I-ASTM A53 ERWumbhobho wentsimbi naUhlobo Ekwinkcazo ye-A53, eyenziwe yinkqubo yokumelana ne-welding, kwaye ifumaneka kuwo omabini amaBanga A kunye neBanga B.

Ilungele ukusetyenziswa koomatshini kunye noxinzelelo kwaye ihlala isetyenziswa njengenjongo jikelele yokuhambisa umphunga, amanzi, igesi kunye nomoya.

Iinzuzo ERW umbhobho yentsimbi, ezifanaixabiso eliphantsikwayeimveliso ephezulu, yenze ibe yinto ekhethiweyo kwizicelo ezininzi zamashishini.

Intsimbi yeBotopngumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Uluhlu lwethu lugcinwe kakuhle kwaye siyakwazi ukuhlangabezana nemfuno ekhawulezayo yabathengi bethu kuluhlu olubanzi lobungakanani kunye nobungakanani.

I-ASTM A53/A53M ibandakanya ezi ndidi zilandelayo kunye namabanga:

Uhlobo E: Ukumelana nombane, iBanga A kunye no-B.

Uhlobo S: Ayinamthungo, amaBanga A no-B.

Uhlobo F: I-Furnace-butt-welded, i-welded eqhubekayo yeBanga A kunye no-B.

Uhlobo EkwayeUhlobo SZimbini iintlobo zemibhobho esetyenziswa ngokubanzi. Okuchasene,Uhlobo FNgokuqhelekileyo isetyenziselwa iityhubhu zedayamitha ezincinci. Ngenxa yenkqubela phambili kwitekhnoloji ye-welding, le ndlela yokuvelisa isetyenziswa ngokuphindaphindiweyo.

Ubungakanani beDamitha: DN 6 - 650 [NPS 1/8 - 26];

Ububanzi bangaphandle: 10.3 - 660 mm [0.405 - 26 in.];

Ubukhulu bodonga kunye neetshathi zobunzima bombhobho wentsimbi:

Iityhubhu ezisicaba zingajongwa kwiTheyibhile X2.2;

Iityhubhu ezinemisonto kunye nezidityanisiweyo zinokujongwa kwiTheyibhile X2.3.

I-ASTM A53 ikwavumela ukubonelelwa kombhobho neminye imilinganiselo ngaphandle kokuba umbhobho uhlangabezana nazo zonke ezinye iimfuno zolu nkcukacha.

ERWisetyenziswa ngokubanzi ukwenza umjikelo ongqukuva, isikwere, kunye noxande wekhabhoni kunye nemibhobho yentsimbi ephantsi.

Oku kulandelayo yinkqubo yemveliso yokuvelisaumbhobho wentsimbi we-ERW ojikelezayo:

a) Ukulungiswa kwezinto: Izinto zokuqala zidla ngokutshisa iikhoyili zentsimbi. Ezi khoyili ziqala zicandwe kwaye zichetywe kububanzi obufunekayo.

b) Ukubumba: Ngokuthe ngcembe, ngokusebenzisa uluhlu lwemiqulu, umgca wenziwa kwisakhiwo setyhubhu evulekileyo. Ngexesha lale nkqubo, imiphetho yomtya isondelelana ngokuthe ngcembe ukulungiselela ukuwelda.

c) Ukuwelda: Emva kokwenza isakhiwo se-tubular, imida yentsimbi yentsimbi ishushu ngokuchasa kombane kwindawo ye-welding. I-high-frequency current igqithiswa kwizinto eziphathekayo, kwaye ukushisa okwenziwa kukuchasana kusetyenziselwa ukutshisa imida ukuya kwindawo yabo yokunyibilika, kwaye emva koko zidityaniswe kunye ngoxinzelelo.

d) Ukukhupha imali: Emva kwe-welding, i-weld burrs (intsimbi engaphezulu kwi-welding) isuswe ngaphakathi nangaphandle kombhobho ukuze kuqinisekiswe indawo epholileyo ngaphakathi kombhobho.

e) Ukusetwa kobungakanani kunye nobude: Emva kokuba i-welding kunye ne-deburring igqityiwe, iityhubhu zigqithiswa kumatshini wokulinganisa ukulungiswa kwe-dimensional ukuze kuqinisekiswe ukuba zihlangabezana nobukhulu obuchanekileyo kunye neemfuno ezijikelezayo. Iityhubhu ziyasikwa zibe ngobude obumiselweyo.

