I-API (i-American Petroleum Institute Standard) i-5L ngumgangatho wamazwe ngamazwe wepayipi yensimbi esetyenziswa kwiinkqubo zokuthutha iipayipi.

I-API 5L igubungela umbhobho wentsimbi kwiintlobo ngeentlobo zezicelo zokuthutha igesi yendalo, i-oyile, kunye nolunye ulwelo.Umhla osebenzayo wohlelo lwama-46: ukusebenza ngoNovemba 1, 2018.

Ukuba ufuna nje ukufumana umbono jikelele we-API 5L, nceda ucofeAPI 5L Pipe Specification Overview.

Amaqhosha okukhangela

Yintoni ehlaziyiweyo kwi-API 5L 46th

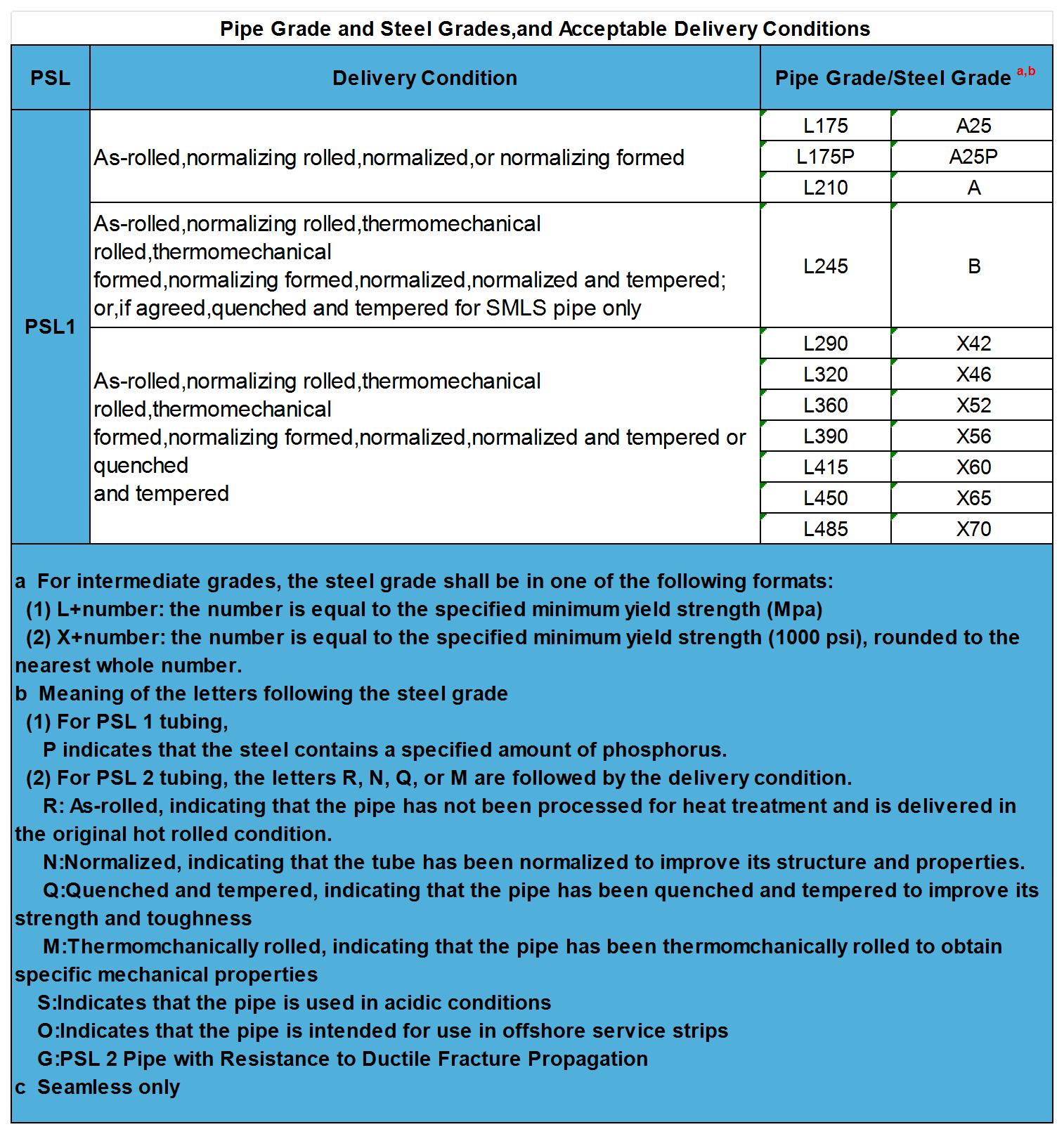

Imvelaphi ye-API 5L PSL

Ukuhlelwa kwamaBanga eNsimbi kunye namaBanga oMbhobho

Unikezelo lwamazwe olwamkelekileyo

Izinto ezikrwada zemibhobho yentsimbi

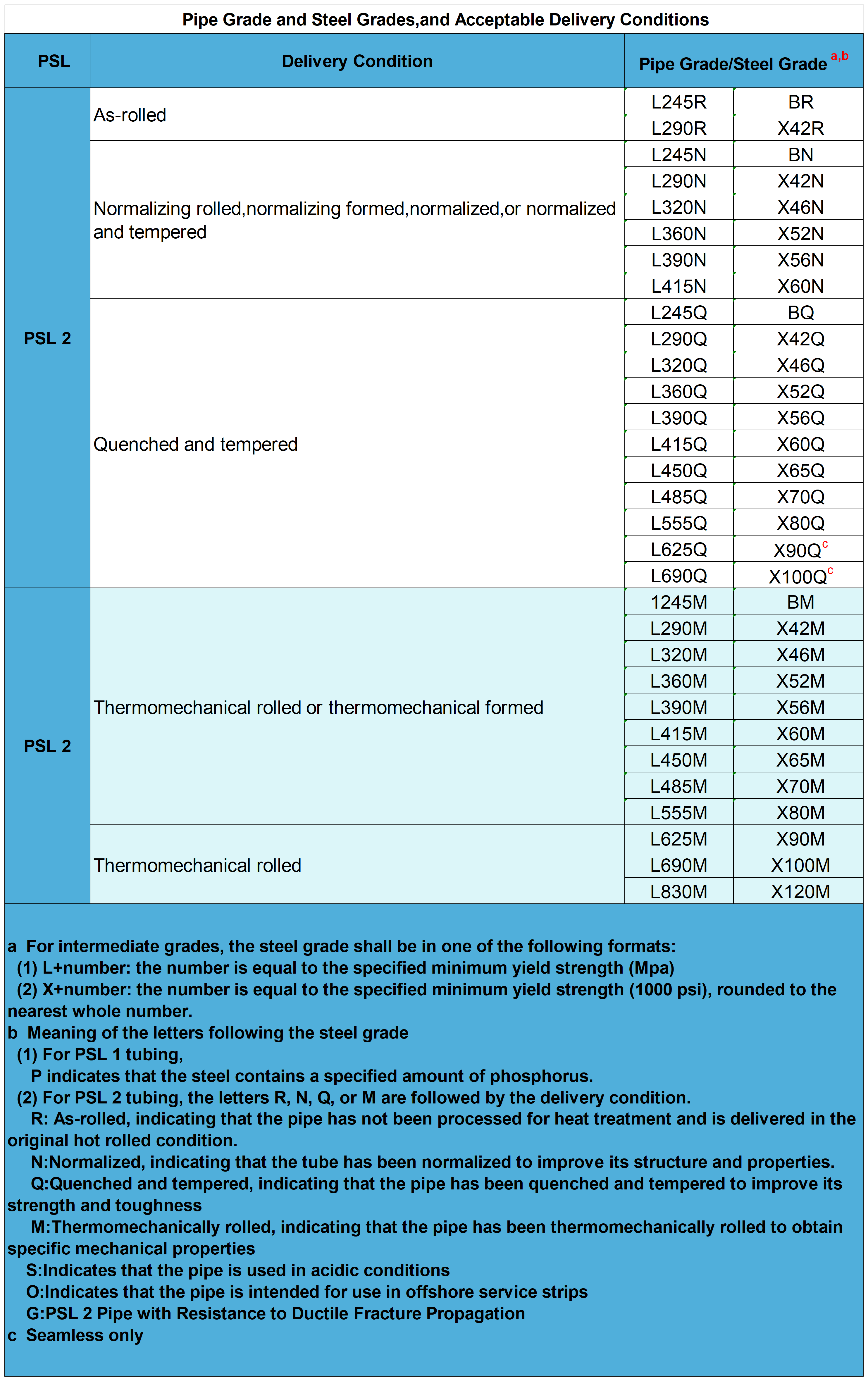

Iindidi zeMbhobho yeNsimbi kunye neziPhelo zeThubhu ezigutyungelwe yi-API 5L

Iinkqubo ezaMkelweyo zokuVelisa kwi-PSL2 ye-Steel Tubing

Ukuhlolwa kokubonakala kunye neziphene eziqhelekileyo ze-API 5L

Ukuhlolwa koMda (Dimensional Deviations)

Izinto zoVavanyo ze-API 5L

Ukumakishwa kwemibhobho kunye nendawo

Umgangatho woLingano

Iimveliso zethu ezinxulumeneyo

Yintoni ehlaziyiweyo kwi-API 5L 46th

Uhlaziyo

Iimfuno ezihlaziyiweyo kunye nezandisiweyo zamalungu agayiweyo;

Iimfuno ezihlaziyiweyo zokuphela kombhobho perpendicularity;

Iimfuno ezihlaziyiweyo zokuvavanya ubulukhuni be-API 5LPSL 2 imibhobho yokusingqongileyo okumuncu kunye ne-API 5L PSL 2 imibhobho yeendawo ezingaselunxwemeni;

Entsha

API 5L PSL 2 umbhobho izicelo ezifuna longitudinal iplasitiki umthamo umthamo.

