I-ASTM A178iityhubhu zentsimbi zizibhobho zokumelana nombane ezidityanisiweyo (ERW) zecarbon kunye nekhabhoni-manganese intsimbiisetyenziswa njengetyhubhu zebhoyila, imibhobho yebhoyila, imibhobho yeheater enkulu, kunye neziphelo zokhuseleko.

Ifanelekile kwiibhubhu zetsimbi ezinobubanzi obungaphandle be-12.7-127mm kunye nobukhulu bodonga phakathi kwe-0.9-9.1mm.

Iityhubhu ze-ASTM A178 zilungele ukuxhathisa iityhubhu ezidityanisiweyo ngeiidayamitha zangaphandle phakathi kwe-1/2 - 5 ku- [12.7 - 127 mm] kunye nobukhulu bodonga phakathi kwe-0.035 - 0.360 kwi- [0.9 - 9.1 mm], nangona ezinye iisayizi zikho ngokuqinisekileyo njengoko zifunwa, ngaphandle kokuba le mibhobho ihlangabezana nazo zonke ezinye iimfuno zolu luhlu.

Kukho amabanga amathathu okumelana neemeko ezahlukeneyo zokusetyenziswa.

IBanga A, iBanga C, kunye neBanga D.

| IBanga | Uhlobo lweCarbon Steel |

| IBanga A | Intsimbi yeCarbon ephantsi |

| IBanga C | Medium-Carbon Steel |

| IBanga D | Intsimbi yeCarbon-Manganese |

Izinto ezinikezelweyo phantsi kolu luhlu ziyakuhambelana neemfuno ezisebenzayo zohlelo lwangoku lweSpecification A450/A450M. ngaphandle kokuba kubonelelwe ngenye indlela apha.

IBanga AkwayeIBanga Cmusa ukukhankanya intsimbi ethile; khetha imathiriyeli efanelekileyo ekrwada njengoko kuyimfuneko.

Intsimbi yeIBanga Duya kubulawa.

Insimbi ebuleweyo iveliswa ngokudibanisa i-deoxidizers (umzekelo, i-silicon, i-aluminium, i-manganese, njl.) kwintsimbi etyhidiweyo ngexesha lenkqubo yokuvelisa isinyithi, ngaloo ndlela ukunciphisa okanye ukuphelisa umxholo we-oksijini wensimbi.

Olu nyango luphucula i-homogeneity kunye nokuzinza kwentsimbi, iphucula iimpawu zayo zomatshini, kwaye iphucula ukuxhathisa ukubola.

Iintsimbi ezibuleweyo ke zisetyenziswa ngokubanzi kwizicelo apho inqanaba eliphezulu le-homogeneity kunye neempawu ezigqwesileyo zomatshini ezifunekayo, njengokwenziwa kweenqanawa zoxinzelelo, iibhoyila, kunye namacandelo amakhulu esakhiwo.

Iityhubhu zentsimbi zenziwe kusetyenziswa iERWinkqubo yokuvelisa.

I-ERW (i-Electric Resistance Welded)yinkqubo efanelekileyo yokuvelisa umbhobho we-carbon steel.

Ngeengenelo zamandla aphezulu wokuwelda, umphezulu ogudileyo wangaphakathi nangaphandle, isantya semveliso ekhawulezayo, kunye nexabiso eliphantsi, isetyenziswa ngokubanzi kumasimi amaninzi oshishino nolwakhiwo.

I-ASTM A178umbhobho wentsimbikufuneka iphathwe ubushushungexesha lenkqubo yokuvelisa. Isetyenziselwa ukuphucula iimpawu zomatshini kunye nokuzinza kwesakhiwo sombhobho, kunye nokuphelisa uxinzelelo olunokuthi lwaziswa ngexesha lenkqubo ye-welding.

Emva kwe-welding, yonke imibhobho iya kunyangwa kubushushu obuyi-1650°F [900°C] okanye ngaphezulu ize ilandelwe kukupholisa emoyeni okanye kwigumbi lokupholisa lesithando somoya esilawulwayo.

Imibhobho ebandayoiya kunyangwa ubushushu emva kokuba kugqitywe ubushushu bokugqibela obuyi-1200°F [650°C] okanye ngaphezulu.

