AS 1579 umbhobho wentsimbingumbhobho wentsimbi odityanisiweyo we-arc we-butt osetyenziselwa ukuthutha amanzi kunye namanzi amdaka kunye nedayamitha yangaphandle eyi-≥ 114 mm kunye neemfumba zemibhobho ezinoxinzelelo olulinganisiweyo olungadlulanga kwi-6.8 MPa.

Iimfumba zemibhobho ngamalungu ajikelezayo esakhiwo aqhutywa emhlabeni kwaye awasetyenziselwa ukulawula uxinzelelo lwangaphakathi.

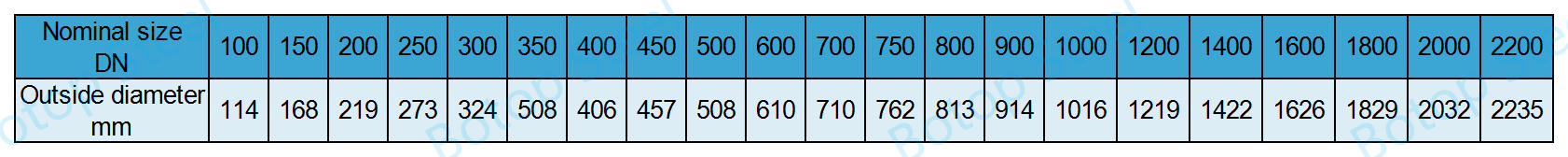

Ubuncinci bedayamitha yangaphandle yi-114mm, nangona kungekho mda okhethekileyo kubungakanani bombhobho kodwa ubukhulu obukhethiweyo bunikezelwa.

Iza kuveliswa ukusuka kumabakala ahlalutyiweyo okanye okwakhiwa kwentsimbi eshushu eqengqelekayo ehambelana ne-AS/NZS 1594 okanye AS/NZS 3678.

Ngokuxhomekeke ekusetyenzisweni kokugqibela kusahlelwa ngolu hlobo lulandelayo:

Imibhobho evavanywe nge-Hydrostaticiya kuveliswa ukusuka kuhlalutyo okanye umgangatho wesakhiwo sentsimbi eshushu esongwayo ehambelana ne-AS/NZS 1594 okanye i-AS/NZS 3678.

Iimfumba kunye nombhobho ongena-hydrostatically ovavanyiweyoiya kuveliswa ukusuka kwibakala lolwakhiwo lwentsimbi ehambelana ne-AS/NZS 1594 okanye i-AS/NZS 3678.

Kungenjalo,iimfumbainokuveliswa ukusuka kwinqanaba lokuhlalutya elithobela i-AS/NZS 1594., apho intsimbi iya kuvavanywa ngoomatshini ngokuhambelana ne-AS 1391 ukubonisa ukuba iyahlangabezana neemfuno zokuqina ezichazwe ngumthengi.