Imvelaphi ye-API 5L PSL

PSL: Isifinyezo seNqanaba lokuCaciswa kwePipeline;

Yahlulwe yaba: API 5L PSL 1 kunye API 5L PSL 2.

Ukuhlelwa kwamaBanga eNsimbi kunye namaBanga oMbhobho

L + inombolo(unobumba L ulandelwa bubuncinane obukhankanyiweyo bamandla emveliso kwiMPa):

L175, L175P, L210, L245, L290, L320, L360, L390, L415, L450, L485, L555, L625, L690, L830

X + inombolo(inani elilandela unobumba u-X lichaza awona mandla asezantsi kwi-1000 psi):

X42, X46, X52, X56, X60, X65, X70, X80, X90, X100, X120.

Kwaye ibakala A kunye nebakala b.IBakala A=L210 IBakala B=L 2459

Unikezelo lwamazwe olwamkelekileyo

Qaphela: I-L415/X60 okanye amabakala aphezulu akufunekanga asetyenziswe endaweni ye-L360/X52 okanye amabanga asezantsi ngaphandle kwesivumelwano somthengi.

Izinto ezikrwada zemibhobho yentsimbi

Ingot, billet, billet, strip (coil) okanye ipleyiti.

Phawula:

1. Imathiriyeli ekrwada yeAPI 5L PSL2umbhobho wentsimbi uya kuba yintsimbi ecolekileyo yentlenga.

2. Umtya wensimbi (ikhoyili) okanye ipleyiti esetyenziselwa ukwenziwa kwe-API 5L PSL2 umbhobho wensimbi awuyi kuthwala nayiphi na i-welds tack.

Iindidi zeMbhobho yeNsimbi kunye neziPhelo zeThubhu ezigutyungelwe yi-API 5L

Umbhobho wentsimbi odityanisiweyo

Umbhobho weCW:Inkqubo yokwenziwa komthungo ngokufudumeza umcu eziko kunye nokucinezela ngoomatshini umphetho owenziweyo kunye, apho iikhoyili ezilandelelanayo zomcu ziye zadityaniswa ukuze kubonelelwe ngokuqukuqelayo okuqhubelekayo kwesixhobo sokusila kwisixhobo sokusila.

COWHPipe:Imveliso ye-tubular enomthungo omnye we-helical oveliswe yindibaniselwano ye-arc yentsimbi yegesi kunye ne-arc ye-arc ye-welding, apho i-gas metal arc weld bead ayisuswanga ngokupheleleyo ngokudlula kwe-arc welding.

INKOMO Umbhobho:Imveliso ye-tubular ene-longitudinal seams enye okanye ezimbini eziveliswa ngokudityaniswa kwe-arc yensimbi yegesi kunye ne-arc welding ephantsi kwamanzi, apho i-gas metal arc weld bead ayisuswanga ngokupheleleyo ngokudlula kwe-arc welding.

Umbhobho we-EW:Imveliso yeTubula enomthungo omnye welongitudinal oveliswe yi-welding yombane ephantsi okanye ephezulu.

Umbhobho we-HFW:I-EWpipe eveliswe' kunye ne-welding yangoku frequency ilingana okanye ngaphezulu kwe-70 kHz.

Umbhobho we-LFW:Umbhobho we-EW uveliswa nge-welding current frequency engaphantsi kwe-70 kHz.

Umbhobho we-LW:Imveliso yeTubula enomthungo omnye welongitudinal oveliswe yilaser welding.

Umbhobho we-SAWH:Imveliso yeTubula enomthungo omnye we-helical oveliswe yinkqubo ye-arc welding ephantsi kwamanzi.

SAWLUmbhobho:Imveliso yeTubula enothungelwano olunye okanye ezimbini zelongitudinal eziveliswe ngokuntywiliselwa kwe-arc.

Umbhobho wentsimbi ongenamthungo

Umbhobho we-SMLS:Umbhobho wentsimbi eshushu eqengqelekayo kunye nombhobho wentsimbi ongenamthungo oqengqelekayo, kukho ezinye iindlela zokusetyenzwa, ezinjengomzobo obandayo, umzobo obandayo, ukubumba, njl.

Iintlobo ze-API 5L PSL2 zemibhobho yezicelo ezizodwa

Ukuchasana noKwandiswa kokuqhekeka kweDuctile (G)

Umbhobho woMqathango weNkonzo emuncu (S)

Umbhobho woMqathango weNkonzo yoLwandle (O)

Ifuna iLongitudinal Plastic Strain Capacity Pipe

Iintlobo zokuphela kombhobho

Isiphelo seSokethi, isiphelo esiFlethi, iSiphelo seFlethi esiKhethekileyo sokuBamba, isiphelo esinemisonto.

Phawula:

1. Iziphelo zesokethi, iziphelo zemibhobho yeeclamps ezikhethekileyo, kunye neziphelo zemibhobho enentambo zeze-API 5L PSL1 kuphela.

2. I-L175 P / A25 P ibakala lensimbi ye-API 5L I-PSL1 ipayipi yensimbi iya kulungiswa ngeephelo ezinentambo, kunye ne-API 5L PSL1 ipayipi yensimbi yamanye amabakala ensimbi iya kutshintshwa ngeephelo ezisicaba.

3. I-API 5L PSL 2 iityhubhu ziya kuhanjiswa ngeziphelo ezicaba.

Iinkqubo ezaMkelweyo zokuVelisa kwi-PSL2 ye-Steel Tubing

| Itheyibhile 3-Iindlela ezaMkelweyo zokuVelisa kwi-PSL 2 Umbhobho | ||||

| Uhlobo loMbhobho | Ukuqala iMateria | Ukwenziwa kwemibhobho | Ubushushu bombhobho Unyango | Ukuhanjiswa Imeko |

| I-SMLS | Ingot, bloom, okanye billet | Njengoko-iqengqiwe | - | R |

| Ukwenziwa kwesiqhelo | - | N | ||

| Ukubumba okushushu | Ukuqheleka | N | ||

| Ukuhlamba kunye nokufudumala | Q | |||

| Ukubumba okushushu kunye nokubanda ukugqiba | Ukuqheleka | N | ||

| Ukuhlamba kunye nokufudumala | Q | |||

| HFW | Ikhoyili eqingqelweyo eqhelekileyo | Ukubumba okubandayo | Ukunyanga ubushushua kwindawo ye-weld kuphela | N |

| I-Thermomechanical-rolled ikhoyili | Ukubumba okubandayo | Ukunyanga ubushushua kwindawo ye-weld kuphela | M | |

| Ukunyanga ubushushua kwindawo ye-weld kunye nokunciphisa uxinzelelo lombhobho wonke | M | |||

| Njengoko-iqengqiwe okanye Ikhoyili ye-thermomechanical-rolled | Ukubumba okubandayo | Ukuqheleka | N | |

| Ukucima kunye ukucaphuka | Q | |||

| Ukumila okubandayo kulandele kushushu ukunciphisa phantsi kolawulo ubushushu obubangela ukuba imeko eqhelekileyo | - | N | ||

| Ukubumba okubandayo kulandele ukwenza i-thermomechanical yombhobho | - | M | ||

| SAW okanye INKOMAZI | Iqhelekile okanye iqhelekile- ikhoyili eqengqelekayo okanye ipleyiti | Ukubumba okubandayo | - | N |

| Njengoko-iqengqiwe i-thermomechanical-rolled normalizing-roli, okanye iqhelekile | Ukubumba okubandayo | Ukuqheleka | N | |

| I-Thermomechanical-rolled ikhoyili okanye ipleyiti | Ukubumba okubandayo | - | M | |

| Ucinywe kwaye unomsindo ipleyiti | Ukubumba okubandayo | - | Q | |

| Njengoko-iqengqiwe i-thermomechanical-rolled normalizing-roli, okanye ikhoyili eqhelekileyo okanye ipleyiti | Ukubumba okubandayo | Ukucima kunye ukucaphuka | Q | |

| Njengoko-iqengqiwe i-thermomechanical-rolled normalizing-roli, okanye ikhoyili eqhelekileyo okanye ipleyiti | Ukwenziwa kwesiqhelo | - | N | |

| aJonga i-ISO 5L 8.8 ngonyango olusebenzayo lobushushu | ||||

Ukuhlolwa kokubonakala kunye neziphene eziqhelekileyo ze-API 5L

Imbonakalo

Umphandle wangaphandle wombhobho uya kuba lula kwaye ukhululekile kwiziphene ezinokuchaphazela amandla kunye nokutywinwa kweempawu zombhobho.

