ASTM A500 yi-welded welded kunye ne-seamless carbon steel structural tubing ye-welded, riveted, okanye iibhulorho eziboshiweyo kunye nezakhiwo zokwakha kunye neenjongo zesakhiwo ngokubanzi.

IBanga Byityhubhu yesakhiwo sentsimbi yekhabhoni eguquguqukayo eguquguqukayo epholileyo edibeneyo okanye engenamthungo enamandla emveliso engekho ngaphantsi kwe-315 MPa [46,000 psi] kunye namandla okuqina angekho ngaphantsi kwe-400 MPa [58,000], esetyenziswa kwiintlobo ngeentlobo zezakhiwo kunye noomatshini bezakhiwo ezigqwesileyo kunye nokuqina kweeprojekthi zayo ezibalaseleyo.

I-ASTM A500 ihlela umbhobho wentsimbi ngokwamanqanaba amathathu,ibakala B,ibakala C, kunye nebakala D.

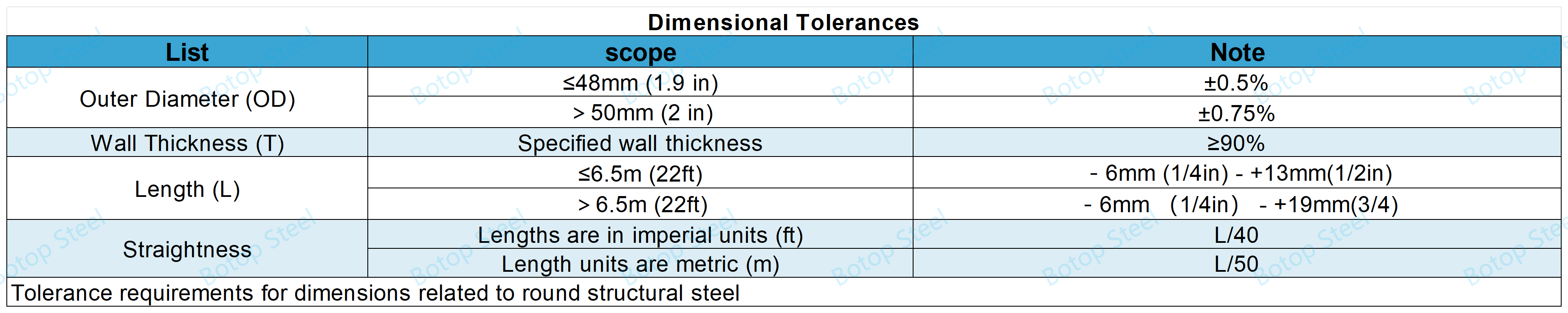

Kwimibhobho enengaphandle ubukhulu ≤ 2235mm [88in]kwayeubukhulu bodonga ≤ 25.4mm [1in].

Nangona kunjalo, ukuba inkqubo ye-welding ye-ERW isetyenzisiweyo, imibhobho kuphela enobukhulu obungama-660 mm kunye nobukhulu bodonga lwama-20 mm bunokwenziwa.

Ukuba ufuna ukuthenga umbhobho ngobukhulu obukhulu bodonga, ungakhetha ukusebenzisa inkqubo ye-SAW welding.

I-CHS: Amacandelo akwisetyhula angenanto.

I-RHS: Amacandelo angaphantsi kwesikwere okanye uxande.

I-EHS: Amacandelo akwi-Elliptical hollow.

Intsimbi iya kwenziwa yinye okanye ngaphezulu kwezi nkqubo zilandelayo:i-oksijeni esisiseko okanye isithando somlilo sombane.

Inkqubo ye-Oxygen esisiseko: Le yindlela yanamhlanje ekhawulezayo yokuvelisa intsimbi, enciphisa umthamo wekhabhoni ngokuvuthela ioksijini kwintsimbi yehagu etyhidiweyo ngelixa isusa ezinye izinto ezingafunekiyo ezifana nesulfure kunye nephosphorus. Kufanelekile ukuveliswa ngokukhawuleza kwezinto ezininzi zetsimbi.

Inkqubo yesithando soMbane: Inkqubo yeSithando soMbane isebenzisa i-arc yombane ephezulu yokushisa ukunyibilikisa i-scrap kunye nokunciphisa ngokuthe ngqo isinyithi, kwaye iluncedo ngokukhethekileyo ekuveliseni amabakala akhethekileyo kunye nokulawula iingoma ze-alloy, kunye nokuveliswa kwebhetshi encinci.

Iityhubhu ziya kwenziwa yiUkumelana nombane (ERW)inkqubo.