Xa uhlalutyo lwemveliso lwenziwa, ukuphindaphinda kokuhlolwa kunqunywe ngolu hlobo lulandelayo.

| Ukuhlelwa | Ukuphindaphinda koHlolo |

| Idayamitha yangaphandle ≤ 3in [76.2mm] | 250 iipcs / ixesha |

| Idayamitha yangaphandle > 3in [76.2mm] | 100 iipcs / ixesha |

| Ukwahlula ngenani lobushushu betyhubhu | Ngenani lobushushu ngalinye |

Iimfuno zepropathi yoomatshini azisebenzi kwityhubhu encinci kune-1/8 in. [3.2 mm] ngaphakathi kwedayamitha okanye 0.015 [0.4 mm] ubukhulu.

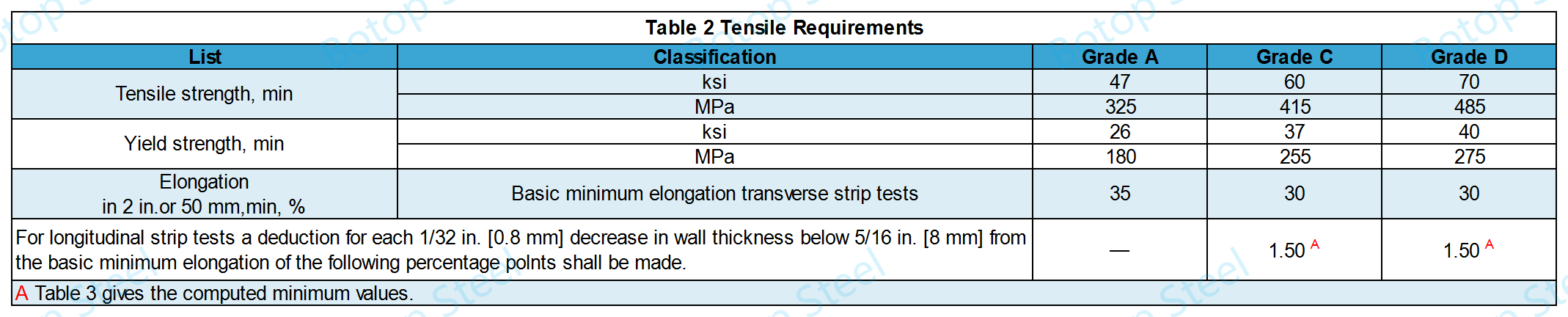

1. Ipropathi yeTensile

Kwiiklasi C kunye no-D, uvavanyo lwe-tensile luya kwenziwa kwiityhubhu ezimbini kwiqashiso nganye.

Kwi-tubing yeBakala A, uvavanyo lwe-tensile aludli ngokufuneka. Oku kungenxa yokuba iityhubhu yeBakala A isetyenziselwa ikakhulu izicelo ezinoxinzelelo oluphantsi kunye nobushushu obuphantsi.