Iziphene ezinkulu

Imiphetho eneNibbled:Imiphetho ene-Nibbled inokufunyanwa ngokufanelekileyo ngokuhlolwa okubonakalayo.

Ukutsha kweArc:Ukutshiswa kwe-arc kuya kugwetywa njengesiphene.

Ukutshisa kwe-arc linani leendawo ezineziphene zendawo ezenziwe ngokunyibilika kwendawo yesinyithi ebangelwa yi-arc phakathi kwe-electrode okanye i-electrode ephantsi kunye nomphezulu wombhobho wentsimbi.

Iindawo zoqhagamshelwano ziindawo eziphazamisayo kufuphi nomgca we-weld wepayipi ye-EW, ebangelwa ukudibanisa phakathi kwe-electrode enikezela ngoku i-welding current kunye nomphezulu wombhobho.

Delamination:Nakuphi na ukucoleka okanye ukubandakanywa okunabela phezu komphezulu wombhobho okanye ubuso obugutyungelwe yi-6.4 mm (0.250 in) ngobude obujikelezayo ekuhlolweni okubonakalayo kuya kuthathwa njengesiphene.

Unxaxhi lwejiyometri:Ukuphambuka kwejometri (umzekelo, ibhloko ecaba okanye i-pout, njl. njl.), ngaphandle kwe-drop pit, ebangelwa yinkqubo yokwenza ityhubhu okanye umsebenzi wokuvelisa.Umgama phakathi kwendawo egqithiseleyo kunye nokwandiswa kwe-contour yesiqhelo yombhobho, oko kukuthi, ubunzulu obungaphezu kwe-3.2 mm (0.125 in), buya kuthathwa njengesiphene.

Imigodi yokulahla iya kuba ≤ 0.5 D nakweliphi na icala.

Ukuqina: Xa uhlolo olubonwayo lubonisa ukuqina okukrokrelwayo, umvavanyi wobulukhuni ophathwayo uya kusetyenziswa ukwenza uvavanyo lokuqina, kunye nenqaku elinye lokujongwa ngexabiso lobulukhuni obungaphezulu kwe-35 HRC, 345 HV10, okanye 327 HBW iya kuthathwa njengesisiphene xa ubungakanani I-indentation inkulu kune-50 mm (2.0 ngo) kulo naliphi na icala.

Ukuphatha isiphene

Nceda ubhekisele kwiimfuno ezifanelekileyo kwi-API 5L kwiSihlomelo C sokuphatha.

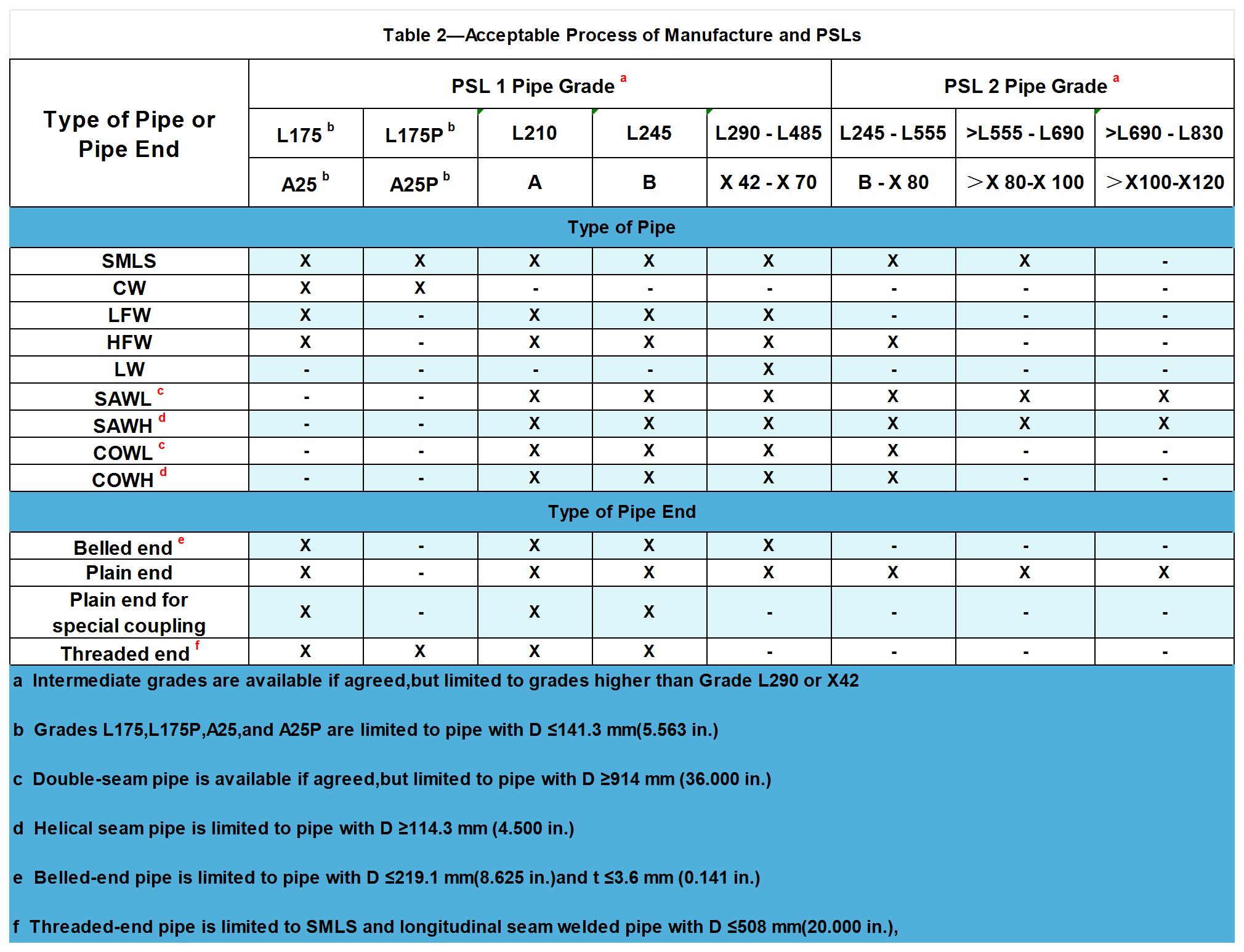

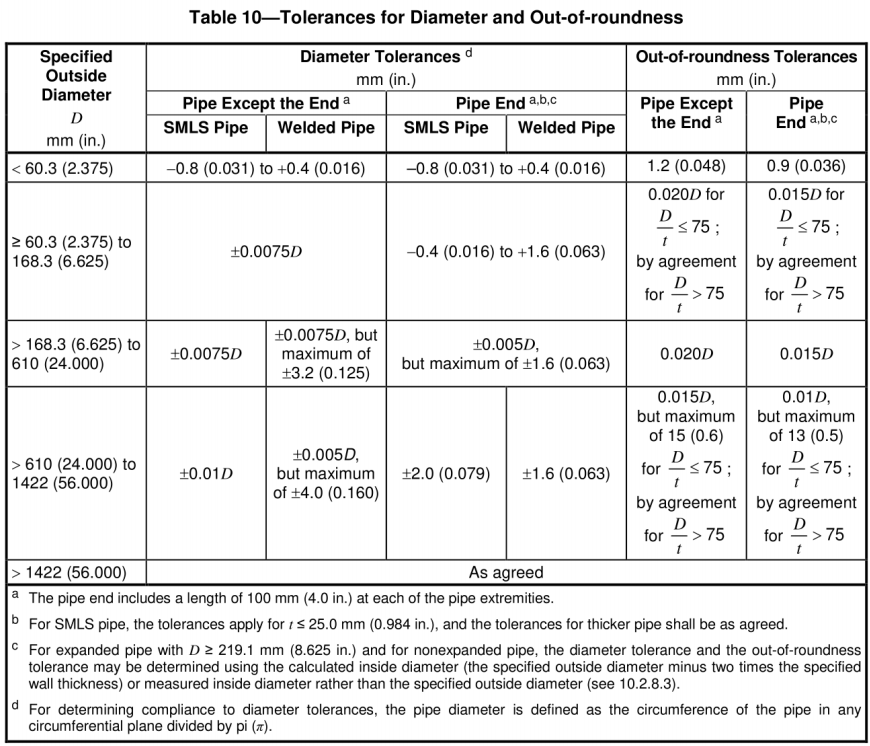

Ukuhlolwa koMda (Dimensional Deviations)

