I-JIS G 3461 ipayipi yentsimbiingenamthungo (SMLS) okanye i-electric-resistance-welded (RW) ibhobho yentsimbi yekhabhoni, isetyenziswa ikakhulu kwiibhoyila kunye nokutshintsha ubushushu kwizicelo ezinjengokuqonda ukutshintshiselana kobushushu phakathi kwangaphakathi nangaphandle kombhobho.

STB340yinqanaba lombhobho wentsimbi yekhabhoni kwinqanaba le-JIS G 3461. Inamandla asezantsi e-340 MPa kunye ne-175 MPa encinci yesivuno.

Yimathiriyeli ekhethwayo kwizicelo ezininzi zemizi-mveliso ngenxa yokomelela kwayo okuphezulu, ukuzinza okuhle kwe-thermal, ukuguquguquka, ukuxhathisa ukubola, ukusebenza kakuhle kweendleko, kunye nokuqhubekeka kakuhle.

JIS G 3461unamabanga amathathu.STB340, STB410, STB510.

STB340: Ubuncinci bamandla obunzima: 340 MPa; Ubuncinci bamandla esivuno: 175 MPa.

STB410: Ubuncinci bokuqina kwamandla: 410 MPa; Ubuncinci boBume beSivuno: 255 MPa.

STB510:Ubuncinci bokuqina kwamandla: 510 MPa; Ubuncinci boBume beSivuno: 295 MPa.

Enyanisweni, akunzima ukufumanisa ukuba i-JIS G 3461 ibakala ihlelwa ngokobuncinci bamandla obunzima bombhobho wensimbi.

Njengoko ibakala lezinto landa, amandla ayo okuqina kunye nesivuno ayanda ngokufanelekileyo, okuvumela ukuba izinto eziphathekayo zimelane nemithwalo ephezulu kunye noxinzelelo lweendawo zokusebenza ezifuna kakhulu.

