EN 10219 S355J0Hyii-welded epholileyoumbhobho wentsimbi yolwakhiwo ukuyaEN 10219, kunye nokomelela kwesivuno esincinci355 MPa(ubukhulu bodonga lombhobho ≤ 16 mm) kunye nempembelelo yamandla ubuncinane27 J ku-0°C.

Eyenziwe ngokusebenzisa i-welding yombane okanye i-arc ye-welding ye-arc ephantsi kwamanzi ngaphandle kwesidingo sonyango olulandelayo lokufudumala, zifanelekile kuluhlu olubanzi lwezicelo zezakhiwo kunye nobunjineli bezakhiwo, kubandakanywa amacandelo abalulekileyo okwakhiwa njengemfumba yokuxhasa isiseko.

I-BS EN 10219 nguMgangatho waseYurophu EN 10219 owamkelwa yi-UK.

Ibandakanya i-welded epholileyosetyhula, isikwere, uxande, kunye ne-ellipticalamacandelo akhiweyo angenanto.

CFCHS = icandelo elijikelezayo elenziwe ngokubanda;

CFRHS = indawo ebandayo eyenziwe isikwere okanye icandelo elinomngxuma elixande;

Sisebenza ngokukhethekileyo ekunikezeni icandelo elikwizinga eliphezulu lesetyhula elingenanto (CHS) umbhobho wentsimbi ukuhlangabezana neemfuno zakho zobunjineli ezahlukeneyo.

Ubunzima bodonga ≤40mm;

Isetyhula: Idayamitha yangaphandle ukuya kuthi ga kwi-2500 mm;

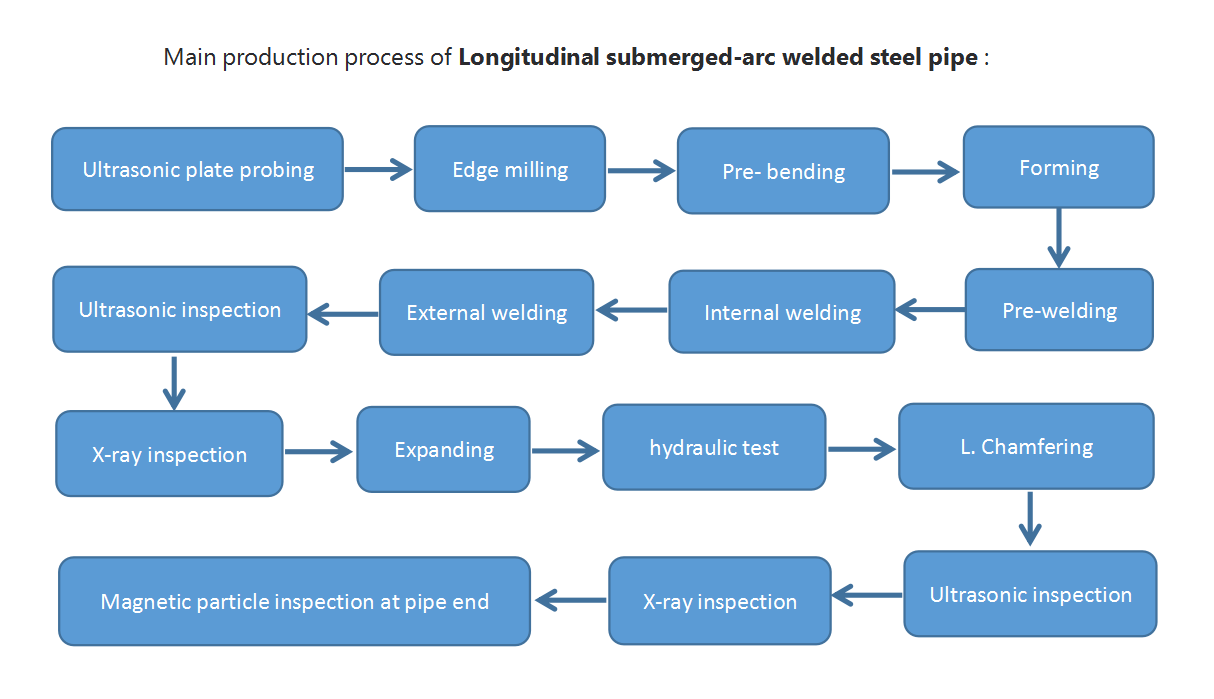

Amacandelo okwakhiwa kwemingxuma kuya kwenziwa ngeukuwelda kombane okanye ukuwelda kwe-arc emanzini (SAW).

