I-ASTM A519iityhubhu iyakwenziwa ngenkqubo engenamthungo kwaye iyakugqitywa kushushu okanye igqitywe ngokubanda njengoko kuchaziwe.

Kwimibhobho engqukuva enedayamitha yangaphandle engadlulanga kwi-12 3/4 kwi (325 mm).

Iityhubhu zentsimbi zisenokwenziwa kwisikwere, uxande, okanye ezinye iimilo njengoko kufuneka.

I-ASTM A519 inokuhlelwa ngokwezinto zentsimbi:Intsimbi yeCarbonkunye ne-Alloy Steel.

Intsimbi yekhabhoniyahlulwe yabaIkhabhoni ephantsi MT(Iityhubhu zoomatshini),Intsimbi yeCarbon ephezulukwayeI-Desulfurized okanye i-Rephosphorized, okanye zombiniIntsimbi yeCarbon, ukuze ihambelane neemfuno ezahlukeneyo zamashishini kunye neemeko zesicelo.

Xa kungekho bakala lichaziweyo, abavelisi banokhetho lokunikezelaMT1015 okanye MTX1020amabanga.

Ububanzi bangaphandle: 13.7 - 325 mm;

Ubunzima bodonga: 2-100mm.

Intsimbi inokwenziwa ngayo nayiphi na inkqubo.

Intsimbi inokuphoswa kwiingothi okanye iphoswe ngomsonto.

Imibhobho iya kwenziwa ngu ainkqubo engenamthungokwaye iyakugqitywa kushushu okanye igqitywe ngokubanda, njengoko kuchaziwe.

Iityhubhu zentsimbi ezingenamthungo zizityhubhu ezingenamithungo edityanisiweyo kuyo yonke indawo.

Iibhubhu ezigqityiweyo ezibandayozinconywa kwiimfuno eziphezulu zokuchaneka kwe-dimensional kunye nomgangatho womphezulu.

Eyona nkxalabo kukusebenza kakuhle kweendleko kunye nokuqina kwempahla,umbhobho wensimbi oshushu ogqityiweyoinokuba lolona khetho lufanelekileyo.

Okulandelayo yinkqubo yokuvelisa umbhobho wensimbi ongenamthungo oshushu.

Umenzi wensimbi uya kuhlalutya ukushisa kwentsimbi nganye ukumisela ipesenti yezinto ezichaziweyo.

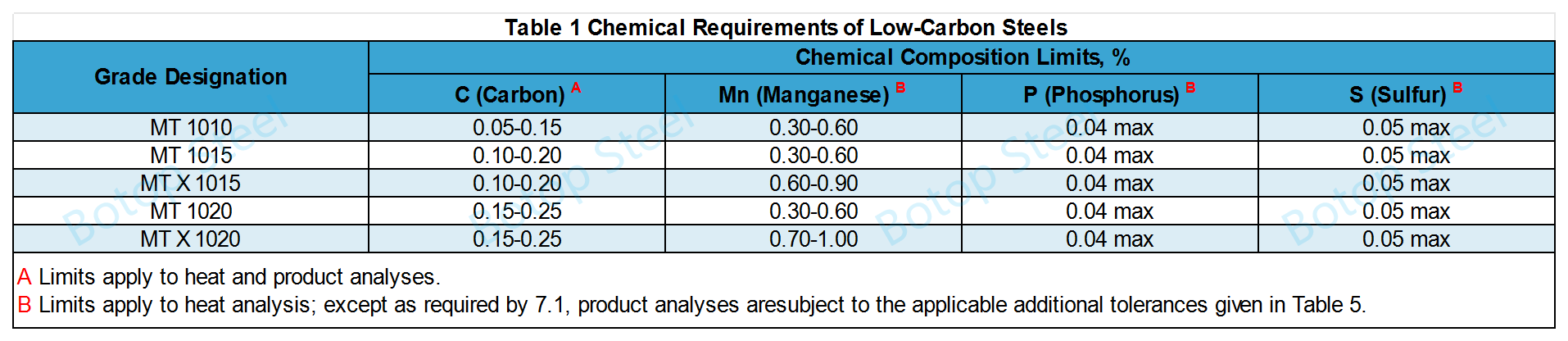

Itheyibhile ye-1 yeeMfuno zeMichiza yeeNsimbi zeKhabhoni ephantsi

Intsimbi ethambileyo yintsimbi enomxholo wekhabhoni ngokuqhelekileyo ayidluli kwi-0.25%. Ngenxa yomxholo wekhabhoni ephantsi, le ntsimbi ine-ductility engcono kunye ne-malleability kwaye ayinzima kwaye yomelele xa ithelekiswa ne-high-carbon steel.

