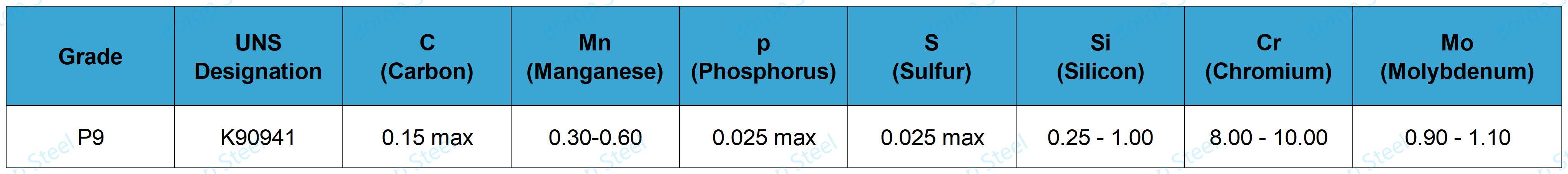

I-ASTM A335 P9, ekwabizwa ngokuba yi-ASME SA335 P9, ngumbhobho wentsimbi ongenamthungo we-ferritic wenkonzo yobushushu obuphezuluINombolo ye-UNS K90941.

Izinto ze-alloying ziyi-chromium kunye ne-molybdenum. Umxholo we-chromium uvela kwi-8.00 - 10.00%, ngelixa umxholo we-molybdenum uphakathi kwe-0.90% - 1.10%.

P9inamandla agqwesileyo kunye nokuxhathisa okuhle kwe-corrosion kwiindawo ezinobushushu obuphezulu kwaye isetyenziswa kakhulu kwiibhoyila, izixhobo zepetrochemical, kunye nezikhululo zamandla apho ubushushu obuphezulu kunye nobume boxinzelelo oluphezulu lufuneka.

⇒ Isixhobo: ASTM A335 P9 / ASME SA335 P9 ingenamthungo ingxubevange umbhobho yentsimbi.

⇒Ngaphandle kwedayimitha: 1/8"- 24".

⇒Ubunzima bodonga: Iimfuno ze-ASME B36.10.

⇒Ishedyuli: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 kunye ne-SCH160.

⇒Ukuchongwa: I-STD (eqhelekileyo), i-XS (eyomelele ngakumbi), okanye i-XXS (i-double extra-strong).

⇒Ubude: Ubude obuthile okanye obuthile.

⇒Ukwenza ngokwezifiso: I-Diameter yangaphandle engekho-standard, ubukhulu bodonga, ubude, njl njl ngokweemfuno.

⇒Izifakelo: Sinokubonelela ngezinto ezifanayo zokugoba, ukugoba iiflange, kunye nezinye iimveliso ezixhasa umbhobho wentsimbi.

⇒Izatifikethi ze-IBR: Isatifikethi se-IBR sinokubonelelwa ukuba siyafuneka.

⇒Isiphelo: Isiphelo esicacileyo, isiphelo se-beveled, okanye isiphelo sombhobho odibeneyo.

⇒Ukupakisha: Ityala leplanga, ibhanti lentsimbi okanye ukupakisha ucingo lwentsimbi, iplastiki okanye umkhuseli wentsimbi yombhobho wentsimbi.

⇒Ezothutho: ngolwandle okanye ngenqwelomoya.

Umbhobho wentsimbi we-ASTM A335 kufuneka ungabinamthungo.

Umbhobho wentsimbi ongenamthungo ngumbhobho wentsimbi ongenawo ukudibanisa yonke into.

Ekubeni umbhobho wentsimbi ongenamthungo awunayo i-welded seams kwisakhiwo sayo, ithintela iingozi ezinokuthi zikhuseleke ezinokudityaniswa nemiba yekhwalithi ye-weld. Olu phawu luvumela umbhobho ongenamthungo ukuba umelane noxinzelelo oluphezulu, kwaye ubume bayo bangaphakathi obufanayo buqinisekisa ngakumbi ukuthembeka kunye nokhuseleko lombhobho kwiindawo ezinoxinzelelo oluphezulu.

Ukongeza, ukuthembeka kwe-ASTM A335 ityhubhu kuphuculwe ngokudityaniswa kwezinto ezithile ze-alloying kubushushu obuphezulu kunye neemeko zoxinzelelo oluphezulu.