I-EN 10219 amacandelo aholoholo aya kusiwa akhiwe ngendlela ebandayo ngaphandle konyango lobushushu olulandelayo, kodwa iiwelds zinokuba zikwimeko edityanisiweyo okanye ephathwe bubushushu.

Ukuba itekhnoloji ye-arc ye-welding ephantsi kwamanzi isetyenzisiwe, ingahlelwa kuyoLSAW(SAWL) (Longitudinal Submerged Arc Welding) kunyeSSAW(HSAW)(I-Spiral Submerged Arc Welding) ngokuxhomekeke kwicala le-weld seam.

LSAWineenzuzo ezibalulekileyo ekwenziweni kweUbubanzi obukhulukwayeimibhobho yentsimbi engqindililikwaye ilungele ngakumbi iimeko zesicelo apho amandla aphezulu, umgangatho, kunye nemilinganiselo echanekileyo ifunwa ngokungqongqo.

JCOEyinkqubo ebaluleke kakhulu kunye nommeli ekuveliseni umbhobho wensimbi we-LSAW. Igama lenkqubo livela kumanyathelo amane aphambili kwinkqubo yokwenza umbhobho: i-J-forming, i-C-forming, i-O-forming, kunye nokwandisa.

Singumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

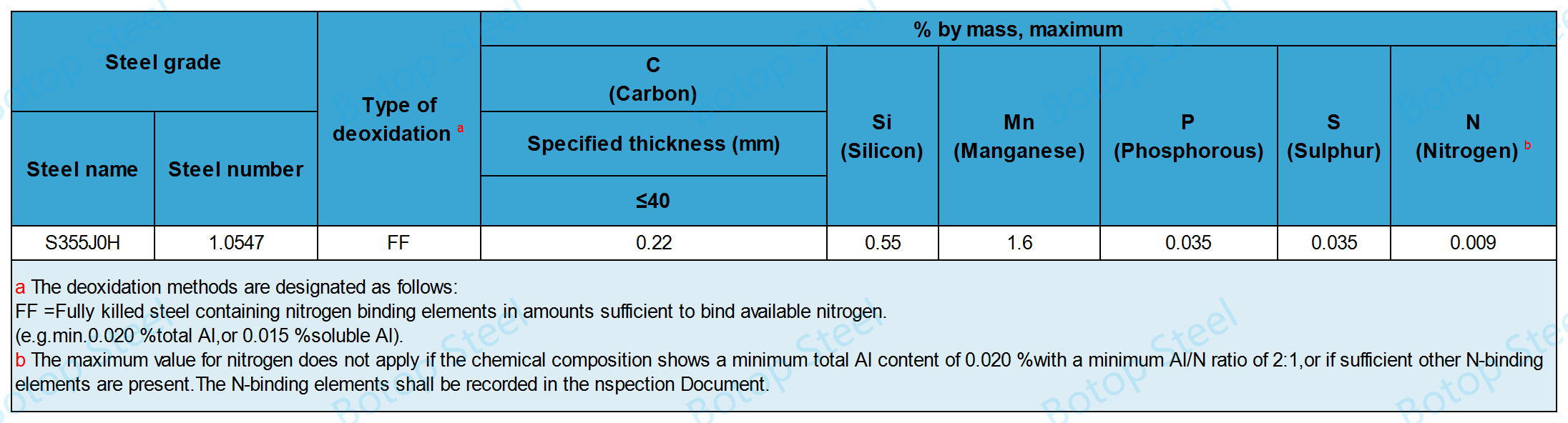

Uhlalutyo lweCast

Uhlalutyo lweekhemikhali zemibhobho yensimbi yezinto eziluhlaza

S355J0H Ubuninzi bexabiso elilinganayo lekhabhoni(CEV): 0.45%.

CEV = C + Mn/6 +(Cr + Mo + V)/5 + (Ni + Cu)/15.