Umbhobho we-ERW yinkqubo yokwenza i-weld ngokudibanisa izinto zetsimbi kwi-cylinder kunye nokusebenzisa ukuxhathisa kunye noxinzelelo kunye nobude bayo.

Iityhubhu zeBakala B zinokuncitshiswa okanye zithotywe uxinzelelo.

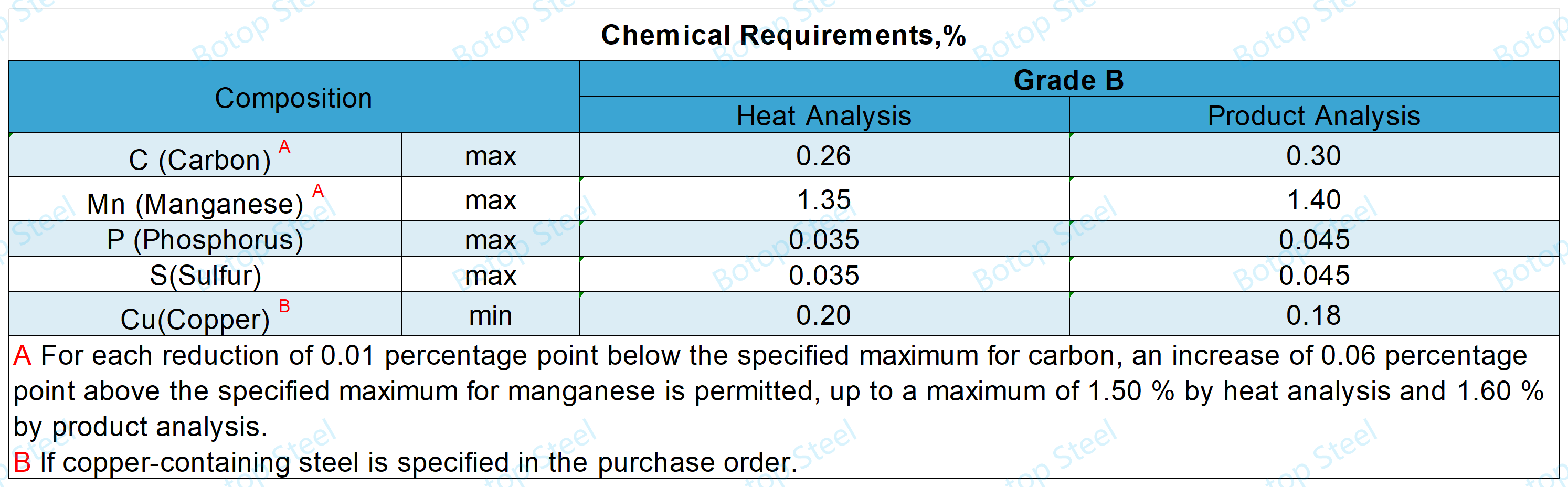

Ukubunjwa kweekhemikhali ze-ASTM A500 zeBanga B zensimbi zibandakanya izixa ezilinganisiweyo zekhabhoni kunye ne-manganese ukuze kuqinisekiswe iimpawu ezintle zoomatshini kunye ne-weldability. Ngexesha elifanayo, amanqanaba e-phosphorus kunye ne-sulfure alawulwa ngokuqinileyo ukuze agweme ukukhwabanisa, kwaye ukongezwa okuphakathi kobhedu kuphucula ukuxhathisa ukubola.

Ezi propati zifaneleke ngokufanelekileyo ukusetyenziswa kolwakhiwo, ngakumbi kwiindawo apho kufuneka i-weldability elungileyo kunye nokuqina.

Imizekelo iya kuhlangabezana neemfuno ezisebenzayo ze-ASTM A370, iSihlomelo A2.

| Uluhlu | IBanga B | |

| Amandla okuqina, min | psi | 58,000 |

| MPa | 400 | |

| Amandla esivuno, min | psi | 46,000 |

| MPa | 315 | |

| Ubude kwi-2 ngo. (50 mm), min,C | % | 23A |

| AIsebenza kubunzima obukhankanyiweyo bodonga (t ) obulingana okanye obukhulu kuno 0.180 ngaphakathi [4.57mm]. Kubunzima obukhankanyiweyo bendonga obukhankanyiweyo, amaxabiso amancinane obude aya kubalwa ngefomula: ipesenti yobude ku-2 in. [50 mm] = 61t+ 12, isondezwe kwipesenti ekufutshane. Kwi-A500M sebenzisa le fomula ilandelayo: 2.4t+ 12, isondezwe kwipesenti ekufutshane. CUbuncinci bexabiso lobude obuchaziweyo busebenza kuphela kuvavanyo olwenziwe phambi kokuthunyelwa kwetyhubhu. | ||

