I-ASTM A501 iBanga Bngumbhobho wentsimbi wekhabhoni odityanisiweyo oshushu owenziwe ngokushushu kwaye ongenamthungo onamandla asezantsi angama-448 MPa (65,000 psi) kwiinkqubo ezahlukeneyo zesakhiwo.

I-ASTM A501yeyokwenziwa kunye nokusebenza kwetyhubhu yentsimbi edityanisiweyo eshushu eyenziwe ngentsimbi yekhabhoni engenamthungo ukulungiselela ukusetyenziswa kolwakhiwo.

Le mibhobho yensimbi ingaba mnyama (engafakwanga) okanye i-galvanized eshushu, leyo yokugqibela iye yanda ukuxhatshazwa kwe-corrosion ngokusebenzisa inkqubo ye-galvanizing, eyenza ifaneleke kwiimeko ezininzi zokusingqongileyo.

Le mibhobho yentsimbi isetyenziswa ngokubanzi kwiibhulorho, izakhiwo, kunye nezinye izicelo ezininzi zesakhiwo.

I-ASTM A501 ihlela umbhobho wentsimbi ngokwamanqanaba amathathu,ibakala A, ibakala B, kunye nebakala C.

IBakala B lelona lisetyenziswa kakhulu kula mabanga mathathu ngenxa yokuba libonelela ngeepropathi ezilungelelaniswe kakuhle kwiinkqubo ezininzi zezakhiwo.

Intsimbi iya kwenziwa nguisiseko-ioksijini okanye i-electric-arc-furnace-steel-making process.

Intsimbi inokuphoswa kwiingothi okanye iphoswe ngomsonto.

Xa iintsimbi zamabakala ahlukeneyo zixutywe ngokulandelelana, umvelisi wensimbi uya kuchonga isiphumo senguqu yenguqu kwaye ayisuse ngokusebenzisa inkqubo emiselweyo eyahlula kakuhle amabakala.

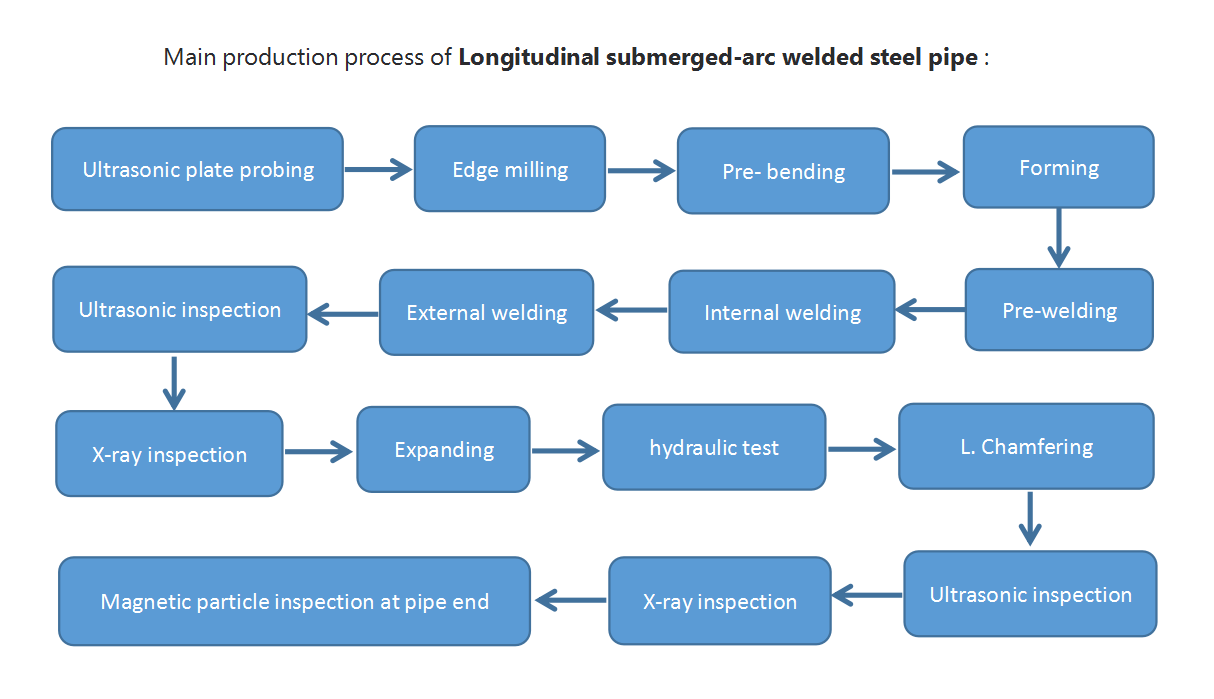

Ityhubhu iya kwenziwa ngenye yezi nkqubo zilandelayo:ingenamthungo; i-furnace-butt-welding (i-welding eqhubekayo); ukuwelda ukuxhathisa kombane (ERW) okanye i-arc efakwe emanzini (SAW)kulandelwa ukufudumeza kwakhona kwi-cross-section kunye nokwakhiwa okushushu ngokunciphisa okanye ukubunjwa kwenkqubo, okanye zombini.

