EN 10219 S275J0H kunye ne-S275J2HNgamacandelwana aqinileyo adityanisiweyo awenziwe ngentsimbi engafakwanga ngokwe-EN 10219.

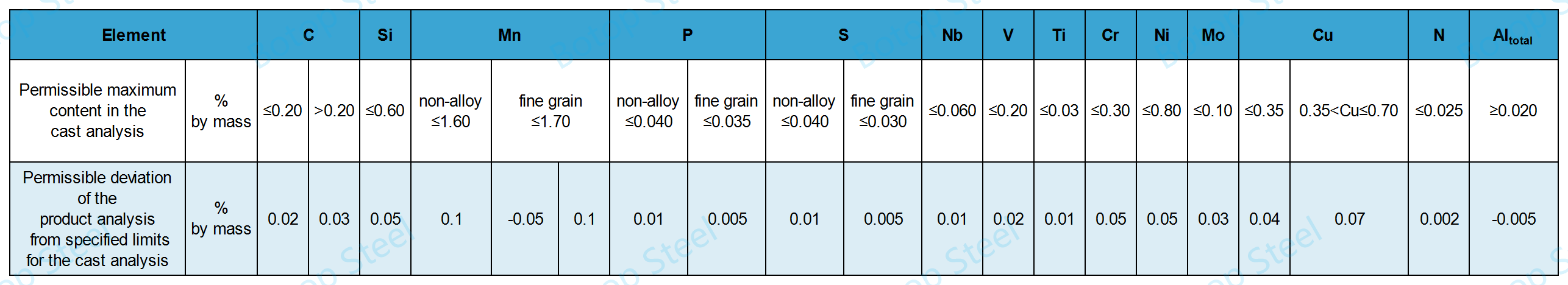

Bobabini banamandla okuvelisa ubuncinci be-275MPa (ubukhulu bodonga ≤16mm). Umahluko ophambili ukwiipropati zempembelelo: i-S275J0H inobuncinane bamandla empembelelo ye-27 J ku-0 ° C, ngelixa i-S275J2H inobuncinane bempembelelo yamandla ye-27 J ku -20 °C.

Ifanelekile kwizicelo kwizakhiwo kunye nezakhiwo zobunjineli ezixhomekeke kwimithwalo elula.

I-BS EN 10219 nguMgangatho waseYurophu EN 10219 owamkelwa yi-UK.

Ubukhulu bodonga ≤40mm, Idayamitha yangaphandle ≤2500mm.

CFCHS sisishunqulelo se-Cold-Formed Circular Hollow Section.

Umgangatho we-EN 10219 ugubungela uluhlu olubanzi lweemilo zentsimbi yesakhiwo esinomgongxo, kubandakanya ukungqukuva, isikwere, uxande, kunye ne-oval, ukuhambelana neemfuno zokusetyenziswa ezahlukeneyo.

Intsimbi yeBotopngokukhethekileyo ekuboneleleni iityhubhu zentsimbi ezingqukuva ezingenanto kwiindidi ngeendidi zobukhulu kunye neenkqubo ukuze zihambelane noluhlu olubanzi lwezicelo zeshishini, ukuqinisekisa ukuba iimfuno ezithile zabathengi bethu zinokufezekiswa.

Ukususela ekusekweni kwayo ngo-2014,Intsimbi yeBotopuye waba ngumthengisi ohamba phambili we-carbon steel pipe eMntla China, owaziwa ngenkonzo ebalaseleyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye neemveliso ezinxulumene nazo, kuqukaI-SMLS, ERW, LSAW, kwayeSSAWumbhobho wensimbi, kunye noluhlu olupheleleyo lwezixhobo zombhobho kunye neeflange. Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.

Sijonge phambili ekusekeni ubudlelwane bentsebenziswano kunye nawe kunye nokudala ikamva lokuphumelela kunye.