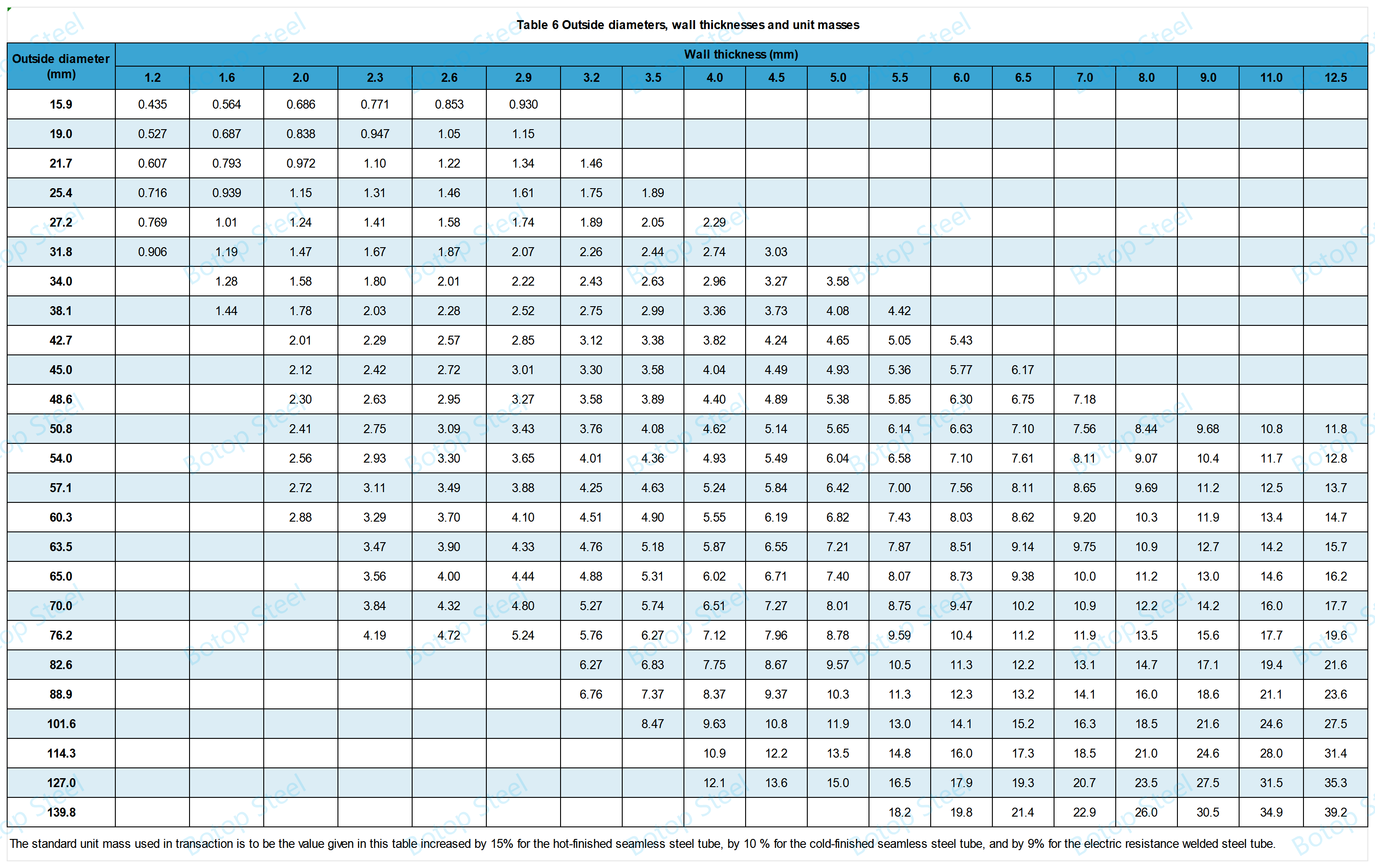

Idayamitha yangaphandle ye-15.9-139.8mm.

Ukusetyenziswa kwiibhoyila kunye nabatshintshisi bobushushu ngokuqhelekileyo abafuni i-diameter ye-tube enkulu kakhulu. Iimitha zetyhubhu ezincinci zonyusa ukusebenza kakuhle kwe-thermal kuba indawo engaphezulu ukuya kumthamo wevolumu yokuhanjiswa kobushushu iphezulu. Oku kunceda ukuhambisa amandla obushushu ngokukhawuleza nangokufanelekileyo.

Imibhobho iya kwenziwa ukusuka kwiintsimbi ebulewe.