f) Ukuhlolwa novavanyo: Umbhobho wensimbi uya kuvavanywa ngokungqongqo kunye nokuhlolwa, kubandakanywa uvavanyo lwe-ultrasonic, uvavanyo lwe-hydrostatic, njl., Ukuqinisekisa ukuba umgangatho wepayipi yensimbi uhlangabezana nemigangatho kunye neenkcukacha.

g) Unyango lomphezulu: Okokugqibela, umbhobho wentsimbi unokuba phantsi konyango olongezelelweyo olufana ne-hot dip galvanizing, ukupeyinta, okanye ezinye iindlela zonyango ezingaphezulu ukubonelela ngokhuseleko olongezelelweyo lwe-corrosion kunye ne-aesthetics.

I-Welds ku-Type E okanye i-Type F yeBanga Bumbhobho uya kunyangwa ubushushu okanye ngenye indlela emva kwe welding ukuze i-martensite enganyangekiyo ingabikho.

Ubushushu bonyango lobushushu buya kuba buncinci1000°F [540°C].

Xa umbhobho obandayo wandiswa, ukwandiswa akuyi kudlula1.5%yobubanzi obuchaziweyo bangaphandle bombhobho.

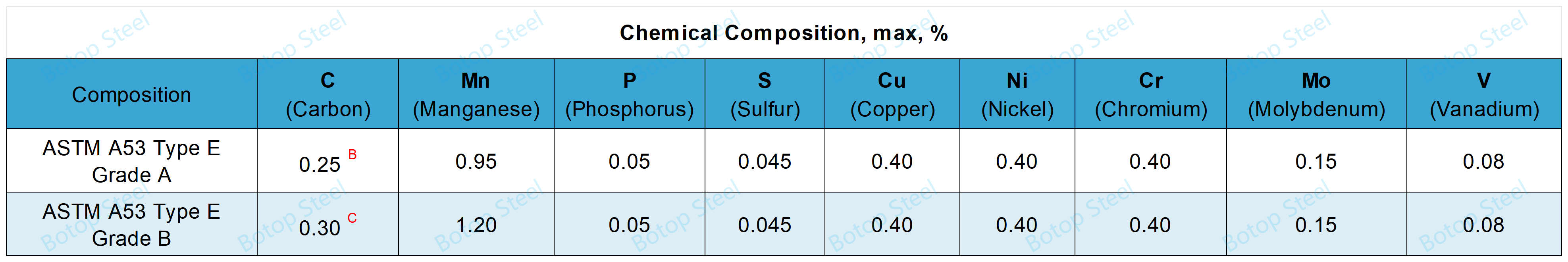

AIzinto ezintlanuCu, Ni, Cr, Mo, kwayeVxa idibene mayingadluli kwi-1.00%.

BNgokucuthwa ngakunye nge-0.01 % ngaphantsi kobuninzi bekhabhoni obuchaziweyo, ukonyuka kwe-0.06 % yemanganese ngaphezu kowona mlinganiselo uphezulu uchaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.35 %.

CKunciphiso ngalunye lwe-0.01 % ngaphantsi kobuninzi bekhabhoni echaziweyo, ukonyuka kwe-0.06 % yemanganese ngaphezu kobuninzi obuchaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.65 %.

Ipropati ye-Tensile

| Uluhlu | Ukuhlelwa | IBanga A | IBanga B |

| Amandla okuqina, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Amandla esivuno, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Ubude kwi-50 mm [2 in.] | Phawula | A,B | A,B |

Qaphela A: Obona buncinane bobude kwisi-2 kwi[50 mm] buya kuba bobo bugqitywe yile nxaki ilandelayo:

e = 625,000 [1940] A0.2/U0.9

e = ubuncinci bobude kwi-2 kwi-50 mm okanye i-50 mm ngepesenti, isondezwe kwipesenti ekufutshane

A = ngaphantsi kwe-0.75 ngo2[500 mm2] kunye nommandla onqamlezileyo wovavanyo lovavanyo loxinzelelo, olubalwe kusetyenziswa idayamitha yangaphandle echaziweyo yombhobho, okanye ububanzi begama lovavanyo lovavanyo loxinzelelo kunye nobukhulu bodonga obuchaziweyo bombhobho, ngexabiso elibaliweyo lijikelezwe kwi-0.01 ekufutshane2 [1 mm2].

