JIS G 3455nguMgangatho woShishino waseJapan (JIS) wenkonzo yoxinzelelo oluphezulu kumaqondo obushushu angama-350 °C okanye ngaphantsi, ikakhulu kumalungu oomatshini.

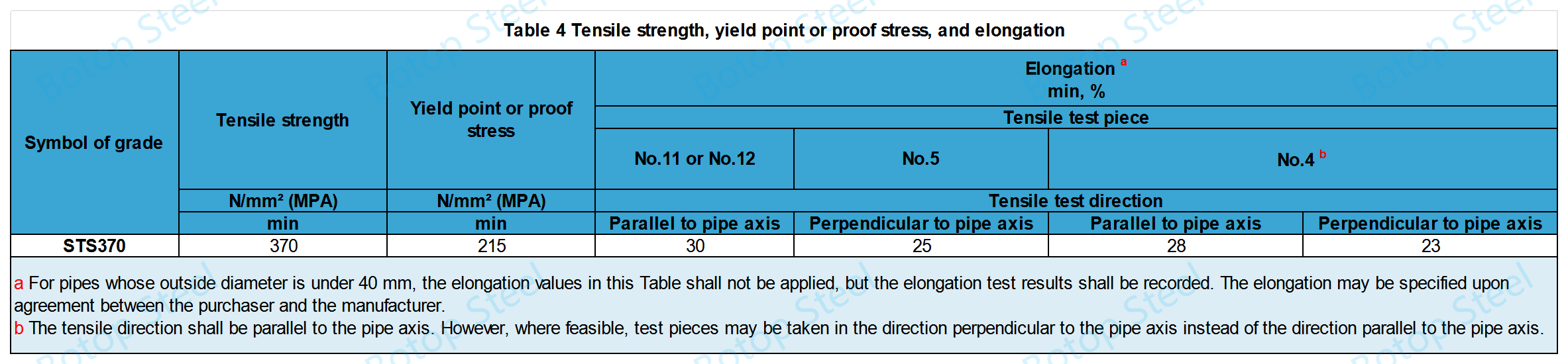

STS370 umbhobho wentsimbingumbhobho wensimbi onegunya elincinane le-370 MPa kunye namandla amancinci angama-215 MPa, kunye nomxholo wekhabhoni ongekho ngaphezu kwe-0.25% kunye nomxholo we-silicon phakathi kwe-0.10% kunye ne-0.35%, kwaye isetyenziswa kakhulu kwizicelo ezifuna amandla aphezulu kunye ne-weldability enhle, njengezakhiwo zokwakha, iibhulorho, iinqanawa kunye neenqanawa zoxinzelelo.

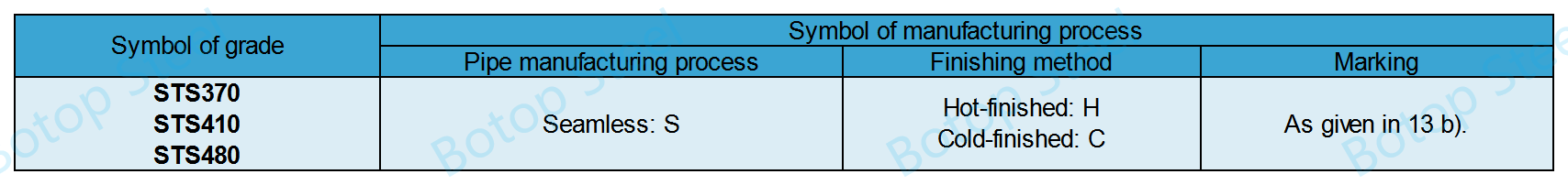

I-JIS G 3455 inamabanga amathathu.STS370, STS410, STA480.

Ngaphandle kwe-diameter ye-10.5-660.4mm (6-650A) (1/8-26B).

Imibhobho iya kwenziwa ukusuka kwiintsimbi ebulewe.

Intsimbi ebuleweyo yintsimbi ekhutshwe ngokupheleleyo ngaphambi kokuba iphoswe kwiingots okanye ezinye iifom. Inkqubo ibandakanya ukongeza i-agent ye-deoxidizing efana ne-silicon, i-aluminiyam, okanye i-manganese kwintsimbi ngaphambi kokuba yomelele. Igama elithi "wabulawa" libonisa ukuba akukho reaction ye-oksijini eyenzekayo kwintsimbi ngexesha lenkqubo yokuqinisa.