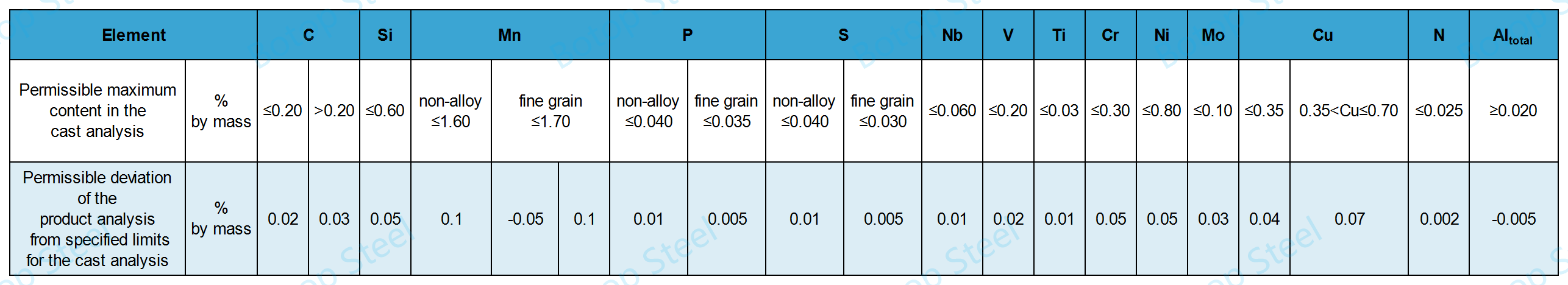

Uhlalutyo lweMveliso

Uhlalutyo lwemichiza yamacandelo agqityiweyo

Ukuphambuka kohlalutyo lwemveliso ukusuka kwimida echazwe kuhlalutyo lokuphosa kuya kuhambelana neemfuno ezingezantsi.

Ukuthomalalisa uxinzelelo kuxinzelelo olungaphezulu kwama-580 °C okanye ngaphezulu kweyure enye kunokukhokelela ekuwohlokeni kweempawu zoomatshini.

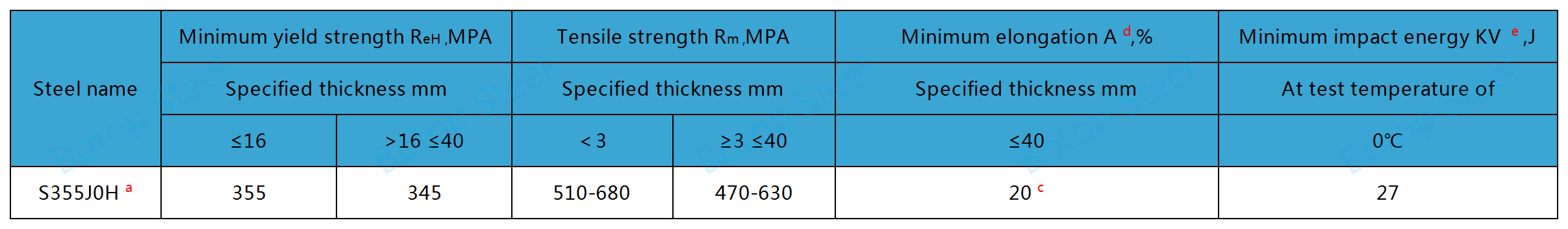

Uvavanyo lwe-tensile luya kwenziwa ngokuhambelana ne-EN 10002-1.

Uvavanyo lwempembelelo luya kwenziwa ngokuhambelana ne-EN 10045-1.

a Iipropati zempembelelo ziqinisekiswa kuphela xa uKhetho 1.3 lucacisiwe.

c Kubukhulu becandelo D/T <15 (isetyhula) kunye (B+H)/2T <12,5 (isikwere kunye noxande) ubuncinci bobude buncitshiswe nge-2.

d Kubunzima obungaphantsi kwe-3 mm bona 9.2.2.

e Ngeempawu zempembelelo zecandelo elincitshisiweyo lovavanyo jonga ku-6.7.2.

Amanqaku: Uvavanyo lwempembelelo ayifuni xa ubukhulu obuchaziweyo bu <6mm.

IiWelds kumacandelo angaphakathi adityaniselwe i-arc welded iya kuvavanywa ngokuhambelana ne-EN 10246-9 yokwamkelwa kweklasi ye-U4 okanye ngeradiyografi ngokuhambelana ne-EN 10246-10 yomgangatho womfanekiso weklasi ye-R2.

Uvavanyo lwe-NDT (RT).

Uvavanyo lwe-NDT (UT).