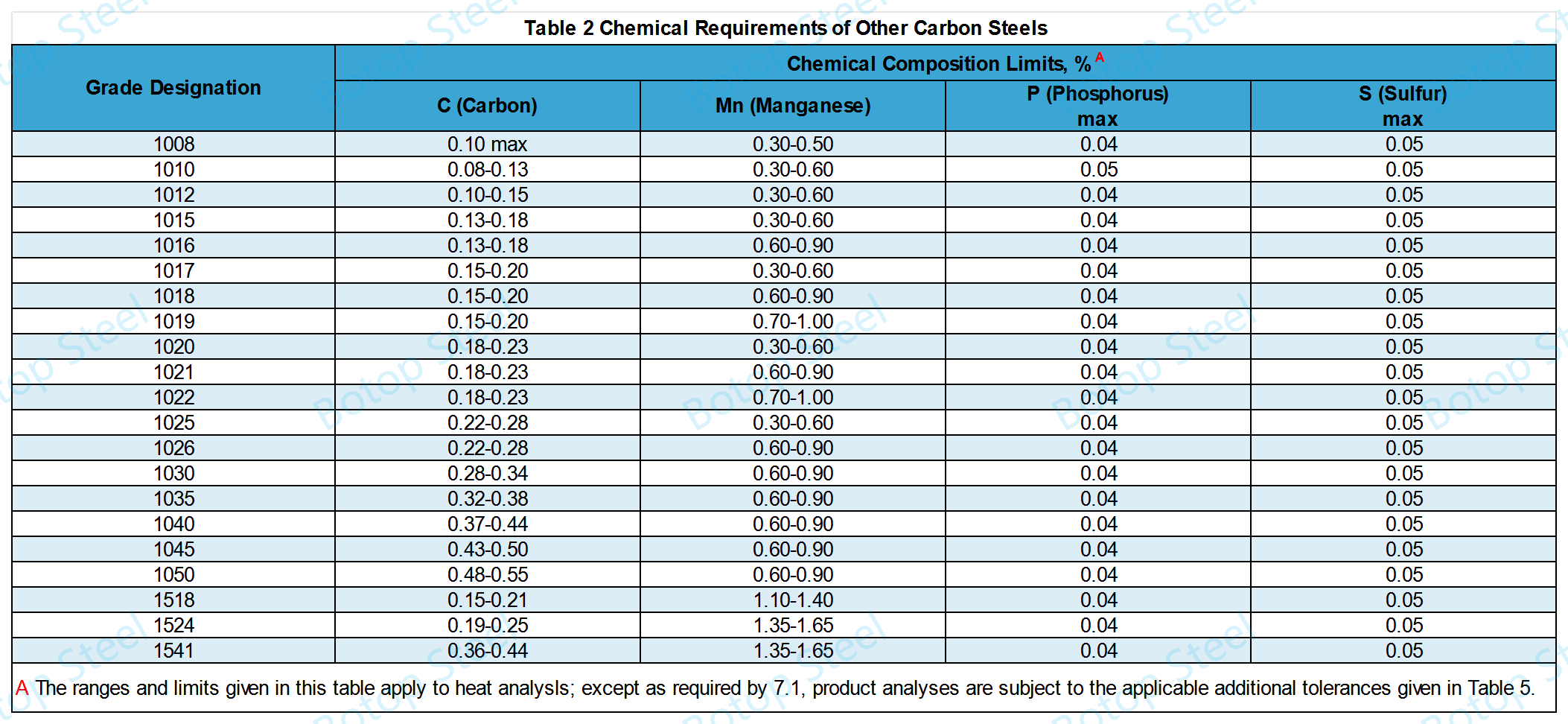

Uluhlu lweeMfuno zeMichiza yezinye iiNsimbi zeCarbon

Iintsimbi zekhabhoni eziphakathi: Iqulethe phakathi kwe-0.25% kunye ne-0.60% yekhabhoni, inika ubunzima obuphezulu kunye namandla kwaye ifuna unyango lobushushu ukuphucula iipropati.