Ngokuphelisa ioksijini, intsimbi ebuleweyo ikhusela ukubunjwa kwamaqamza omoya kwintsimbi etyhidiweyo, ngaloo ndlela igwema i-porosity kunye namaqamu omoya kwimveliso yokugqibela. Oku kubangela intsimbi edibeneyo kunye neshinyeneyo eneempawu eziphezulu zemishini kunye nokunyaniseka kwesakhiwo.

Intsimbi ebuleweyo ifaneleke ngokukodwa kwizicelo ezifuna umgangatho ophezulu kunye nokuqina, njengeenqanawa zoxinzelelo, izakhiwo ezinkulu, kunye nemibhobho eneemfuno eziphezulu.

Ngokusebenzisa intsimbi ebuleweyo ukuvelisa iibhubhu, unokuqiniseka ngokusebenza okungcono kunye nobomi benkonzo obude, ngakumbi kwiindawo eziphantsi kwemithwalo enzima kunye noxinzelelo.

Iveliswe ngokusebenzisa inkqubo yokuvelisa engenamthungo edibeneyo kunye nendlela yokugqiba.

Umbhobho wentsimbi ongenamthungo ogqityiweyo oshushu: SH;

Umbhobho wentsimbi ongenamthungo ogqityiweyo obandayo: SC.

Kwinkqubo yokuvelisa engenamthungo, inokwahlulwa ngokohlulwa ngokwemibhobho yentsimbi engenamthungo kunye nedayamitha yangaphandle engaphezulu kwe-30mm isebenzisa imveliso yokugqiba eshushu, kunye ne-30mm isebenzisa imveliso yokugqiba ebandayo.

Nantsi ukuhamba kwemveliso ye-Hot-finished seamless.

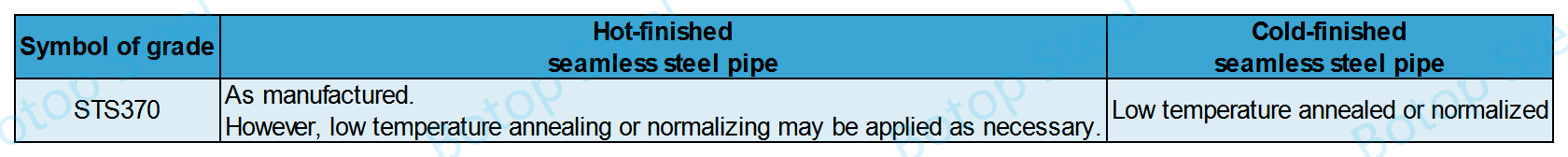

Ukushisa okuphantsi kwe-annealing kusetyenziselwa kakhulu ukuphucula ukusebenza kwezinto, ukunciphisa ubunzima, kunye nokuphucula ukuqina, kwaye ifanelekile kwintsimbi ebandayo.

I-normalizing isetyenziselwa ukuphucula amandla kunye nokuqina kwezinto eziphathekayo, ukwenzela ukuba intsimbi ifaneleke ngakumbi ukumelana noxinzelelo lomatshini kunye nokukhathala, okuhlala kusetyenziselwa ukuphucula ukusebenza kwentsimbi ebandayo.

Ngokusebenzisa ezi nkqubo zokunyanga ukushisa, isakhiwo sangaphakathi sensimbi siphuculwe kwaye iimpawu zayo ziphuculwe, okwenza kube yinto efanelekileyo yokusetyenziswa kwizicelo ezifunwayo zoshishino.