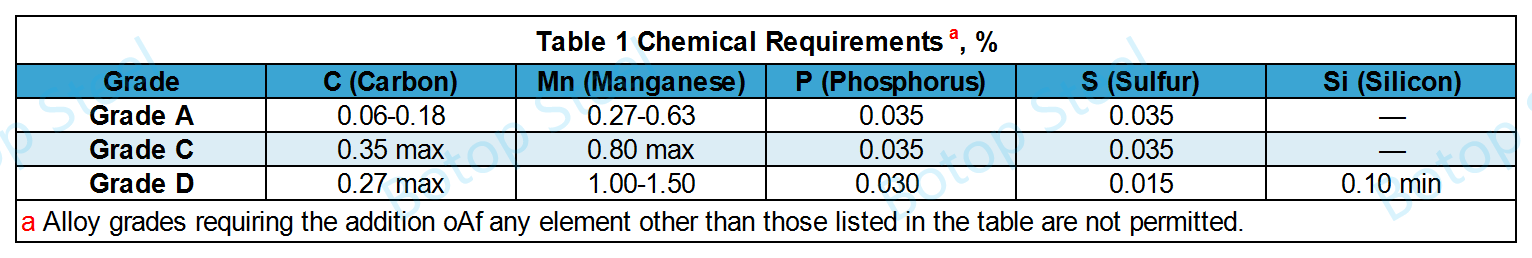

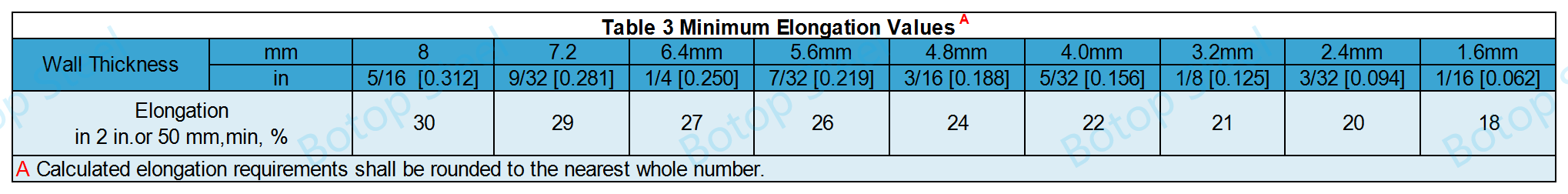

Itheyibhile yesi-3 inika amaxabiso obude obuncinane obaliweyo kwi-1/32 in nganye [0.8 mm] ukuhla kobunzima bodonga.

Ukuba ubukhulu bodonga lombhobho wensimbi abukho enye yale mibhobho yodonga, inokuphinda ibalwe ngefomula.

Iiyunithi ze-intshi: E = 48t + 15.00okanyeIiyunithi ze-ISI: E = 1.87t + 15.00

E = elongation kwi-2 in. okanye 50 mm, %,

t= ubukhulu bomzekelo wokwenyani, ngaphakathi. [mm].

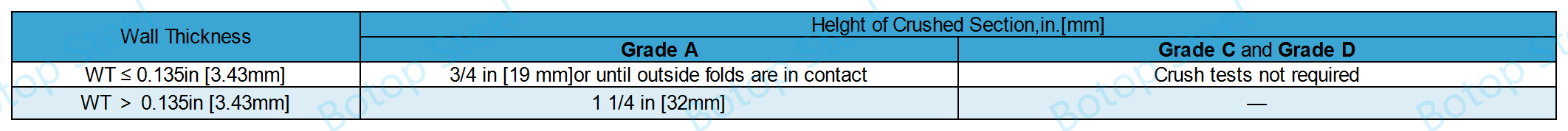

2. Crush Test

Uvavanyo lwe-Extrusion lwenziwa kumacandelo emibhobho engama-2 1/2 intshi [63 mm] ubude ekufuneka imelane ne-longitudinal extrusion ngaphandle kokuqhekeka, ukuqhekeka, okanye ukwahlula kwii welds.

Kwityhubhu engaphantsi kwe-1 [25.4 mm] ngaphandle kwedayamitha, ubude bomzekelo buya kuba ngamaxesha angama-2 1/2 ubukhulu bangaphandle bombhobho. Ukujongwa okuncinci komphezulu akuyi kuba sisizathu sokukhatywa.

3. Uvavanyo lokucaba

Indlela yovavanyo ihambelana neemfuno ezifanelekileyo ze-ASTM A450 iCandelo le-19.

4. Uvavanyo lweFlange

Indlela yovavanyo ihambelana neemfuno ezifanelekileyo ze-ASTM A450 iCandelo lama-22.

5. UVavanyo lwe-Reverse Flattening

Indlela yokulinga ihambelana neemfuno ezifanelekileyo ze-ASTM A450, iCandelo lama-20.

Uvavanyo lombane lwe-Hydrostatic okanye olungonakaliyo lwenziwa kumbhobho wentsimbi nganye.

Iimfuno zihambelana ne-ASTM A450, iCandelo 24 okanye i-26.

Idatha elandelayo ivela kwi-ASTM A450 kwaye ihlangabezana neemfuno ezifanelekileyo zepayipi yensimbi edibeneyo kuphela.

Ukutenxa ubunzima

0 - +10%.

Ukutenxa koDonga lokutyeba

0 - +18%.

Ukutenxa ngaphandle kweDiameter

| Ngaphandle Ububanzi | Ukwahluka okuvumelekileyo | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ±0.004 | ±0.1 |

| 1<OD ≤1½ | 25.4<OD ≤38.4 | ±0.006 | ±0.15 |

| 1½<OD<2 | 38.1< OD<50.8 | ±0.008 | ±0.2 |

| 2≤ OD<2½ | 50.8≤ OD<63.5 | ±0.010 | ±0.25 |

| 2½≤ OD<3 | 63.5≤ OD<76.2 | ±0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ±0.38 |

| 4<OD ≤7½ | 101.6<OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Emva kokufakwa kwibhoyili, ityhubhu kufuneka ikwazi ukumelana nokwandiswa kunye nokugoba ngaphandle kweziphene eziqhekezayo okanye ukuqhekeka kwi-welds.