Intsimbi yekhabhoni ephezulu: Iqulethe phakathi kwe-0.60% kunye ne-1.0% okanye ngaphezulu kwekhabhoni, kwaye inika ubunzima obuphezulu kakhulu kunye namandla, kodwa ubunzima obuphantsi.

ITheyibhile ye-3 yeeMfuno zeMichiza ye-Alloy Steels

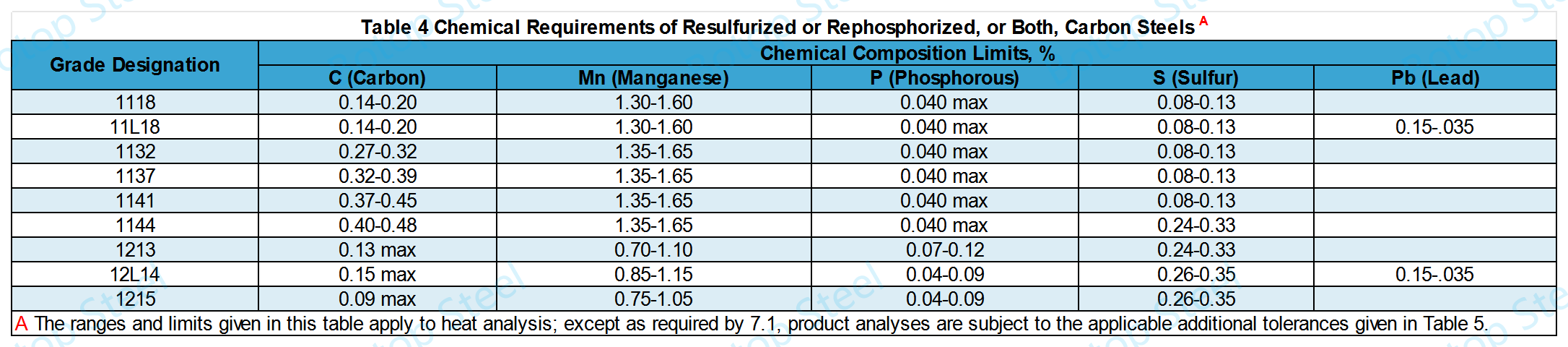

Itheyibhile ye-4 yeeMfuno zeMichiza yeSulfurized okanye iRephosphorized, okanye zombini, iintsimbi zeCarbon