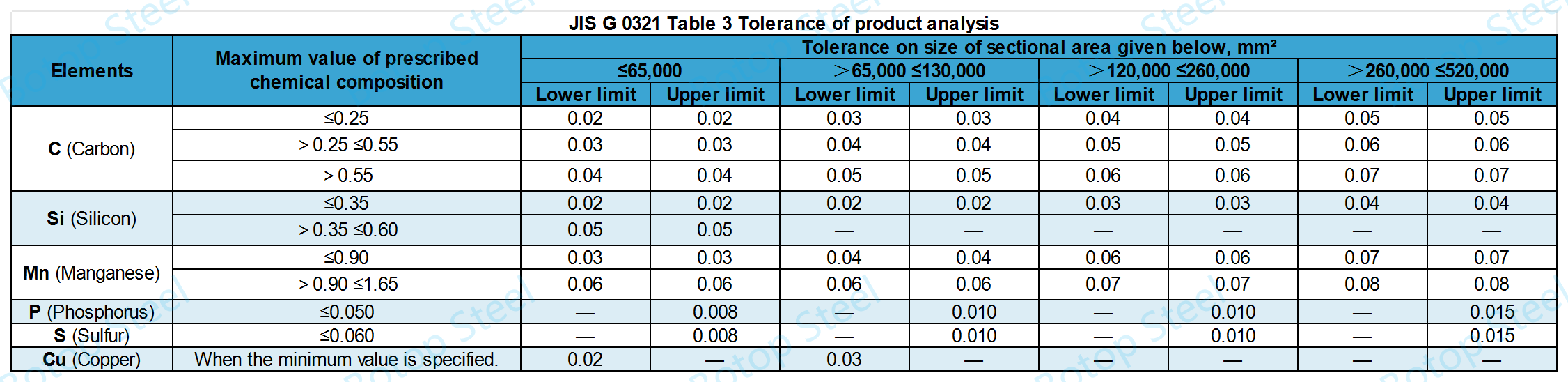

Uhlalutyo lobushushu luya kuhambelana ne-JIS G 0320. Uhlalutyo lwemveliso luya kuhambelana ne-JIS G 0321.

| ibakala | C (iKhabhoni) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| STS370 | 0.25% ubukhulu | 0.10-0.35% | 0.30-1.10% | 0.35% ubukhulu | 0.35% ubukhulu |

Uhlalutyo lobushushuijolise ikakhulu ekuvavanyeni ukubunjwa kweekhemikhali zemathiriyeli ekrwada.

Ngokuhlalutya ukubunjwa kweekhemikhali zezinto eziluhlaza, kunokwenzeka ukuqikelela kwaye ulungelelanise amanyathelo okucubungula kunye neemeko ezinokufunwa kwinkqubo yokuvelisa, njengeeparamitha zonyango lokushisa kunye nokongezwa kwezinto ezixutywayo.

Uhlalutyo lwemvelisouhlalutya ukubunjwa kweekhemikhali zeemveliso ezigqityiweyo ukuqinisekisa ukuthotyelwa kunye nomgangatho wemveliso yokugqibela.

Uhlalutyo lwemveliso luqinisekisa ukuba zonke iinguqu, ukongezwa okanye nakuphi na ukungcola okunokwenzeka kwimveliso ngexesha lenkqubo yokuvelisa iphantsi kolawulo kwaye imveliso yokugqibela ihlangabezana neenkcukacha zobugcisa kunye neemfuno zesicelo.

I-JIS G 3455 amaxabiso ohlalutyo lwemveliso ayisayi kuthobela kuphela iimfuno zezinto ezikule theyibhile ingentla, kodwa noluhlu lonyamezelo luya kuhambelana neemfuno ze-JIS G 3021 Uluhlu 3.

Amaxabiso obude bovavanyo lwesiqwenga esinguNombolo 12 (engqamene ne-axis yombhobho) kunye nesiqwenga soVavanyo esinguNombolo 5 (i-perpendicular ukuya kwi-axis yombhobho) ethathwe kwimibhobho engaphantsi kwe-8 mm ubukhulu bodonga.

| Uphawu lwebakala | Isiqwenga sovavanyo esisetyenzisiweyo | Elongation umz, % | ||||||

| Ubunzima bodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7<8 mm | ||

| STS370 | Inombolo ye-12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| Inombolo yesi-5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Amaxabiso obude kule theyibhile afunyanwa ngokuthabatha i-1.5 % kwixabiso lobude obunikwe kwiThebhile 4 ngokuncipha ngakunye kwe-1 mm kubukhulu bodonga ukusuka kwi-8 mm, kwaye ngokusondeza umphumo ube yinani elipheleleyo ngokoMthetho A we-JIS Z 8401. | ||||||||

Uvavanyo lokucaba lunokushiywa ngaphandle kokuba kuchazwe ngenye indlela ngumthengi.