Uvavanyo lweHydrostatic

Sisebenzisa iindlela ezahlukeneyo zokuvavanya okungonakalisi kunye novavanyo loxinzelelo lwe-hydrostatic ukuqinisekisa amandla kunye nokuqina kombhobho ngamnye. Sibonelela abathengi bethu ngeemveliso zepayipi zentsimbi ezihlangabezana nemigangatho ephezulu yokhuseleko kunye nokuqinisekiswa komgangatho.

Iityhubhu zecandelo elinomgongxo ezenziwe ngokwe-EN 10219 ziyakwazi ukuwelda.

Xa udibanisa, ukuqhekeka okubandayo kwindawo ye-weld ngowona mngcipheko uphambili njengoko ubukhulu, inqanaba lamandla, kunye ne-CEV yemveliso yonyuka. Ukuqhekeka okubandayo kubangelwa yindibaniselwano yezinto ezininzi:

amanqanaba aphezulu e-hydrogen e-diffusible kwi-weld metal;

isakhiwo esine-brittle kwindawo echaphazelekayo kubushushu;

Ugxininiso olubalulekileyo loxinzelelo loxinzelelo kwindawo edibeneyo.

I-EN 10219 imibhobho yentsimbi ilungele ukugalela idiphu eshushu. Ukhetho lunokwenziwa ngokweemfuno zokwenyani.

Iya kuba nomphezulu ogudileyo ohambelana nendlela yokuvelisa esetyenziswayo; amaqhuma, i-voids, okanye i-grooves ye-longitudinal engekho nzulu evela kwinkqubo yokuvelisa ivumelekile ngaphandle kokuba ubukhulu babo obushiyekileyo buphakathi kokunyamezela.

Iziphene zobuso zingasuswa ngokusila, ngaphandle kokuba ubukhulu becandelo elilungisiweyo elinomngxuma abukho ngaphantsi kobuncinci obuvumelekileyo obuchazwe kwi-EN 10219-2.

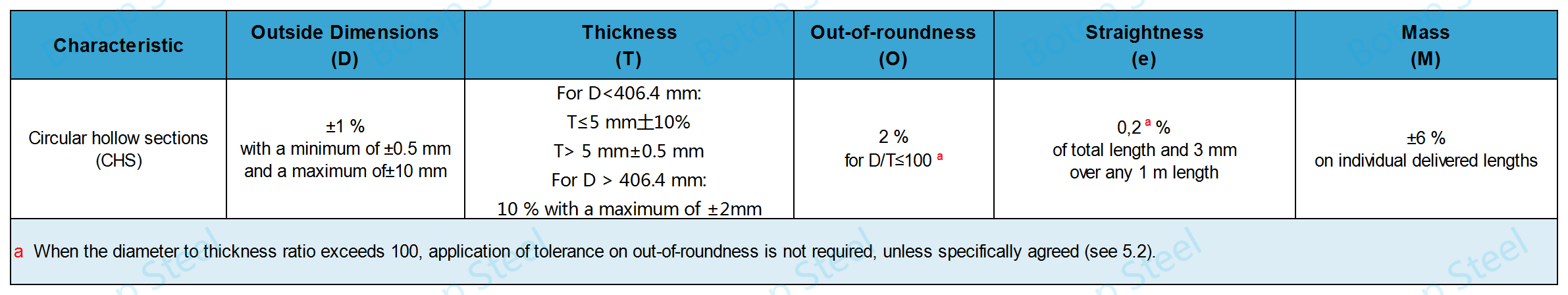

Ukunyamezelana kwiMilo, ukuTwa kunye noMisa

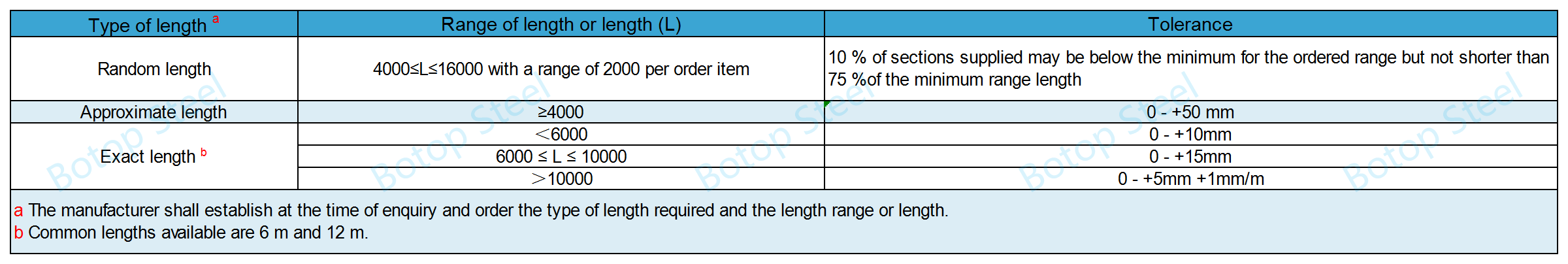

Ukunyamezela Ubude

Weld Height

Imfuno yobude be-weld isebenza kuphela kwiityhubhu ze-SAW.