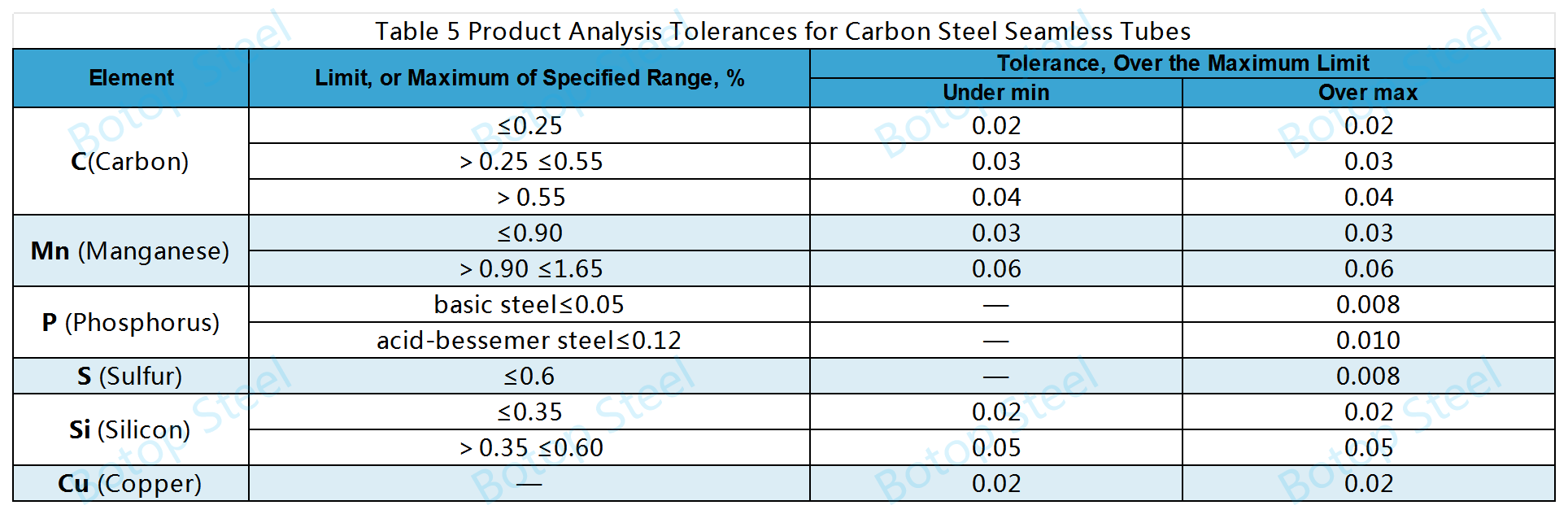

ULUHLU 5 Uhlahlelo lweMveliso Ukunyamezelana ngaphezu okanye ngaphantsi kweRange elichaziweyo okanye uMda

Umenzi kufuneka acelwe kuphela ukuba ahlalutye imveliso ukuba ifunwa ngumyalelo.

I-ASTM A519 ibandakanya ezi zinto zilandelayo zovavanyo:

Uvavanyo loBulukhuni; Iimvavanyo zoxinzelelo; Uvavanyo olungonakalisi; Uvavanyo lokuvutha; Ukucoceka kwentsimbi kunye nokuqina.

| Ukutyunjwa kweBanga | Uhlobo lombhobho | Imeko | UItimate Amandla | Unikeze Amandla | Ukwandiswa kwi-2in.[50mm],% | Rockwell, Ubunzima B Isikali | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Intsimbi yeCarbon | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Intsimbi yeCarbon | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Intsimbi yeCarbon | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Intsimbi yeCarbon | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Intsimbi yeCarbon | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized okanye iRephosphorized, okanye zombini, Iintsimbi zeCarbon | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized okanye iRephosphorized, okanye zombini, Iintsimbi zeCarbon | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Iintsimbi zengxubevange | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Iintsimbi zengxubevange | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

I-HR-Hot Rolled, i-CW-Cold Worked, i-SR-Stress iNcinyiwe, i-A-Annealed kunye ne-N-Normalized.

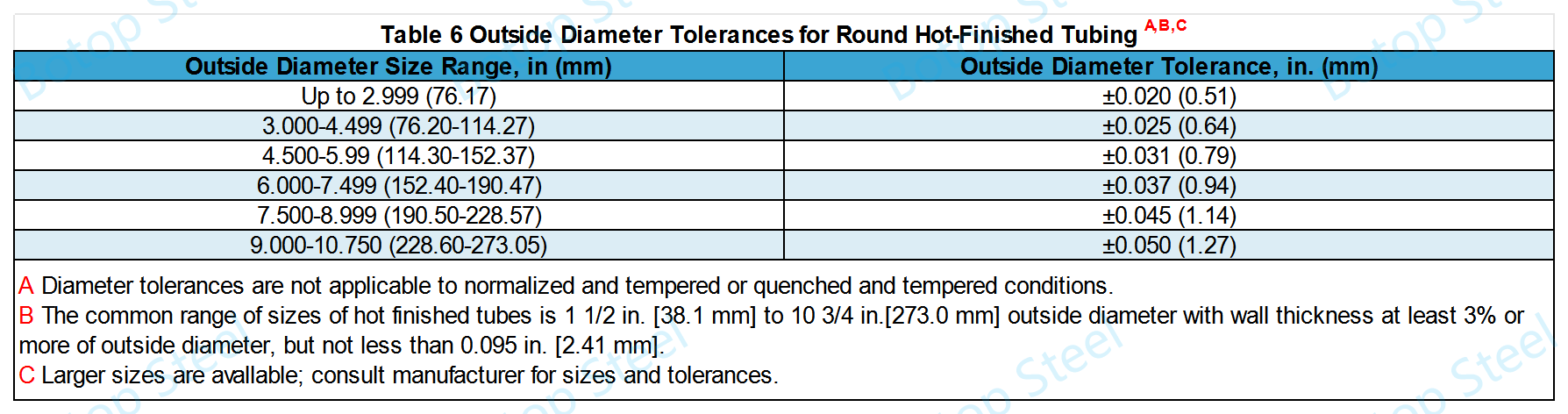

Unyamezelo lweDiameter yangaphandle

ITheyibhile 6 Ukunyamezela kweDayimitha yangaphandleyeRound Hot-Finished Tubing

ITheyibhile ye-12 yaNgaphandle yoNyamezelo lweDiameter yeI-Ground Seamless Tubing

