High-quality comes 1st; assistance is foremost; business enterprise is cooperation” is our business enterprise philosophy which is constantly observed and pursued by our business for Top Grade SSAW LSAW Carbon Welding Steel Pipe Price Per Ton, We welcome new and previous customers from all walks of daily life to make contact with us for long run organization interactions and achieving mutual success!

High-quality comes 1st; assistance is foremost; business enterprise is cooperation” is our business enterprise philosophy which is constantly observed and pursued by our business for China Carbon Steel Pipe and Seamless Steel Pipe, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

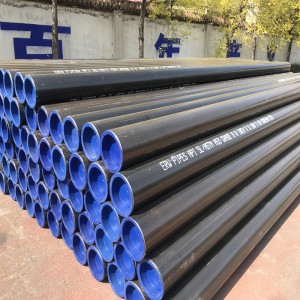

Pipe ordered under this specification is used for high-pressure service at atmospheric and lower temperatures.Mainly used for oil and natural gas transmission.

ASTM A671 LSAW(JCOE) Carbon Steel Pipe shall be double-welded, full-penetration welds made in accordance with procedures and by welders or welding operators qualified in accordance with the ASME Boiler and pressure Vessel Code, Section IX.

All classes other than 10, 11, 12 and 13 shall be heat treated in furnace controlled to ±15℃ and equipped with a recording hydrometer so that heating records are available.

Manufacture: LSAW(JCOE) Steel pipes

Size : O.D.: 406~1500mm W.T.: 6~40mm

Grade: CB60,CB65, CC60,CC65,etc.

Length: 12M or specified length as required.

Ends: Plain End, Beveled End,Grooved ;

|

Chemical Requirements for ASTM A672 B60/B70/C60/C65/C70 LSAW Carbon Steel Pipe |

|||||||||||||

|

Pipe |

Grade |

Composition, % |

|||||||||||

|

C max |

Mn |

P max |

S max |

Si |

Others |

||||||||

|

<=1in (25mm) |

>1~2in (25~50mm) |

>2~4in(50-100mm) |

>4~8in (100~200mm) |

>8in (200mm) |

<=1/2in (12.5mm) |

>1/2in (12.5mm) |

|||||||

|

CB |

60 |

0.24 |

0.21 |

0.29 |

0.31 |

0.31 |

0.98max |

0.035 |

0.035 |

0.13–0.45 |

… |

||

|

65 |

0.28 |

0.31 |

0.33 |

0.33 |

0.33 |

0.98max |

0.035 |

0.035 |

0.13–0.45 |

… |

|||

|

70 |

0.31 |

0.33 |

0.35 |

0.35 |

0.35 |

1.30max |

0.035 |

0.035 |

0.13–0.45 |

… |

|||

|

CC |

60 |

0.21 |

0.23 |

0.25 |

0.27 |

0.27 |

0.55–0.98 |

0.79–1.30 |

0.035 |

0.035 |

0.13–0.45 |

… |

|

|

65 |

0.24 |

0.26 |

0.28 |

0.29 |

0.29 |

0.79–1.30 |

0.79–1.30 |

0.035 |

0.035 |

0.13–0.45 |

… |

||

|

70 |

0.27 |

0.28 |

0.30 |

0.31 |

0.31 |

0.79–1.30 |

0.79–1.30 |

0.035 |

0.035 |

0.13–0.45 |

… |

||

|

Mechanical Properties |

|||||

|

Grade |

|||||

|

|

CB65 |

CB70 |

CC60 |

CC65 |

CC70 |

|

Tensile strength, min: |

|||||

|

ksi |

65 |

70 |

60 |

65 |

70 |

|

Mpa |

450 |

485 |

415 |

450 |

485 |

|

Yield strength, min: |

|||||

|

ksi |

35 |

38 |

32 |

35 |

38 |

|

MPa |

240 |

260 |

220 |

240 |

260 |

1. Outside Diameter-Based on circumferential measurement ±0.5% of the specified outside diameter.

2. Out-of-Roundness-Difference between major and minor outside diameters.

3. Alignment-Using a 10 ft (3m) straightedge placed so that both ends are in contact with the pipe, 1/8 in. (3mm).

4. Thickness-The minimum wall thickness at any point in the pipe shall not be more than 0.01 in. (0.3mm) under the specified nominal thickness.

5. Lengths with unmachined ends shall be within -0,+1/2 in. (-0,+13mm) of that specified. Lengths with machined ends shall be as agreed upon between the manufacturer and the purchaser.

Tension Test—Transverse tensile properties of the welded joint shall meet the minimum requirements for ultimate tensile strength of the specified plate material.

Transverse-guided-weld-bent tests —The bend test shall be acceptable if no cracks or other defects exceeding 1/8 in. (3mm) in any direction are present in the weld metal or between the weld and the base metal after bending.

Radio-graphic Examination-The full length of each weld of class X1 and X2 shall be radiographically examined in accordance with and meet the requirements of the ASME Boiler and Pressure Vessel Code, Section seven, paragraph UW-51.

Manufacturer’s name or mark

Specification number(year-date or required)

Size( OD, W.T, length)

Grade( A or B)

Type of pipe( F, E, or S)

Test pressure( seamless steel pipe only)

Heat Number

Any additional information specified in the purchase order.

Quantity ( feet, meters, or number of lengths)

Name of material( steel pipe, electric fusion welded)

Specification number

Grade and class designations

Size (outside or inside diameter, normal or minimum wall thickness)

Length (specific or random)

End finish

Purchase options

Supplementary requirements, if any.

Bare pipe or Black / Varnish coating/Epoxy coating/3PE coating ( according to customer’s requirements);

In loose;

Both ends with end protectors;

Plain end, bevel end(2″ and above with bevel ends, degree: 30~35°), customized;

Marking.

High-quality comes 1st; assistance is foremost; business enterprise is cooperation” is our business enterprise philosophy which is constantly observed and pursued by our business for Top Grade SSAW LSAW Carbon Welding Steel Pipe Price Per Ton, We welcome new and previous customers from all walks of daily life to make contact with us for long run organization interactions and achieving mutual success!

Top Grade China Carbon Steel Pipe and Seamless Steel Pipe, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.