Umbhobho wentsimbi we-ASTM A556 usetyenziswa ikakhulu njengombhobho wentsimbi otsalwa ngokubanda ongenamthungo kwizifudumezi zamanzi ezondla amanzi.

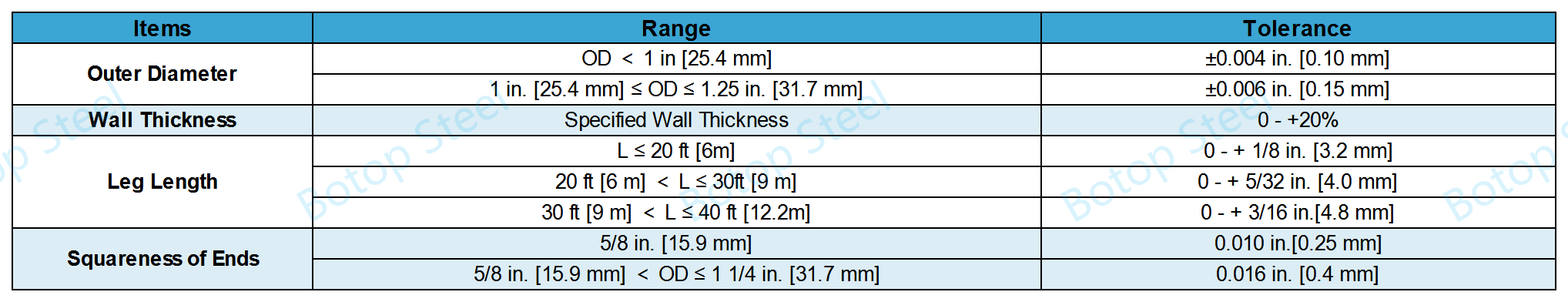

Umda wokusetyenziswa kwayo ngumbhobho wentsimbi ongenamthungo kunye nobukhulu bangaphandle bedayamitha phakathi kwe-15.9-31.8mm kunye nobukhulu bodonga obungekho ngaphantsi kwe-1.1mm.

Eli nqaku ligxile kwipayipi yensimbi kwaye ayibandakanyi i-U-tubes ekhankanywe kumgangatho.

Ububanzi bangaphandle: 5/8 - 1 1/4 ngaphakathi [15.9 -31.8 mm].

Ubunzima bodonga: ≥ 0.045 kwi [1.1 mm].

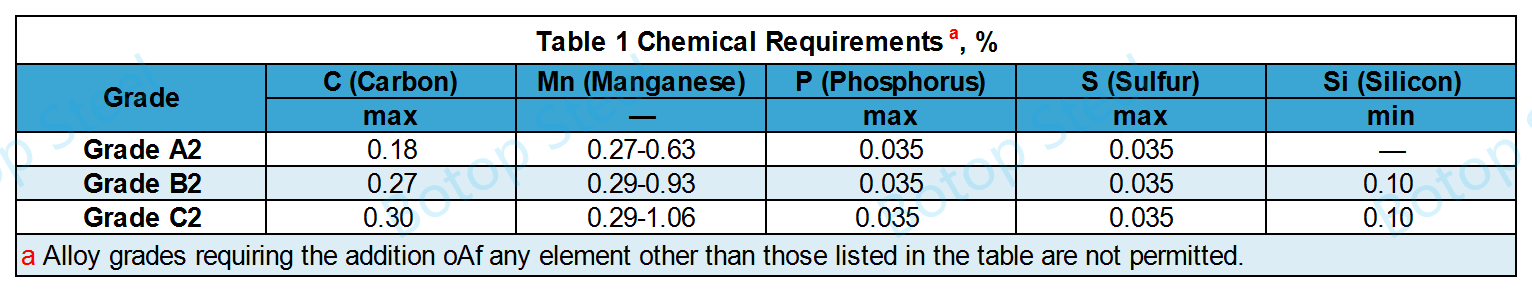

I-ASTM A556 ihlela amabanga amathathu,IBanga A2, IBanga B2, kwayeIBanga C2.

Iityhubhu zentsimbi ziya kwenziwa ngu aengenamthungoinkqubo kwaye iya kutsalwa ngokubanda.

Iityhubhu zentsimbi ezitsalwa ngokubanda ezingenamthungo zinika ukuchaneka komgangatho ophezulu kunye nokugqiba kakuhle komphezulu ngelixa ucokisa i-microstructure kwaye uphucula iipropathi zoomatshini ezifana namandla kunye nokuqina. Isakhiwo esingenamthungo senza iityhubhu zizinzile kwaye zikhuselekile xa ziphantsi koxinzelelo oluphezulu kunye namaqondo okushisa, okwenza ukuba zilungele ukusetyenziswa kwezoshishino ezifuna ukuchaneka okuphezulu kunye nokusebenza.