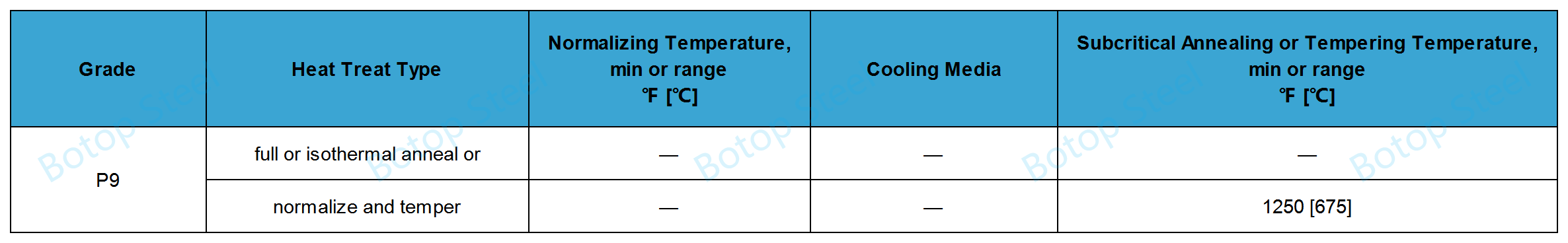

Iindidi zonyango lobushushu ezikhoyo kwizinto ze-P9 zibandakanya ukufakwa okupheleleyo okanye i-isothermal annealing, kunye nokuqhelekileyo kunye nokuvutha. Ubushushu bomzimba bungama-1250°F [675°C].

Izinto eziphambili ze-alloying ze-P9 ziCrkwayeMo, eziyi-chromium-molybdenum alloys.

Cr (Chromium): Njengeyona nto iphambili ye-alloy, i-Cr ibonelela ngamandla aphezulu obushushu obuphezulu kunye nokuchasana ne-oxidation. Yenza ifilimu edibeneyo ye-chromium oxide ebusweni bentsimbi, ukwandisa ukuzinza kunye nokumelana nokubola kombhobho kumaqondo aphezulu.

Mo (Molybdenum): Ukongezwa kwe-Mo kuphucula kakhulu amandla kunye nokuqina kwe-alloys, ngokukodwa kwiindawo eziphezulu zokushisa. I-Mo ikwanceda ekuphuculeni amandla okurhubuluza kwemathiriyeli, oko kukuthi, ukukwazi ukuxhathisa inguquko phantsi kokuvezwa kobushushu ixesha elide.