Beka i-specimen kumatshini kwaye uyicande kude kube umgama phakathi kweeplatifomu ezimbini ufikelele kwixabiso elichaziweyo H. Emva koko khangela i-specimen yokuqhekeka.

Xa uvavanya ukuxhathisa okubalulekileyo umbhobho odityanisiweyo, umgca phakathi kwe-weld kunye nombindi wombhobho u-perpendicular ukuya kulwalathiso loxinzelelo.

H=(1+e)t/(e+t/D)

H: umgama phakathi kweeplatens (mm)

t: Ubunzima bodonga lwetyhubhu (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

e:ichazwe rhoqo kwibakala ngalinye lombhobho.0.08 ye-STS370: 0.07 ye-STS410 kunye ne-STS480.

Ifanelekile imibhobho enobubanzi obungaphandle be-≤ 50 mm.

I-specimen iya kukhululeka kwiintanda xa igobile kwi-90 ° kunye ne-diameter yangaphakathi ngamaxesha ama-6 ngaphandle kobubanzi bombhobho.

I-angle yokugoba iya kulinganiswa ekuqaleni kokugoba.

Yonke ipayipi yensimbi kufuneka ihlolwe i-hydrostatically okanye ingonakalisiukuqinisekisa umgangatho kunye nokhuseleko lombhobho kunye nokuhlangabezana nemigangatho yokusetyenziswa.

Uvavanyo lweHydraulic

Ukuba akukho xinzelelo lovavanyo luchaziweyo, ubuncinci boxinzelelo lovavanyo lwe-hydro luya kumiselwa ngokuhambelana neShedyuli yePipe.

| Ubukhulu bodonga lwegama | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Ubuncinci boxinzelelo lovavanyo lwe-hydraulic, iMpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Xa ubukhulu bodonga lobubanzi obungaphandle bombhobho wensimbi abukho ixabiso eliqhelekileyo kwitheyibhile yobunzima bombhobho wensimbi, kuyimfuneko ukusebenzisa ifomula ukubala ixabiso loxinzelelo.

P=2st/D

P: uxinzelelo lovavanyo (MPa)

t: Ubukhulu bodonga lombhobho (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

s: 60 % yexabiso eliphantsi lenqaku lesivuno okanye ubungqina boxinzelelo olunikiweyo.

Xa ubuncinci boxinzelelo lovavanyo lwe-hydrostatic lwenani lesicwangciso esikhethiweyo lidlula uxinzelelo lovavanyo lwe-P olufunyenwe yifomula, uxinzelelo lwe-P luya kusetyenziswa njengoxinzelelo oluncinci lovavanyo lwe-hydrostatic endaweni yokukhetha olona xinzelelo luphantsi lovavanyo lwe-hydrostatic kwitheyibhile engentla.

Uvavanyo olungonakalisi

Uvavanyo olungonakaliyo lweetyhubhu zetsimbi kufuneka lwenziwe ngouvavanyo lwangoku lwe-ultrasonic okanye eddy.

Kubaultrasoniciimpawu zokuhlola, umqondiso ovela kwisampulu yereferensi equlethe umgangatho wereferensi weklasi ye-UD njengoko kuchaziweI-JIS G 0582iya kuthathwa njengenqanaba le-alam kwaye iya kuba nophawu olusisiseko olulingana okanye olukhulu kunomgangatho we-alam.

Uvakalelo olusemgangathweni lweeddy yangokuUviwo luya kuba ludidi lwe-EU, i-EV, i-EW, okanye i-EX echazwe kuyoJIS G 0583, kwaye akuyi kubakho zimpawu zilingana okanye ezinkulu kuneempawu ezisuka kwisampulu yereferensi equlethe umgangatho wereferensi wolu didi lukhankanyiweyo.

NgokungakumbiIitshathi zobunzima bombhobho kunye neeShedyuli zemibhobhongaphakathi komgangatho, unganqakraza ngapha.