Nangona kunjalo, iityhubhu zentsimbi ezingenamthungo ezitsalwa ngokubanda zibiza kakhulu ukuvelisa ngenxa yokuba inkqubo yazo yokuvelisa inzima kwaye ifuna imisebenzi entsonkothileyo kunye nezixhobo. Ukongeza, ukusebenza kwabo okuphantsi kwemveliso, ngakumbi kwimveliso yomthamo omkhulu, akukhona ukonga njengenkqubo yokuqengqeleka eshushu, kwaye kwezinye iimeko kunokubakho ukulahleka kwezinto ezininzi, ukunciphisa ukusetyenziswa kwazo kwizicelo ezithile.

Iityhubhu ezitsalwa yingqele ziya kunyangwa ubushushu emva kokuba kugqitywe ubushushu obuyi-1200°F [640°C] okanye ngaphezulu ukuze kuqinisekwe ukuba i-ductility iyanelisa ukuqengqeleka kwi-tube sheets kunye nokuhlangabezana neempawu zomatshini njengoko kuchaziwe.

Ukuba uhlalutyo lwemveliso lwenziwe, bhekisa kwi-ASTM A751 ngeendlela zovavanyo.

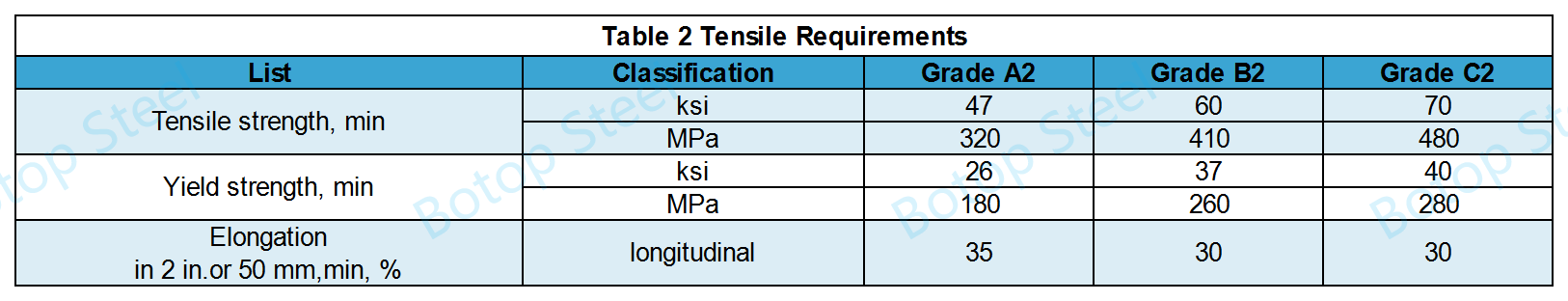

1. Ipropathi yeTensile

Indlela yovavanyo: ASTM A450 Icandelo lesi-7.

Kwiibhetshi ukuya kuthi ga kwiityhubhu ezingama-50, ityhubhu enye iya kukhethwa ukuze ivavanywe.

Kwiibhetshi ezingaphezulu kweetyhubhu ezingama-50, iityhubhu ezi-2 ziya kukhethwa ukuze zivavanywe.

2. Ubulukhuni

Indlela yovavanyo: ASTM A450 Icandelo lama-23.

Iisampulu ezivela kwiityhubhu zovavanyo ezimbini kwiqashiso ngalinye ziya kuvavanywa ukuqina kweBrinell okanye iRockwell.

Ubunzima bombhobho we-Rockwell abuyi kudlula oko kuboniswe kwitheyibhile.

| IBanga | Ukuqina |

| IBanga A2 | 72 HRBW |

| IBanga B2 | 79 HRBW |

| IBanga C2 | 89 HRBW |

3. Uvavanyo lokucaba

Indlela yovavanyo: ASTM A450 Icandelo le-19.

Uvavanyo lwe-flat flat luya kwenziwa kwi-specimen enye ukusuka ekupheleni kwetyhubhu yentsimbi egqityiweyo ekukhethweni kwe-tubes engekho ngaphezu kwe-125 kwiqashiso ngalinye.

4. Uvavanyo oluvuthayo

Indlela yovavanyo: ASTM A450 Icandelo 21.

Iimvavanyo ezivuthayo ziya kuqhutywa kwi-specimen enye ukusuka ekupheleni kwetyhubhu egqityiweyo, kunye ne-tubes engekho ngaphezu kwe-125 ekhethiweyo kwibhetshi nganye.

Akukho vavanyo olunyanzelekileyo lwe-hydrostatic kwimibhobho yentsimbi.

Nangona kunjalo, wonke umbhobho we-U kufuneka uvavanywe nge-hydrostatically ngolwelo olungadlekiyo.

Ityhubhu nganye iya kuvavanywa ngesixhobo sovavanyo esingonakalisiyo esikwaziyo ukubona iziphene kuwo wonke umnqamlezo wetyhubhu emva kokunyangwa kobushushu bomhlaba emva komzobo wokugqibela obandayo.