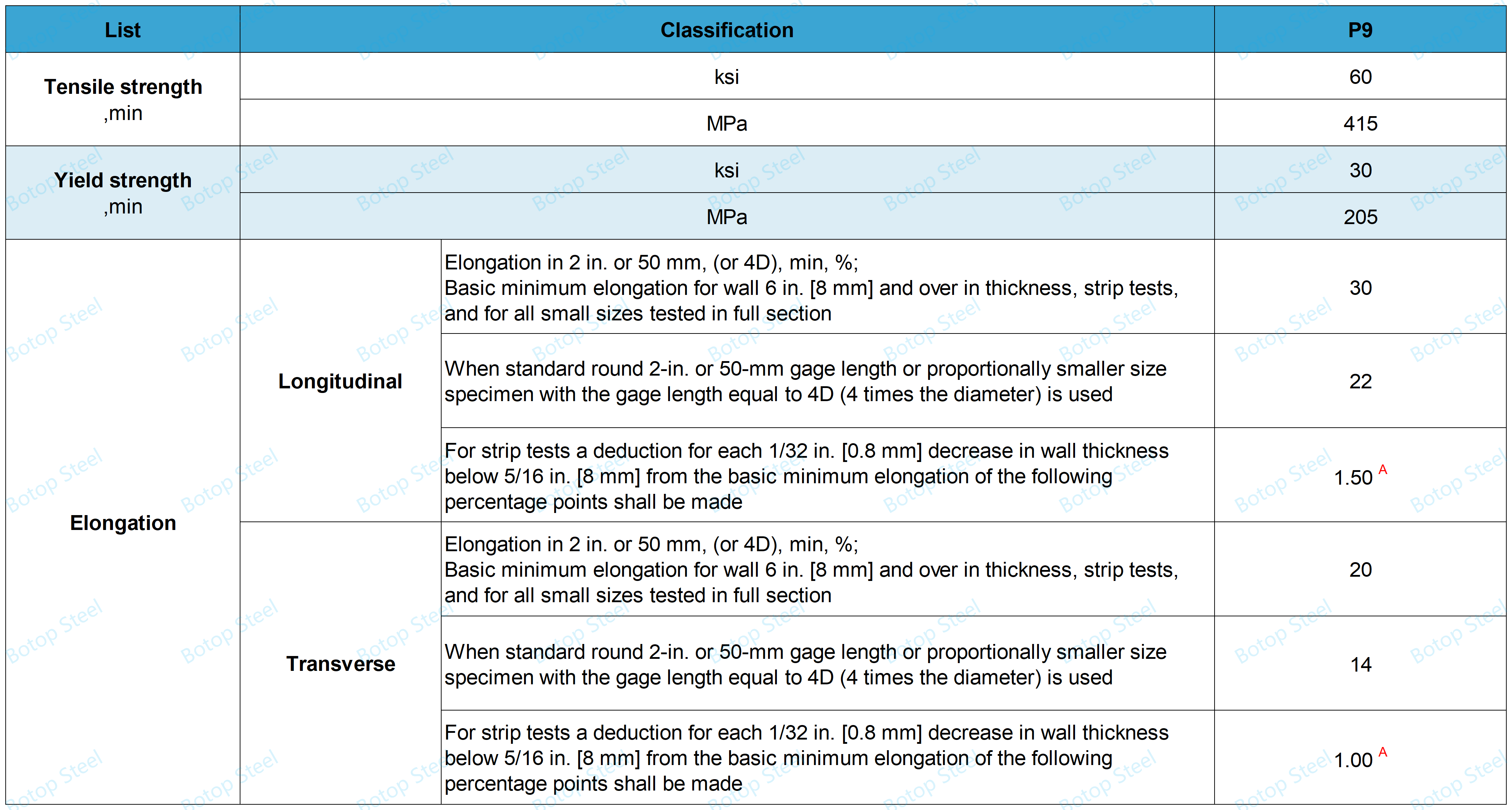

Iipropati ze-Tensile

P5, P5b, P5c, P9,P11, P15, P21, kunye neP22: Amandla okuqina kunye nesivuno ayafana.

I-P1, i-P2, i-P5, i-P5b, i-P5c, i-P9, i-P11, i-P12, i-P15, i-P21, kunye ne-P22: Ubude obufanayo.