Itshathi yobunzima bombhobho kunye nokuphambuka kobunzima

Ifomula yobunzima

M=(DT)×T×C

M bubunzima ngeyunithi yobude;

I-D yi-diameter yangaphandle echaziweyo, echazwe ngeemilimitha (ii-intshi);

I-T yindonga echaziweyo yodonga, echazwe kwiimilimitha (ii-intshi);

C yi-0.02466 yokubala kwiiyunithi ze-SI kunye ne-10.69 yokubala kwiiyunithi ze-USC.

I-PIPE WIGHT TARTS NESHEDYULI

iitafile zobunzima bombhobho kwi-API 5L zibhekiselwa kuyoISO 4200kwayeASME B36.10M, enika amaxabiso asemgangathweni wombhobho ochaziweyo ngaphandle kwedayamitha kunye nobukhulu bodonga obuchaziweyo.

Ishedyuli 40 kunye IShedyuli 80zincanyathiselwe ngezantsi, ukuba ungathanda ukubona ishedyuli yombhobho epheleleyo,nceda ucofe apha!

Ukutenxa ubunzima

Umgangatho wombhobho ngamnye ngokumalunga nethiyori: ubunzima: 95% ≤ ubunzima bethiyori ≤ 110;

Ukuphambuka kunye neetyhubhu ezicacileyo ezongezelelweyo: 5% ≤ 110% yobunzima bethiyori;

I-L175, L175P, A25, kunye ne-A25P amabakala ensimbi: 95% ≤ 110% yobunzima bethiyori.

Idayamitha yaNgaphandle kunye noluhlu lokutyeba kweendonga

| Itheyibhile ye-9-Ivumelekileyo echazwe ngaphandle kwe-Diameter yangaphandle kunye noBungqimba obuchaziweyo bodonga | ||

| I-Diameter yangaphandle ecacisiweyo D mm (ngaphakathi) | Ubungqingqwa boDonga obucacisiweyo t mm (ngaphakathi) | |

| Ubukhulu bokukhanya obukhethekileyoa | Ubungakanani obuqhelekileyo | |

| ≥10.3 (0.405)ukuya<13.7 (0.540) | - | ≥1.7 (0.068)ukuya≤2.4 (0.094) |

| ≥13.7 (0.540)ukuya<17.1 (0.675) | - | ≥2.2 (0.088)ukuya≤3.0 (0.118) |

| ≥17.1 (0.675)ukuya<21.3 (0.840) | - | ≥2.3 (0.091)ukuya≤3.2 (0.125 |

| ≥21.3 (0.840)ukuya<26.7 (1.050) | - | ≥2.1 (0.083)ukuya≤7.5(0.294) |

| ≥26.7(1.050)ukuya<33.4(1.315) | - | ≥2.1 (0.083)ukuya≤7.8 (0.308) |

| ≥33.4(1311}5)ukuya<48.3 (1.900) | - | ≥2.1 (0.083)ukuya≤10.0 (0.394) |

| ≥48.3 (1.900)ukuya<60.3 (2.375) | - | ≥2.1 (0.083)ukuya≤12.5 (0.492) |

| ≥60.3 (2.375)ukuya<73.0 (2.875) | ≥2.1 (0.083)ukuya≤3.6 (0.141) | >3.6 (0.141)ukuya≤14.2 (0.559) |

| ≥73.0 (2.875)ukuya<88.9(3.500) | ≥2.1 (0.083)ukuya≤3.6 (0.141) | >3.6 (0.141)ukuya≤20.0 (0.787) |

| ≥88.9 (3.500)ukuya<101.6(4.000) | ≥2.1 (0.083)ukuya≤4.0 (0.156) | >4.0 (0.156)ukuya≤22.0 (0.866) |

| ≥101.6(4.000)ukuya<168.3 (6.625) | ≥2.1 (0.083)ukuya≤4.0 (0.156) | >4.0(0.156)ukuya≤25.0 (0.984) |

| ≥168.3 (6.625)ukuya<219.1 (8.625) | ≥2.1 (0.083)ukuya≤4.0 (0.156 | >4.0 (0.156)ukuya≤40.0(1.575) |

| ≥219.1 (8.625)ukuya<273.1 (10.750) | ≥3.2 (0.125)ukuya≤4.0 (0.156 | >4.0 (0.156)ukuya≤40.0 (1.575 |

| ≥273.1 (10.750)ukuya<323.9 (12.750) | ≥3.6 (0.141)ukuya≤5.2 (0.203) | >5.2 (0.203)ukuya≤45.0 (1.771) |

| ≥323.9(12.750)ukuya<355.6(14.000) | ≥4.0 (0.156)ukuya≤5.6 (0.219) | >5.6 (0.219)ukuya≤45.0(1.771 |

| ≥355.6(14.000)ukuya<457(18.000) | ≥4.5 (0.177)ukuya≤7.1 (0.281) | >7.1 (0.281)ukuya≤45.0(1.771 |

| ≥457 (18.000)ukuya<559 (22.000) | ≥4.8 (0.188)ukuya≤7.1 (0.281) | >7.1 (0.281)ukuya≤45.0(1.771) |

| ≥559 (22.000)ukuya<711(28.000) | ≥5.6 (0.219)ukuya≤7.1 (0.281) | >7.1 (0.281)ukuya≤45.0(1.771) |

| ≥711 (28.000)ukuya<864(34.000) | ≥5.6(0.219)ukuya≤7.1 (0.281) | >7.1 (0.281)ukuya≤52.0 (2.050) |

| ≥864 (34.000)ukuya<965(38.000) | - | ≥5.6 (0.219)ukuya≤52.0 (2.050) |

| ≥965(38.000)ukuya<1422 (56.000) | - | ≥6.4 (0.250)ukuya≤52.0 (2.050) |

| ≥1422(56.000)ukuya<1829 (72.000) | - | ≥9.5 (0.375)ukuya≤52.0 (2.050 |

| ≥1829(72.000)ukuya<2134(84.000) | - | ≥10.3 (0.406)ukuya≤52.0 (2.050) |

| aUmbhobho onodibaniso lwedayamitha yangaphandle echaziweyo kunye nobukhulu bodonga obuchaziweyo uchazwa njengombhobho okhethekileyo wobukhulu bokukhanya;ezinye iindibaniselwano ezinikwe kule theyibhile zichazwa njengombhobho wobungakanani obuqhelekileyo. | ||

I-Diameter kunye ne-Roundness Deviation

Ukutenxa koDonga lokutyeba

| Uluhlu lwe-11-Ukunyamezelwa koDonga olutyebileyo | |

| Ukutyeba kweendonga t mm (kwi.) | Ukunyamezelanaa mm (kwi.) |

| Umbhobho we-SMLSb | |

| ≤4.0 (0.157) | +0.6(0.024) -0.5 (0.020) |

| >4.0 (0.157)ukuya<25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | +3.7 (0.146)okanye+0.1t, nokuba yeyiphi enkulu -3.0 (0.120)okanye-0.1t, nokuba yeyiphi enkulu |

| Umbhobho odityanisiweyocd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| >5.0 (0.197)ukuya ku<15.0 (0.591) | ±0.1t |

| ≥15.0 (0.591) | ±1.5 (0.060) |

| aUkuba umyalelo wokuthenga ukhankanya unyamezelo oluthabatha ubungakanani bodonga obuncinane kunexabiso elisebenzayo elinikiweyo kule theyibhile, ukunyamezela okudityanisiweyo kobukhulu bodonga kuya kwandiswa ngesixa esaneleyo ukugcina uluhlu olusebenzayo lonyamezelo. bNgombhobho one-D2 355.6 mm (14.000 in.) kunye ne-1 2 25.0 mm (0.984 in.), ukunyamezela kobunzima bodonga ekuhlaleni kunokugqithisa ukunyamezela kobunzima bodonga nge-0.05t eyongezelelweyo, ngaphandle kokuba ukunyamezela kobunzima (bona 9.14) akugqithiswanga. cUkunyamezela kunye nokunyamezela kodonga akusebenzi kwindawo ye-weld. dJonga ku-9.13.2 ukufumana izithintelo ezongezelelweyo. | |

Ukutenxa kobude

Ukunyamezelwa kwetyhubhu yobude obusisigxina: Ukutenxa kobude kufuneka kube yi-500 mm (i-intshi ezingama-20).

