I-ASTM A335 P11umbhobho wentsimbi ngumbhobho wensimbi ongenamthungo we-ferritic ophantsi we-alloy wenkonzo yobushushu obuphezulu, ukutyunjwa kwe-UNS K11597.

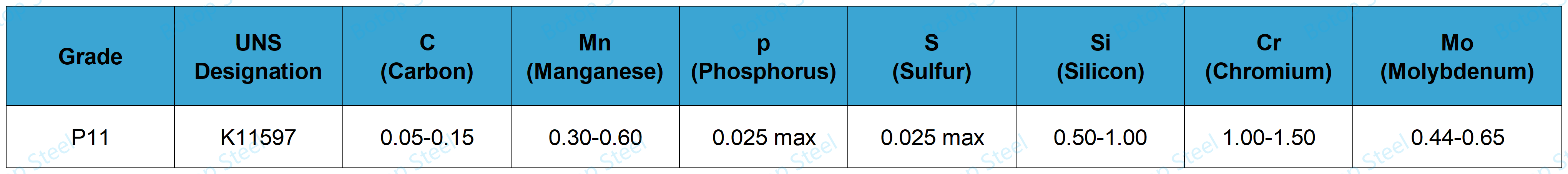

I-P11 i-alloy ye-chromium-molybdenum enomxholo we-chromium we-1.00-1.50% kunye nomxholo we-molybdenum we-0.44-0.65%.

Iqhele ukusetyenziswa kwiibhoyila, ii-superheaters, kunye nokutshintsha ubushushu kwizikhululo zamandla kunye nezityalo zekhemikhali.

Iimfuno zobugcisa zeASME SA335kwayeI-ASTM A335ziyafana, ukuze kube lula unikezelo, siya kusebenzisa "ASTM A335" ukubhekisa kule migangatho mibini.

Izinto eziphathekayol: I-ASTM A335 P11 ipayipi yentsimbi engenamthungo;

OD: 1/8"- 24";

WT: ngokwenxa yeASME B36.10iimfuno;

Ishedyuli: SCH10, SCH20, SCH30,I-SCH40, SCH60,SCH80, SCH100, SCH120, SCH140 kunye ne-SCH160;

Ukuchongwa: STD, XS, XXS;

Ukwenza ngokwezifiso: Ubungakanani bombhobho obungekho semgangathweni buyafumaneka, ubungakanani obulungiselelweyo buyafumaneka xa uceliwe;

Ubude: Ubude obuthile kunye nobungenamkhethe;

Izatifikethi ze-IBR: Sinokuqhagamshelana nombutho wokuhlola umntu wesithathu ukufumana isatifikethi se-IBR ngokweemfuno zakho, imibutho yethu yokuhlola intsebenziswano yi-BV, SGS, TUV, njl.;

Isiphelo: Isiphelo seflethi, i-beveled, okanye isiphelo sombhobho odibeneyo;

Umphezulu: Umbhobho okhanyayo, ipeyinti, kunye nolunye ukhuseleko lwexeshana, ukususwa komhlwa kunye nokupolisha, igalvanized kunye neplastiki egqunywe, kunye nolunye ukhuseleko lwexesha elide;

Ukupakisha: Icala leplanga, ibhanti yentsimbi okanye ukupakisha ucingo lwentsimbi, iplastiki okanye umkhuseli wentsimbi yombhobho wentsimbi, njl.

Ngaphandle kokuba kucaciswe ngenye indlela kwi-A335, imathiriyeli enikezelwe phantsi kolu luhlu iya kuhambelana neemfuno ezisebenzayo zohlelo lwangoku lweNkcazo.A999/A999M.

Umbhobho wentsimbi we-ASTM A335 kufuneka ubeengenamthungo. Iityhubhu zentsimbi ezingenamthungo zinika ukuthembeka okukhulu kunye nokufana xa ziphantsi koxinzelelo oluphezulu kunye neendawo zokushisa.