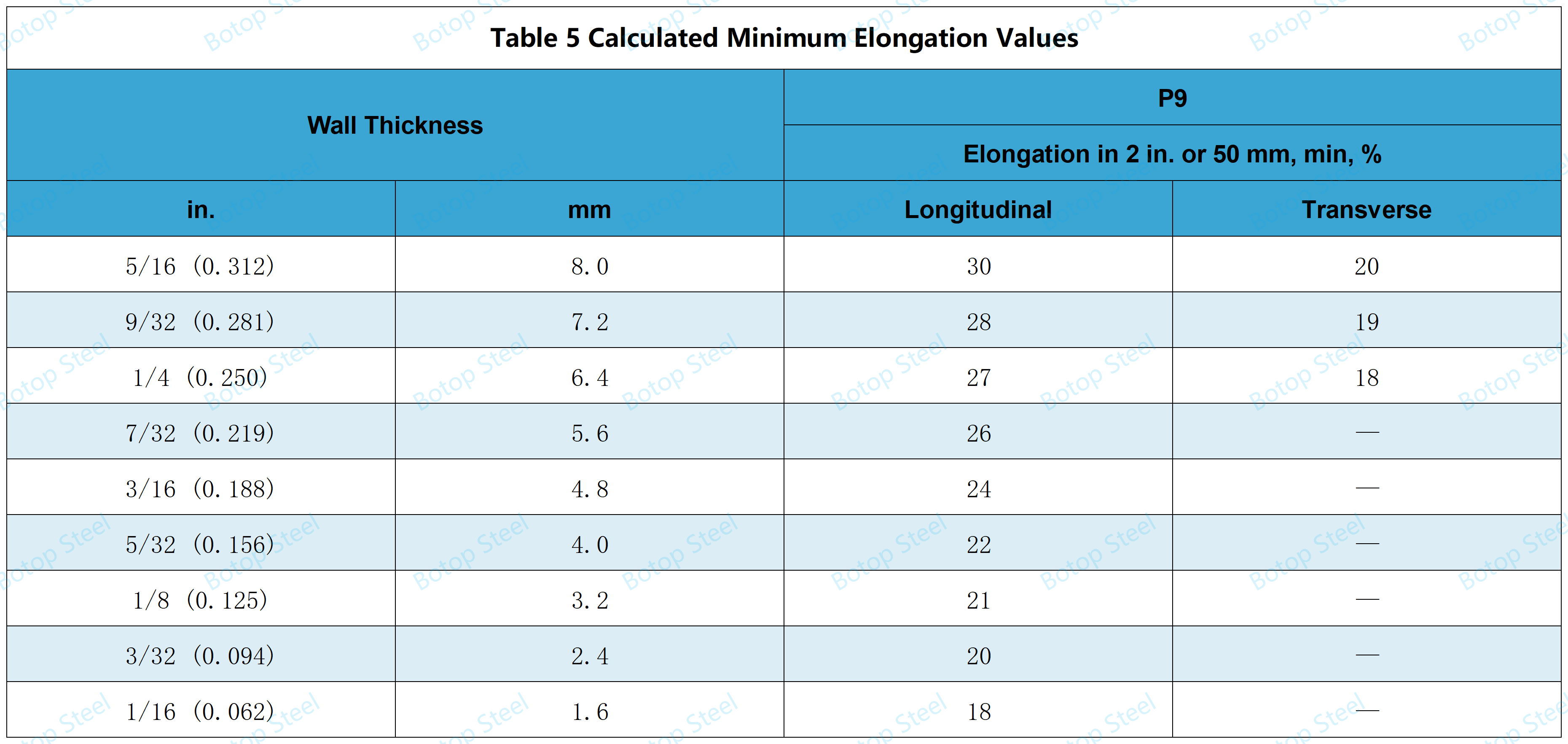

AItheyibhile 5 inika amaxabiso amancinci abaliweyo.

Apho ubukhulu bodonga buphakathi kwala maxabiso mabini angentla, elona xabiso lisezantsi lobude limiselwa ngale fomula ilandelayo:

I-Longitudinal, i-P9: E = 48t + 15.00 [E = 1.87t + 15.00]

Transverse, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

apho:

E = elongation kwi-2 in. okanye 50 mm, %,

t = ubukhulu bokwenyani besampulu, ngaphakathi [mm].

Ukuqina

I-P9 ayifuni uvavanyo lobulukhuni.

P1, P2, P5, P5b, P5c, P9, P11, P12, P15, P21, P22, kunye neP921: Akukho vavanyo lokuqina olufunekayo.

Xa i-diameter yangaphandle> 10 in. [250 mm] kunye nobukhulu bodonga ≤ 0.75 in [19 mm], zonke ziya kuvavanywa nge-hydrostatically.

Uxinzelelo lokulinga lungabalwa ngokusebenzisa le equation ilandelayo.

P = 2St/D

P= uxinzelelo lovavanyo lwe-hydrostatic kwi-psi [MPa];

S= uxinzelelo eludongeni lombhobho kwi-psi okanye [MPa];

t= ubukhulu bodonga obuchaziweyo, ubukhulu bodonga oluqhelekileyo ngokwenombolo yeshedyuli ekhankanyiweyo ye-ANSI okanye amaxesha angama-1.143 obona buncinane obuchaziweyo bodonga, ngo. [mm];

D= icaciswe ngaphandle kwe-diameter, i-diameter yangaphandle ehambelana nobukhulu bombhobho we-ANSI obuchaziweyo, okanye i-diameter yangaphandle ebalwa ngokudibanisa i-2t (njengoko kuchazwe ngasentla) kwi-diameter yangaphakathi echaziweyo, kwi-. [mm].