U=ubuncinane obuchaziweyo bamandla etensile, psi [MPa].

Qaphela B: Jonga kwiTheyibhile X4.1 okanye iTheyibhile X4.2, nokuba yeyiphi esebenzayo, kubuncinane bamaxabiso obude obufunekayo kwindibaniselwano eyahlukahlukeneyo yomzekelo wovavanyo loxinzelelo kunye namandla achaziweyo asezantsi etensile.

Bend Test

Ngombhobho we-DN ≤ 50 [NPS ≤ 2], ubude obaneleyo bombhobho buya kukwazi ukugoba kubanda nge-90 ° malunga ne-cylindrical mandrel, ububanzi obuphindwe kalishumi elinesibini kububanzi obuchazwe ngaphandle kombhobho, ngaphandle kokuphuhlisa iintanda kuyo nayiphi na indawo kwaye ngaphandle kokuvula i-weld.

Iphinda-phinda-yomelele ngakumbi(iklasi yobunzima:XXS) umbhobho phezu kwe-DN 32 [NPS 1 1/4] akufuneki ukuba ifakwe kuvavanyo lokugoba.

Uvavanyo lokucaba

Uvavanyo lokucaba luya kwenziwa kumbhobho odityanisiweyo ngaphezulu kwe-DN 50 kubunzima obungaphezulu ebomeleleyo (XS) okanye ukhaphukhaphu.

Ilungele udidi E, iBanga A kunye no-B; kunye noHlobo F, iityhubhu zeBanga B.

Iityhubhu zentsimbi ezingenamthungo akufuneki zivavanywe.

Ixesha lovavanyo

Kubo bonke ubukhulu bohlobo lwe-S, uhlobo lwe-E, kunye noHlobo lwe-F yeBanga B, uxinzelelo lovavanyo luya kugcinwa ubuncinane be-5.

Uvavanyo lwe-hydrostatic luya kusetyenziswa, ngaphandle kokuvuza ngomthungo we-weld okanye umzimba wombhobho.

Uvavanyo loxinzelelo

Umbhobho ocacileyoiya kuvavanywa nge-hydrostatically kuxinzelelo olusebenzayo olunikezelweyoUluhlu X2.2,

Umbhobho odityanisiweyo kunye nokudibanisaiya kuvavanywa nge-hydrostatically kuxinzelelo olusebenzayo olunikezelweyoUluhlu X2.3.

Kwimibhobho yensimbi ene-DN ≤ 80 [NPS ≤ 80], uxinzelelo lovavanyo aluyi kudlula i-17.2MPa;

Kwimibhobho yensimbi ene-DN>80 [NPS>80], uxinzelelo lovavanyo aluyi kudlula i-19.3MPa;

Uxinzelelo oluphezulu lovavanyo lunokukhethwa ukuba kukho iimfuno ezikhethekileyo zobunjineli, kodwa oku kufuna uthethathethwano phakathi komenzi kunye nomthengi.

Ukumakisha

Ukuba umbhobho wavavanywa nge-hydrostatic, ukumakisha kufuneka kuboniseuvavanyo loxinzelelo.

Ezi mfuno zilandelayo zisebenza kuHlobo lwe-E nakwi-Type F yeBanga B loMbhobho.

Umbhobho ongenamthungo uneemfuno ezongezelelweyo ezingaxoxwanga kolu xwebhu.

Iindlela zoVavanyo

Imibhobho eveliswa ngoomatshini bokwandiswa okungashushu kunye nokunciphisa: DN ≥ 50 [NPS ≥ 2], iiiweldikwicandelo ngalinye lombhobho kufuneka baphumelele uvavanyo lombane olungonakalisi, kwaye indlela yokuvavanya kufuneka ihambelane neE213, E273, E309 okanye E570umgangatho.

Imibhobho ye-ERW eveliswa ngomatshini wokunciphisa i-hot stretch-ehlisa ubukhulu: DN ≥ 50 [NPS ≥ 2]Icandelo ngalinyeUmbhobho uya kuhlolwa ngokupheleleyo ngokupheleleyo ngovavanyo lombane olungonakalisi, oluya kuhambelana neE213, E309, okanyeE570imigangatho.