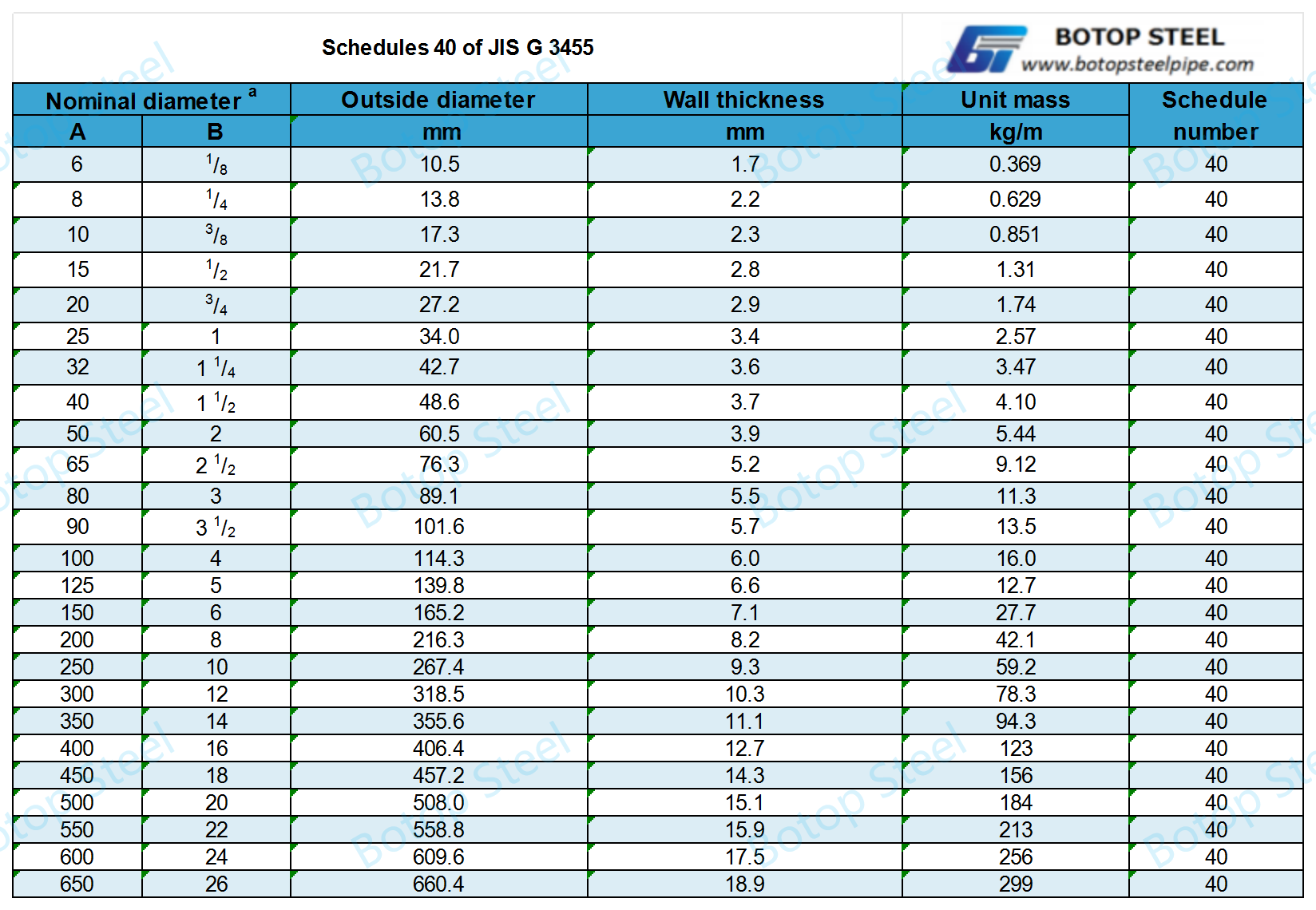

Umbhobho weShedyuli ye-40 ifaneleka ngokufanelekileyo kwizicelo ezisezantsi ukuya eziphakathi ngenxa yokuba inika ubuninzi bodonga oluphakathi oluthintela ubunzima obuninzi kunye neendleko ngelixa uqinisekisa amandla aneleyo.