Ukunyamezela imibhobho yobude:

| Uluhlu lwe-12-Ukunyamezelwa koMbhobho woBude obuNgaqhelekanga | |||

| Random Ubude Ukutyunjwa m(ft) | Ubuncinane Ubude m (ft) | Ubuncinci boBude obuphakathi Kwinto nganye yee-odolo m (ft) | Ubude Obuninzi m (ft) |

| Umbhobho odityanisiweyo kunye nodityanisiweyo | |||

| 6(20) | 4.88(16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9(30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67(35.0) | 13.72(45.0 |

| Umbhobho ocacileyo | |||

| 6(20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00(26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72(45.0) |

| 15(50) | 5.33 (17.5) | 13.35(43.8) | 16.76(55.0) |

| 18(60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24(80) | 8.53 (28.0) | 21.34(70.0) | 25.91(85.0) |

Ukutenxa kokuTlolo

Ukuphambuka okupheleleyo kumgca ochanekileyo phezu kobude bonke bombhobho kuya kuba <0.2% yobude bombhobho;

Ukutenxa kwendawo ukusuka kumgca othe ngqo kuya kuba <3.2 mm (0.125 in) ngaphezu kwe-1.5 m (5.0 ft) ubude bombhobho ngamnye.

Ukutenxa kwe-Angle ye-Bevel

Umbhobho one-t > 3.2 mm (0.125 in) iziphelo ezisicaba ziya kwenziwa ngomatshini nge-weld bevel kunye ne-engile ye-bevel ye-30 ° -35 °.

Ububanzi boMphezulu weNgcambu ePhuhlisiwe

1.6 mm (0.063 in) kunye nokutenxa kwe-± 0.8 mm (0.031 ngaphakathi).

Uluhlu lwe-engile ye-Inner Cone (kuphela kumbhobho wentsimbi ongenamthungo)

| Itheyibhile ye-13-Eyona Enkulu ye-Angle yeTaper yangaphakathi ye-SMLS Pipe | |

| Ubungqingqwa boDonga obucacisiweyo t mm (ngaphakathi) | Ubuninzi beAngle yeTaper izidanga |

| <10.5(0.413) | 7.0 |

| 10.5 (0.413)ukuya ku<14.0 (0.551) | 9.5 |

| 14.0 (0.551)ukuya ku<17.0 (0.669) | 11.0 |

| ≥17.0 (0.669) | 14.0 |

Umbhobho End squareness (ngaphandle-kwe-squareness)

I-out-of-squareness ilinganiswa njengesithuba phakathi kokuphela kombhobho kunye nomlenze wokuphela kombhobho, oya kuba ngu-1.6 mm (0.063 in.).

Welding Seam Ukutenxa

Ulungelelwaniso lweMicu/yePhepha:

I-electro-welded (EW) kunye ne-laser-welded (LW) ipayipi, ukungahambi kakuhle akufanele kubangele ubuninzi bodonga oluseleyo kwi-weld engaphantsi kobuncinci obuvumelekileyo bodonga.

Kwi-Submerged Arc Welded (SAW) kunye ne-Combination Welded (COW) umbhobho, ukulungelelaniswa akufanele kudlule amaxabiso ahambelanayo anikwe kwiThebhile 14 ye-API 5L.

Burrs (i-electro-welded (EW) kunye ne-laser-welded (LW) iityhubhu):

Iibhula zangaphandle ziya kususwa kwindawo egungxulwayo kakhulu (ngemathiriyeli esisiseko).

Iibhula zangaphakathi aziyi kwandiswa nge-1.5 mm (0.060 in) ngaphaya kwecontour yetyhubhu, kwaye ubukhulu bodonga kwindawo yokususa i-burr abuyi kuba ngaphantsi kobuncinci obuvumelekileyo bodonga.

Weld Height(I-Summerged Arc Welding (SAW) kunye neNdibaniselwano yokuWelding (COW) Umbhobho):

Susa ubude obuseleyo be-weld yangaphakathi ngaphakathi ubuncinane be-100 mm (4.0 in) yesiphelo sombhobho ekupheleni kombhobho, kwaye ugaye i-weld ukuze inganyuki ngaphezu kwe-0.5 mm (0.020) ngaphezu komhlaba. wombhobho osecaleni.

Izinto zoVavanyo ze-API 5L

Ukuqulunqwa kwemichiza

Indlela yoVavanyo: Jonga kwi-ISO 9769 okanye i-ASTM A751.

Ukubunjwa kweekhemikhali ze-API 5L PSL1 kunye ne-API 5L PSL2 ipayipi yensimbi t> 25.0 mm (0.984 in) iya kugqitywa ngothethwano olusekelwe kwimichiza yeekhemikhali kwiitafile ezihambelanayo.

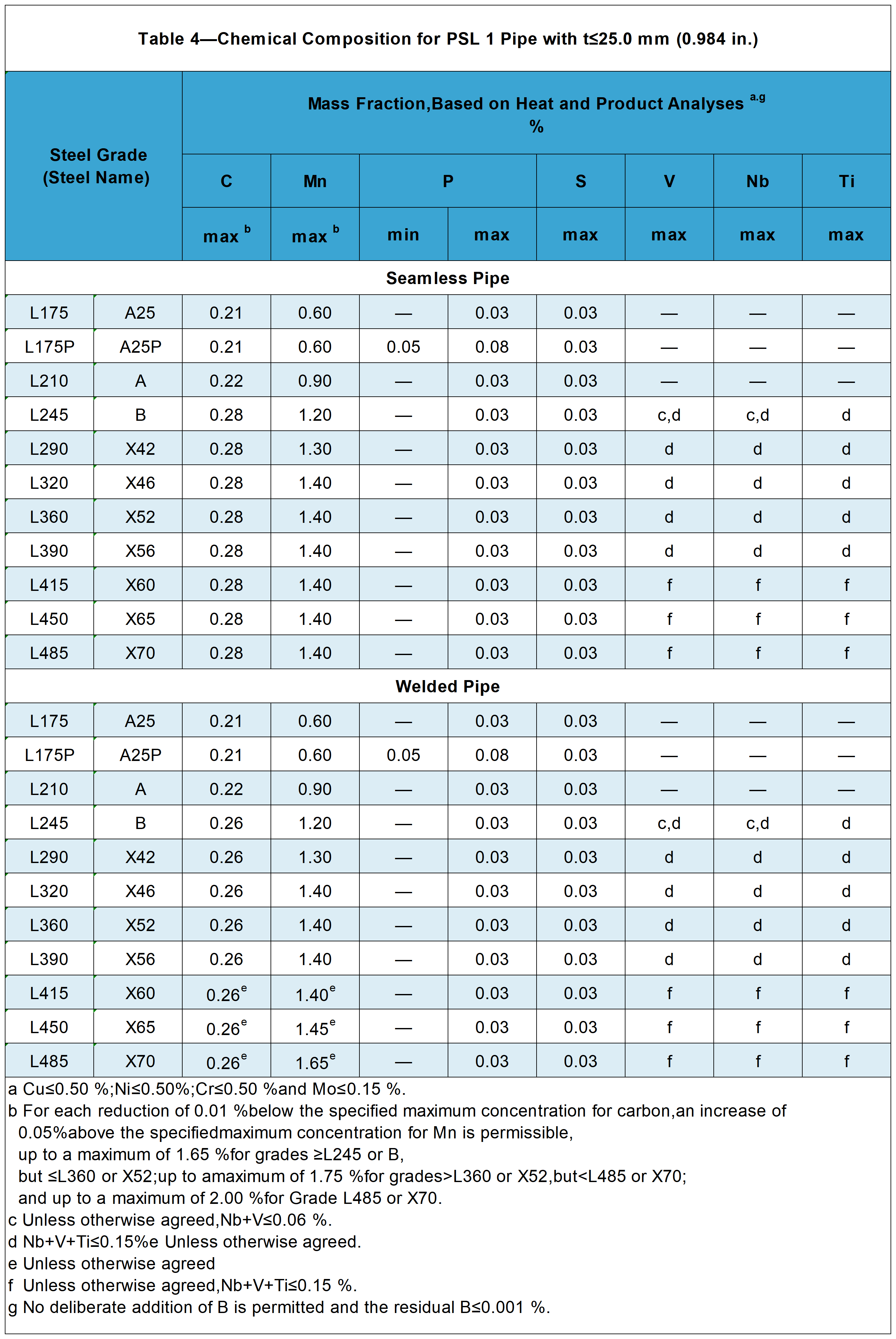

Ukuqulunqwa kwemichiza ye-PSL 1 Umbhobho one-t≤25.0 mm (0.984 in.)

