I-ASTM A335 P91, kwaziwa njengeASME SA335 P91, ngumbhobho wensimbi ongenamthungo we-ferritic alloy wenkonzo yobushushu obuphezulu, i-UNS No. K91560.

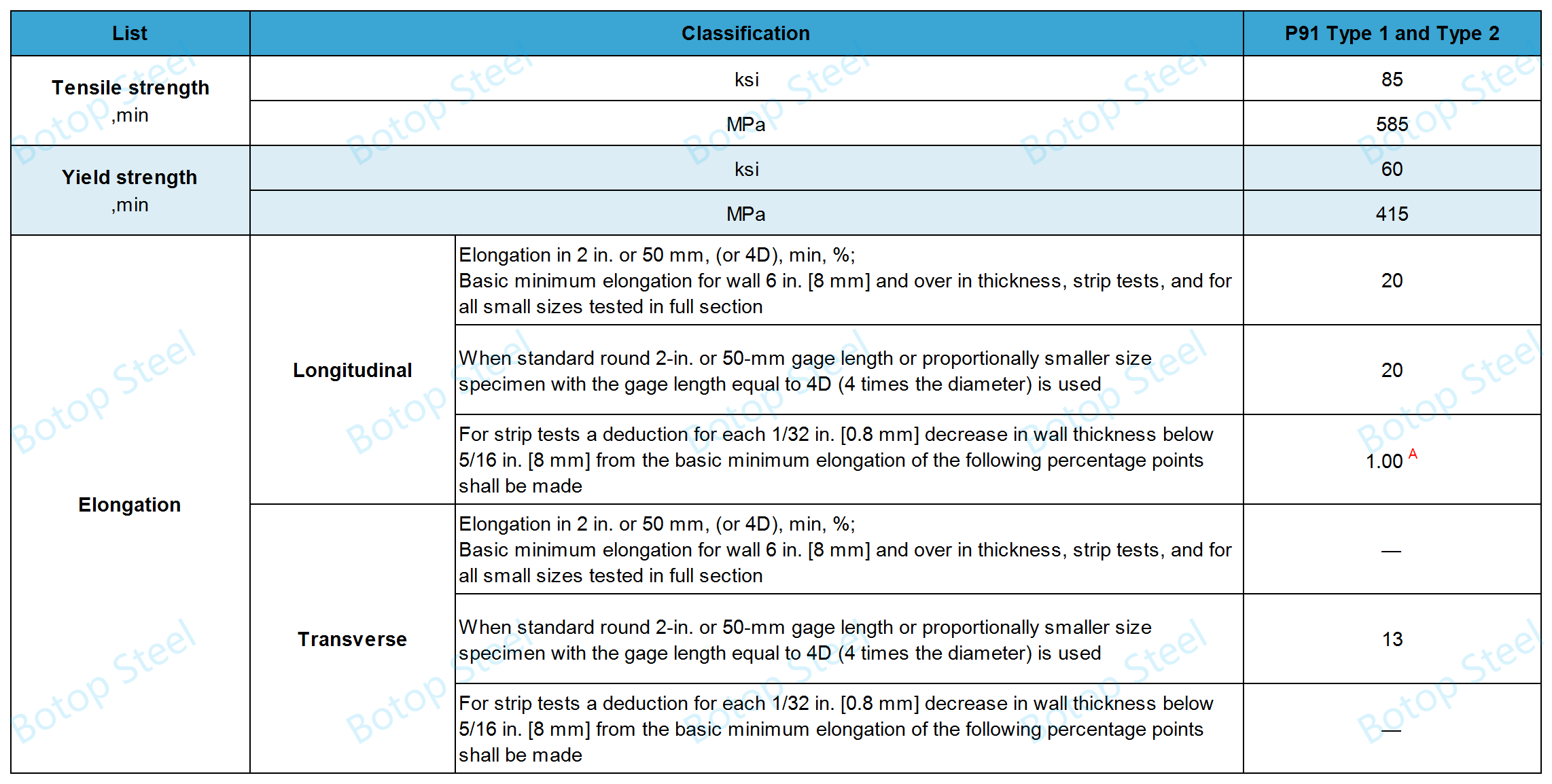

Inobuncinciamandla okuqina angama-585 MPa(85 ksi) kunye nobuncinciisivuno amandla 415 MPa(60 ksi).

