I-BS EN 10210 S355J0H, inombolo yentsimbi 1.0547, yeyecandelo lentsimbi yesakhiwo esinomngxuma eshushu kwaye inombhobho wentsimbi ongenamthungo okanye odityanisiweyo, osetyenziswa kakhulu kwizakhiwo ezifuna ukomelela okuphezulu kunye nokuqina okuhle, okufana nezakhelo ezinkulu zokwakha kunye neebhulorho.

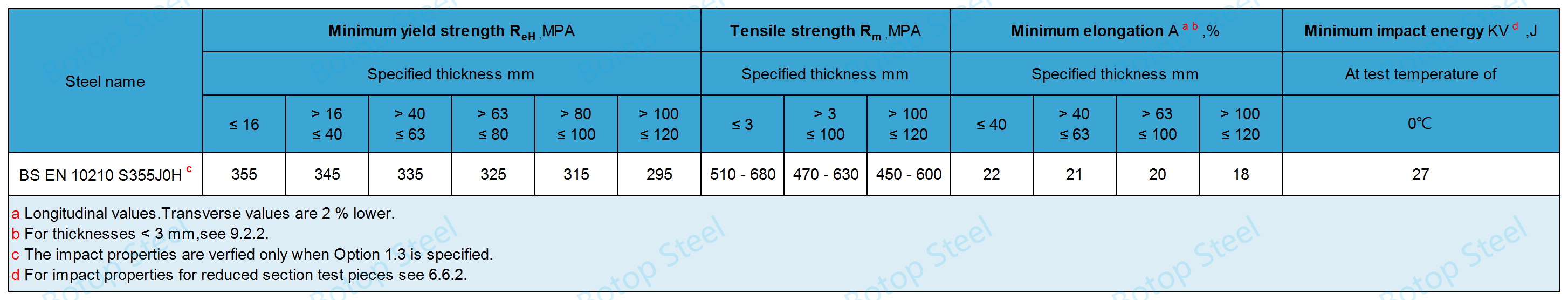

Isixhobo se-S355J0H sineempawu zomatshini ukuba amandla esivuno esincinci yi-355MPa xa ubukhulu bodonga bungagqithi kwi-16 mm kwaye budibana namandla empembelelo amancinci angama-27J ku-0℃.

I-BS EN 10210 iqulethe iintlobo ngeentlobo zeemilo ezinqamlezayo, ezinjengesetyhula, isikwere, uxande, okanye i-elliptical, iBotop Steel igxile kwiityhubhu zentsimbi ezijikelezayo ezinobukhulu obahlukeneyo, ikubonelela ngemigangatho ephezulu kunye nemigangatho yemathiriyeli yentsimbi ehambelanayo nentengiso ngokuthe ngqo kumzi-mveliso kunye nexabiso elikhuphisanayo.

Qaphela: Zonke iimfuno ezikolu xwebhu ziyasebenza nakwi-EN 10210.

Ubunzima bodonga ≤120mm.

Isetyhula (HFCHS): Ububanzi bangaphandle ukuya kwi-2500 mm;

Isikwere (HFRHS): Imilinganiselo yangaphandle ukuya kwi-800 mm x 800 mm;

I-Rectangular (HFRHS): Imilinganiselo yangaphandle ukuya kwi-750 mm x 500 mm;

I-Elliptical (HFEHS): Imilinganiselo yangaphandle ukuya kwi-500 mm x 250 mm.

| Ibakala Steel | Uhlobo lwe ukukhutshwa kweoksijinia | % ngobunzima, ubukhulu | |||||||

| C | Si | Mn | P | S | Nb,c | ||||

| Igama lentsimbi | Inombolo yentsimbi | Ubukhulu obuxeliweyo (mm) | |||||||

| ≤40 | >40 ≤120 | ||||||||

| I-BS EN 10210 S355J0H | 1.0547 | FN | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

aFN = Intsimbi yokuvala ayivumelekanga;

bKuvumelekile ukuba kugqithwe amaxabiso achaziweyo ukuba kunyuso ngalunye lwe-0.001 % N the P, max. umxholo ukwancitshiswe nge-0.005%. Umxholo we-N wohlalutyo lwe-cast, nangona kunjalo, awuyi kuba ngaphezu kwe-0.012%;

cIxabiso eliphezulu le-nitrogen alisebenzi ukuba ukubunjwa kweekhemikhali kubonisa ubuncinane be-Al umxholo we-0.020 % kunye nomlinganiselo we-Al/N ubuncinane we-2: 1, okanye ukuba kukho ezinye izinto ezaneleyo ze-N-binding. Izinto ezibophelelayo ze-N ziya kubhalwa kuXwebhu loHlolo.

