EN 10210 S355J2Hyintsimbi yecandelo elinomngxuma elishushu eligqityiweyo ngokwesakhiwoEN 10210kunye namandla amancinci okuvunwa kwe-355 MPa (ubunzima bodonga ≤ 16 mm) kunye neempawu zempembelelo ezintle kumaqondo okushisa aphantsi ukuya kwi-20 ° C, okwenza kube yinto efanelekileyo yokusetyenziswa kuluhlu olubanzi lwezakhiwo kunye nezakhiwo zobunjineli.

Ewe, EN 10210 =I-BS EN 10210.

I-BS EN 10210 kunye ne-EN 10210 ziyafana kumxholo wobugcisa kwaye zombini zimele imigangatho yaseYurophu yoyilo, yokwenziwa, kunye neemfuno zamacandelo angaphakathi kwe-thermoformed.

I-BS EN 10210 yinguqulelo eyamkelwe e-UK, ngelixa i-EN 10210 ingumgangatho waseYurophu ngokubanzi. Iibhodi ezahlukeneyo zokumisela umgangatho zingenza isimaphambili somgangatho ngezifinyezo zesizwe, kodwa umxholo ongundoqo womgangatho uhlala ungaguquguquki.

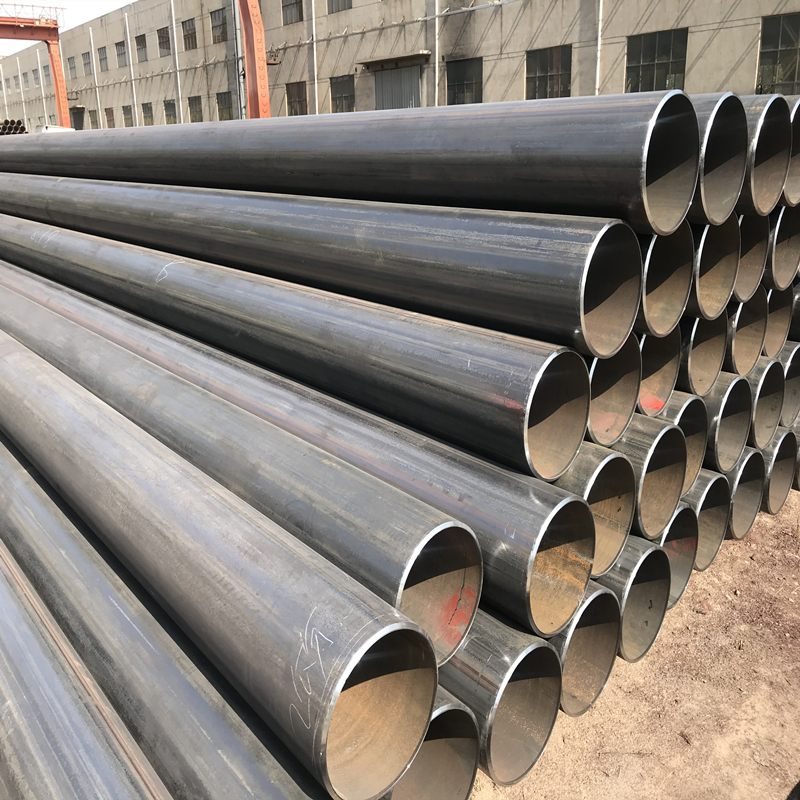

Amacandelo angenanto angahlelwa njengesetyhula, isikwere okanye uxande, okanye i-elliptical.

Kwakhona ngenxa yokuba yinkqubo egqityiweyo eshushu ngokuhambelana ne-EN 10210, esi sishunqulelo silandelayo sinokusetyenziswa.

HFCHS= amacandelo ashushu agqityiweyo asetyhula;

HFRHS= isikwere esigqityiweyo esishushu okanye amacandelo anomngxuma oxande;

HFEHS= kushushu kugqitywe amacandelo angumngxunya.