P91ubukhulu becala iqulathe izinto ezidibanisa izinto ezinje ngechromium kunye nemolybdenum, kunye neentlobo ngeentlobo zezinye izinto ezidibanisayo zongezwa, ezizezointsimbi ephezulu-alloy, ngoko inamandla amakhulu kunye nokumelana nokugqwesa okugqwesileyo.

Ukongeza, iP91 ifumaneka kwiindidi ezimbini,Uhlobo loku-1kwayeUhlobo lwesi-2, kwaye isetyenziswa ngokuqhelekileyo kwizityalo zamandla, iindawo zokucokisa, izibonelelo zekhemikhali izixhobo ezibalulekileyo, kunye nemibhobho kwiindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu.

Ipayipi yensimbi ye-P91 ihlelwe kwiindidi ezimbini, Uhlobo loku-1 kunye noHlobo lwe-2.

Zombini ezi ntlobo ziyafana ngokweempawu zoomatshini kunye nezinye iimfuno ezinjengonyango lobushushu,kunye nomahluko omncinci ekubunjweni kweekhemikhali kunye nokugxila kwisicelo esithile.

Ukwakhiwa kweekhemikhali: Xa kuthelekiswa noHlobo lwe-1, ukubunjwa kweekhemikhali zoHlobo lwe-2 lungqongqo kwaye luqulethe izinto ezidibeneyo zokubonelela ukushisa okungcono kunye nokuxhathisa ukubola.

Usetyenziso: Ngenxa yokwakheka kweekhemikhali eziphuculweyo, udidi lwesi-2 lufaneleke ngakumbi kumaqondo obushushu aphezulu kakhulu okanye iindawo ezingcolisekileyo, okanye kwizicelo apho kufuneka amandla aphezulu kunye nokuqina.

Umbhobho wentsimbi we-ASTM A335 kufuneka ubeengenamthungo.

Inkqubo yokuvelisa engenamthungo yahlulahlulweukugqiba okushushukwayeebandayo.

Ngezantsi umzobo wenkqubo yokugqiba eshushu.

Ngokukodwa, i-P91, i-high-alloy iron pipe, ehlala isetyenziswa kwiindawo ezibuhlungu ngokuxhomekeke kumaqondo okushisa aphezulu kunye noxinzelelo, umbhobho wensimbi ongenamthungo ugxininiswe ngokufanayo kwaye unokwenziwa kwi-thick-walled, ngaloo ndlela uqinisekisa ukhuseleko oluphezulu kunye nokusebenza kakuhle kweendleko.

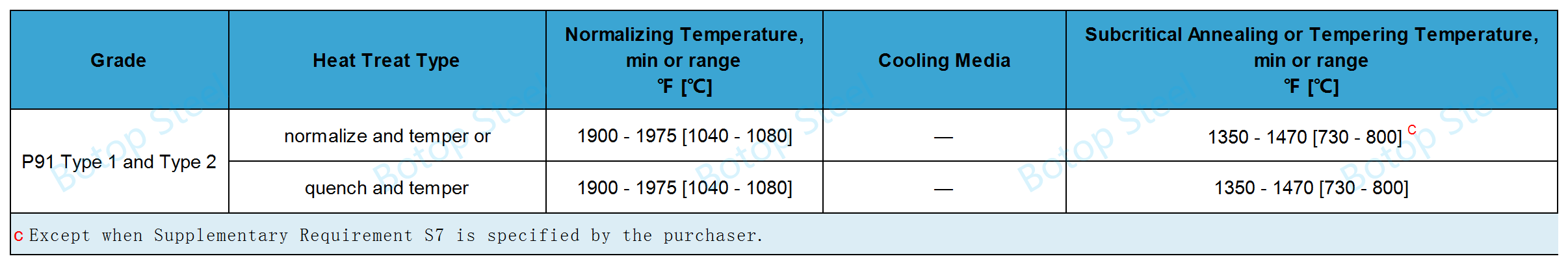

I-P91 Yonke imibhobho kufuneka iphathwe ngobushushu ukuze kulungiswe i-microstructure yombhobho, iphucule iimpawu zayo zomatshini, kwaye ikhulise ukuchasana nokushisa okuphezulu kunye noxinzelelo.