Ingenamthungo inokwahlulwa ngokuthe ngqo njengokutsalwa ngokubanda kwaye kushushu kugqityiwe, kuxhomekeke kwisicelo esithile kunye nobukhulu.

Umzobo obandayo udla ngokusetyenziselwa iidamitha ezincinci okanye kwiibhubhu ezifuna ukuchaneka okuphezulu kunye nomgangatho omhle womphezulu. Ukugqitywa okushushu ngokuqhelekileyo kusetyenziselwa ukuvelisa imibhobho yentsimbi emikhulu ethe tye kunye nengqindilili.

Ngezantsi itshathi yokuhamba kwenkqubo yokuvelisa umbhobho wensimbi ongenamthungo oshushu.

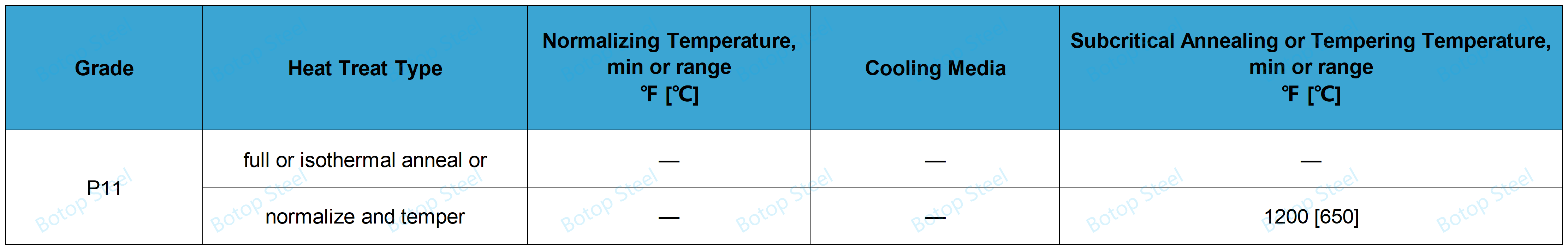

Ubushushu bonyango lwemathiriyeli ye-P11 lunokuthi lube luzele okanye lufakwe kwi-isothermal okanye lufudumeze emva kokuqheleka, kwaye xa luqhelekile kwaye lufudumala, ubushushu bobushushu bufanele bube bubuncinci be-1200 ° F (650 ° C).

Ukusuka kwimichiza, sinokuyibona ngokulula loo ntoI-P11 yingxubevange yechromium-molybdenum.

I-Chromium-molybdenum alloys yiklasi yeentsimbi ezine-chromium (Cr) kunye ne-molybdenum (Mo) njengezona zinto ziphambili zokudibanisa. Ukongezwa kwezi zinto kwandisa kakhulu amandla, ubunzima, ukuxhathisa ukunxiba, kunye nokumelana nokubola kwentsimbi. Kwiqondo lokushisa eliphezulu, ii-alloys ze-Cr-Mo ziyakwazi ukugcina iimpawu ezintle zoomatshini kunye nesakhiwo esizinzile.

Cr: iphucula ukuxhathisa kwe-oxidation kunye nokumelana nokugqwala kwe-alloy, inceda ukwenza ifilimu ye-oxide eyomeleleyo, kwaye ikhusela izinto eziphathekayo kwimidiya ephazamisayo.

Mo: Ukuphucula amandla e-alloy, ngokukodwa kwiqondo lokushisa eliphezulu, kuphucula ukuxhathisa kwe-creep, kunye nokwandisa amandla aphezulu okushisa kwezinto.