| Ubungakanani ngaphandle kweDayimitha, kwi.[mm] | Unyamezelo lwangaphandle lweDayimitha yoBubungakanani kunye noBubude obunikiweyo, ngaphakathi. [mm] | |||

| Ngaphezulu | Ngaphantsi | Ngaphezulu | Ngaphantsi | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] xa L≤16ft[4.9m] | 0.000 | 0.004 [0.10] xa L>16ft[4.9m] | 0.000 |

| 1 1/4 [31.8]< OD ≤2[50.8] | 0.005 [0.13] xa L≤16ft[4.9m] | 0.000 | 0.006 [0.15] xa L>16ft[4.9m] | 0.000 |

| 2 [50.8]< OD ≤3 [76.2] | 0.005 [0.13] xa L≤12ft[3.7m] | 0.000 | 0.006 [0.15] xa L≤16ft[4.9m] | 0.000 |

| 3 [76.2]< OD ≤4 [101.6] | 0.006 [0.15] xa L≤12ft[3.7m] | 0.000 | 0.006 [0.15] xa L≤16ft[4.9m] | 0.000 |

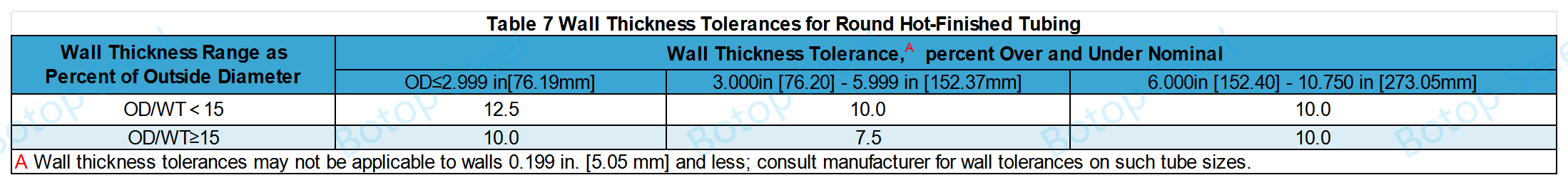

Unyamezelo lokutyeba kodonga

Itheyibhile 7 Ukunyamezela Ukutyeba kweendongayeRound Hot-Finished Tubing

ITheyibhile ye-10 yoNyamezelo lokutyeba kweendongayeRound Cold-Worked Tubing

| Ukutyeba kweendonga kuluhlu njenge Ipesenti yoMdayamitha waNgaphandle | Unyamezelo lokutyeba kodonga ngaphezulu naPhantsi kweNominal, % | |

| OD≤1.499in[38.07mm] | OD≥1.500 kwi [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT>25 | 12.5 | 10.0 |