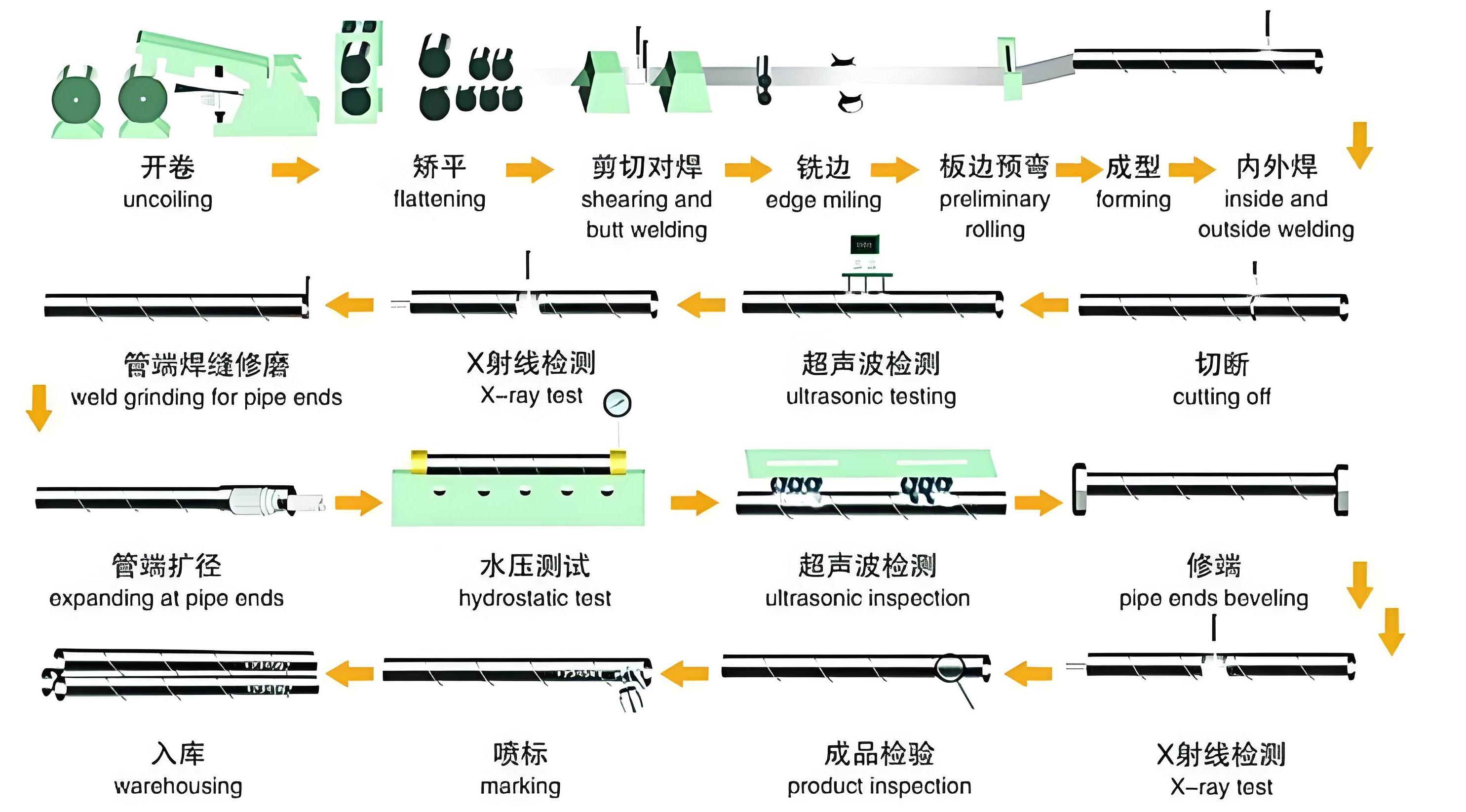

I-AS 1579 yentsimbi yombhobho yenziwa kusetyenziswawelding arc.

Zonke iiwelds ziya kungena ngokupheleleyo kwiiwelds zebutt.

I-arc welding isebenzisa ubushushu be-arc yombane ukunyibilikisa izinto zetsimbi kunye nokwenza udibaniso oludityanisiweyo phakathi kweentsimbi ukwenza ubume bemibhobho yentsimbi eqhubekayo.

Inkqubo yokuvelisa i-arc welding eqhelekileyo yi-SAW (i-Submerged Arc Welding), eyaziwa ngokubaDSAW, enokuthi ihlelwe ngokweLSAW(SAWL) kunye ne-SSAW (HSAW) ngokolwalathiso lwe-butt weld.

Ukongeza kwi-SAW, kukho ezinye iintlobo ze-arc welding ezifana ne-GMAW, i-GTAW, i-FCAW, kunye ne-SMAW. Iindlela ezahlukeneyo zokudibanisa i-arc zineempawu zazo kunye neemeko zesicelo, kwaye ukukhethwa kwendlela efanelekileyo yokudibanisa i-welding kuxhomekeke kwiinkcukacha zombhobho wensimbi oza kuveliswa, uhlahlo lwabiwo-mali kunye neemfuno zomgangatho.