WeldduncedotEst: Ukusebenzisa i-specimen ubuncinane i-intshi ezi-4 (i-100 mm) ubude, thambisa umboniso nge-weld kwi-90 ° ukuya kwicala lokulayisha kude kube umgama phakathi kwamacwecwe ungaphantsi kwe-2/3 yobubanzi obungaphandle bombhobho. umfuziselo awuyi kuqhekeka okanye wophuke ngaphakathi okanye ngaphandle komphezulu ngexesha lenkqubo.

Uvavanyo lwe-ductility yombhobho: qhubeka uhlambulule i-specimen kude kube umgama phakathi kwamacwecwe ungaphantsi kwe-1/2 ye-diameter yangaphandle yombhobho. ngeli xesha, umbhobho akufanele ube nokuqhekeka okanye ukuphuka kwiindawo zangaphakathi nangaphandle.

IngqibelelotEst: Qhubeka uthambisa umfuziselo de kwenzeke ukwaphuka okanye de iimfuno zobunzima bodonga zihlangatyezwe. Ukuba ubungqina be-ply peeling, izinto ezingazinzanga, okanye i-welds engaphelelanga ifunyenwe ngexesha lovavanyo lwe-flattening, i-specimen iya kugwetywa ngokunganelisiyo.

Uvavanyo oluvuthayo luyafumaneka kwiityhubhu ezijikelezayo ≤ 254 mm (10 in) ububanzi, kodwa akunyanzelekanga.

Zonke iityhubhu aziyi kuba nasiphako kwaye ziya kuba nesiphelo esifana nomsebenzi.

Ukungafezeki komphezulu kuya kubalwa njengeziphene xa ubunzulu bazo bunciphisa ukutyeba kodonga oluseleyo ukuya ngaphantsi kwe-90 % yobukhulu bodonga obuchaziweyo.

Iziphene ukuya kuthi ga kwi-33% yobukhulu bodonga obuchaziweyo obunzulu bunokupheliswa ngokupheleleyo ngokusika okanye ukugaya ukugqiba isinyithi.

Ukuba i-welding ye-filler isetyenzisiweyo, inkqubo ye-welding emanzi iya kusetyenziswa kwaye i-weld metal ephumayo iya kususwa ukuze igcine indawo epholileyo.

Iziphene ezingaphezulu, ezifana namanqaku okuphatha, ukungunda okuncinci okanye amanqaku okuqengqeleka, okanye imingxunya enzulu, azijongwa njengeziphene ngaphandle kokuba zinokususwa ngaphakathi kobunzima obuchaziweyo bodonga.

Olu lwazi lulandelayo kufuneka lubandakanywe:

Igama lomenzi: Oku kunokuba ligama elipheleleyo lomenzi okanye isifinyezo.

Uphawu okanye uphawu loRhwebo: Igama lebrendi okanye uphawu lwentengiso olusetyenziswa ngumenzi ukwahlula iimveliso zalo.

Iinkcukacha zoMyili: ASTM A500, ekungafunekiyo iquke unyaka wokupapashwa.

Ileta yeBanga: B, C okanye ibakala D.

Kwiityhubhu zesakhiwo ≤ 100mm (4in) ububanzi, iilebula zingasetyenziselwa ukuphawula ulwazi lokuchongwa ngokucacileyo.