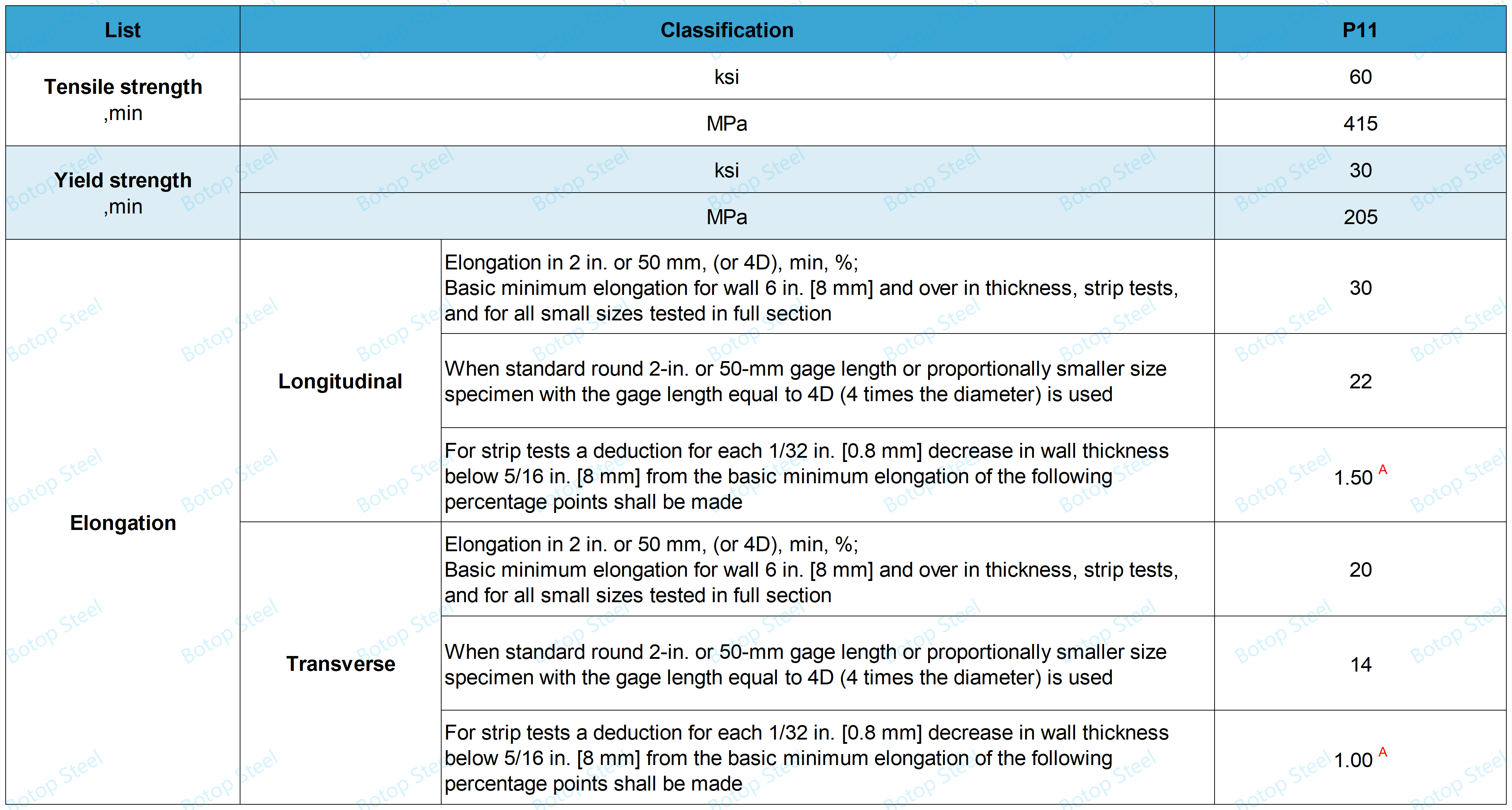

1. Ipropathi yeTensile

Uvavanyo lwe-tensile luqhele ukusetyenziswa ukulinganisa iunikeze Amandla, tensile strength, kwayeelongation yenkqubo yokulinga yombhobho wentsimbi, kwaye isetyenziswa ngokubanzi kwiipropati eziphathekayo zovavanyo.