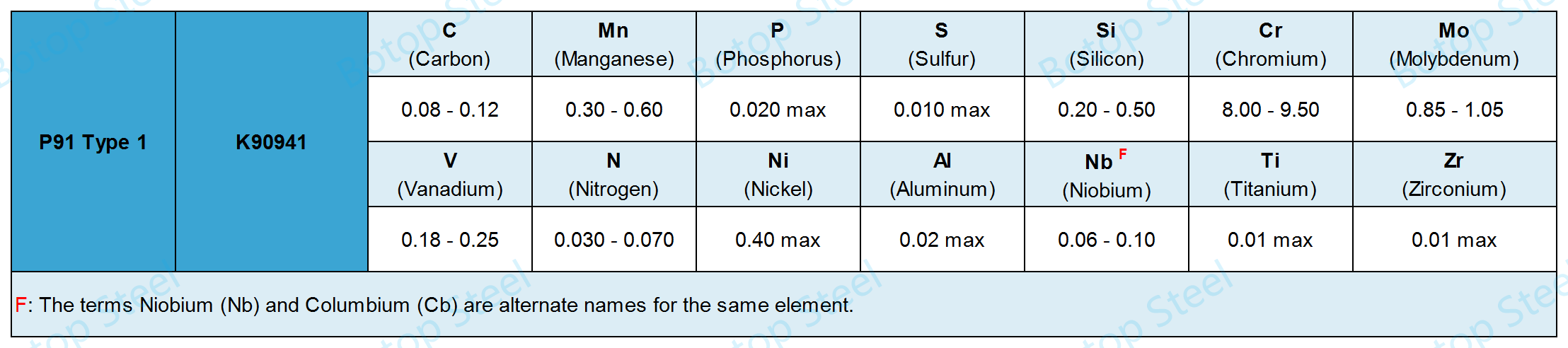

I-P91 Uhlobo lwe-1 Amacandelo eMichiza

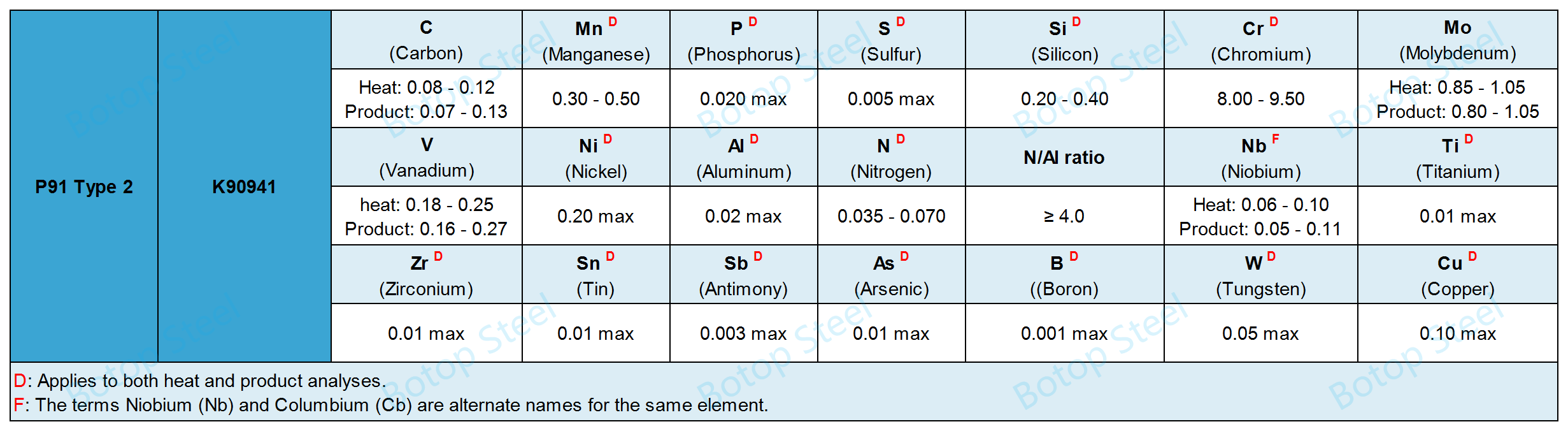

I-P91 Uhlobo lwe-2 Amacandelo eMichiza

Ngemifanekiso emibini engentla, kulula ukubona umahluko phakathi kwe-Type 1 kunye ne-Type 2 izinto zekhemikhali kunye nezithintelo.

1. Ipropathi yeTensile

Uvavanyo lwe-tensile luqhele ukusetyenziswa ukulinganisa iunikeze Amandla, tensile strength, kwayeelongation yenkqubo yokulinga yombhobho wentsimbi, kwaye isetyenziswa ngokubanzi kwiipropati eziphathekayo zovavanyo.