Inkqubo ye-welding ye-SAW yahlulahlulweLSAW(SAWL) kunye ne-SSAW (HSAW).

Ukubunjwa kokugqibela kobume kuya kwenziwa ngenkqubo yokubumba eshushu.

Kuya kuvunyelwa ukongeza unyango oluqhelekileyo lobushushu kwityhubhu enobunzima bodonga olukhulu kune-13mm [1/2 in].

| IiMfuno zeMichiza ye-ASTM A501 yeBakala B,% | |||

| Ukuqamba | IBanga B | ||

| Uhlalutyo lobushushu | Uhlalutyo lweMveliso | ||

| C (iKhabhoni)B | max | 0.22 | 0.26 |

| Mn (Manganese)B | max | 1.40 | 1.45 |

| P (Phosphorus) | max | 0.030 | 0.040 |

| S(Isulfure) | max | 0.020 | 0.030 |

| Cu(Copper)B (xa kuxelwa intsimbi yobhedu) | imiz | 0.20 | 0.18 |

| BKunciphiso ngalunye lwepesenti ye-0.01 yenqaku elingaphantsi kobuninzi obuchaziweyo bekhabhoni, ukunyuka kwepesenti ye-0.06 ngaphezulu kweqondo eliphezulu elichaziweyo kuvumelekile, ukuya kutsho kubuninzi be-1.60 % ngohlalutyo lobushushu kunye ne-1.65 % ngohlalutyo lwemveliso. | |||

Uhlalutyo lwemveliso luya kwenziwa kusetyenziswa iisampulu zovavanyo ezithathwe kubude obubini betyhubhu ukusuka kwiqashiso ngalinye lobude obungama-500, okanye iqhezu layo, okanye amaqhekeza amabini esitokhwe esiqengqelekile esisicaba kwiqashiso ngalinye lomyinge wesitokhwe esiqengqelekayo esisicaba.

Imizekelo ye-tensile iya kuhambelana neemfuno ezisebenzayo zoVavanyo lweNdlela kunye neeNgcaciso ze-A370, iSihlomelo A2.

| Iimfuno ze-ASTM A501 zeBakala B | |||

| Uluhlu | Ukutyeba kweendonga mm [ngaphakathi] | IBanga B | |

| Tensile strength, umz, psi[MPa] | Konke | 65000 [448] | |

| Unikeze Amandla, umz, psi[MPa] | ≤25 [1] | 46,000 [315] | |

| >25 [1] kunye ≤ 50 [2] | 45,000 [310] | ||

| >50 [2] kunye ≤ 76 [3] | 42,500 [290] | ||

| >76 [3] kunye ≤ 100 [4] | 40,000 [280] | ||

| Elongation, umz, % | - | 24 | |

| Amandla anempembelelo | umz,umndilili, ft/Ibf [J] | - | 20 [27] |

| umz,omnye, ft/Ibf [J] | - | 14 [19] | |

Iisampulu zovavanyo loxinzelelo ziya kuba yimizekelo yovavanyo lobude obupheleleyo okanye iisampulu zovavanyo lomcu welongitudinal.

Yetyhubhu edityanisiweyo, nayiphi na imizekelo yovavanyo lomcu welongitudinal iya kuthathwa kwindawo ubuncinci i-90° ukusuka kwiweld kwaye iya kulungiswa ngaphandle kokucaba kubude begeyiji.

Uvavanyo lomtya welongitudinaliisampulu ziyakususwa zonke iibhula.

Iisampulu zovavanyo loxinzelelo aziyi kuqulatha ukungafezeki komphezulu okunokuphazamisana nomiselo olululo lweempawu zoxinzelelo.

Ubunzima beendonga ≤ 6.3mm [0.25in] ayifuni uvavanyo lwempembelelo.

| Unyamezelo lwe-ASTM A501 Dimensional | ||

| Uluhlu | ububanzi | Phawula |

| Ububanzi bangaphandle (OD) | ≤48mm (1.9 ngaphakathi) | ±0.5mm [1/48 kwi] |

| >50mm (2 ngaphakathi) | ± 1% | |

| Ukutyeba kodonga (T) | Ubukhulu bodonga obuchaziweyo | ≥90% |

| Ubunzima | ubunzima obuchaziweyo | 96.5%-110% |

| Ubude (L) | ≤7m (22 ft) | -6mm (1/4in) - +13mm (1/2in) |

| 7-14m (22-44 ft) | -6mm (1/4in) - +19mm (3/4) | |

| Ukuthe tye | Ubude bukwiyunithi yobukhosi (ft) | L/40 |

| Iiyunithi zobude zizimetriki (m) | L/50 | |

Ityhubhu yolwakhiwo ayinaziphene kwaye iya kuba nesiphelo esigudileyo esibangelwa yinkqubo yokwenziwa kwe-hot rolling.