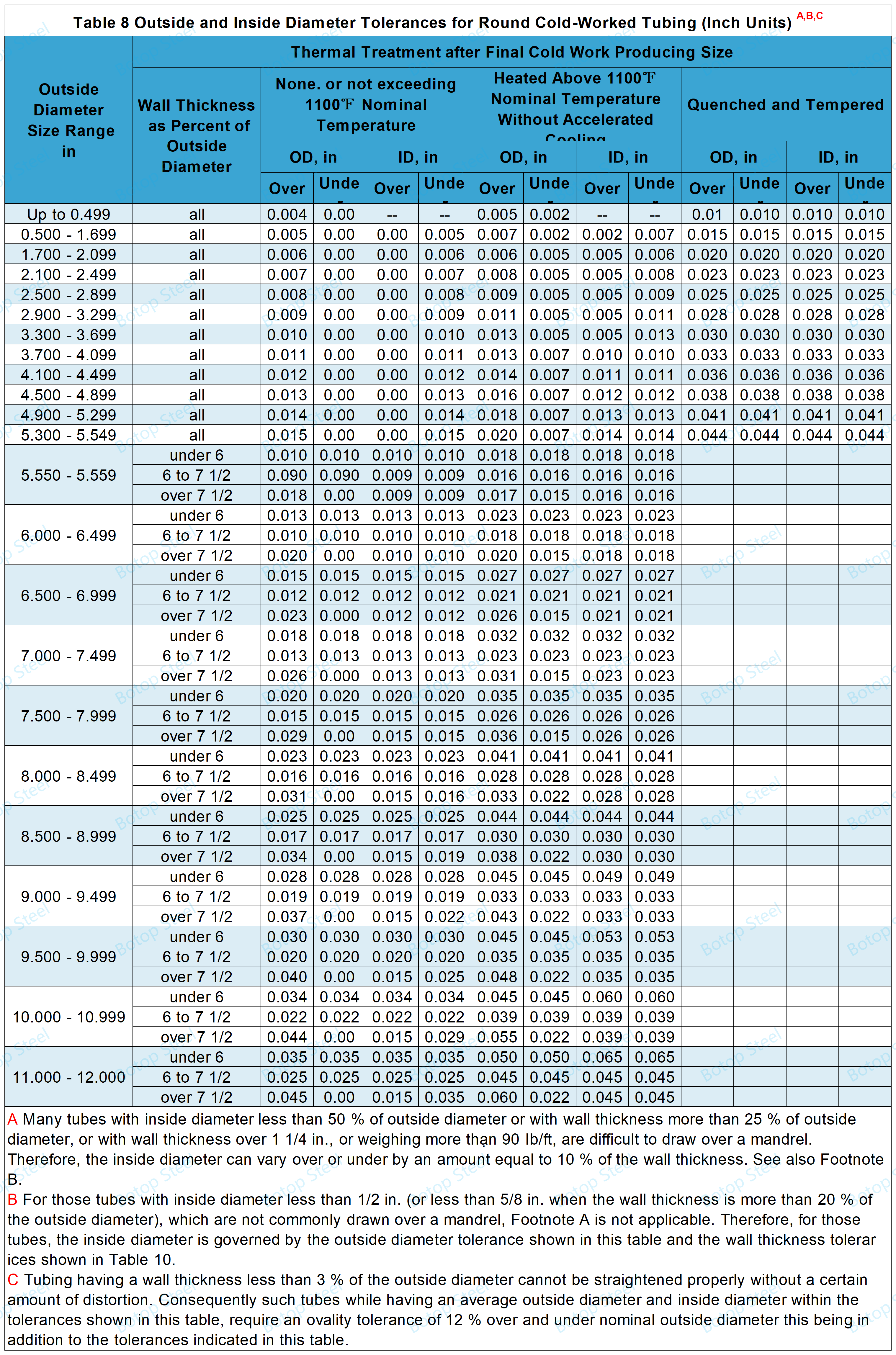

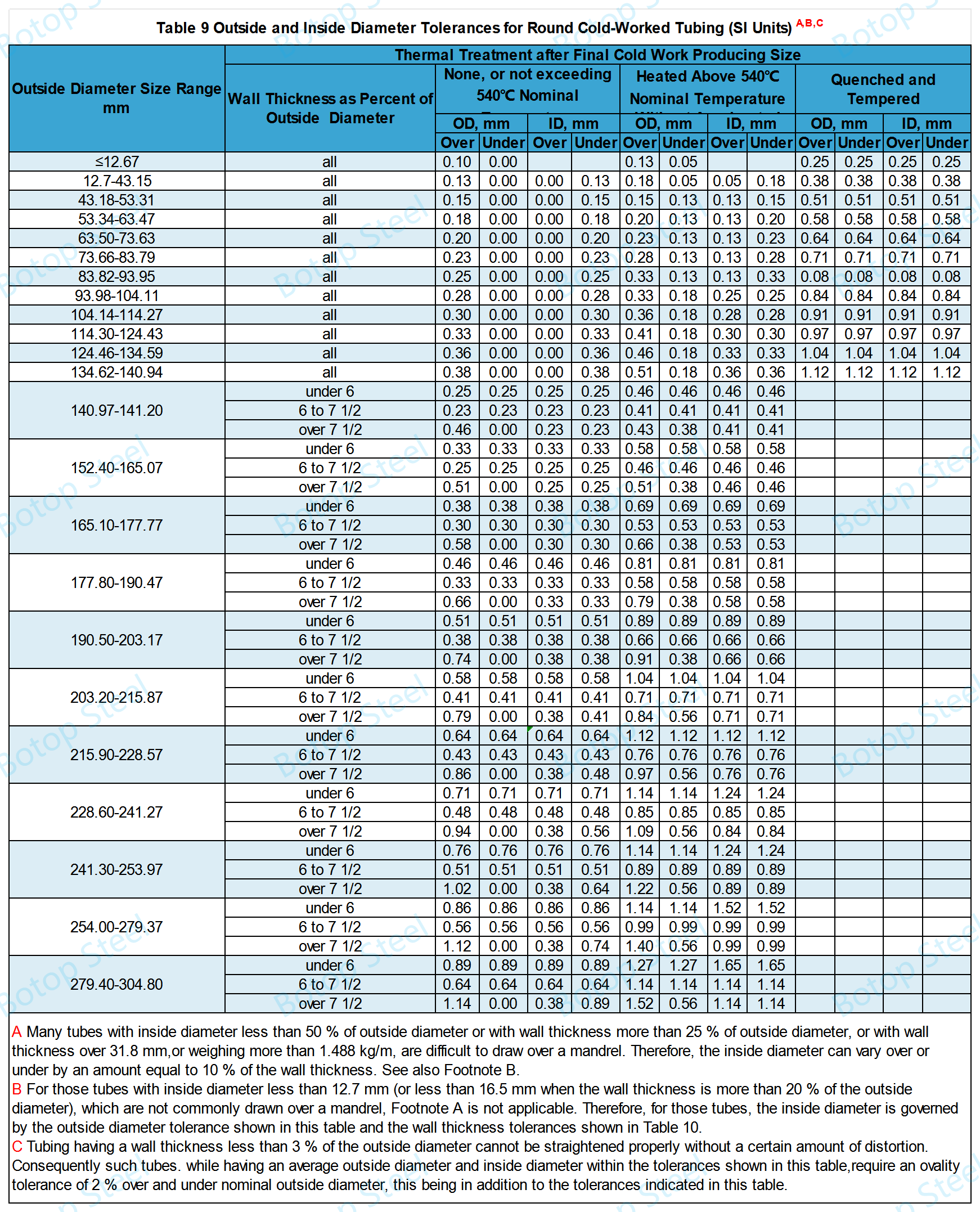

Ngaphandle naNgaphakathi Ukunyamezela kweDiameter

ITheyibhile 8 Ngaphandle naNgaphakathi Ukunyamezela kweDiameter yeIityhubhu eRounding eBanda-eSebenzayo (iiYunithi ze-intshi)

ITheyibhile 9 Ngaphandle naNgaphakathi Ukunyamezelwa kweDiameteryeRound Cold-Worked Tubing (iiYunithi zeSI)

Unyamezelo lweDiameter yangaphandle kunye noDonga lokutyeba

ITheyibhile ye-11 yaNgaphandle kweDiameter kunye noNyamezelo lweDongaye-Rrough-Turned Steel Tubing engenamthungo

| Ubungakanani obuchaziweyo ngaphandle kweDamitha, ngaphakathi [mm] | Ngaphandle kobubanzi, ngaphakathi [mm] | Ukutyeba kweendonga, % |

| <6 3/4 [171.4] | ±0.005 [0.13] | ±12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ±0.010 [0.25] | ±12.5 |