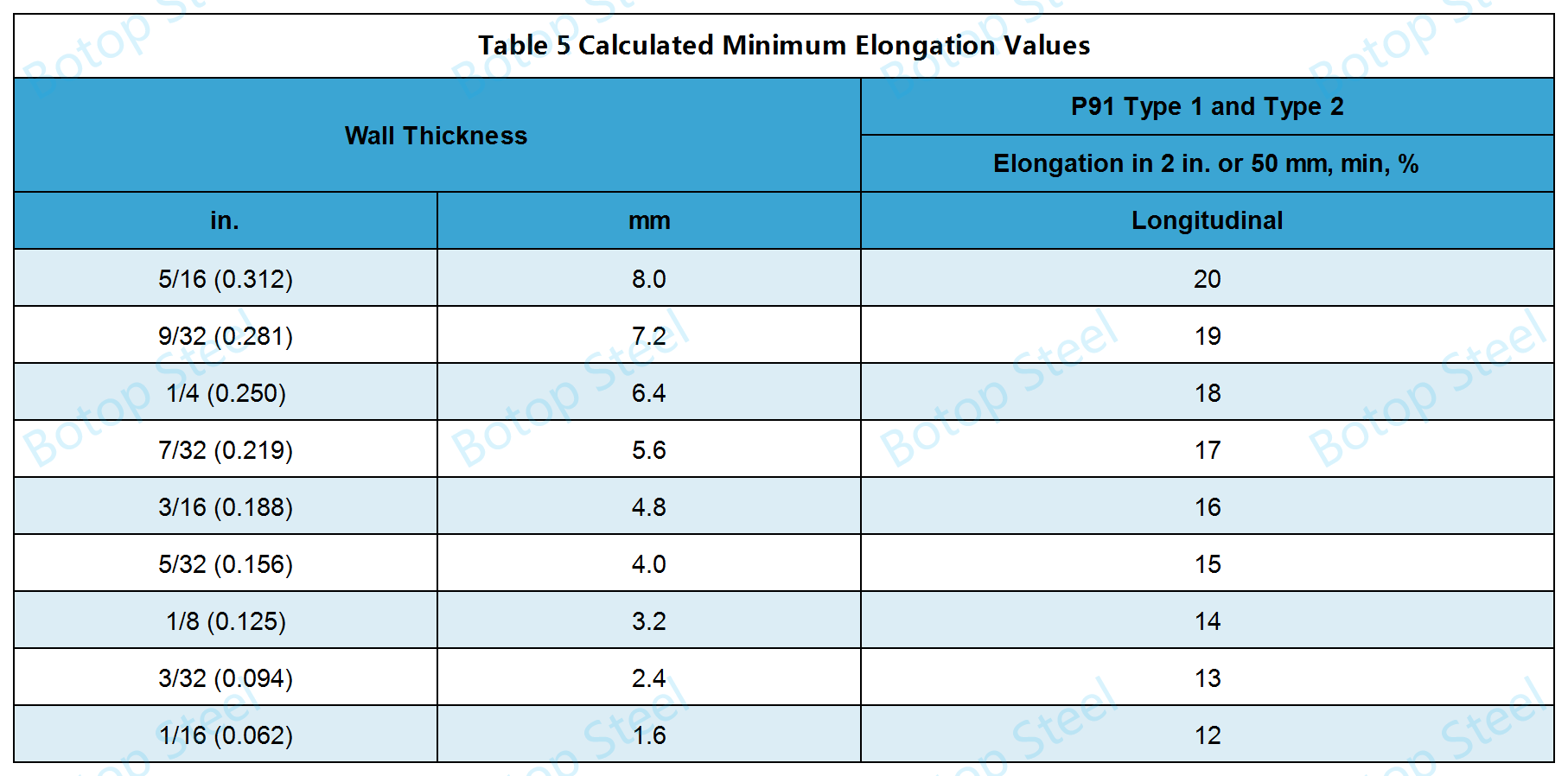

AItheyibhile 5 inika amaxabiso amancinci abaliweyo.

Apho ubukhulu bodonga buphakathi kwala maxabiso mabini angentla, elona xabiso lisezantsi lobude limiselwa ngale fomula ilandelayo:

I-Longitudinal, i-P91: E = 32t + 15.00 [E = 1.25t + 15.00]

apho:

E = elongation kwi-2 in. okanye 50 mm, %,

t = ubukhulu bokwenyani besampulu, ngaphakathi [mm].

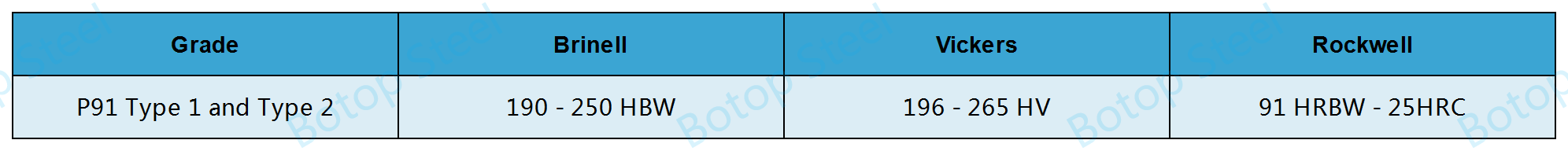

2. Ubulukhuni

Iindlela ezahlukeneyo zokuvavanya ubulukhuni zinokusetyenziswa, kubandakanya iVickers, iBrinell, kunye neRockwell.

Ubunzima bodonga <0.065 ngaphakathi [1.7 mm]: Akukho vavanyo lokuqina olufunekayo;

I-0.065 ngaphakathi [1.7 mm] ≤ ubukhulu bodonga <0.200 ngaphakathi [5.1 mm]: Uvavanyo lobulukhuni be-Rockwell luya kusetyenziswa;

Ubunzima bodonga ≥ 0.200 in. [5.1 mm]: ukusetyenziswa okukhethiweyo kovavanyo lobulukhuni beBrinell okanye uvavanyo lobulukhuni lwe-Rockwell.

Uvavanyo lobulukhuni beVickers lusebenza kubo bonke ubukhulu bodonga lwetyhubhu. Indlela yokuvavanya iqhutyelwa ngokuhambelana neemfuno ze-E92.

3. Uvavanyo lokucaba

Iimvavanyo ziya kuqhutywa ngokuhambelana neCandelo lama-20 lomgangatho we-ASTM A999.

4. Uvavanyo lwe-Bend

Bend 180 ° kwiqondo lokushisa, akukho zintanda ziya kubonakala ngaphandle kwendawo egobileyo.

Ubungakanani> I-NPS25 okanye i-D / t ≥ 7.0: Uvavanyo lokugoba kufuneka lwenziwe ngaphandle kovavanyo lwe-flattening.