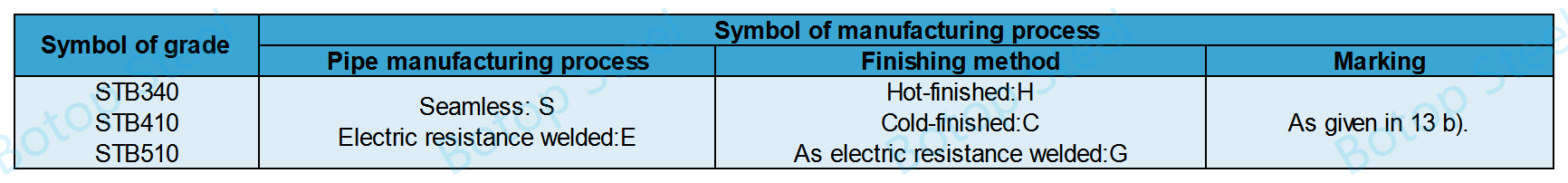

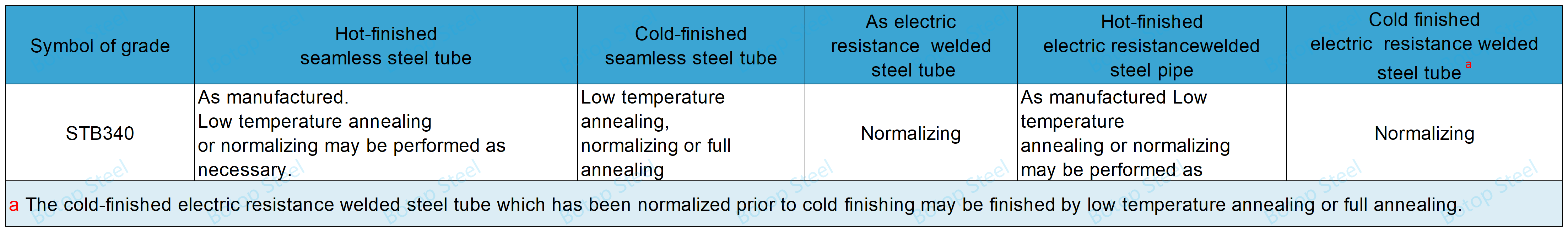

Ukudibanisa iindlela zokuvelisa umbhobho kunye neendlela zokugqiba.

Ngokweenkcukacha, zinokuhlelwa ngolu hlobo lulandelayo:

ityhubhu yentsimbi engenamthungo egqityiweyo eshushu: SH

ityhubhu yentsimbi engenamthungo egqityiweyo ebandayo: SC

Njengokumelana nombane ityhubhu yentsimbi edityanisiweyo: EG

Ubushushu obugqityiweyo bokumelana nombane obudityanisiweyo ityhubhu yentsimbi: EH

Ukumelana nombane ogqityiweyo ogqityiweyo ityhubhu yentsimbi edityanisiweyo: EC

Nantsi ukuhamba kwemveliso ye-Hot-finished seamless.

Kwinkqubo yokuvelisa engenamthungo, inokwahlulwa ngokohlulwa ngokwemibhobho yentsimbi engenamthungo kunye nedayamitha yangaphandle engaphezulu kwe-30mm isebenzisa imveliso yokugqiba eshushu, kunye ne-30mm isebenzisa imveliso yokugqiba ebandayo.

Iindlela zokuhlalutya i-thermal ziya kuhambelana nemigangatho ye-JIS G 0320.

Izinto ezidibanisayo ngaphandle kwezo zinokongezwa ukufumana iipropati ezithile.

Xa imveliso ihlaziywa, ixabiso lokuphambuka lokubunjwa kweekhemikhali zombhobho liya kuhlangabezana neemfuno zeThebhile 3 ye-JIS G 0321 yeepayipi zetsimbi ezingenamthungo kunye neThebhile 2 ye-JIS G 0321 kwimibhobho yensimbi echasayo.

| Uphawu lwebakala | C (iKhabhoni) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| max | max | max | max | ||

| STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| Umthengi unokuchaza isixa se-Si ukuba sibe kuluhlu lwe-0.10 % ukuya kwi-0.35%. | |||||

Ukubunjwa kweekhemikhali ze-STB340 zenzelwe ukuqinisekisa iipropati ezaneleyo zomatshini kunye nokuguquguquka ngelixa usenza izinto ezifanelekileyo kwi-welding kunye nokusetyenziswa kwiindawo eziphezulu zokushisa.

| Uphawu lwebakala | Amandla okuqina a | Inqaku lesivuno okanye uxinzelelo lobungqina | Elongation min, % | ||

| Ngaphandle kwedayimitha | |||||

| <10mm | ≥10mm <20mm | ≥20mm | |||

| N/mm² (MPA) | N/mm² (MPA) | Isiqwenga sovavanyo | |||

| No.11 | No.11 | No.11/No.12 | |||

| imiz | imiz | Umkhombandlela wovavanyo lwe-tensile | |||

| Ngokunxuseneyo kwi-axis yetyhubhu | Ngokunxuseneyo kwi-axis yetyhubhu | Ngokunxuseneyo kwi-axis yetyhubhu | |||

| STB340 | 340 | 175 | 27 | 30 | 35 |

Qaphela: ngokukodwa kwiityhubhu zokutshintsha ubushushu, umthengi unokuthi, apho kuyimfuneko, achaze ixabiso eliphezulu lamandla okuqina. Kule meko, elona xabiso lamandla e-tensile liyakuba lixabiso elifunyenwe ngokudibanisa i-120 N/mm² kwixabiso kule theyibhile.