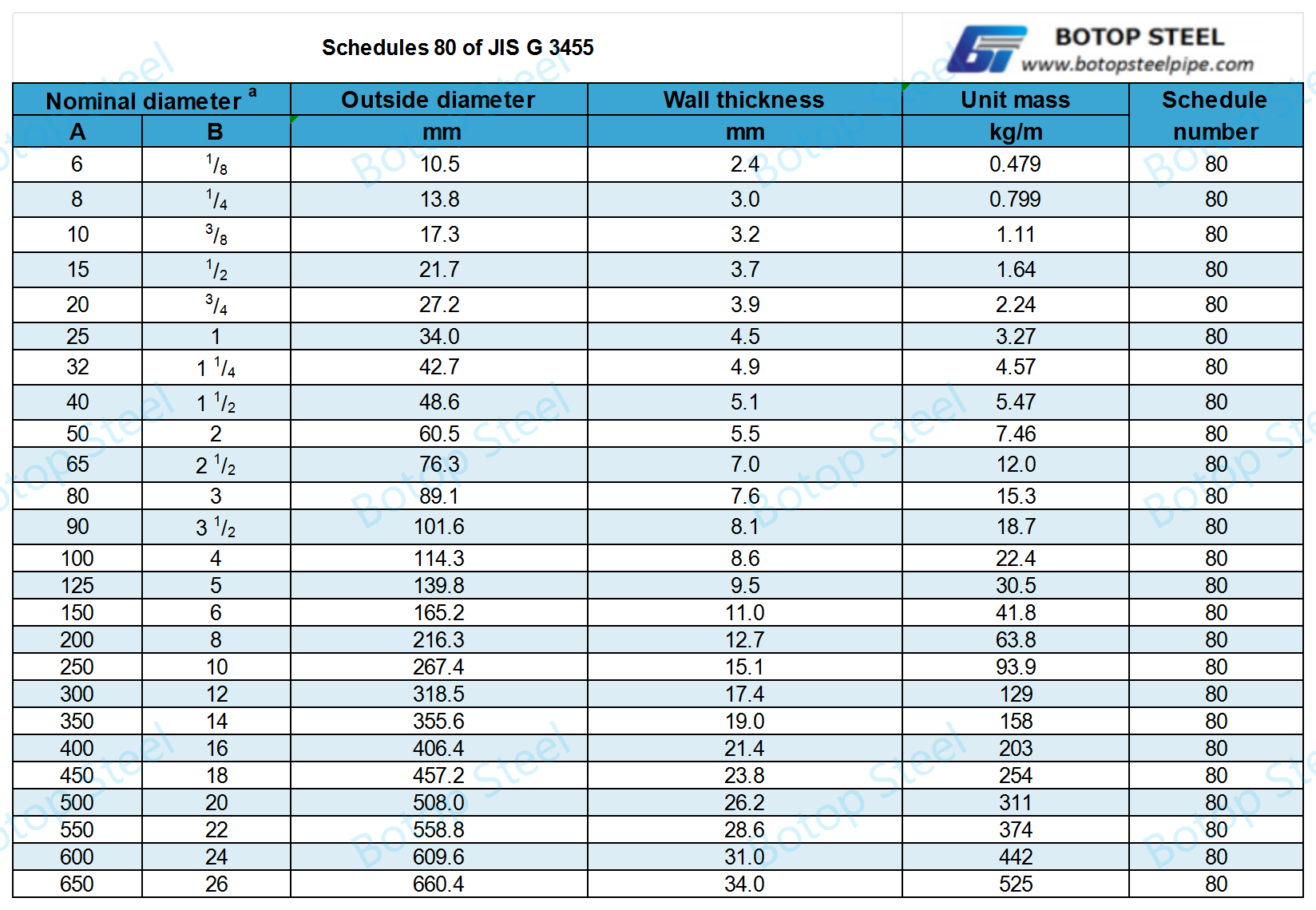

Imibhobho yeShedyuli ye-80 isetyenziswa ngokubanzi kwiindawo zoshishino ezifuna ukuphathwa koxinzelelo oluphezulu, njengeenkqubo zokucutshungulwa kweekhemikhali kunye nemibhobho yokuhambisa i-oyile kunye negesi, ngenxa yokukwazi ukumelana noxinzelelo oluphezulu kunye neempembelelo eziqinileyo zoomatshini ngenxa yobunzima bodonga olubanzi, ukubonelela ngokhuseleko olongezelelweyo, ukhuseleko, kunye nokuqina.