Umjikelo: Idayamitha yangaphandle ukuya kuthi ga kwi-2500 mm;

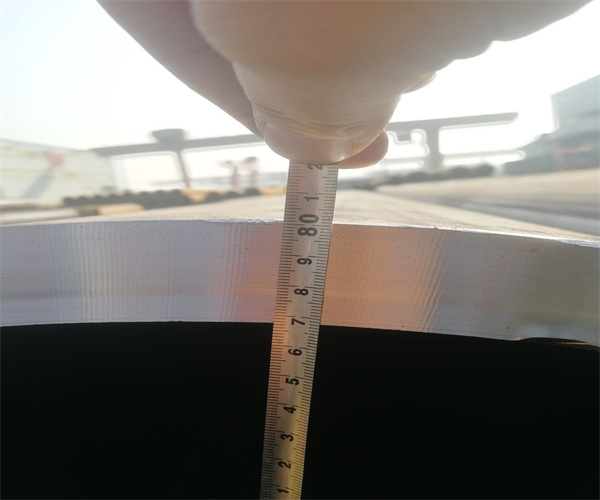

Ubunzima beendonga ukuya kuthi ga kwi-120 mm.

Kakade ke, akukho ndlela yokuvelisa iityhubhu zale sayizi kunye nobukhulu bodonga ukuba inkqubo ye-welding ye-ERW isetyenziswa.

I-ERW inokuvelisa iityhubhu ukuya kwi-660mm kunye nobukhulu bodonga obuyi-20mm.

Isinyithi sinokwenziwa nokuba kusetyenziswe aingenamthungo okanye i-weldinginkqubo.

Phakathi kweiinkqubo welding, iindlela ze-welding eziqhelekileyo ziqukaERW(i-welding ukumelana nombane) kunyeSAW(i-arc iwelding ephantsi kwamanzi).

Phakathi kwabanye,ERWbubuchule bokuwelda obudibanisa iindawo zentsimbi kunye ngobushushu obuxhathisayo kunye noxinzelelo. Obu buchule busebenza kuluhlu olubanzi lwezinto kunye nobukhulu kwaye buvumela inkqubo ye-welding esebenzayo.

SAW, kwelinye icala, yindlela ye-welding esebenzisa i-granular flux ukugubungela i-arc, ebonelela ngokungena nzulu kunye nomgangatho ongcono we-weld kwaye ifaneleke ngokukodwa ukuwelda iipleyiti ezishinyeneyo.

Okulandelayo, yinkqubo ye-ERW, eyindlela yokuvelisa esebenza kakhulu esetyenziswa ngokubanzi ukuvelisa uluhlu olubanzi lweetyhubhu zentsimbi kunye neeprofayili.

Kufuneka kuqatshelwe ukuba kumacandelo angaxutywanga kunye ne-fine-grain-grain hollow eyenziwe yinkqubo ye-welding, ukulungiswa kwe-welds akuvumelekanga ngaphandle kwe-arc welding.

Iimpawu JR, JO, J2 kunye neK2 - kushushu kugqityiwe,

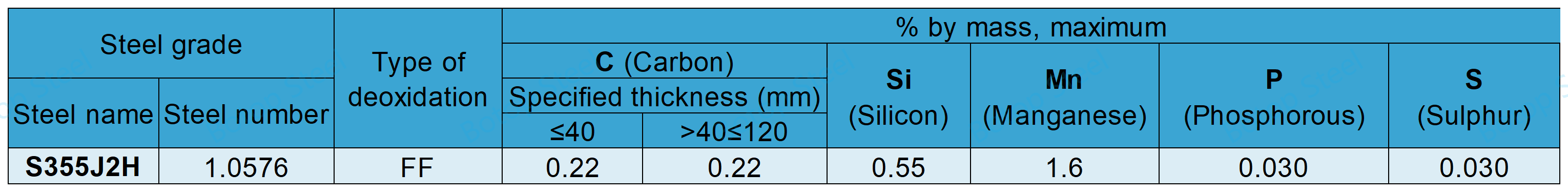

Ubuncinci amandla okuvelisa i-S355J2H yensimbi yombhobho ayilungiswanga, iya kutshintsha kunye nobukhulu bodonga oluhlukeneyo.