Ityhubhu yeheater enkulu iya kukwazi ukumelana nayo yonke imisebenzi eyimfuneko yokwenziwa, ukuwelda, kunye nokugoba ngaphandle kweziphene.

Isetyenziswa kakhulu kwiityhubhu zebhoyila, imibhobho yebhoyila, imibhobho yeheater enkulu, kunye neziphelo ezikhuselekileyo.

I-ASTM A178 iBanga AIsiqulatho sekhabhoni esisezantsi setyhubhu siyinika ukuwelda okulungileyo kunye nokuqina okuphezulu kwizicelo ezingafakwanga kuxinzelelo oluphezulu.

Isetyenziswa ikakhulu kuxinzelelo oluphantsi kunye nobushushu obuphakathi izicelo ezifana nezibiyitha zoxinzelelo oluphantsi (umzekelo, iibhoyila zasekhaya, izakhiwo ezincinci zeeofisi, okanye iibhoyila zasefektri) kunye nezinye izitshintshi zobushushu kwiindawo ezinobushushu obuphantsi.

I-ASTM A178 iBanga Cinekhabhoni ephezulu kunye nomxholo wemanganese onika le ityhubhu amandla angcono kunye nokumelana nobushushu kwiimeko zokusebenza ezifuna kakhulu.

Ilungele ukusetyenziswa koxinzelelo oluphakathi kunye nobushushu obuphakathi obufana neebhoyila zemizi-mveliso kunye namanzi ashushu, ezifuna uxinzelelo oluphezulu kunye namaqondo obushushu kunebhoilers zasekhaya.

I-ASTM A178 iBanga Diibhubhu zinomxholo ophezulu we-manganese kunye nomxholo ofanelekileyo we-silicon ukunika amandla agqwesileyo kunye nokumelana nokushisa, okwenza ukuba zizinze kwiindawo eziphakamileyo zokushisa kunye noxinzelelo oluphezulu kwaye zilungele ukumelana neemeko zokusebenza ezigqithisileyo.

Ngokuqhelekileyo isetyenziswa kwiindawo ezinoxinzelelo oluphezulu kunye nobushushu obuphezulu, obufana neebhoyila zesikhululo samandla kunye ne-industrial superheaters.

1. I-ASTM A179 / ASME SA179: Umthungo wentsimbi ethambileyo yokutshintsha ubushushu kunye neetyhubhu ze-condenser zenkonzo ye-cryogenic. Ngokuyintloko isetyenziswe kwiindawo eziphantsi zoxinzelelo, ifana neekhemikhali kunye neepropathi zomatshini kwi-ASTM A178.

2. I-ASTM A192 / ASME SA192: Iityhubhu zebhoyila ye-carbon steel ezingenamthungo kwinkonzo yoxinzelelo oluphezulu. Ngokuyintloko isetyenziselwa ukwenziwa kweendonga zamanzi, i-economizers kunye namanye amacandelo oxinzelelo kwiibhoyili ze-ultra-high.

3. ASTM A210 / ASME SA210: Igubungela ibhoyila ye-carbon ephakathi kunye ne-alloy steel boiler kunye ne-superheater tubes kubushushu obuphezulu kunye neenkqubo zebhoyila zoxinzelelo oluphakathi.

4. DIN 17175: Iityhubhu zentsimbi ezingenamthungo kunye nemibhobho yokusetyenziswa kuxinzelelo oluphezulu kunye neendawo zokushisa eziphezulu. Isetyenziswa kakhulu ekwenzeni imibhobho yomphunga kwiibhoyili kunye neenqanawa zoxinzelelo.

5. EN 10216-2: Ichaza iimeko zobugcisa kwiityhubhu ezingenamthungo kunye nemibhobho ye-non-alloy kunye ne-alloy steels eneempawu ezichaziweyo eziphezulu zokushisa kwezicelo phantsi koxinzelelo.

6. I-JIS G3461: Igubungela iityhubhu zensimbi zekhabhoni kwiibhoyili kunye nokutshintsha ubushushu. Ifanelekile kwiimeko eziqhelekileyo zokutshintsha ubushushu obuphantsi kunye noxinzelelo oluphakathi.

Singumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Ngayo nayiphi na imibuzo okanye ukufunda ngakumbi malunga neminikelo yethu, ungalibazisi ukuqhagamshelana nathi. Izisombululo zakho ezifanelekileyo zemibhobho yentsimbi ngumyalezo nje osuka kude!