Ityhubhu nganye iya kubhalwa ngolu lwazi lulandelayo.

a)Uphawu lwebakala;

b)Uphawu lwendlela yokuvelisa;

c)ImilinganiseloUmzekelo 50AxSch80 okanye 60.5x5.5;

d)Igama lomenzi okanye uphawu lokuchonga.

Xa i-diameter yangaphandle yetyhubhu nganye incinci kwaye kunzima ukuphawula ityhubhu nganye, okanye xa umthengi efuna ukuba inyanda nganye yeetyhubhu imakishwe, inyanda nganye inokumakishwa ngendlela efanelekileyo.

I-STS370 ilungele iinkqubo ezisezantsi zoxinzelelo kodwa ezinobushushu obuphezulu.

Iinkqubo zokufudumeza: Kwimizila yokufudumala yedolophu okanye kwiinkqubo zokufudumeza izakhiwo ezinkulu, i-STS370 ingasetyenziselwa ukuthutha amanzi ashushu okanye umphunga kuba inokumelana noxinzelelo kunye nokutshintsha kweqondo lokushisa kwinkqubo.

Izityalo zamandla: Ekuveliseni umbane, inani elikhulu lemibhobho ye-steam ephezulu iyadingeka, kwaye i-STS370 iyona nto ifanelekileyo yokuvelisa le mibhobho kuba inokumelana nexesha elide lobushushu obuphezulu kunye neendawo zokusebenza zoxinzelelo oluphezulu.

Iinkqubo zomoya ezicinezelweyo: Kwimizila kunye nemigca yokuvelisa ngokuzenzekelayo, umoya ocinezelweyo ngumthombo obalulekileyo wamandla, kwaye ipayipi yensimbi ye-STS370 isetyenziselwa ukwakha imibhobho yezi nkqubo ukuqinisekisa ukuhanjiswa komoya okukhuselekileyo nokusebenzayo.

Ukusetyenziswa kolwakhiwo kunye noomatshini ngokubanzi: Ngenxa yeempawu zayo ezilungileyo zoomatshini, i-STS370 ingasetyenziselwa ukwenziwa kwezinto ezahlukeneyo zesakhiwo kunye nezomatshini, ngakumbi kwizicelo apho kufuneka amandla athile oxinzelelo.

I-JIS G 3455 STS370 yintsimbi ye-carbon steel esetyenziswa kwinkonzo yoxinzelelo oluphezulu. Ezi mathiriyeli zilandelayo zinokuthathwa njengezilinganayo okanye ziphantse zilingane:

1. I-ASTM A53 iBanga B: Ilungele ukusetyenziswa ngokubanzi kolwakhiwo kunye noomatshini kunye nokuthuthwa kwamanzi.

2. API 5L iBanga B: Kuxinzelelo oluphezulu lweoyile kunye nemibhobho yokuthutha igesi.

3. DIN 1629 St37.0: Kubunjineli boomatshini ngokubanzi kunye nokwakhiwa kweenqanawa.

4. EN 10216-1 P235TR1: Umbhobho wensimbi ongenamthungo wokushisa okuphezulu kunye noxinzelelo oluphezulu.

5. I-ASTM A106 iBanga B: Umbhobho we-carbon steel ongenamthungo kwinkonzo yobushushu obuphezulu.

6.I-ASTM A179: Iityhubhu zentsimbi ezithambileyo ezitsalwa ngokubanda ezingenamthungo kunye nemibhobho yenkonzo yobushushu obuphantsi.

7. DIN 17175 St35.8: Izinto zetyhubhu ezingenamthungo kwiibhoyili kunye neenqanawa zoxinzelelo.

8. EN 10216-2 P235GH: Iityhubhu ezingenamthungo kunye nemibhobho ye-non-alloy kunye ne-alloy steel ye-high-temperature kunye ne-high-pressure environments.

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi. Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange.

Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.