Imigangatho ngokwayo ayicacisi ngokuthe ngqo ukubunjwa kweekhemikhali ezithile kunye neempawu zomatshini, njengoko oku kudla ngokuxhomekeke kwimigangatho ethile yentsimbi efana ne-AS / NZS 1594 okanye i-AS / NZS 3678, echaza iinkcukacha zeekhemikhali kunye neemfuno zepropathi yomatshini wentsimbi esetyenziselwa ukwenza le mibhobho.

U-AS 1579 ukhankanya kuphela ukulingana kwekhabhoni.

I-carbon equivalent (CE) yensimbi ayiyi kudlula i-0.40.

CE=Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

I-CE yiparameter ebalulekileyo esetyenziselwa ukuvavanya i-weldability yentsimbi. Inceda ukuqikelela ukuqina okunokuthi kwenzeke kwintsimbi emva kwe-welding kwaye ke ivavanye ukuwelda kwayo.

Uvavanyo loxinzelelo lwe-Hydrostatic luyafuneka kuwo onke amanzi okanye umbhobho wentsimbi wamanzi amdaka asetyenziselwa ukuthutha.

Iimfumba zemibhobho zihlala zingafuneki ukuba zivavanywe nge-hydrostatically kuba zisetyenziselwa ukuthwala imithwalo yesakhiwo kunoxinzelelo lwangaphakathi.

ImiGaqo yoMfuniselo

Umbhobho uvalwe kwisiphelo ngasinye kwaye ucinezele i-hydrostatically.

Ihlolwe amandla kuxinzelelo olumele uxinzelelo loyilo lombhobho. Ivavanyelwa ukuxinana kokuvuza kuxinzelelo olulinganisiweyo lombhobho.

Iingcinezelo Zokulinga

Uxinzelelo oluphezulu olulinganisiweyo lombhobho wensimbi ngu-6.8 MPa.Olu buninzi luchazwe ngumda wezixhobo zokuvavanya uxinzelelo lwe-8.5 MPa.

Pr= 0.72×(2×SMYS×t)/OD okanye iPr= 0.72×(2×NMYS×t)/OD

Pr: Uxinzelelo olulinganisiweyo, kwi-MPa;

I-SMYS: Ubuncinci obuchaziweyo bamandla esivuno, kwiMPa;

NMYS: Amandla esivuno esincinci, kwiMPa;

t: Ubukhulu bodonga, kwi-mm;

OD: Idayimitha yangaphandle, nge-mm.

Kwiimeko ezingxamisekileyo, uxinzelelo lwexeshana lunokukhokelela ekwandeni koxinzelelo lombhobho. Phantsi kwezi meko, ubuninzi boxinzelelo oludibeneyo oluvumelekileyo luya kugqitywa ngumyili, kodwa aluyi kudlula i-0.90 x SMYS.

Pt= 1.25Pr

Emva kovavanyo lwamandla, akuyi kubakho ukugqabhuka okanye ukuvuza kumbhobho wokuvavanya.

Ama-90% obona mandla buncinane obuchaziweyo (SMYS) okanye obona buncinane bamandla esivuno (NMYS) okanye 8.5 MPa, nokuba yeyiphi engaphantsi.

Pl=Pr

Uvavanyo lokuvuza luya kwenziwa kumbhobho.

Ekuvavanyeni ukuvuza, akuyi kubakho ukuvuza okubonakalayo kumphezulu wombhobho.

Yonke imibhobho yovavanyo lwe-non-hydrostatic iya kuba nobunzima bodonga obungekho ngaphantsi kwe-8.0 mm.

Umbhobhoiya kuba ne-100% yeewelds zayo ezingonakalisiyo zivavanywa ngeendlela ze-ultrasonic okanye ze-radiographic ngokuhambelana ne-AS 1554.1 Udidi lwe-SP kwaye luhambelane nemigaqo echaziweyo yokwamkelwa.

Uvavanyo olungonakaliyo lweewelds zemfumbakwiimfumba zemibhobho. Iziphumo zovavanyo ziya kuhambelana ne-AS/NZS 1554.1 yeemfuno zeClass SP. Ukuba uhlolo lubonisa ukungathotyelwa kweleyibhile, i-weld yonke kuloo mfumba yombhobho iya kuhlolwa.