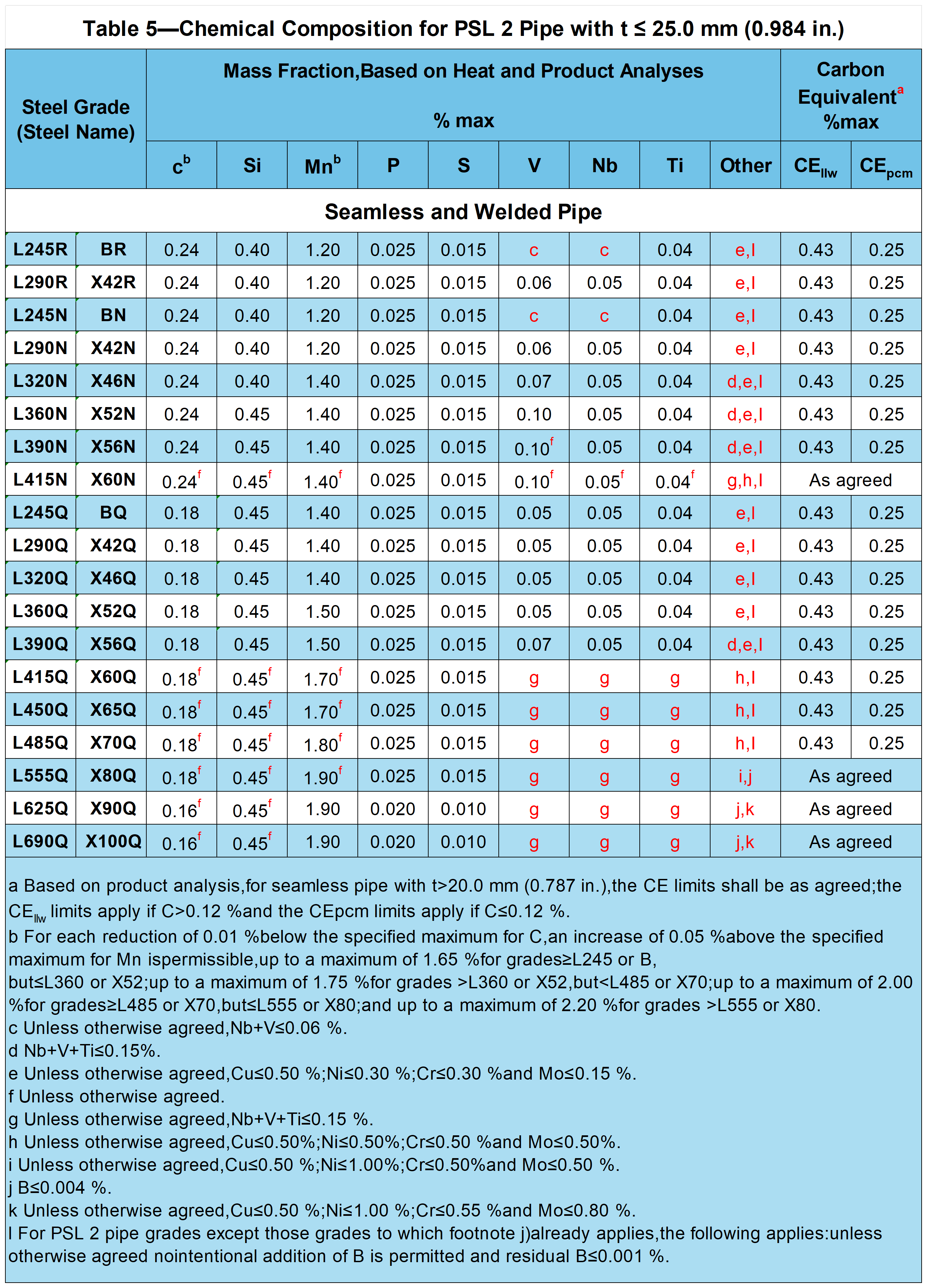

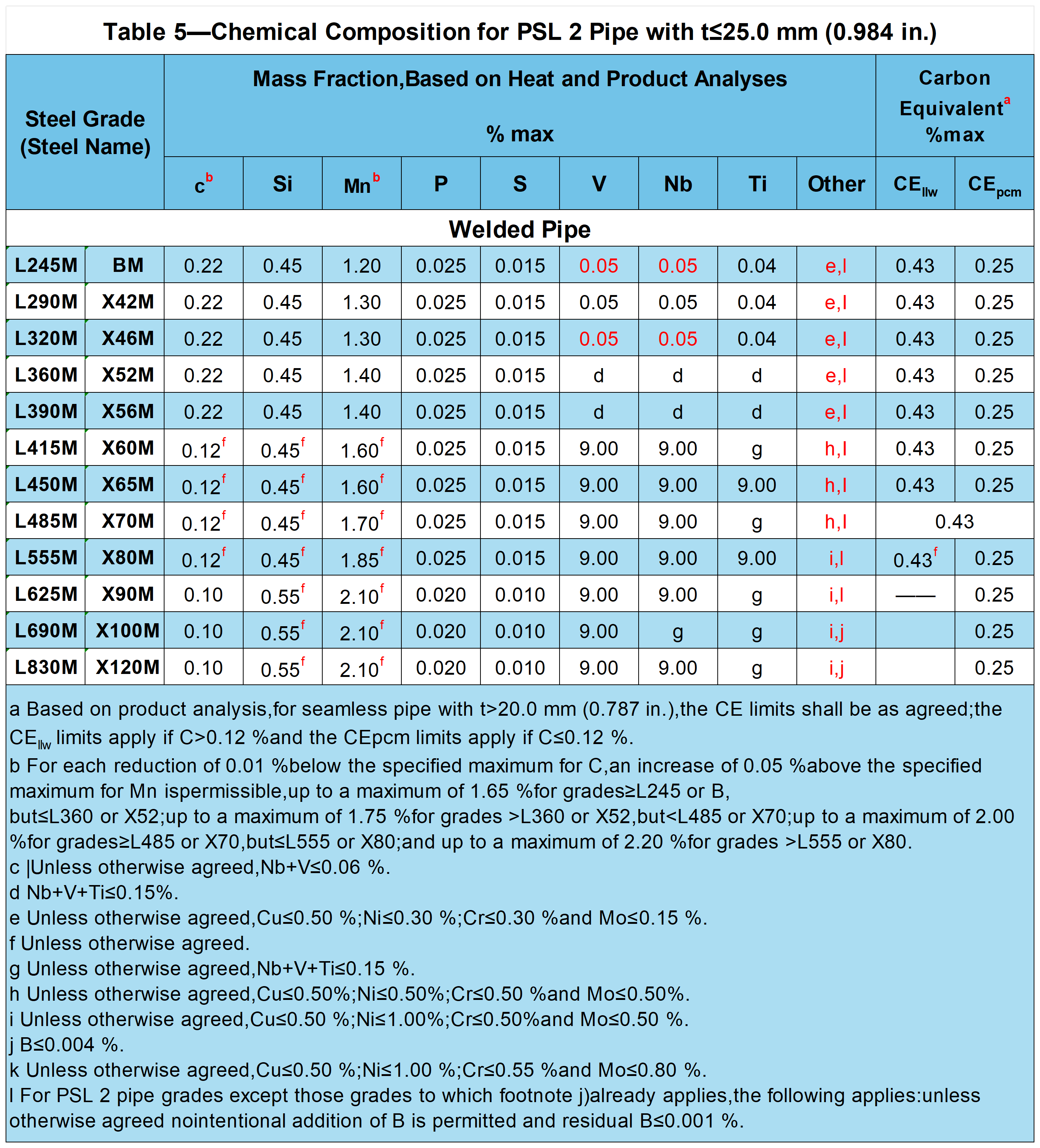

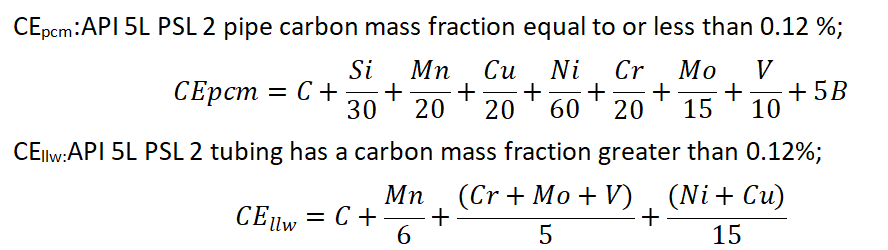

Ukwakhiwa kweMichiza ye-PSL 2 Umbhobho one-t≤25.0 mm (0.984 in.)