Xa uvavanyo lwe-tensile luqhutyelwa kwisiqwenga soVavanyo No.

| Uphawu lwebakala | Isiqwenga sovavanyo esisetyenzisiweyo | Elongation umz, % | ||||||

| Ubunzima bodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7<8 mm | ||

| STB340 | Inombolo ye-12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

Amaxabiso obude kule theyibhile abalwa ngokuthabatha i-1.5 % kwixabiso lobude obunikwe kwiThebhile 4 kwi-1 mm nganye yokuncipha kobukhulu bodonga lwetyhubhu ukusuka kwi-8 mm, kwaye ngokusondeza umphumo kwinani elipheleleyo ngokoMthetho A we-JIS Z 8401.

Indlela yokuvavanya iya kuhambelana ne-JIS Z 2245. Ubunzima besicatshulwa sovavanyo buya kulinganiswa kwi-cross-section okanye indawo yangaphakathi kwiindawo ezintathu zovavanyo ngalunye.

| Uphawu lwebakala | Ukuqina kwe-Rockwell (intsingiselo yexabiso lezithuba ezintathu) I-HRBW |

| STB340 | 77 ubuninzi. |

| STB410 | 79 ubuninzi. |

| STB510 | 92 ubuninzi. |

Olu vavanyo aluyi kwenziwa kwiityhubhu zodonga oluyi-2 mm okanye ngaphantsi. Ukuxhathisa kombane iibhubhu zetsimbi ezidibeneyo, uvavanyo luya kwenziwa kwisahlulo ngaphandle kwe-weld okanye imimandla echaphazelekayo yokushisa.

Ayisebenzisi kwiityhubhu zentsimbi ezingenamthungo.

Indlela yoVavanyo Beka i-specimen kumatshini kwaye uyicande de umgama phakathi kwamaqonga amabini ufikelele kwixabiso elichaziweyo H. Emva koko jonga i-specimen yokuqhekeka.

Xa uvavanya ukuxhathisa okubalulekileyo umbhobho odityanisiweyo, umgca phakathi kwe-weld kunye nombindi wombhobho u-perpendicular ukuya kulwalathiso loxinzelelo.

H=(1+e)t/(e+t/D)

H: umgama phakathi kweeplatens (mm)

t: Ubunzima bodonga lwetyhubhu (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

e:ichazwe rhoqo kwibakala ngalinye lombhobho. STB340: 0.09; STB410: 0.08; STB510: 0.07.

Ayisebenzisi kwiityhubhu zentsimbi ezingenamthungo.

Esinye isiphelo se-specimen sivutha kwiqondo lokushisa (5 ° C ukuya ku-35 ° C) kunye nesixhobo se-conical kwi-angle ye-60 ° de i-diameter yangaphandle ikhuliswe ngumlinganiselo we-1.2 kwaye ihlolwe ukuqhekeka.

Le mfuneko iyasebenza nakwiityhubhu ezinobubanzi obungaphandle obungaphezu kwe-101.6 mm.

Uvavanyo lwe-reverse flattening lungashiywa xa kusenziwa uvavanyo lokuvutha.

Sika ubude be-100 mm ubude bovavanyo ukusuka kwelinye icala lombhobho kwaye usike isiqwenga sovavanyo kwisiqingatha se-90 ° ukusuka kumgca we-weld kumacala omabini omjikelezo, uthabathe isiqingatha esiqulethe i-weld njengeqhekeza lovavanyo.

Kwiqondo lobushushu begumbi (5 °C ukuya kuma-35 °C) thambisa umfuziselo ube yipleyiti eneweld ngaphezulu kwaye ujonge umfuziselo wokubona iintanda kwiweld.

Yonke ipayipi yensimbi kufuneka ihlolwe i-hydrostatically okanye ingonakalisiukuqinisekisa umgangatho kunye nokhuseleko lombhobho kunye nokuhlangabezana nemigangatho yokusetyenziswa.