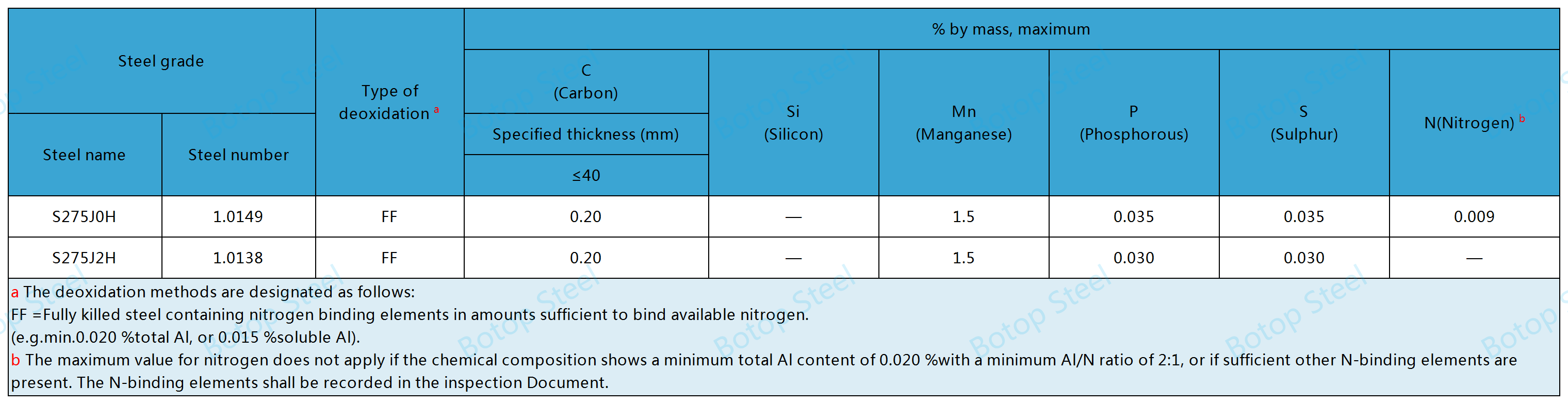

Intsimbi ekrwada yokwenziwa kwamacandelo angaphakathi abandayo afakwe kwi-deoxidized kwaye kufuneka ihlangabezane neemeko ezithile zokuhanjiswa.

Iimfuno ezifanelekileyo ze-S275J0H kunye ne-S275J2H zeziFF(Intsimbi ebulewe ngokupheleleyo equlethe izinto ezibophelelayo zenitrogen ngokwezixa ezaneleyo zokubopha initrogen ekhoyo (umz. min.0,020 % iyonke iAl okanye i-0,015% enyibilikayo iAl)).

Imeko yokuhanjiswa: I-Rolled or normalized/normalized rolled (N) ye-JR, J0, J2, kunye ne-K2 steels.

Imibhobho yentsimbi ukuya kwi-EN 10219 inokuveliswa ngabo bobabiniERW(i-electro resistance welding) kunyeSAW(i-arc welding ephantsi kwamanzi) iinkqubo zokuvelisa.

Imveliso yeIityhubhu ze-ERWinenzuzo yokukhawuleza kwaye ifikeleleke ngakumbi kwaye ihlala ikhethelwa iiprojekthi ezifuna imveliso emikhulu kunye neendleko eziphezulu.

ERWiityhubhu zidla ngokusetyenziselwa ukuvelisa iidiameter ezincinci kunye nokuqina kodonga oluncinci, ngelixaSAWiityhubhu zifaneleke ngakumbi kwiidayamitha ezinkulu kunye neendonga ezityebileyo. Nceda ukhethe uhlobo olufanelekileyo lombhobho wentsimbi kwiprojekthi yakho.

Imibhobho ye-ERW eyenziwe ngokwe-EN 10219 ayidli ngokufuna ukuchetywa kwe-weld yangaphakathi.

Oku kungenxa yokuba iityhubhu ze-EN 10219 zisetyenziswa ikakhulu kulwakhiwo, olufana nolwakhiwo kunye nobunjineli bomatshini, apho iimfuno zenkangeleko ye-weld zihlala zingqongqo kuneenqanawa zoxinzelelo okanye imibhobho yoxinzelelo oluphezulu. Ngoko ke, ukuba nje amandla kunye nokunyaniseka kwe-weld kuhlangabezana neemfuno zomgangatho, i-welds yangaphakathi ingasetyenziselwa ngaphandle kokunciphisa okongeziweyo.

Akukho unyango olulandelayo lobushushu lwenziwayo, ngaphandle kokuba i-weld ingaba kwimeko edibeneyo okanye ephethwe ngubushushu.

Uhlahlelo lweCast (Ukwakheka kwemichiza yeMathiriyeli ekrwada)

Zombini i-S275J0H kunye ne-S275J2H zinexabiso eliphezulu elilingana nekhabhoni (CEV) ye-0.40%.