Iipropati ze-Tensile

Iindlela zokuvavanya: Kuya kwenziwa ngokuhambelana ne-ISO 6892-1 okanye i-ASTM A370.

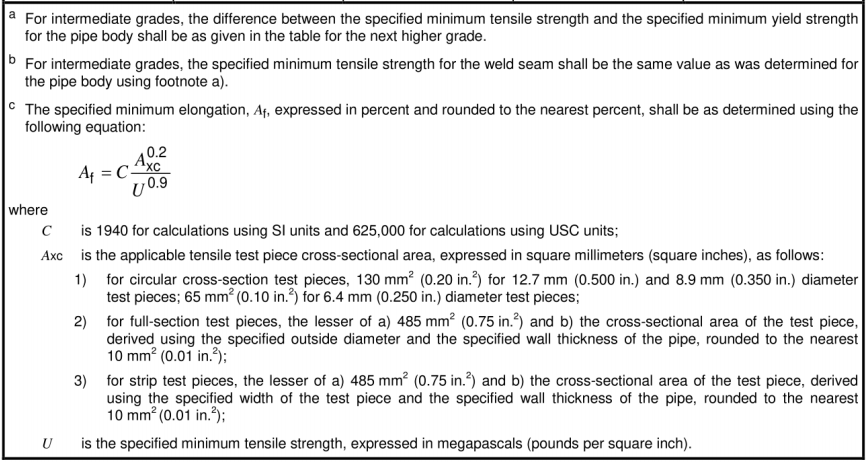

Iimfuno zeziphumo zovavanyo lwe-Tensile ye-PSL 1 Pipe

| Itheyibhile 6-IiMfuno zeziphumo zovavanyo lwe-Tensile ye-PSL 1 iPipe | ||||

| IBanga lombhobho | Umzimba wombhobho wePipe engenamthungo kunye neWelded | I-Weld Seam ye-EW, I-LW, i-SAW, kunye ne-COW Pipe | ||

| Unikeze Amandlaa Rukuya.5 MPa(psi) | Tensile strengtha Rm MPa(psi) | Ukwandisa (kwi-50 mm okanye 2 ngaphakathi.) Af % | Tensile strengthb Rm MPa(psi) | |

| imiz | imiz | imiz | imiz | |

| L175 okanye A25 | 175(25,400) | 310(45,000) | c | 310(45,000) |

| I-L175P okanye i-A25P | 175(25,400) | 310(45,000) | c | 310 (45,000) |

| L210 okanye A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 okanye B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| L290 okanye X42 | 290(42,100) | 415(60,200) | c | 415 (60,200) |

| L320 okanye X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 okanye X52 | 360 (52,200) | 460(66,700) | c | 460 (66,700) |

| L390 okanye X56 | 390 (56,600) | 490(71,100) | c | 490(71,100) |

| L415 okanye X60 | 415 (60,200) | 520(75,400) | c | 520 (75,400) |

| L450 okanye X65 | 450(65,300) | 535(77,600) | c | 535(77,600) |

| L485 okanye X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

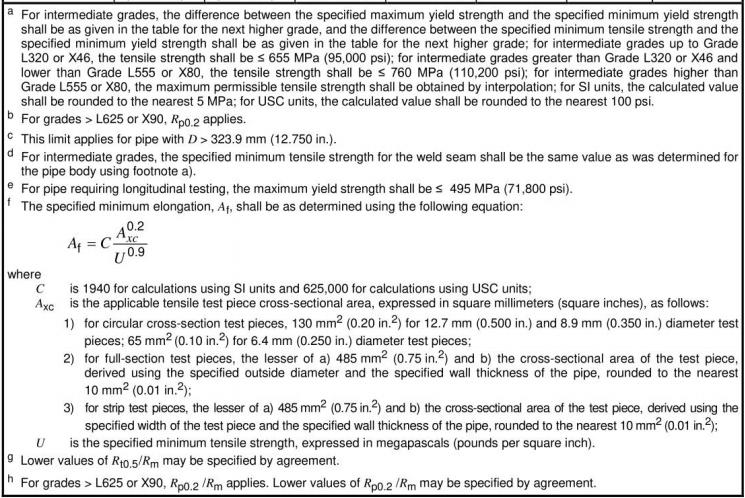

Iimfuno zeziphumo zovavanyo lwe-Tensile ye-PSL 2 Pipe

| Itheyibhile 7-IiMfuneko zeziphumo zovavanyo lwe-Tensile ye-PSL 2 Pipe | |||||||

| IBanga lombhobho | Umzimba wombhobho wePipe engenamthungo kunye neWelded | Weld Seam yeHFW SAW kunye Umbhobho weNkomo | |||||

| Unikeze Amandlaa Rto.5 MPa(psi) | Tensile strengtha Rm MPa (psi) | Umlinganiseloac Rt0.5/Rm | Ukwandisa (kwi-50 mm okanye 2 ngaphakathi.) Af % | Ukuqina Amandlad Rm MPa (psi) | |||

| imiz | max | imiz | max | max | imiz | imiz | |

| L245R okanye BR I-L245N okanye i-BN L245Q okanye BQ L245M okanye BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R okanye X42R L290N okanye X42N L290Q okanye X42Q L290M okanye X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N okanye X46N L320Q okanye X46Q L320M okanye X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N okanye X52N L360Q okanye X52Q L360M okanye X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N okanye X56N L390Q okanye X56Q L390M okanye X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N okanye X56N L390Q okanye X56Q L390M okanye X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N okanye X60N I-L415Q okanye i-X60Q L415M okanye X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q okanye X65Q L450M okanye X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q okanye X70Q L485M okanye X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q okanye X80Q L555M okanye X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M okanye X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q okanye X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M okanye X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q okanye X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M okanye X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Ubude bepesenti ngexesha lekhefu kuya kuxelwa kwimizekelo enegeyiji yobude obuyi-50 mm (2 in).

Kwimizekelo enobude be-gauge obungaphantsi kwe-50 mm (2 in), i-elongation kwikhefu iya kuguqulwa ibe yi-elongation kwi-50 mm (2 in) ngokuhambelana ne-ISO 2566-1 okanye i-ASTM A370.

Uvavanyo loxinzelelo lweHydrostatic

Indlela yokuvavanya: API 5L 10.2.6.

Zonke iisayizi zombhobho ongenamthungo (SMLS) kunye nombhobho odibeneyo kunye ne-D ≤ 457 mm (18.000 in) uya kuba nexesha lokuzinzisa elingekho ngaphantsi kwemizuzwana ye-5.umbhobho odityanisiweyo nge D > 457 mm (18.000 in) uya kuba nexesha lokuzinzisa elingekho ngaphantsi kwemizuzwana ye-10.

Bend Test

Iindlela zoVavanyo: Uvavanyo lokugoba luya kuhambelana neemfuno ze-ISO 8491 okanye ze-ASTM A370.

Akukho nxalenye yomfanekiso iya kuqhekeka kwaye i-weld ayiyi kuqhekeka.

Ibanga le-L175P / A25P yintsimbi ephuculweyo ye-phosphorus enika ukusebenza okungcono kwe-threading kunentsimbi ye-L175 / A25 kodwa kunzima ukugoba.

Uvavanyo lokucaba

Iindlela zoVavanyo: Uvavanyo loxinzelelo luya kuhambelana neemfuno ze-ISO 8492 okanye ze-ASTM A370.

Umgama phakathi kwamacwecwe amabini uya kuba ngowokuba kungabikho kuqhekeka kweweld kuya kwenzeka de kube umgama ochaziweyo ufinyelelwe.

UVavanyo oluKhokelwayo lokugoba

Iindlela zoVavanyo: Uvavanyo lokugoba olukhokelwayo luya kuhambelana neemfuno ze-ISO 5173 okanye ze-ASTM A370.

Uvavanyo lobulukhuni

Indlela yokuvavanya: Uvavanyo lokuqina ngokwe-ISO 6506, ISO 6507, ISO 6508, okanye i-ASTM A370.

Xa amaqhuma aqinileyo akrokrelekayo afunyanwa ekuhlolweni kwenkangeleko, umvavanyi wobulukhuni ophathwayo kufuneka asetyenziswe kuvavanyo lobulukhuni.