Ukutyunjwa kwezinto eziphathekayo kwi-BS EN 10210 kusekwe kumandla azo asezantsi esivuno kubukhulu bodonga lwe-16mm kunye neempawu zempembelelo kumaqondo obushushu athile. Amandla esivuno, amandla okuqina, kunye nobude be-BS EN 10210 S355J0H kuncipha njengoko ubukhulu bodonga bukhula.

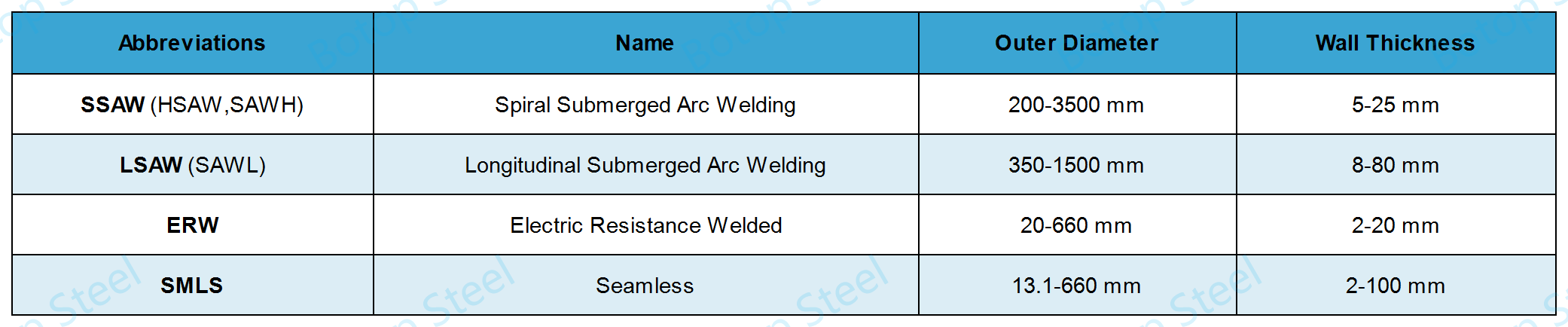

I-BS EN 10210 ivumela imveliso kusetyenziswa iinkqubo ezahlukeneyo zokuvelisa, ezihlala zibandakanya i-seamless, i-LSAW, i-SSAW, kunye neenkqubo ze-ERW zokuwelda.

Ngezantsi uluhlu lweesayizi zeenkqubo eziqhelekileyo zokuvelisa.

Ukusuka kolu thelekiso lungasentla, kunokubonwa ukuba umbhobho wentsimbi ongenamthungo unenzuzo engokwemvelo kwimveliso yombhobho wentsimbi enodonga olungqingqwa, ngakumbi umbhobho wentsimbi onodonga olungqindilili oluncinci, kodwa ubukhulu bawo buya kulinganiselwa. Ukuba ufuna ukuvelisa imibhobho yensimbi kunye nobubanzi obungaphezulu kwe-660mm, kuya kuba nzima ngakumbi.

Umbhobho omnyama

Oku kubhekiselele kumbhobho wentsimbi ngaphandle konyango lomphezulu.

Ukugquma koKhuseleko okwethutyana

Ukuthintela ukubola kweemibhobho zetsimbi ngexesha lokugcina, ukuthutha, okanye ukufakela, indlela eqhelekileyo kukugubungela umphezulu wombhobho ngoluhlu lwepeyinti okanye i-varnish.

I-Anti-corrosion Coating

Kukho iintlobo ezininzi ze-anti-corrosion coatings, kuquka ipeyinti, i-FBE,3LPE, kunye nentsimbi. Uhlobo ngalunye lwengubo luneempawu ezizodwa kunye neendawo ezisebenzayo. Umhlwa kunye nomhlwa zinokuthintelwa ngokufanelekileyo ngokufaka i-anti-corrosion coating efanelekileyo kwiindawo zentsimbi.

I-TS EN 10210 Idiphu eshushu yokwalekwa ngegalvanized kumphezulu wemibhobho yentsimbi iya kuthobela iimfuno ezifanelekileyo ze-EN ISO 1461.