Ngokukodwa, amandla okuvunwa kwe-S355J2H abekwe ngokwemigangatho xa ubukhulu bodonga bungaphantsi okanye bulingana ne-16mm, kodwa xa ubuninzi bodonga bunyuka, amandla okuvelisa aya kuncitshiswa, ngoko akusiyo yonke i-S355J2H ipayipi yensimbi inokufikelela kumlinganiselo omncinci wamandla we-355MPa.

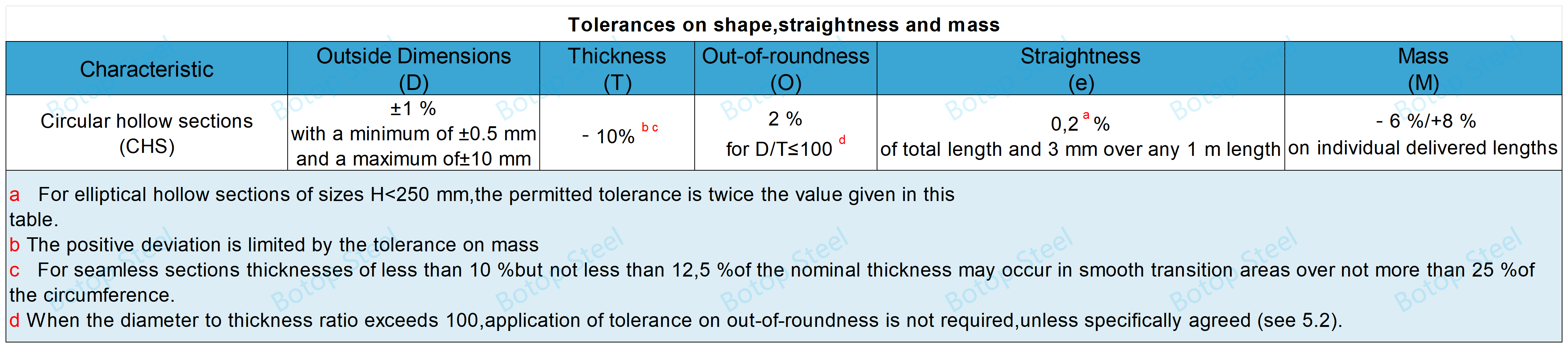

Ukunyamezela kwimilo, ukuthe tye kunye nobunzima

Ukunyamezela ubude

| Uhlobo lobudea | Uluhlu lobude okanye ubude L | Ukunyamezelana |

| Ubude obungacwangciswanga | 4000≤L≤16000 kunye noluhlu lwe-2000 into nganye ye-odolo | I-10% yamacandelo anikezelweyo anokuba ngaphantsi kobuncinane boluhlu oluodolweyo kodwa angabi mfutshane kune 75 % yobude obuncinane boluhlu |

| Ubude obuqikelelweyo | 4000≤L≤16000 | ±500 mmb |

| Ubude obuchanekileyo | 2000≤L≤6000 | 0 - +10mm |

| 6000c | 0 - +15mm | |

| aUmvelisi uya kuseka ngexesha lophando kwaye aodole uhlobo lobude obufunekayo kunye noluhlu lobude okanye ubude. bOntion 21 unyamezelo kubude annrevimata yi 0 - +150mm cUbude obuqhelekileyo obukhoyo buyi-6 m kunye ne-12 m. | ||

Umbhobho wensimbi we-S355J2H ngumbhobho wentsimbi yesakhiwo esinamandla aphezulu kunye nokusebenza kakuhle kwe-welding kunye nokuqina kwefuthe eliphantsi lobushushu, ngoko unoluhlu olubanzi lokusetyenziswa kwiindawo ezininzi zoshishino.