Uvavanyo lweMpembelelo yeCVN ye-API 5L PSL2 Umbhobho weNtsimbi

Iindlela zoVavanyo: Uvavanyo lwempembelelo ye-charpy luya kuhlangabezana neemfuno ze-ASTM A370.

Uvavanyo lwe-DWT lwe-API 5L PSL2 Umbhobho odityanisiweyo

Indlela yokuvavanya: Uvavanyo lwe-DWT luya kuhambelana ne-API5L3.

Ukuhlolwa okukhulu kunye noVavanyo lweMetallographic

Ukunxaxha kweweld yangaphakathi nangaphandle yombhobho we-arc odityanisiweyo (SAW) kunye ne-combi-welded (COW) iya kujongwa ngohlolo olukhulu.

Kwiityhubhu ezifuna unyango lobushushu be-weld, uvavanyo lwesinyithi luya kwenziwa ukuqinisekisa ukuba yonke i-HAZ iphathwe ngokufanelekileyo ubushushu kwicala eligcweleyo eludongeni.

Kwimibhobho engadingi unyango olushushu lwe-weld, uvavanyo lwe-metallographic luya kwenziwa ukuze kuqinisekiswe ukuba akukho ntsalela ye-martensite engapheliyo.

Uvavanyo olungaLonakalisi (kuphela imibhobho emithathu yenjongo eyodwa ye-API 5L PSL2)

Indlela yovavanyo: API 5L Annex E.

Ukumakishwa kwemibhobho kunye nendawo

Izinto eziqhelekileyo zokumakisha kwiityhubhu zentsimbi:

Igama lomenzi wemibhobho okanye ukuphawula;

Ukumakisha "API Spec 5L".(Ngokuphangaleleyo ishunqulelwe kwi-API 5L.) Iimveliso ezihambelana nomgangatho omnye ohambelanayo zinokuphawulwa ngegama lomgangatho ngamnye.

I-Diameter yangaphandle ecacisiweyo

Ubukhulu bodonga obuchaziweyo

Ibakala lombhobho (igama lentsimbi)

Uhlobo lombhobho

Ubude (ubude bombhobho kwi-m ukuya kweyona kufutshane yi-0.01 m (kwi-ft ukuya kweyona ndawo ikufutshane yeshumi lonyawo))

Indawo yokumakishwa kwemibhobho yentsimbi

D ≤ 48.3 mm (1.900 in) umbhobho wensimbi: Iithebhu eziqhubekayo zenziwe kunye nobude bombhobho wensimbi okanye ezinokuthi zigcinwe kwi-bundle yensimbi yombhobho.

Umbhobho ono D > 48.3 mm (1.900 ngaphakathi):

Umphandle wangaphandle: Ukuqala kwindawo kumphezulu ongaphandle wombhobho phakathi kwe-450 mm kunye ne-760 mm (1.5 ft kunye ne-2.5 ft) ukusuka kwelinye icala lombhobho.

Umphezulu wangaphakathi: Qala ukuphawula kwindawo yangaphakathi yombhobho ubuncinane be-150 mm (6.0 in) ukusuka kwelinye icala lombhobho.

Umgangatho woLingano

Umbhobho wamazwe ngamazwe kunye nommandla kunye nemigangatho yetyhubhu apho i-API 5L ilingana okanye, kwiimeko ezithile, ukhetho olulolunye, kunye nenani lemigangatho yesicelo-specific:

Imigangatho yamazwe ngamazwe neyengingqi

1. I-ISO 3183 - Umgangatho wemibhobho yehlabathi jikelele kwishishini leoli kunye negesi epapashwe yi-International Organization for Standardization kwaye inxulumene ngokusondeleyo ne-API 5L.

2. I-EN 10208 - uMgangatho waseYurophu wemibhobho yentsimbi yokuthutha i-fuel gases kunye nolwelo.

3. I-GB / T 9711 - umgangatho wesizwe waseTshayina kwiinkqubo zokuthutha iipayipi kwi-oyile kunye negesi yegesi.

4. I-CSA Z245.1 - i-Canadian Standard covering line pipe yokuthutha i-oyile kunye negesi.

5. I-GOST 20295 - iMigangatho yaseRashiya yepayipi yomgca wensimbi yokuthutha ioli kunye neemveliso zeoli.

6. IPS (iMigangatho ye-Iranian Petroleum) - iMigangatho ye-Iranian Petroleum yombhobho womgca we-oyile kunye ne-gas industry.

7. I-JIS G3454, i-G3455, i-G3456 - iMigangatho yoShishino lwaseJapan yokuhambisa imibhobho yeeklasi ezahlukeneyo zoxinzelelo.

8. I-DIN EN ISO 3183 - iMigangatho yoShishino yaseJamani esekelwe kwi-ISO 3183 yepayipi yomgca.

9. I-AS 2885 - iMigangatho yase-Australia yeenkqubo zombhobho wentambo yokuthutha ioli kunye negesi.

Ukusetyenziswa kweMigangatho eKhethekileyo

1. I-API 5CT - Umgangatho we-American Petroleum Institute ye-oil well casing kunye ne-tubing, leyo, nangona isetyenziswe ngokuyinhloko kwimithombo yeoli, ibalulekile kwishishini leoli kunye negesi.

2. I-ASTM A106 - Umbutho waseMelika woVavanyo kunye neMathiriyeli umgangatho womgangatho ongenamthungo kunye ne-welded carbon steel pipe yenkonzo yobushushu obuphezulu.

3. I-ASTM A53 - Iziko leSizwe loVavanyo kunye neMathiriyeli umgangatho wepayipi yensimbi engenamthungo kunye ne-welded, ngokuqhelekileyo isetyenziselwa ukuthuthwa kwamanzi kwindawo yokushisa okanye ukushisa okuphantsi.

4. I-ISO 3834 - i-International Organisation for Standardization umgangatho weemfuno zomgangatho, ugxininise kwiinkqubo zokuqinisekisa umgangatho weentsimbi ezidibeneyo.

5. I-dnv-os-f101 - umgangatho woluntu wokuhlelwa kweNorway kwiinkqubo zemibhobho yenkwili kwi-offshore oil kunye nemibhobho yokuhambisa igesi.

6. I-MSS SP-75 - Umgangatho woMbutho weMigangatho yabavelisi ogxile kumandla aphezulu, ubukhulu besangqa setyhula kwimibhobho yentsimbi edityanisiweyo.

Ulawulo loMgangatho kunye neMigangatho yokuLungela kokusiNgqongileyo

1. I-NACE MR0175 / ISO 15156 - Iimfuno zezinto ezisetyenziselwa ukukhutshwa kweoli kunye negesi kwindawo enesulfure ene-hydrocarbon, leyo, ngelixa ijongene nokukhethwa kwezinto eziphathekayo, ibalulekile ekuqinisekiseni ukuxhathisa kwe-corrosion yezinto ezisetyenziswa kwi-oyile kunye ne-gas industry.

Iimveliso zethu ezinxulumeneyo

API 5L PSL1&PSL2 GR.B Longitudinal Submerged-arc Umbhobho oDidiweyo

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Umbhobho wentsimbi yeCarbon

API 5L GR.B Ukutyeka koDonga olunzima uMbhobho wentsimbi ongenamthungo wokuLungiswa koomatshini

I-API 5L Gr.X52N PSL 2 iSeamless Steel Pipe ACC.Ukuya kwi-IPS-M-PI-190(3) kunye ne-NACE MR-01-75 ngenkonzo emuncu

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 iOyile kunye neGas Carbon Umbhobho wentsimbi ongenamthungo

I-API 5L GR.B Umbhobho womgca ongenamthungo woxinzelelo kunye nolwakhiwo

I-API 5L/ASTM A106/ASTM A53 Gr.B Umbhobho wentsimbi yeCarbon engenamthungo

IBotopSteel yiNgcali yaseTshayinaImibhobho yentsimbi yeKhabhoni eDidiweyo uMvelisi & nababoneleliNgaphezulu kweminyaka eli-16 kunye neeToni ezingama-8000+ zombhobho womgca ongenamthungo kwiStokhwe kwiNyanga nganye.Sikulungele ukukuphendula kwiiyure ezininzi ezingama-24 kamsinya nje emva kokufumana isicelo esinye kunye nokuphuhlisa iingenelo ezingenamda kunye nombutho malunga nokunokwenzeka.

tags: API 56 46th, Dimensional Deviations, PSL1, PSL2,ababoneleli, abavelisi, iifektri, abagcini bempahla, iinkampani, ihoseyili, thenga, ixabiso, ikowuti, isambuku, ukuthengiswa, ixabiso.

Ixesha lokuposa: Mar-22-2024