Ukunyamezela Ubude

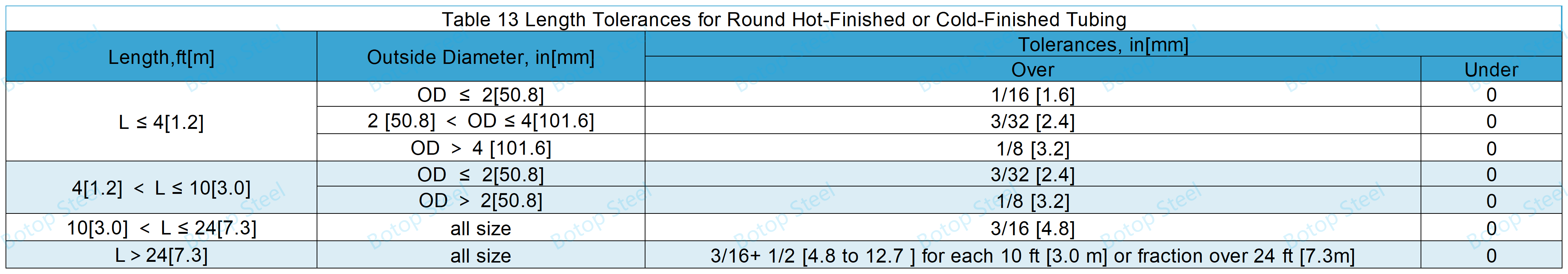

Uluhlu lwe-13 loNyamezelo loBudeyeRound Hot-Finished or Cold-Finished Tubing

Unyamezelo oluthe tye

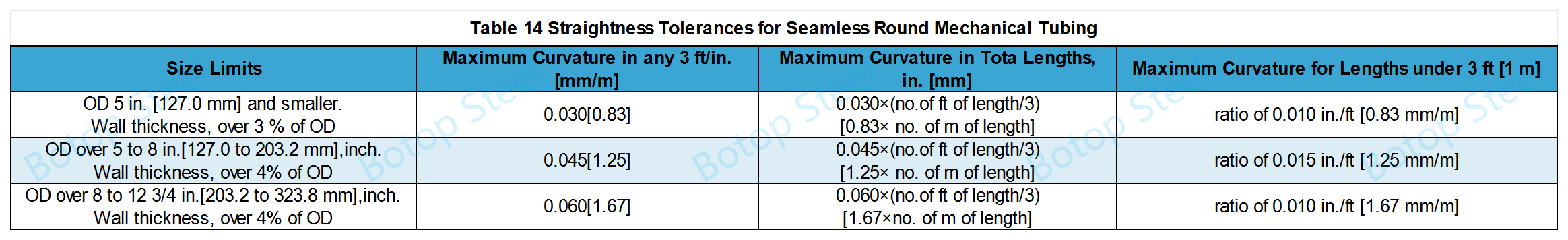

ITheyibhile ye-14 yokuNyamezelwa kokuLungileyoyeTubing yoMechanical eRound engenamthungo

Umbhobho kufuneka ugqunywe ngefilimu yeoli ngaphambi kokubunjwa ukuze uthintele ukurusa.

I-oyile yokuthintela umhlwa inokuphinda isetyenziswe kwindawo yangaphakathi nangaphandle yombhobho.

I-Aviation kunye ne-aerospace: Ukwenziwa kwezinto ezibalulekileyo ezifana neenjini zenqwelo-moya kunye neenkqubo zokuxhasa iziphekepheke.

Ishishini lamandla: izixhobo zokuqhuba kunye ne-high-pressure boiler piping production.

Ukwenziwa koomatshini kunye nezixhobo: Amacandelo aphambili enza uluhlu olubanzi loomatshini boshishino kunye nezixhobo.

Izixhobo zezemidlalo: Ukwenziwa kwezakhelo zebhayisekile ezisebenza kakhulu kunye nezinye izibonelelo zemidlalo.

Ukwakha nokwakha: Izinto zenkxaso yezakhiwo zezakhiwo kunye nezicelo kwiindawo ezinoxinzelelo oluphezulu.

1. I-EN 10297-1: I-E355, i-25CrMo4, i-42CrMo4, njl. Ezi zixhobo zinokuthathwa njengezilingana nezinye iintsimbi zekhabhoni kunye ne-alloy kwi-ASTM A519.

2. I-DIN 1629: I-St52, i-St37.4, njl. Ngokuqhelekileyo isetyenziselwa iinjongo zoomatshini kunye nezakhiwo, ezi zifana namabakala ensimbi ethambileyo kwi-ASTM A519.

3. I-JIS G3445: I-STKM13A, i-STKM13B, njl. Ezi ziibhobho ze-carbon steel ezisetyenziselwa iinjongo zoomatshini kunye nezakhiwo.

4. BS 6323:CFS 3, CFS 4, CFS 8, njl. Ezi ziityhubhu zentsimbi ezingenamthungo nezidityanisiweyo ukwenzela iinjongo zemoto, ezoomatshini, nezobunjineli ngokubanzi.

5. I-GB / T 8162: 20 #, 45 #, 40Cr, 20CrMo, njl. Iityhubhu zentsimbi ezingenamthungo kunye nemibhobho yesakhiwo esiqhelekileyo kunye nesakhiwo soomatshini.

6. I-ISO 683-17: 100Cr6, njl., esetyenziswa ngokuqhelekileyo ekuveliseni ukuzala, inokufumana isicelo kubunjineli bemishini kwaye inezicelo ezifanayo kwiintsimbi ezithile ze-alloy ze-ASTM A519.

Xa ukhetha izinto ezilinganayo, kubalulekile ukubhekisela kwinkcazo yokwakheka kweekhemikhali kunye neenkcukacha zepropathi yomatshini ukuqinisekisa ukuba izinto ezikhethiweyo ziya kuhlangabezana neemfuno zokusebenza kwesicelo esithile.

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi. Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange.

Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.