I-S725J0H kunye ne-S275J2H ene-CEV ephezulu ye-0.4% ibonisa i-weldability engcono kunye nomngcipheko omncinci wokuqina kunye nokuqhekeka ngexesha le-welding.

Inokubalwa kusetyenziswa le fomula ilandelayo:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

Uhlalutyo lweMveliso (Ubume beMichiza yeeMveliso ezigqityiweyo)

Ngethuba lokuveliswa kwentsimbi, ukubunjwa kweekhemikhali kunokutshintsha ngenxa yezizathu ezininzi, kwaye olu tshintsho lunokuchaphazela iipropati kunye nomgangatho wentsimbi.

Umbhobho ogqityiweyo wokugqibela wemichiza yeekhemikhali kufuneka ihambelane nokwakheka kweekhemikhali zokuphosa kunye nokuphambuka kwayo okuvumelekileyo.

Iiparamitha zepropathi zoomatshini ziquka ukomelela kwesivuno, ukomelela, ukomelela, kunye namandla empembelelo.

Ukuthomalalisa uxinzelelo kuxinzelelo olungaphezulu kwama-580 ℃ okanye ngaphezulu kweyure enye kunokukhokelela ekuwohlokeni kweempawu zoomatshini.

Amanqaku:

Uvavanyo lwempembelelo ayifunwa xa ubukhulu obuchaziweyo bu <6mm.

Iimpawu zempembelelo ye-JR kunye ne-J0 yeetyhubhu zekhwalithi aziqinisekiswanga ngaphandle kokuba kucacisiwe.

I-EN 10219 iiWelds kwimibhobho yentsimbi ye-ERW inokuvavanywa ngokukhetha enye yezi zilandelayo.

I-EN 10246-3 kwinqanaba lokwamkelwa kwe-E4, ngaphandle kokuba umbhobho ojikelezayo/ubuchule bekhoyili yepanekuku abuyi kuvunyelwa;

EN 10246-5 kwinqanaba lokwamkelwa F5;

I-EN 10246-8 kwinqanaba lokwamkelwa kwe-U5.

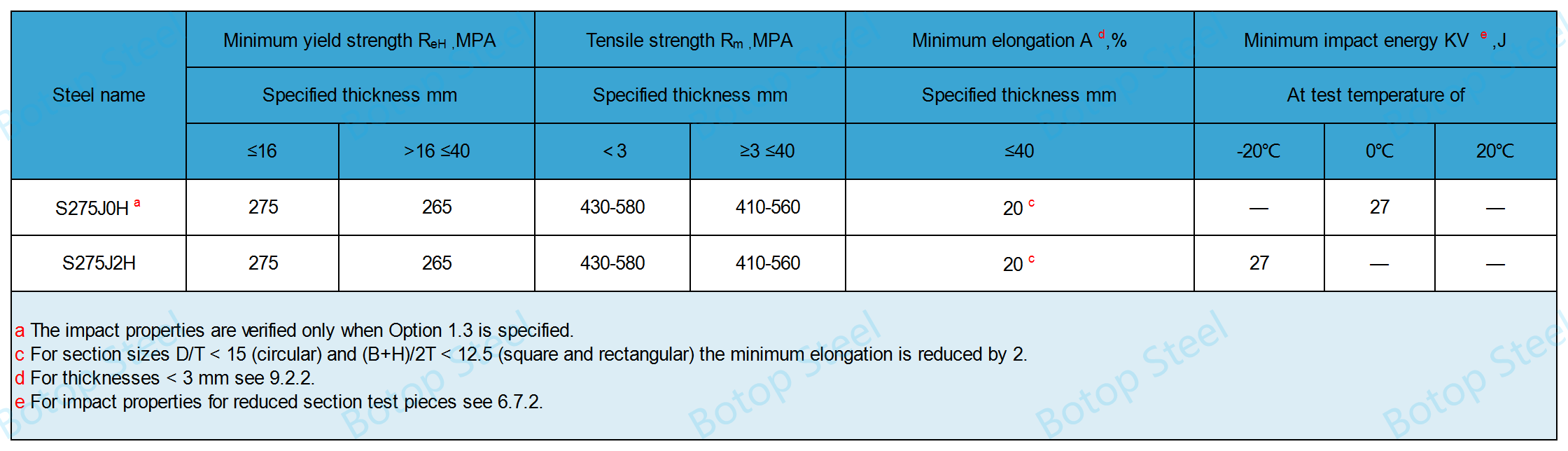

Ukubalwa kobunzima bethiyori yeetyhubhu ze-EN 10219 zinokusekelwa kuxinaniso lwetyhubhu ye-7.85 kg/dm³.