Iindlela zovavanyo ezingonakalisiyo zeNkcazoE213, IinkcukachaE309(yemathiriyeli ye-ferromagnetic), UkucaciswaE426(kwimathiriyeli engeyiyo eyemagnetic), okanye UbaluloE570inokukhethelwa uvavanyo.

Ukunyamezela okulandelayo akusebenzi kwinxalenye egobileyo ye-U-tube.

Umbhobho ogqityiweyo kufuneka ukhululeke kwisikali kodwa unokuba nefilimu ye-oxide engaphezulu.

Iityhubhu ezigqityiweyo ziya kuthi nkqo ngokufanelekileyo kwaye zibe neziphelo ezigudileyo ezingenazo iibhula. Iityhubhu ziya kuba nesiphelo esifana nesomsebenzi kwaye aziyi kuba naziphene ezingaphezulu ezingenakususwa ngaphakathi konyamezelo oluvumelekileyo eludongeni.

Ukususwa kokungafezeki komphezulu okufana namanqaku okuphatha, amanqaku okulungelelanisa, i-mandrel ekhanyayo kunye namanqaku okufa, imigodi enzulu, kunye neepateni zesikali aziyi kufunwa ukuba zingaphakathi kokunyamezela kodonga oluvumelekileyo.

Ububanzi bangaphakathi nangaphandle bombhobho ogqityiweyo kufuneka bufakwe ukuthintela ukubola ngexesha lokuthutha.

Iingubo eziqhelekileyo ziiioli zokuthintela umhlwa, iivanishi, okanyeiipeyinti.

Ukukhethwa kwezinto zokugqoka ngokuqhelekileyo kuxhomekeke kwiimfuno ezithile zesicelo sombhobho wensimbi, indawo yokusetyenziswa okujoliswe kuyo, kunye nobude bokukhusela.

Izifudumezi zamanzi ze-tubular feed: Le yenye yezona zicelo eziqhelekileyo ze-ASTM A556 zentsimbi ye-tubing.

Kwishishini lamandla, izifudumezi zamanzi ezondla zisetyenziselwa ukufudumeza amanzi kwibhoyila, ngokuqhelekileyo ngokukhupha umphunga. Ukusetyenziswa kolu hlobo lwe-tubing yensimbi kuvumela ukuhanjiswa ngokufanelekileyo kwamandla ashushu, ukuphucula ukusebenza kakuhle kwamandla kunye nokusebenza kwenkqubo.

Izitshintshi zobushushu kunye ne-condensers: Ngenxa yeempawu zayo ezibalaseleyo zokufudumeza ubushushu kunye nokumelana nokubola, i-ASTM A556 i-tubing yensimbi nayo ifanelekile ukusetyenziswa kwezinye iintlobo zokutshintsha ubushushu kunye ne-condensers, ezisetyenziselwa uluhlu olubanzi lweekhemikhali, i-petrochemical, kunye nezinye iinkqubo zoshishino.

Iinkqubo zoxinzelelo oluphezulu lomphunga: Ubushushu obuphezulu kunye noxinzelelo oluphezulu lwe-ASTM A556 ityhubhu luyenza ilungele ukusetyenziswa kwiinkqubo zoxinzelelo oluphezulu kunye nezinye izicelo ezifuna uxinzelelo oluphezulu kakhulu kunye nokumelana nobushushu.

I-ASTM A179/A179M- Lo ngumgangatho owenziwe ngokubanda owenziwe nge-carbon steel ubushushu bentsimbi kunye neetyhubhu ze-condenser zenkonzo ye-cryogenic.

I-ASTM A192/A192M- Icacisa iimfuno zobugcisa kwiityhubhu zebhoyila zentsimbi ezingenamthungo kwiibhoyila ezisetyenziswa kwinkonzo yoxinzelelo oluphezulu.

I-ASTM A210/A210M- Umgangatho wekhabhoni engenamthungo ephakathi kunye neetyhubhu zebhoyila zentsimbi ye-carbon-manganese kwiibhoyila kunye nezifudumezi ezinkulu.

I-ASTM A213/A213M- Ibonelela ngemigangatho yebhoyila yensimbi engenamthungo ye-ferritic kunye ne-austenitic alloy steel, iheater, kunye neetyhubhu zokutshintsha ubushushu.

I-ASTM A249/A249M- Umgangatho osebenzayo kwibhoyila yensimbi edityanisiweyo ye-austenitic, iheater enkulu, isitshintshi sobushushu, kunye neetyhubhu zecondenser.

I-ASTM A334/A334M- Umgangatho wekhabhoni engenamthungo kunye ne-welded kunye ne-alloy steel tubing yenkonzo ye-cryogenic.

Nganye yale migangatho igubungela iibhubhu zetsimbi ezisetyenziselwa ukutshintshiselana kobushushu, iibhoyili okanye izicelo ezifanayo. Ngowuphi umgangatho okhethiweyo uxhomekeke kwiimfuno ezithile zesicelo, ezifana nobushushu bokusebenza, umlinganiselo woxinzelelo, kunye nokuxhathisa okulindelweyo.

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange. Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.