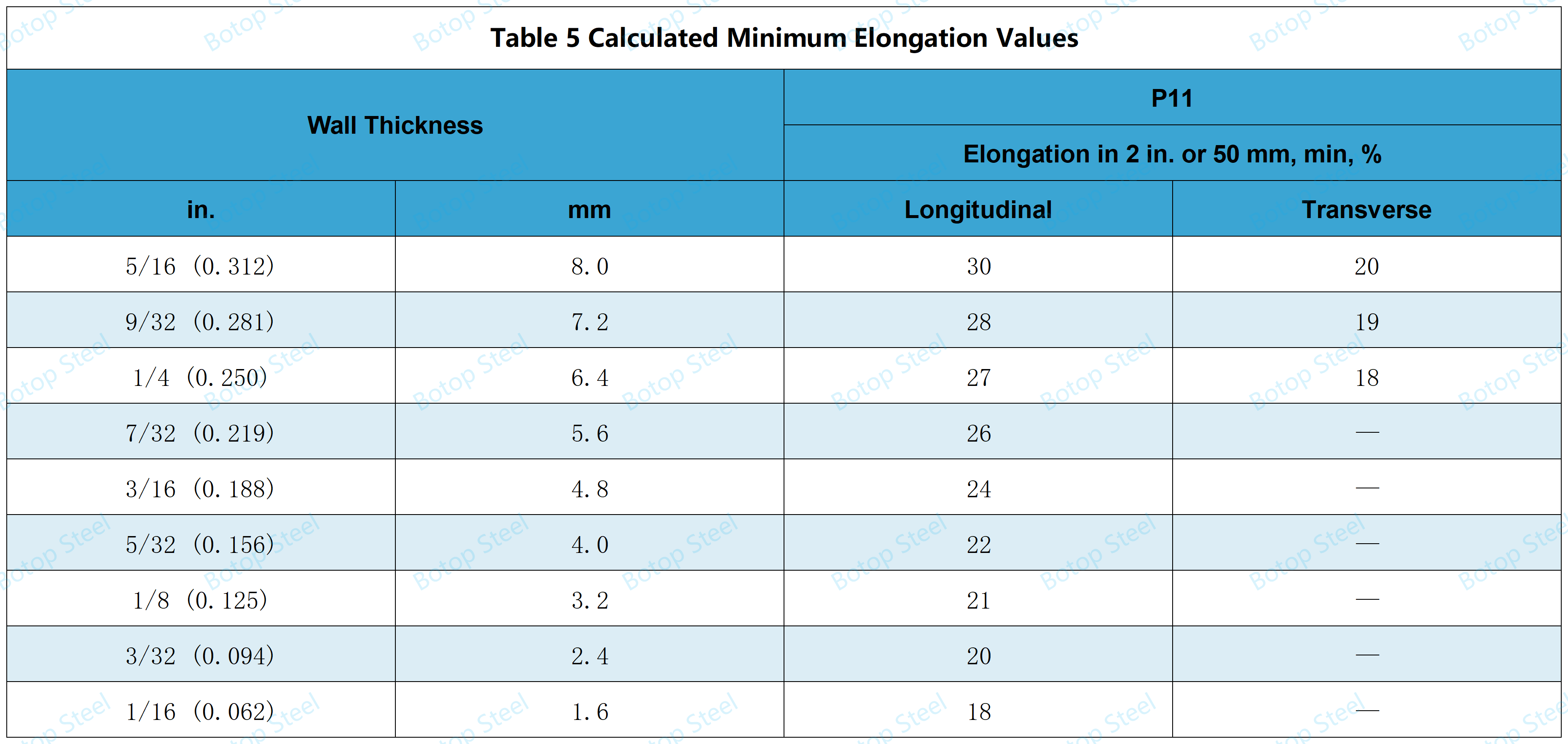

AItheyibhile 5 inika amaxabiso amancinci abaliweyo.