Ixesha lokulinga: gcina ubuncinane ii-5s, akukho kuvuza.

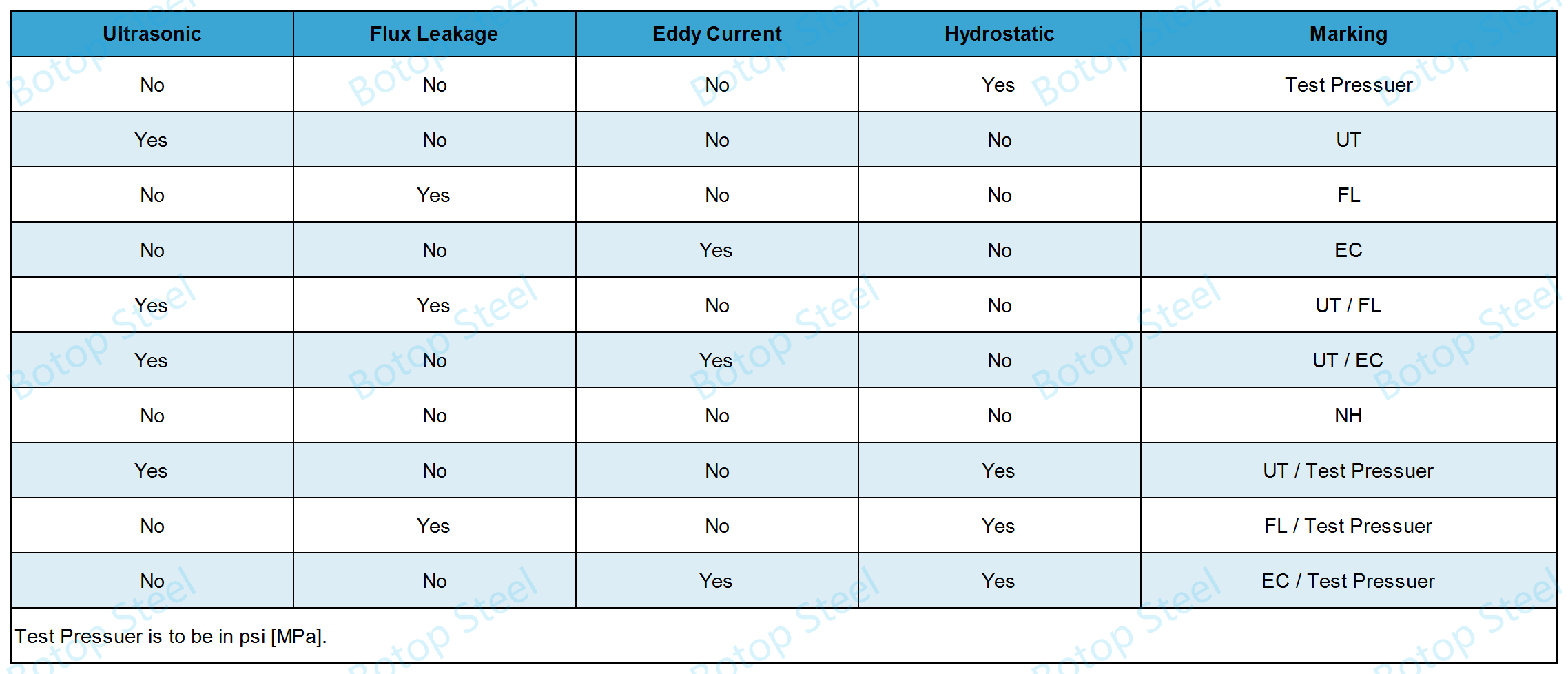

Xa umbhobho ungasayi kuvavanywa ngamanzi, uvavanyo olungonakalisi luya kwenziwa kumbhobho ngamnye ukufumanisa iziphene.

Uvavanyo olungonakaliyo lwezinto ze-P9 kufuneka lwenziwe ngenye yeendlelaE213, E309 or E570.