5. P91 IiNkqubo zoMfuniselo oziKhethayo

Ezi zinto zilandelayo zovavanyo azifuneki izinto zovavanyo, ukuba ziyimfuneko zinokumiselwa ngothethwano.

S1: Uhlalutyo lwemveliso

S3: Uvavanyo lokucaba

I-S4: Isakhiwo seMetal kunye noVavanyo lwe-Etching

S5: Iifotomicrographs

I-S6: Iifotomicrographs zamaqhekeza ngamnye

I-S7: Unyango olulolunye ubushushu-iBanga le-P91 Uhlobo lwe-1 kunye noHlobo lwe-2

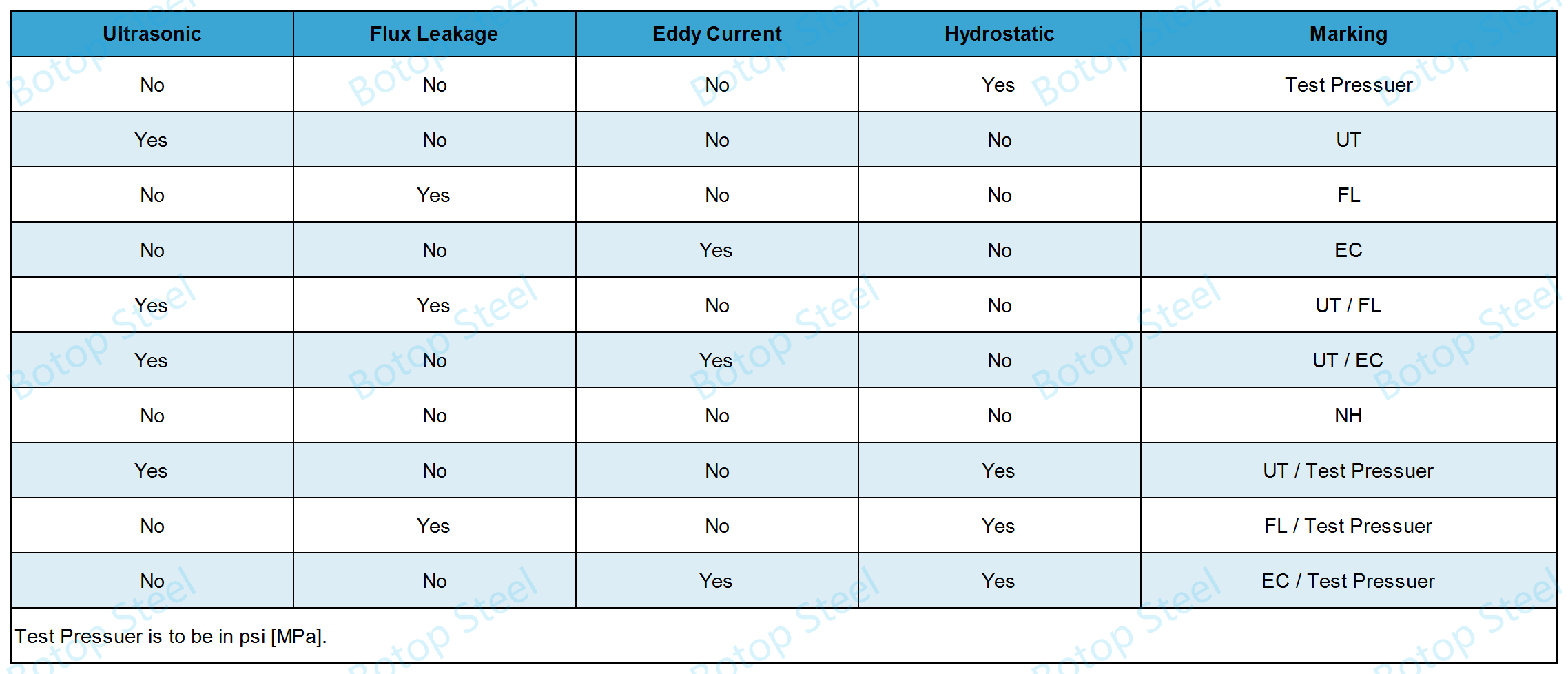

Uvavanyo lwe-P91 yamanzi luya kuhambelana nezi mfuno zilandelayo.