1. Ukwakha: isetyenziswe kwiibhulorho, iinqaba, izakhiwo zesakhelo, uthutho lukaloliwe, iindlela ezihamba ngaphantsi, iifreyimu zephahla, iipaneli zodonga, kunye nezinye izakhiwo zokwakha.

2. Inkqubo yemibhobho: Isetyenziswa njengemibhobho yokuthutha ulwelo, ngakumbi kwiimeko apho kufuneka amandla aphezulu kunye noxinzelelo loxinzelelo.

3. Ubunjineli baselwandle kunye nolwandle: isetyenziswe kwizakhiwo zeenqanawa, amaqonga angaphandle konxweme, kunye nezinye izakhiwo zobunjineli baselwandle.

4. Ishishini lamandla: isetyenziswa kumaziko ombane afana neenqaba zamandla omoya, amaqonga okomba ioli, kunye nemibhobho.

5. Iinqanawa zoxinzelelo: isetyenziswe ekwenzeni iinqanawa zoxinzelelo ngokuthobela i-welding ethile kunye neemfuno zonyango lokushisa.

6. Ishishini lezemigodi: isetyenziselwa ulwakhiwo lwezakhiwo zenkxaso yomgodi, iinkqubo zokuhambisa, kunye nezixhobo zokusetyenzwa kwentsimbi ekrwada.

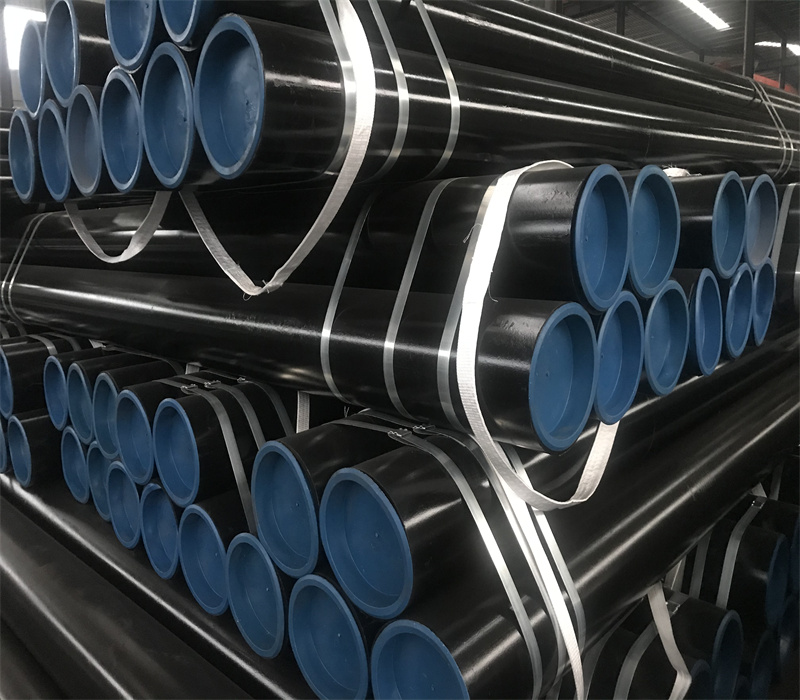

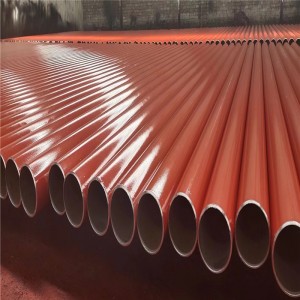

Umbhobho ongenanto okanye uMnyama / iVarnish yokugqoka (elungiselelwe);

kwimiyanda okanye ngokukhululekileyo;

Zombini ziphela kunye nabakhuseli bokugqibela;

Isiphelo esingenanto, isiphelo se-bevel (2"nangaphezulu ngeencam zebevel, idigri: 30 ~ 35 °), intambo kunye nokudityaniswa;

Ukumakisha.