M=(DT)×T×0.02466

M bubunzima ngeyunithi yobude;

D sisixa sangaphandle esixeliweyo, iiyunithi kwi-mm;

T bubunzima obuchaziweyo bodonga, iiyunithi kwi-mm.

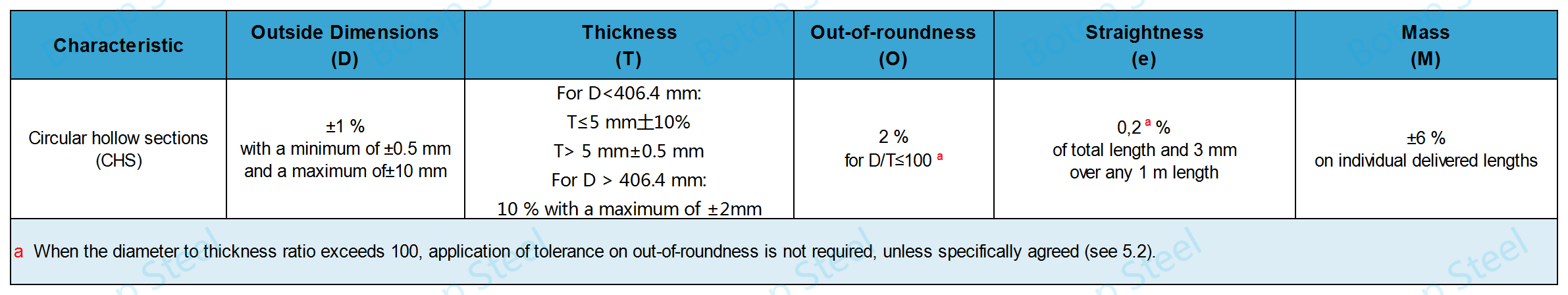

Ukunyamezelana kwiMilo, ukuTwa kunye noMisa

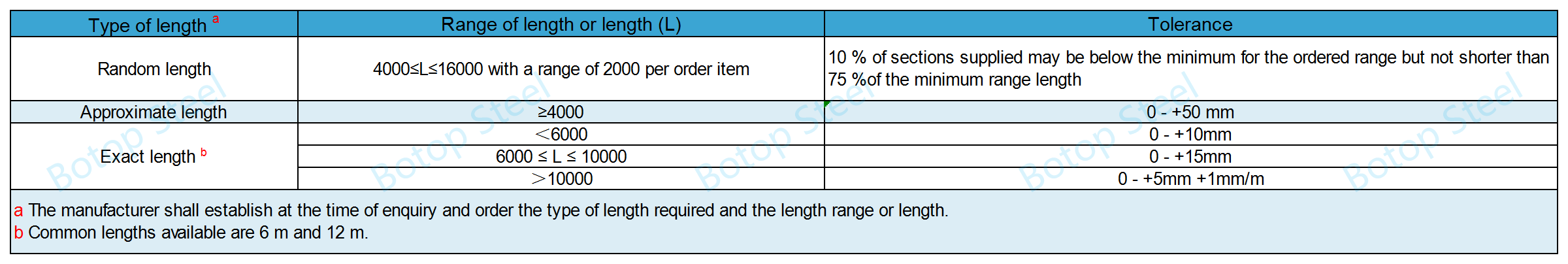

Ukunyamezela Ubude

Iityhubhu zecandelo elinomgongxo ezenziwe ngokwe-EN 10219 ziyakwazi ukuwelda.

Xa udibanisa, ukuqhekeka okubandayo kwindawo ye-weld ngowona mngcipheko uphambili njengoko ubukhulu, inqanaba lamandla, kunye ne-CEV yemveliso yonyuka. Ukuqhekeka okubandayo kubangelwa yindibaniselwano yezinto ezininzi:

amanqanaba aphezulu e-hydrogen e-diffusible kwi-weld metal;

isakhiwo esine-brittle kwindawo echaphazelekayo kubushushu;

Ugxininiso olubalulekileyo loxinzelelo loxinzelelo kwindawo edibeneyo.