Uvavanyo lweHydraulic

Bamba ingaphakathi lombhobho ubuncinane okanye uxinzelelo oluphezulu lwe-P (P max 10 MPa) ubuncinane imizuzwana emi-5, emva koko khangela ukuba umbhobho unokumelana noxinzelelo ngaphandle kokuvuza.

P=2st/D

P: uxinzelelo lovavanyo (MPa)

t: Ubukhulu bodonga lwetyhubhu (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

s: 60 % yexabiso eliphantsi elichaziweyo lenqaku lesivuno okanye ubungqina boxinzelelo.

Uvavanyo olungonakalisi

Uvavanyo olungonakaliyo lweetyhubhu zetsimbi kufuneka lwenziwe ngouvavanyo lwangoku lwe-ultrasonic okanye eddy.

Kubaultrasoniciimpawu zokuhlola, umqondiso ovela kwisampulu yereferensi equlethe umgangatho wereferensi weklasi ye-UD njengoko kuchaziweI-JIS G 0582iya kuthathwa njengenqanaba le-alam kwaye iya kuba nophawu olusisiseko olulingana okanye olukhulu kunomgangatho we-alam.

Uvakalelo olusemgangathweni lweeddy yangokuUviwo luya kuba ludidi lwe-EU, i-EV, i-EW, okanye i-EX echazwe kuyoJIS G 0583, kwaye akuyi kubakho zimpawu zilingana okanye ezinkulu kuneempawu ezisuka kwisampulu yereferensi equlethe umgangatho wereferensi wolu didi lukhankanyiweyo.

NgokungakumbiIitshathi zobunzima bombhobho kunye neeShedyuli zemibhobhongaphakathi komgangatho, unganqakraza ngapha.

Thatha indlela efanelekileyo yokuleyibheliza olu lwazi lulandelayo.

a) Uphawu lwebakala;

b) Uphawu lwendlela yokuvelisa;

c) Imilinganiselo: i-diameter yangaphandle kunye nobukhulu bodonga;

d) Igama lomenzi okanye uphawu lokuchonga.

Xa ukumakishwa kwityhubhu nganye kunzima ngenxa yobukhulu balo obuncinane bangaphandle okanye xa kucelwe njalo ngumthengi, ukumakishwa kunokunikwa kwi-bundle nganye yeetyhubhu ngendlela efanelekileyo.

I-STB340 isetyenziswa ngokuqhelekileyo ekwenzeni imibhobho yamanzi kunye nemibhobho ye-flue kwiibhoyili ezahlukeneyo zoshishino, ngakumbi kwiindawo apho ukuchasana nokushisa okuphezulu kunye noxinzelelo kuyadingeka.

Ngenxa yeempawu zayo ezilungileyo zokuqhuba ubushushu, kukwafanelekile ukwenza imibhobho yokutshintsha ubushushu, inceda ukuhambisa ubushushu ngokufanelekileyo phakathi kweendaba ezahlukeneyo.

Isenokusetyenziswa ukuthutha ubushushu obuphezulu okanye ulwelo olunoxinzelelo oluphezulu, olufana nomphunga okanye amanzi ashushu, kwaye lusetyenziswa kakhulu kwimichiza, amandla ombane, nakumashishini okuvelisa oomatshini.

I-ASTM A106 iBanga A

DIN 17175 St35.8

DIN 1629 St37.0

BS 3059-1 iBanga 320

EN 10216-1 P235GH

GB 3087 20 #

GB 5310 20G

Nangona ezi zixhobo zinokuthi zifane ngokubhekiselele kwimichiza kunye neempawu ezisisiseko, iinkqubo ezithile zokunyanga ukushisa kunye nomatshini unokuchaphazela iipropati zemveliso yokugqibela.

Ke ngoko, uthelekiso oluneenkcukacha kunye novavanyo olufanelekileyo kufuneka lwenziwe xa kukhethwa izixhobo ezilinganayo kwizicelo ezisebenzayo.

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi. Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange.

Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.