| Ukutyeba, mm | Ubude be-weld bead, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

I-EN 10219 S355J0H intsimbi yombhobho yimathiriyeli eyomeleleyo kunye ne-corrosion-resistant elungele kakuhle uluhlu olubanzi lwezakhiwo kunye nezakhiwo zobunjineli, kubandakanywa usetyenziso lwemfumba yombhobho.

1. Ingqumba yombhobho: Umbhobho wensimbi we-S355J0H ulungele ukusetyenziswa njengemfumba yesiseko ngenxa yamandla ayo kunye nokumelana nokubola kwaye isetyenziswa ngokubanzi ekwakhiweni kwee-wharves, iibhulorho, iziseko zokwakha, kunye nezinye iiprojekthi ezifuna iziseko ezinzulu.

2. Izakhiwo zokwakha: Ngokuqhelekileyo isetyenziselwa amacandelo afana nezakhiwo zamathambo, iikholamu ezixhasayo, kunye nemiqadi yezakhiwo.

3. Ukuthutha ngemibhobho: Ikwakufanelekele ukusetyenziswa njengombhobho wokuthutha ioyile negesi kumgama omde. Nangona kunjalo, idla ngokugqunyelelwa ukwandisa ubomi benkonzo, umz. 3LPE, FBE, igalvanized, njl.

4. Oomatshini bokwakha: Ingasetyenziselwa ukwenza izibiyeli kunye neenxalenye zoomatshini abahlukeneyo bokwakha.

5. Amaziko oluntu: ezinje ngeebleachers kumabala emidlalo kunye nezinye izakhiwo zenkxaso kumaziko amakhulu oluntu.

EN 10210 S355J0H: Icandelo elinomgobo wezakhiwo ezidityanisiweyo ze-thermoforming. Nangona isetyenziselwa kakhulu i-thermoforming, ukubunjwa kwayo kweekhemikhali kunye nezixhobo zemishini zifana nezo ze-S355J0H kwaye zingasetyenziselwa njengento efanelekileyo efanayo.

I-ASTM A500 iBanga C: Isetyenziselwa ukwenza i-welded okanye i-seamless cold-formed round, square, kunye neetyhubhu ezixande kwizicelo zesakhiwo. I-ASTM A500 yeBanga C ibonelela ngesivuno esifanayo kunye namandla okuqina kwizakhiwo kunye nezakhiwo zoomatshini.

CSA G40.21 350W: Le yinkcazo yeCanadian Standards Association ehlanganisa uluhlu olubanzi lwamabakala ensimbi yesakhiwo. I-350W ye-steel yebakala inesivuno esifanayo kunye namandla okuqina kwi-S355J0H.

I-JIS G3466 STKR490: Esi sikwere kunye ne-rectangular tube material yokusetyenziswa kwesakhiwo njengoko kuchazwe kwi-Japan Industrial Standard (JIS). Ifanelekile kwizakhiwo zokwakha kunye neenjongo zemishini.

Ukususela ekusekweni kwayo ngo-2014,Intsimbi yeBotopuye waba ngumthengisi ohamba phambili we-carbon steel pipe eMntla China, owaziwa ngenkonzo ebalaseleyo, iimveliso ezikumgangatho ophezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange. Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.

ASTM A252 GR.3 Structural LSAW(JCOE) Carbon Steel Pipe

BS EN10210 S275J0H LSAW(JCOE) uMbhobho wentsimbi

I-ASTM A671/A671M LSAW ipayipi yentsimbi

ASTM A672 B60/B70/C60/C65/C70 LSAW LSAW Umbhobho wentsimbi yeCarbon

API 5L X65 PSL1/PSL 2 LSAW Carbon Steel Pipe / API 5L Grade X70 LSAW Steel Pipe

EN10219 S355J0H Ulwakhiwo LSAW(JCOE) Umbhobho wentsimbi