Idayamitha yangaphandle>10in. [250mm] kunye nobunzima bodonga ≤ 0.75in. [19mm]: oku kufuneka kube luvavanyo lwe-hydrostatic.

Ezinye iisayizi zokuvavanya umbane ongonakaliyo.

Kwintsimbi ye-ferritic alloy kunye neetyhubhu zensimbi ezingenasici, udonga luphantsi koxinzelelo olungekho ngaphantsiI-60% yowona mandla esivuno esincinci achaziweyo.

Uxinzelelo lovavanyo lwe-hydro luya kugcinwa ubuncinane 5sngaphandle kokuvuza okanye ezinye iziphene.

Uxinzelelo lwe-hydraulicingabalwa kusetyenziswa ifomula:

P = 2St/D

P= uxinzelelo lovavanyo lwe-hydrostatic kwi-psi [MPa];

S = uxinzelelo lwendonga yombhobho kwi-psi okanye [MPa];

t = ubukhulu bodonga obuchaziweyo, ubukhulu bodonga lwegama ngokwenombolo yeshedyuli ekhankanyiweyo ye-ANSI okanye amaxesha ayi-1.143 ubukhulu obuchaziweyo obuncinci bodonga, ngo. [mm];

D = icaciswe ngaphandle kwe-diameter, i-diameter yangaphandle ehambelana nobukhulu bombhobho we-ANSI ochaziweyo, okanye i-diameter yangaphandle ebalwa ngokudibanisa i-2t (njengoko kuchazwe ngasentla) kwi-diameter echaziweyo yangaphakathi, ngo-. [mm].

Umbhobho weP91 uhlolwe ngendlela yovavanyo lwe-E213. Umgangatho we-E213 uxhalabele ngokuyintloko ngovavanyo lwe-ultrasonic (UT).

Ukuba ichazwe ngokuthe ngqo kumyalelo, inokuphinda ihlolwe ngokwendlela yovavanyo ye-E309 okanye ye-E570.

Umgangatho we-E309 uqhele ukujongana nokuhlolwa kwe-electromagnetic (eddy current), ngelixa i-E570 iyindlela yokuhlola ebandakanya ii-eddy current arrays.

Ukwahluka okuvumelekileyo kwiDamitha

Kuba umbhobho uyalelwe ukubangaphakathi ngaphakathi, i-diameter yangaphakathi ayisayi kwahluka ngaphezu kwe-±1% ukusuka kwidayamitha echaziweyo yangaphakathi.

Iiyantlukwano ezivumelekileyo kuDonga olutyebileyo

Imilinganiselo yobukhulu bodonga iya kwenziwa kusetyenziswa iikhalitha zoomatshini okanye zilinganiswe ngokufanelekileyo izixhobo zovavanyo ezingonakalisiyo zokuchaneka okufanelekileyo. Kwimeko yempikiswano, umlinganiselo ogqitywe kusetyenziswa iikhalitha zoomatshini uya kuphumelela.

Ubuncinane bodonga olungqingqwa kunye nedayamitha yangaphandle yokuhlolwa ukuze kuthotyelwe le mfuno yombhobho oyalelwa yi-NPS [DN] kunye nenombolo yeshedyuli ibonisiweASME B36.10M.

Iziphene

Ukungafezeki komphezulu kuthathwa njengeziphene ukuba zidlula i-12.5% yobukhulu bodonga lwegama okanye ukugqithisa ubuncinci bodonga.

Ukungafezeki

Iimpawu zoomatshini, ukukrazuka, kunye nemingxuma, nakuphi na ukungafezeki okunzulu kune-1/16 in. [1.6 mm].