Apho ubukhulu bodonga buphakathi kwala maxabiso mabini angentla, elona xabiso lisezantsi lobude limiselwa ngale fomula ilandelayo:

I-Longitudinal, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

apho:

E = elongation kwi-2 in. okanye 50 mm, %,

t = ubukhulu bokwenyani besampulu, ngaphakathi [mm].

2. Ubulukhuni

Umbhobho weBakala P11 awufuni ukuvavanywa kobunzima.

Ixabiso lereferensi yobulukhuni linikiwe ngezantsi.

Imeko eyongezelelweyo:

Ubunzima buhlala buphakathi kwe-150 kunye ne-200 HB.

Imeko eqhelekileyo kunye neyomsindo:

Ubunzima buqala malunga ne-170 ukuya kwi-220 HB.

Imeko yokuqina kunye nobushushu:

Ukuqina kunokufikelela kwi-250 ukuya kwi-300 HB okanye ngaphezulu, kuxhomekeke kwiqondo lokushisa kunye nexesha.

3. IiNkqubo zoMfuniselo oziKhethayo

Ezi zinto zilandelayo zovavanyo azifuneki izinto zovavanyo, ukuba ziyimfuneko zinokumiselwa ngothethwano.

Uhlalutyo lweMveliso

Uvavanyo lokucaba

Bend Test

Ulwakhiwo lweMetal kunye novavanyo lwe-Etching

Iifotomicrographs

Iifotomicrographs zamaqhekeza ngamnye

I-P11 hydrotest iya kuhambelana nezi mfuno zilandelayo.

Idayamitha yangaphandle>10in. [250mm] kunye nobunzima bodonga ≤ 0.75in. [19mm]: oku kufuneka kube luvavanyo lwe-hydrostatic.

Ezinye iisayizi zokuvavanya umbane ongonakaliyo.

Ezi mfuno zilandelayo zovavanyo lwe-hydrostatic zihlanganiswe kwiimfuno ze-ASTM A999:

Kwintsimbi ye-ferritic alloy kunye neetyhubhu zensimbi ezingenasici, udonga luphantsi koxinzelelo olungekho ngaphantsiI-60% yowona mandla esivuno esincinci achaziweyo.

Uxinzelelo lovavanyo lwe-hydro luya kugcinwa ubuncinane 5sngaphandle kokuvuza okanye ezinye iziphene.

Uxinzelelo lwe-hydraulicingabalwa kusetyenziswa ifomula:

P = 2St/D

P= uxinzelelo lovavanyo lwe-hydrostatic kwi-psi [MPa];

S = uxinzelelo lwendonga yombhobho kwi-psi okanye [MPa];

t = ubukhulu bodonga obuchaziweyo, ubukhulu bodonga lwegama ngokwenombolo yeshedyuli ekhankanyiweyo ye-ANSI okanye amaxesha ayi-1.143 ubukhulu obuchaziweyo obuncinci bodonga, ngo. [mm];

D = icaciswe ngaphandle kwe-diameter, i-diameter yangaphandle ehambelana nobukhulu bombhobho we-ANSI ochaziweyo, okanye i-diameter yangaphandle ebalwa ngokudibanisa i-2t (njengoko kuchazwe ngasentla) kwi-diameter echaziweyo yangaphakathi, ngo-. [mm].

Umbhobho ngamnye uya kuhlolwa ngendlela yoviwo engonakalisiyo ngokuhambelana ne-PracticeE213, ZiqheliseniE309, okanye ZiqheliseniE570.

Ukwahluka okuvumelekileyo kwiDamitha

Kuba umbhobho uyalelwe ukubangaphakathi ngaphakathi, i-diameter yangaphakathi ayisayi kwahluka ngaphezu kwe-±1% ukusuka kwidayamitha echaziweyo yangaphakathi.