E213: Ukuziqhelanisa noVavanyo lwe-Ultrasonic ye-Metal Pipe kunye neTubing;

E309: Ukuziqhelanisa noVavanyo lwangoku lwe-Eddy yeeMveliso zeTubula zensimbi usebenzisa i-Magnetic Saturation;

E570: Ukuziqhelanisa noVavanyo lwe-Flux yokuvuza kweeMveliso ze-Ferromagnetic Steel Tubular;

Ukwahluka okuvumelekileyo kwiDamitha

Ukutenxa kwe-Diameter kungahlelwa ngokwe-1. ngokusekelwe kwi-diameter yangaphakathi okanye i-2. ngokusekelwe kwi-dimeter ye-nominal okanye yangaphandle.

1. Idayimitha yangaphakathi: ±1%.

2. I-NPS [DN] okanye i-diameter yangaphandle: Oku kuhambelana nezitenxo ezivumelekileyo kwitheyibhile engezantsi.

Iiyantlukwano ezivumelekileyo kuDonga olutyebileyo

Ubunzima bodonga lombhobho kuyo nayiphi na indawo abuyi kudlula ukunyamezela okuchaziweyo.

Ubuncinane bodonga olungqingqwa kunye nedayamitha yangaphandle yokuhlolwa ukuze kuthotyelwe le mfuno yombhobho oodolwe yi-NPS [DN] kunye nenombolo yeshedyuli ibonisiweASME B36.10M.

Imixholo yokumakisha: Igama lomenzi okanye uphawu lokuthengisa; inombolo esemgangathweni; ibakala ubude kunye nesimboli esongezelelweyo "S".

Iimpawu zoxinzelelo lwe-hydrostatic kunye novavanyo olungonakalisi kwitheyibhile engezantsi kufuneka kwakhona zibandakanywe.

Indawo yokumakisha: Ukumakisha kufuneka kuqale malunga nee-intshi ezili-12 (300 mm) ukusuka ekupheleni kombhobho.

Kwimibhobho ukuya kwi-NPS 2 okanye ngaphantsi kwe-3 ft (1 m) ubude, ukumakishwa kolwazi kunokuncanyathiselwa kwithegi.

Umbhobho wensimbi we-ASTM A335 P9 usetyenziswa kakhulu kwiibhoyila, izixhobo zepetrochemical power stations, njl., ezifuna ukumelana nobushushu obuphezulu kunye noxinzelelo oluphezulu ngenxa yobushushu obuphezulu kunye nokumelana noxinzelelo oluphezulu.

Iibhoyila: Ngokukodwa kwimibhobho ye-steam ephambili kunye ne-reheater piping ye-supercritical kunye ne-ultra-supercritical boilers kumaqondo aphezulu kakhulu kunye noxinzelelo.

Izixhobo zePetrochemical: Njengemibhobho ye-cracker kunye ne-high-temperature piping, ephethe umphunga ophezulu wokushisa kunye neekhemikhali, zifuna izinto ezinokushisa okuphezulu kunye nokuxhathisa ukubola.

Izikhululo zombane: Kwimibhobho ephambili yomphunga kunye nezifudumezi ezinoxinzelelo oluphezulu, kunye nemibhobho yeinjini yomoya yangaphakathi ukumelana nexesha elide lobushushu obuphezulu kunye noxinzelelo.

Izinto zeP9 zinamabanga azo asemgangathweni kwiinkqubo ezahlukeneyo zemigangatho yesizwe.

EN 10216-2: 10CrMo9-10;

GB/T 5310: 12Cr2Mo;

I-JIS G3462: STBA 26;

ISO 9329: 12CrMo195;

I-GOST 550: 12ChM;

Ngaphambi kokukhetha nayiphi na imathiriyeli elinganayo, kucetyiswa ukuba uthelekiso lwentsebenzo eneenkcukacha kunye novavanyo lwenziwe ukuze kuqinisekiswe ukuba enye imathiriyeli iya kuhlangabezana neemfuno zoyilo lwangaphambili.

Ukususela ekusekweni kwayo ngo-2014,Intsimbi yeBotopuye waba ngumthengisi ohamba phambili we-carbon steel pipe eMntla China, owaziwa ngenkonzo ebalaseleyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange. Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.

Nceda uzive ukhululekile ukuba uqhagamshelane nathi ukuba unayo naziphi na iimfuno okanye imibuzo malunga ityhubhu yentsimbi. Sijonge phambili ekufumaneni ulwazi lwakho kwaye sijonge ukukunceda.