Amanqaku kunye nama-abrasions achazwa njengamanqaku ekhebula, i-dinges, amanqaku esikhokelo, amanqaku okuqengqeleka, imikrwelo yebhola, amanqaku, amanqaku okufa, njalo njalo.

Ukulungisa

Iziphene zingasuswa ngokusila, ngaphandle kokuba udonga oluseleyo lungekho ngaphantsi kobuncinane bodonga.

Ukulungiswa kwakhona kunokwenziwa ngokuwelda kodwa kufuneka kuhambelane neemfuno ezifanelekileyo ze-A999.

Zonke ii-welds zokulungisa kwi-P91 ziya kwenziwa ngenye yeenkqubo ze-welding ezilandelayo kunye nezinto ezisetyenziswayo: SMAW, A5.5 / A5.5M E90XX-B9: SAW, A5.23 / A5.23M EB9 + i-neutral flux; GTAW, A5.28/A5.28M ER90S-B9; kunye neFCAW A5.29/A5.29M E91TI-B9. Ukongeza, isixa somxholo we-Ni + Mn wazo zonke izinto ezisetyenziselwa ukuwelda ezisetyenziselwa ukulungiswa kwe-weld P91 Uhlobo lwe-1 kunye noHlobo lwe-2 aluyi kudlula i-1.0%.

Umbhobho we-P91 kufuneka uphathwe ubushushu kwi-1350-1470 ° F [730-800 ° C] emva kokulungiswa kwe-weld.

Umphezulu wangaphandle wombhobho wensimbi ohloliweyo uya kuba nezi zinto zilandelayo:

Igama lomenzi okanye uphawu lokuthengisa; inombolo esemgangathweni; ibakala ubude kunye nesimboli esongezelelweyo "S".

Iimpawu zoxinzelelo lwe-hydrostatic kunye novavanyo olungonakalisi kwitheyibhile engezantsi kufuneka kwakhona zibandakanywe.

Ukuba umbhobho ulungiswa nge-welding, iya kuphawulwa "WR".

p91 Uhlobo (uHlobo loku-1 okanye uhlobo lwesi-2) kufuneka luboniswe.

EN 10216-2: X10CrMoVNb9-1 okanye 1.4903;

I-JIS G 3462: STPA 28;

GB/T 5310: 10Cr9Mo1VNb;

Ezi zilinganisi zisondele kakhulu ekubunjweni kweekhemikhali kunye neempawu zoomatshini kwi-ASTM A335 P91.

Izinto eziphathekayol: I-ASTM A335 P91 ipayipi yentsimbi engenamthungo;

OD: 1/8"- 24";

WT: ngokwenxa yeASME B36.10iimfuno;

Ishedyuli: SCH10, SCH20, SCH30,I-SCH40, SCH60,SCH80, SCH100, SCH120, SCH140 kunye ne-SCH160;

Ukuchongwa:I-STD (eqhelekileyo), i-XS (eyomelele ngakumbi), okanye i-XXS (i-double extra-strong);

Ukwenza ngokwezifiso: Ubungakanani bombhobho obungekho semgangathweni buyafumaneka, ubungakanani obulungiselelweyo buyafumaneka xa uceliwe;

Ubude: Ubude obuthile kunye nobungenamkhethe;

Izatifikethi ze-IBR: Sinokuqhagamshelana nombutho wokuhlola umntu wesithathu ukufumana isatifikethi se-IBR ngokweemfuno zakho, imibutho yethu yokuhlola intsebenziswano yi-BV, SGS, TUV, njl.;

Isiphelo: Isiphelo seflethi, i-beveled, okanye isiphelo sombhobho odibeneyo;

Umphezulu: Umbhobho okhanyayo, ipeyinti, kunye nolunye ukhuseleko lwexeshana, ukususwa komhlwa kunye nokupolisha, igalvanized kunye neplastiki egqunywe, kunye nolunye ukhuseleko lwexesha elide;

Ukupakisha: Icala leplanga, ibhanti yentsimbi okanye ukupakisha ucingo lwentsimbi, iplastiki okanye umkhuseli wentsimbi yombhobho wentsimbi, njl.