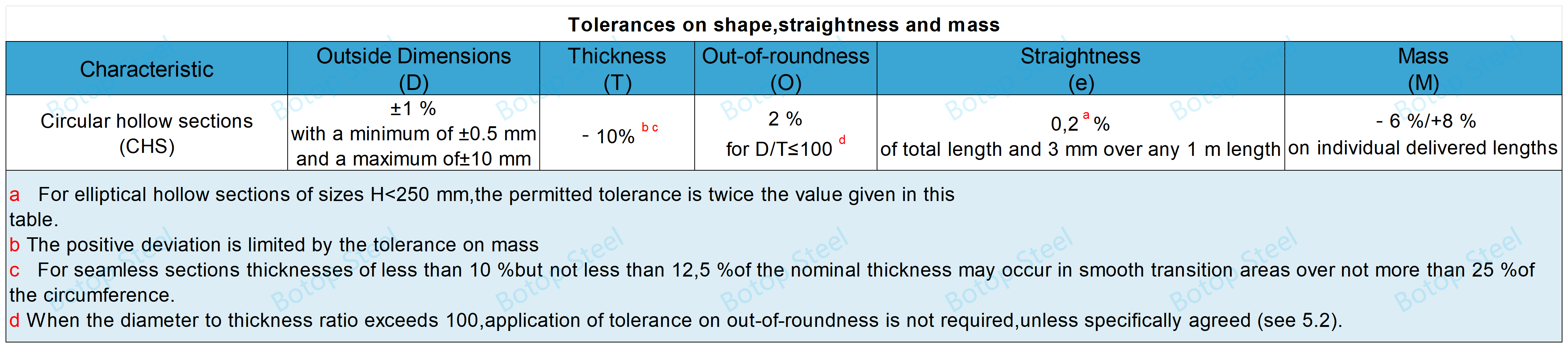

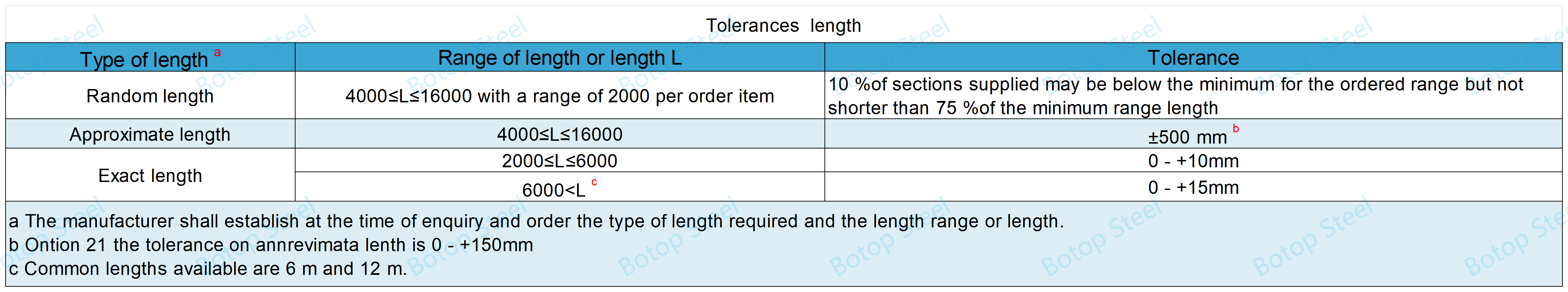

Ukunyamezelana kwiMilo, ukuTwa kunye noMisa

Ukunyamezela kuBude

Umthungo Ubude be-SAW Weld

| Ukutyeba, T | Ubude be-weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Ukuphakama komthungo we-weld weld ngokuqhelekileyo akugqithisi kakhulu ngaphaya kombhobho, kwaye ngexesha lenkqubo yokuvelisa, i-weld seam iphathwa ukwenzela ukuba igungxulwe ngokubalulekileyo kunye nomphezulu wombhobho kwaye ingabonakali ibonakala.

I-BS EN 10210 S355J0H isetyenziswa ngokubanzi kwizakhiwo zokwakha, ukwenziwa koomatshini, imibhobho yothutho, ulwakhiwo lweziseko ezingundoqo, iinqanawa, kunye nobunjineli baselwandle. Amandla ayo aphezulu kunye nokuqina okuhle kuyenza ibe ntle kwiiprojekthi ezifana neebhulorho, izakhiwo eziphakamileyo, izityalo zemizi-mveliso, iikhreyini, imibhobho yeoli kunye negesi, kunye neenqaba zamandla omoya.

| GB/T | IGOST | I-ASTM | I-JIS |

| I-GB/T 1591 Q345B | I-GOST 19281 09G2S | I-ASTM A501 iBanga C | JIS G 3101 SS490 |

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange. Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.

Ezinye iimveliso eziyeleleneyo:

Qhagamshelana nathi ngekowuti yasimahla kunye nokubonisana ngeprojekthi yakho.