Qaphela: Umatshini woKwandiswa kweDayimitha yoKwandiswa kwe-Hot Stretch ngumatshini oqhubeka usolula kwaye ucinezele iityhubhu zentsimbi ngama-roller kumaqondo obushushu aphezulu ukulungelelanisa ububanzi kunye nobukhulu bodonga.

Ukumakisha

Ukuba ityhubhu ifakwe kuviwo olungonakalisi, kuyimfuneko ukubonisaNDEekumakishweni.

IMisa

±10%.

Umbhobho we-DN ≤ 100 [NPS ≤ 4], ulinganiswe njengebhetshi.

Imibhobho DN > 100 [NPS > 4], ilinganiswe ngamaqhekeza enye.

Ububanzi

Ngombhobho we-DN ≤40 [NPS≤ 1 1/2], ukuhluka kwe-OD akuyi kudlula ± 0.4 mm [1/64 in.].

Ngombhobho we-DN ≥50 [NPS>2], ukuhluka kwe-OD akuyi kudlula ± 1%.

Ukutyeba

Ubuncinci bodonga lobungqimba abuyi kuba ngaphantsi87.5%yobukhulu bodonga obuchaziweyo.

Ikhaphukhaphu kunobunzima obunamandla ngakumbi (XS).:

a) umbhobho ocacileyo: 3.66 - 4.88m [12 - 16 ft], Akukho ngaphezu kwe-5% yenani lilonke.

b) ubude obuphindwe kabini: ≥ 6.71 m [22 ft], Ubuncinane obuphakathi ubude be-10.67m [35 ft].

c) ubude obungacwangciswanga obunye: 4.88 -6.71m [16 - 22 ft], hayi ngaphezulu kwe-5 % yenani lilonke lobude obuthungelweyo obunikezelweyo buzijoyinti (iziqwenga ezibini zidityaniswe kunye).

Ubunzima obugqithisileyo (XS) okanye ubunzima: 3.66-6.71 m [12 - 22 ft], akukho ngaphezu kwe-5% iyonke yombhobho 1.83 - 3.66 m [6 - 12 ft].

Ukugqitywa kombhobho wensimbi we-ASTM A53 kufumaneka kumnyama okanye kufakwe igalvanized.

Mnyama: Iityhubhu zensimbi ngaphandle konyango lwangaphezulu, ngokuqhelekileyo zithengiswa ngokuthe ngqo emva kwenkqubo yokuvelisa, kwezo zicelo apho kungekho mfuneko yokumelana ne-corrosion.

Imibhobho yegalvanized kufuneka ihlangabezane neemfuno ezifanelekileyo.

Inkqubo

I-zinc iya kugqunywa ngaphakathi nangaphandle ngenkqubo ye-hot-dip.

Impahla engekasilwa

I-zinc esetyenziselwa ukugquma iya kuba naliphi na ibakala le-zinc elihambelana neemfuno zeNkcazoI-ASTM B6.

Imbonakalo

Umbhobho owenziwe igalati mawungabi neendawo ezingagqunywanga, amaqamza omoya, iidiphozithi eziqukuqelayo, kunye nokufakwa kwe-slag erhabaxa. Izibonda, izibonda, iiglobhu, okanye izixa ezikhulu zediphozithi zinc eziphazamisana nokusetyenziswa okucetywayo kwezixhobo aziyi kuvunyelwa.

Ubunzima bokugquma obuGalvanized

Kuya kumiselwa ngovavanyo lwe-peel ngokwendlela yovavanyo ye-ASTM A90.

Ubunzima bokugquma akufunekanga bube ngaphantsi kwe-0.55 kg/m² [1.8 oz/ft²].

ASTM A53 ERW umbhobho wentsimbiidla ngokusetyenziswa kwizicelo zoxinzelelo oluphantsi ukuya oluphakathi ezifana nobunjineli bakamasipala, ulwakhiwo, kunye nombhobho wolwakhiwo lomatshini. Iimeko zokusetyenziswa okuqhelekileyo ziquka ukuhambisa amanzi, umphunga, umoya, kunye nolunye ulwelo olunoxinzelelo oluphantsi.

Ngokwazi ukuwelda okulungileyo, zikulungele ukwenza imisebenzi ebandakanya ukujiya, ukugoba, kunye nokujiya.