahankeun tekanan anu tangtu pikeun sahenteuna 5 detik tanpa bocor.

Nilai tekanan patali jeung jadwal No.. tina pipa baja.

| Ketebalan témbok nominal | Nomer jadwal: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Tekanan uji hidrolik minimum, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Test Non-destructive

Upami pamariksaan ultrasonik dianggo, éta kedah dumasar kana standar anu langkung ketat tibatan sinyal kelas UD di JIS G 0582.

Upami tés arus eddy dianggo, éta kedah dumasar kana standar anu langkung ketat tibatan sinyal kelas EY dina JIS G 0583.

| diaméterna nominal | Diaméter luar | Kandel témbok | Unit massa | Nomer jadwal (Sch No.) | |

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0,629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0,675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

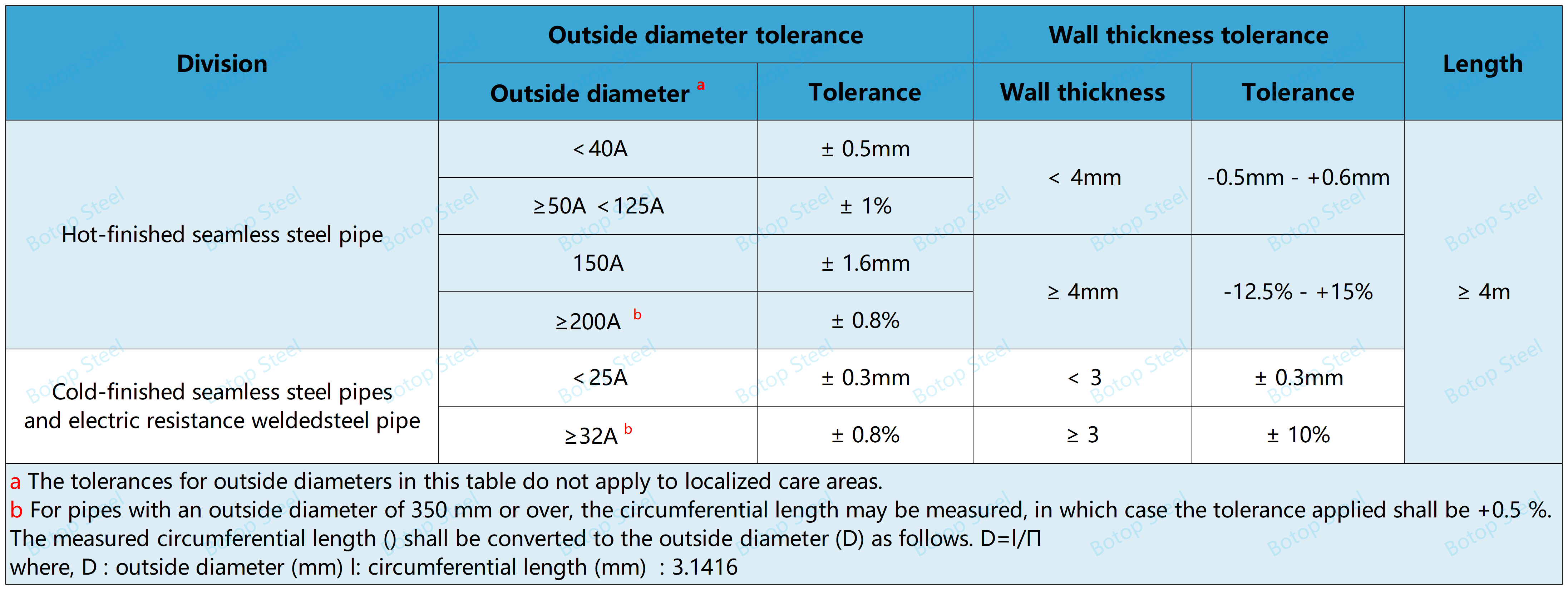

JIS G 3454 The tolerances pikeun diaméter luar, ketebalan témbok, eccentricity, sarta panjang wajib minuhan sarat handap.

Kusabab ngadegna di 2014, Botop Steel geus jadi supplier ngarah tina pipa baja karbon di Cina Kalér, dipikawanoh pikeun layanan unggulan, produk kualitas luhur, sarta solusi komprehensif.

Pausahaan nawarkeun rupa-rupa pipa baja karbon jeung produk patali, kaasup seamless, ERW, LSAW, sarta pipa baja SSAW, kitu ogé lineup lengkep fittings pipe na flanges.

Produk husus na ogé ngawengku alloy tinggi-grade na stainless steels austenitic, tailored pikeun minuhan tungtutan rupa proyék pipa.

Mangga wartosan kami, kami baris nyadiakeun Anjeun sareng kualitas luhur, pipa baja baku kalayan layanan profésional sarta efisien. Botop ngarep pisan ngalayanan anjeun.