Iiyantlukwano ezivumelekileyo kuDonga olutyebileyo

Imilinganiselo yobukhulu bodonga iya kwenziwa kusetyenziswa iikhalitha zoomatshini okanye zilinganiswe ngokufanelekileyo izixhobo zovavanyo ezingonakalisiyo zokuchaneka okufanelekileyo. Kwimeko yempikiswano, umlinganiselo ogqitywe kusetyenziswa iikhalitha zoomatshini uya kuphumelela.

Ubuncinane bodonga olungqingqwa kunye nedayamitha yangaphandle yokuhlolwa ukuze kuthotyelwe le mfuno yombhobho oyalelwa yi-NPS [DN] kunye nenombolo yeshedyuli ibonisiweASME B36.10M.

Ngokuqhelekileyo isetyenziswa kwiibhoyila, ii-superheaters, kunye nokutshintsha ubushushu kwizikhululo zamandla kunye nezityalo zekhemikhali.

Iibhoyila: I-P11 isetyenziswa ngokubanzi ekwakhiweni kweebhoyili ngenxa yokuchasana nokushisa okuphezulu kunye noxinzelelo, ngokukodwa kumacandelo aphantsi kokushisa okukhulu kunye noxinzelelo.

Iheater enkulu: Isetyenziselwa ukunyusa ubushushu bomphunga ukunyusa ngakumbi ukusebenza kakuhle kwe-thermal. i-p11 iqinisekisa ukuba amandla kunye nokuqina kwezinto eziphathekayo zigcinwa nakwiqondo lokushisa eliphezulu.

Izitshintshi zobushushu: I-P11 iphucula i-corrosion kunye nobushushu obuphezulu bokuchasana nobushushu, ngaloo ndlela iphucula ukuthembeka kunye nokhuseleko lwezixhobo.

Iinkqubo zombhobho: Iinkqubo zemibhobho kwizityalo zekhemikhali zihlala zifuna ukuthutha ulwelo olunobushushu obuphezulu okanye umphunga. amandla aphezulu obushushu kunye neepropathi ezilungileyo zoomatshini zeP11 ziyenza ilungele ezi zicelo.

a) Ilingana ngantoni iASTM A335 P11?

GB/T 5310: 12CrMo;

I-DIN 17175: 10CrMo9-10 (1.7380);

EN 10216-2: 10CrMo9-10;

BS 3604: 10CrMo9-10;

I-JIS G3462: STPA23;

GOST 550-75: 12Kh1MF.

b)Ngaba i-P11 yintsimbi ye-alloy ephantsi?

Ewe, i-P11 yintsimbi ephantsi ye-alloy.

Intsimbi ephantsi ye-alloy yi-iron-carbon alloy apho enye okanye ngaphezulu kwezinto ezixubileyo (umzekelo, i-chromium, i-molybdenum, i-nickel, njl.) yongezwe, kunye nomxholo odibeneyo we-alloying ngokubanzi ukusuka kwi-1 ukuya kwi-5%.

c)Yintoni amandla okuqina e-ASTM A335 P11?

Ubuncinci bamandla obunzima be-415 MPa [60 ksi].

d)Yintoni amandla esivuno se-ASTM A335 P11?

Ubuncinci bamandla obunzima be-205 MPa [30 ksi].

e) Uthini umlinganiselo wobushushu we-ASTM A335 P11?

Kwiindawo ezine-oxidizing: Ubuninzi benkonzo yobushushu bobushushu bumalunga ne-593°C (1100°F).

Kwiindawo ezingenayo i-oxidizing: ubuninzi benkonzo yobushushu obumalunga nama-650°C (1200°F) bunokufikelelwa.

f)Ngaba i-A335 P11 yimagnethi?

Inemagnethi kubushushu begumbi. Le propati inokuba luncedo kwizicelo ezithile, njengaxa imathiriyeli ifuneka ukuba ihambelane nesixhobo sokubona imagnethi.

g)Lithini ixabiso le-ASTM A335 P11?

Amaxabiso ayahluka kwimarike, qhagamshelana nathi ukuze ufumane isicatshulwa esichanekileyo.