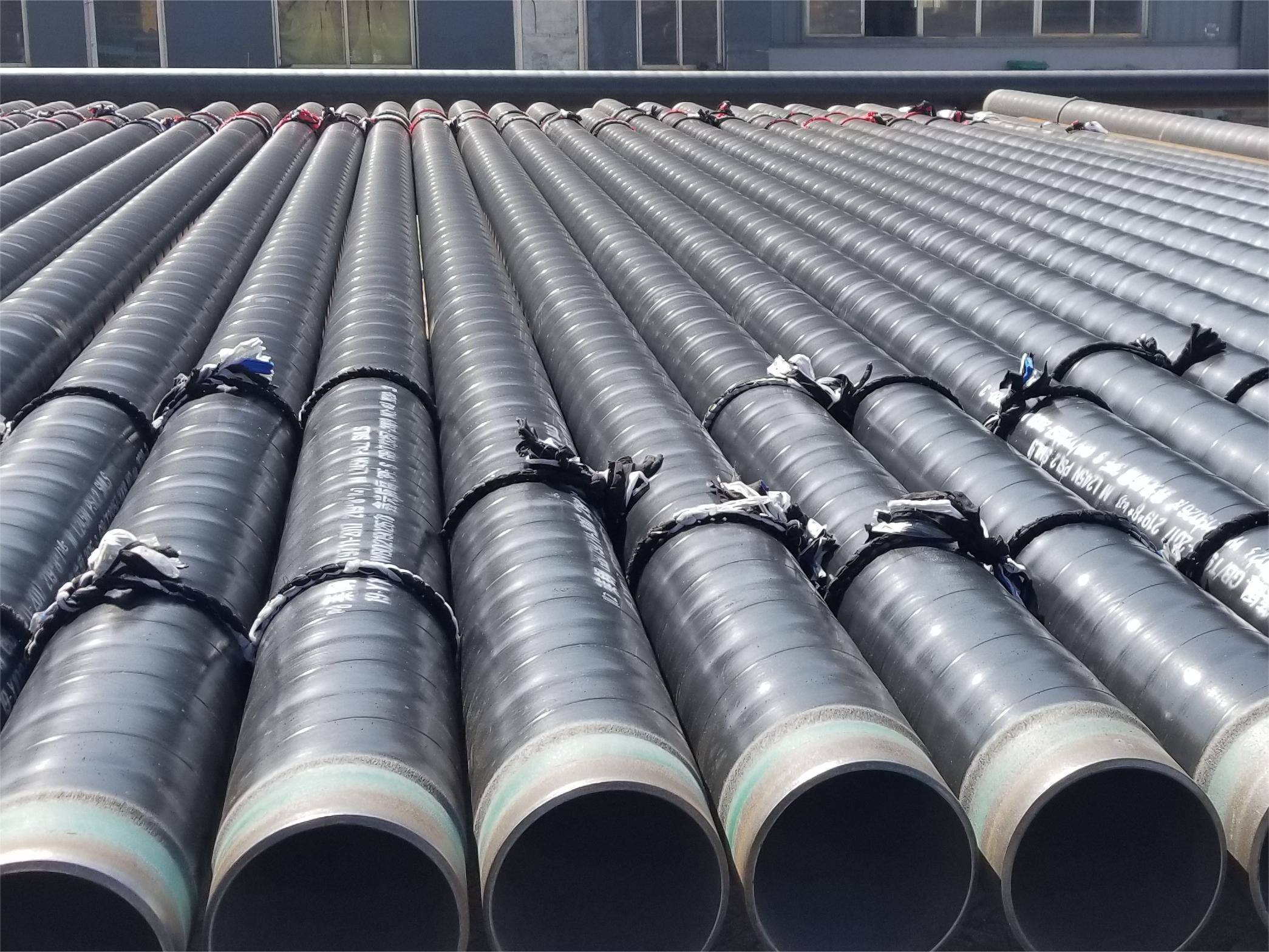

Ngokuyintloko isetyenziselwa iinjongo zesakhiwo, inika amandla afunekayo omatshini kunye ne-weldability ukuxhasa ukuyila kunye nokwakhiwa kwezakhiwo zobunjineli kunye nobunjineli.

Lo mbhobho wensimbi usetyenziswa ngokubanzi kwizakhiwo zokwakha, iibhuloho, izibonelelo zoshishino, kunye neentlobo zezinye izinto ezifuna amandla kunye nokuqina.

I-ASTM A370: Iindlela zoVavanyo kunye neeNkcazo zoVavanyo lweMechanical yeeMveliso zetsimbi.

I-ASTM A700: Isikhokelo sokuPakisha, ukuMakisha, kunye neendlela zokuLayisha kwiiMveliso zeNtsimbi zoThutho.

I-ASTM A751: Iindlela zoVavanyo kunye neZiqhelo zokuHlalutywa kweMichiza yeeMveliso zeNtsimbi.

ISigama se-ASTM A941 esiNxulumana neNtsimbi, iNtsimbi eNgatyiwayo, ii-alloys eziNxulumeneyo, kunye neeFerroalloys.

Ngokweemfuno zabathengi, unyango oluchasayo lwemibhobho yentsimbi lunokwenziwa ngeendlela ezininzi ezahlukeneyo ukuze kuphuculwe ukuxhathisa kwe-corrosion kunye nokwandisa ubomi bayo benkonzo.

Kubandakanya ivanishi, ipeyinti, igalvanization, 3PE, FBE, kunye nezinye iindlela.

Singumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Ukuba ufuna ukwazi ulwazi oluthe kratya malunga neemveliso zentsimbi yombhobho, ungaqhagamshelana nathi!