Xa ubunzulu beziphene kumphezulu wombhobho budlula i-10% yobunzima bodonga olubizwa ngokuba yi-nominal, ezi ziphene ziya kuthathwa njengezingahambelaniyo. Ukulungiswa kwe-welding kuya kuvunyelwa kuphela xa kuvunyelwene phakathi komthengi kunye nomvelisi. Ngaphambi kokulungiswa nge-welding, iziphene eziza kulungiswa kufuneka zisuswe ngokupheleleyo ngokusika okanye iindlela zokugaya.

Ukuze umbhobho wolwakhiwo ube shushu-diphu yenziwe ngegalvan, olu gqumo luyakuhambelana neemfuno ezifanelekileyo zeNkcazo.I-ASTM A53.

Ubude betyhubhu yolwakhiwo ngalunye kufuneka buphawulwe ngendlela efanelekileyo, njengokuqengqeleka, isitampu, isitampu, okanye ukupeyinta.

Ukumakishwa kwe-ASTM A501 kufuneka kube nale ngcaciso ilandelayo ubuncinane:

Igama lomenzi

Uphawu okanye uphawu lwentengiso

Ubungakanani

Igama lomgangatho (unyaka wokupapashwa awufunwa)

IBanga

Kwimibhobho yesakhiwo <50 mm [2 kwi] OD, kuvumelekile ukuphawula ulwazi lwensimbi kwilebula efakwe kwi-bundle nganye.

I-ASTM A501 yeBanga B yensimbi idibanisa amandla kunye ne-ductility kunye nenkqubo yokuvelisa i-hot-forming, eyenza ukuba ifaneleke kwiintlobo ezahlukeneyo zezicelo zesakhiwo.

Ukwakha nokwakha: Ngokuqhelekileyo isetyenziselwa ukwakhiwa kunye nezicelo zokwakha apho amandla aphezulu kunye nokuqina kwezinto eziqinileyo zifunekayo. Oku kuquka izakhiwo, amabala emidlalo, iibhulorho, nezinye izakhiwo.

Amaziko oShishino: Ngenxa yamandla ayo aphezulu, ifanelekile ukuba isetyenziswe kumaziko emizi-mveliso afana neefektri kunye neendawo zokugcina iimpahla apho imfezeko yolwakhiwo ibalulekile.

Izibonelelo zezothutho: eli bakala lisetyenziswa ekwenzeni iziseko zothutho, kuquka izikhululo zikaloliwe, izikhululo zeenqwelo-moya, kunye neendlela ezidlulayo.

Amacandelo oLwakhiwo: Ikwasetyenziswa ngokuqhelekileyo ekwenzeni amacandelo ezakhiwo ezifana neentsika, imiqadi, kunye neetrasi, ezenza isakhelo sezakhiwo ezahlukahlukeneyo.

Ukwenziwa kwezixhobo: Kwimveliso yezixhobo ezinzima kunye noomatshini, ingasetyenziselwa iindawo ezifuna amacandelo aphezulu okwakhiwa.

Umvelisi uya kunika umthengi isatifikethi sokuthobela esichaza ukuba imveliso yathathwa iisampulu, yavavanywa, yaza yahlolwa ngokuhambelana nale nkcazelo kunye nazo naziphi na ezinye iimfuno ezichazwe kumyalelo wokuthenga okanye kwikhontrakthi kwaye zonke ezo mfuno zihlangatyeziwe. Isiqinisekiso sokuthotyelwa siya kubandakanya inombolo ethile kunye nonyaka wokukhutshwa.

IBotop Steel ngumvelisi wePipe yentsimbi yeCarbon eDidiweyo ekumgangatho ophezulu kunye nomthengisi ovela eTshayina, ekwangumbhobho wentsimbi ongenamthungo.

I-Botop Steel izinikele ngamandla kumgangatho kwaye isebenzisa ulawulo olungqongqo kunye novavanyoqinisekisa ukuthembeka kwemveliso. Iqela layo elinamava libonelela ngezisombululo zobuqu kunye nenkxaso yeengcali, kugxilwe ekwanelisekeni kwabathengi. Sijonge phambili ekusebenzeni nawe.