Imibhobho kunye nezixhobo ezisetyenziselwa ukuhanjiswa kwamanzi kunye nogutyulo lwelindle ziya kukhuselwa kwi-corrosion ngokukhethwa kwengubo efanelekileyo Ukwaleka kuya kusetyenziswa ngokuhambelana ne-AS 1281 kunye ne-AS 4321.

Kwimeko yamanzi okusela, kufuneka bahambisane ne-AS / NZS 4020. Injongo kukuqinisekisa ukuba ezi mveliso, xa zidibene nenkqubo yokubonelela ngamanzi, azichaphazeli kakubi umgangatho wamanzi, njengokungcoliswa kweekhemikhali, ukungcoliswa kwe-microbiological, okanye ukuguqulwa kwencasa kunye nokubonakala kwamanzi.

Umphandle wangaphandle wombhobho, ongekho ngaphezu kwe-150 mm ukusuka ekupheleni, uya kuphawulwa ngokucacileyo nangokusisigxina ngolu lwazi lulandelayo:

a) Inombolo yesiriyeli eyahlukileyo, oko kukuthi inombolo yetyhubhu;

b) Indawo yokwenziwa;

c) Idayamitha yangaphandle kunye nobukhulu bodonga;

d) Inombolo yomgangatho, okt AS 1579;

e) Igama lomenzi okanye uphawu lokuthengisa;

f) Iqondo loxinzelelo lombhobho we-Hydrostatic (kuphela kumbhobho wentsimbi ophantsi kovavanyo lwe-hydrostatic);

g) Ukumakishwa kovavanyo olungonakalisi (NDT) (kuphela kumbhobho wensimbi oye wavavanywa ngokungenakonakala).

Umvelisi uya kubonelela uMthengi ngesatifikethi esayiniweyo esichaza ukuba umbhobho wenziwe ngokuhambelana neemfuno zoMthengi kunye nalo Mgangatho.

I-ASTM A252: Yenzelwe iimfumba zemibhobho yentsimbi kwaye iqulethe iimpawu zomatshini ezineenkcukacha kunye neenkcukacha zokwakheka kweekhemikhali kwiiklasi ezintathu zokusebenza.

EN 10219: inxulumene neetyhubhu zentsimbi ezidityanisiweyo ezipholileyo ezisetyenziselwa ulwakhiwo olubandakanya iimfumba zemibhobho.

ISO 3183: Umbhobho womgca wensimbi kwishishini leoli kunye negesi, kunye neemfuno zomgangatho kunye namandla ezenza ukuba zilungele ukuthwala iimfumba zemibhobho.

API 5L: Isetyenziselwa ikakhulu kwimibhobho yokuthutha kwishishini leoli kunye negesi, imigangatho ephezulu yomgangatho nayo yenza ukuba ifaneleke ukwenza iimfumba ezixhomekeke kwimithwalo ephezulu.

CSA Z245.1: Ichaza imibhobho yentsimbi kunye nezixhobo zokuthutha ioli kunye negesi, nazo zifanelekile kwiimfumba zepayipi.

I-ASTM A690: Yenzelwe iimfumba zemibhobho yensimbi ezisetyenziselwa kwiindawo zaselwandle kunye neendawo ezifanayo, kugxininisa ukuxhathisa ukubola.

JIS A 5525: Umbhobho wentsimbi wokugquma umgangatho waseJapan weemfumba zemibhobho, kubandakanywa izinto eziphathekayo, ukuveliswa, ubungakanani kunye neemfuno zokusebenza.

I-GOST 10704-91: Umbhobho wentsimbi yomthungo odityaniswe ngombane ukuze usetyenziswe kwizakhiwo nakwizakhiwo zobunjineli, kuquka iimfumba zemibhobho.

I-GOST 20295-85: Iinkcukacha zemibhobho yentsimbi edityanisiweyo yombane yokuthutha ioli kunye negesi, ebonisa ukusebenza kwabo phantsi koxinzelelo oluphezulu kunye nakwiindawo ezinzima, ezisebenzayo kwiimfumba zemibhobho.

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange.

Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.