Umphezulu wombhobho wensimbi kufuneka ube bushelelezi kwaye ukhululeke kuzo naziphi na iziphene eziya kuchaphazela ukusebenza kwemveliso, njengokuqhekeka, imigodi, imikrwelo okanye ukubola.

Amaqhuma, i-grooves, okanye i-grooves e-shallow longitudinal eyenziwe yinkqubo yokuvelisa iyamkeleka nje ukuba ubuninzi bodonga obuseleyo bungaphakathi kokunyamezela, isiphene sinokususwa ngokusila, kunye nokulungiswa kodonga olulungisiweyo luhlangabezana neemfuno zobunzima obuncinci.

Intsimbi yeBotopayinikezeli kuphela iityhubhu zentsimbi ezikumgangatho ophezulu ngokuhambelana ne-EN 10219, ikwabonelela ngoluhlu olubanzi lweenketho zokugquma umphezulu weetyhubhu zetsimbi ukuze zihambelane neemfuno ezithile zabathengi bayo kwiiprojekthi zobunjineli ezahlukeneyo. Ezi ngubo zenzelwe ukunyusa ukuxhathisa kwe-corrosion ye-tubes kunye nokongeza ukhuseleko olongezelelweyo, ngaloo ndlela ukwandisa ubomi babo benkonzo.

Hot-dip Galvanizing

3LPE (HDPE) Ukugquma

FBE Coating

I-Varnish yokubeka

Ipeyinti yokubeka

Cement Weight Coating

Amacandelo ebhulorho: Izakhiwo ezingezona eziphambili zokuthwala imithwalo ezisetyenziswa kwiibhulorho, ezifana neentsimbi kunye neeparapets.

Iintsika zokwakha: Iikholamu zenkxaso kunye nemiqadi esetyenziswa kwisakhiwo kunye nobunjineli boluntu.

Iinkqubo zombhobho: imibhobho yokuthutha ulwelo kunye neegesi, ngakumbi kwizicelo ezifuna iqondo lokuguquguquka kunye nokumelana nokuhlwa.

Izakhiwo zethutyana: izixhaso zethutyana kunye nezakhelo ezifanelekileyo kulwakhiwo kunye neziza zobunjineli.

Ezi zicelo zithatha inzuzo yeempawu ezibalaseleyo zomatshini kunye ne-weldability ye-S275J0H kunye ne-S275J2H ukuhlangabezana neemfuno zezakhiwo ezilula kodwa ezizinzileyo.

ASTM A500:Inkcazo esemgangathweni ye-Cold-Formed Welded kunye ne-Seamless Carbon Steel Structural Tubing kwiMijikelo kunye neeMilo.

I-ASTM A501: Inkcazo esemgangathweni ye-Hot-Formed Welded kunye ne-Seamless Carbon Steel Structural Tubing.

EN 10210: Amacandelo ashushu agqityiweyo esakhiwo esingeyo-alloyi kunye neentsimbi ezicolekileyo eziziinkozo.

EN 10219: Amacandelo angumngxuma adityanisiweyo adityanisiweyo angeyo-alloyi kunye neentsimbi eziziinkozo ezicolekileyo.

JIS G 3466: Isikwere sentsimbi yeCarbon kunye neetyhubhu ezixande kwisakhiwo ngokubanzi.

AS/NZS 1163: Amacandelo angenamngxuma wentsimbi akhiwe abandayo.

Le migangatho isetyenziswa ngokubanzi kwihlabathi jikelele, kwaye inceda ekuqinisekiseni ukuba iityhubhu zensimbi zesakhiwo zihlangabezana nemilinganiselo yokusebenza elindelekileyo kwizicelo zobunjineli ezahlukeneyo. Xa ukhetha umgangatho wombhobho wensimbi, kubalulekile ukuqwalasela iimfuno zesicelo esithile, imimiselo yengingqi, kunye neemfuno zokusebenza.

ASTM A252 GR.3 Structural LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) uMbhobho wentsimbi

I-ASTM A671/A671M LSAW ipayipi yentsimbi

ASTM A672 B60/B70/C60/C65/C70 LSAW LSAW Umbhobho wentsimbi yeCarbon

API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Grade X70 LSAW Steel Pipe

EN10219 S355J0H Ulwakhiwo LSAW(JCOE) Umbhobho wentsimbi