AS/NZS 1163ichaza amacandelo abandayo, aqinileyo, anokuxhathisa, amacandelo entsimbi yolwakhiwo lwemibhobho yolwakhiwo jikelele kunye nezicelo zobunjineli ngaphandle konyango lobushushu olulandelayo.

Iinkqubo ezisemgangathweni ezisebenza e-Australia naseNew Zealand.

Amaqhosha okukhangela

Ukuhlelwa ngokweMilo yamacandelo ahlukeneyo

AS/NZS 1163 uHlelo lweBanga eliPhakathi

Impahla engekasilwa

Inkqubo yokuVelisa

AS / NZS 1163 Ukwakhiwa kweMichiza

AS/NZS 1163 Tensile Test

AS/NZS 1163 Uvavanyo lweMpembelelo

Uvavanyo olubandayo lokucaba

Uviwo olungonakalisi

Ukunyamezela kwiMilo kunye neMisa

Ukunyamezela Ubude

I-AS/NZS 1163 SSHS Uluhlu lobungakanani boMbhobho kunye neTayibhile zobunzima zibandakanyiwe

Ukulungiswa kweZiphene zangaPhandle kunye nezoKuthambisa

Iigalvanized

AS/NZS 1163 Ukumakisha

Usetyenziso lwe-AS/NZS 1163

Iimveliso zethu ezinxulumeneyo

Ukuhlelwa ngokweMilo yamacandelo ahlukeneyo

Iindidi ezintathu kwi-AS/NZS 1163 zinokuhlelwa ngokwemilo yecandelo lomnqamlezo, ezi:

Amacandelo angaphakathi kwisetyhula (CHS)

Amacandelo anomngxuma oxande (RHS)

Amacandelwana aMgongxo wesikwere (SHS)

Ingqwalasela yale nqaku kukushwankathela iimfuno zeetyhubhu zetsimbi ezinamacandelwana angenanto ajikelezayo.

AS/NZS 1163 uHlelo lweBanga eliPhakathi

Amabanga amathathu kwi-AS/NZS 1163 esekwe kowona mandla asezantsi esivuno (MPA) semveliso egqityiweyo:

C250, C350 kunye neC450.

Ngokuhambelana ne-0 ℃ inqanaba lovavanyo lwempembelelo yobushushu obuphantsi ukuba umbhobho wentsimbi unokudibana nawo:

C250L0, C350L0 kunye neC450L0.

Umgangatho ukwachaza ukuba indlela echanekileyo yokuvakalisa umgangatho wombhobho wentsimbi yile:

AS/NZS 1163-C250 or AS/NZS 1163-C250L0

Impahla engekasilwa

i-coil epholileyo eshushu okanye i-coil epholileyo

Ikhoyili eqengqelekayo ebandayo yikhoyili eqengqelekayo eshushu eye yaphantsi kokuncipha okuqengqelekayo okubandayo okungaphezulu kwe-15%.Ikhoyili iya kuba nomjikelo we-annealing subcritical ophinda uhlaziye isakhiwo kwaye wenze iinkozo ezintsha ze-ferrite.Iimpawu ezibangelwayo zifana nekhoyili eshushu.

I-fine-grained steel ichazwe njengento ekrwada kwiikhoyili zetsimbi.Iintsimbi ezinobukhulu obuziinkozo be-austenitic yenombolo 6 okanye ecolekileyo xa zivavanywa ngokuhambelana ne-AS 1733.

Le ntsimbi iveliswa yi-Basic Oxygen Method (BOS) okanye iinkqubo ze-Electric Arc Furnace (EAF) kwaye zingacocwa nge-Vacuum Arc Remelting (VAR), i-Electroslag Remelting (ESR), okanye ngeenkqubo zentsimbi yesibini ezifana ne-Vacuum Degassing okanye i-Calcium Injection. .

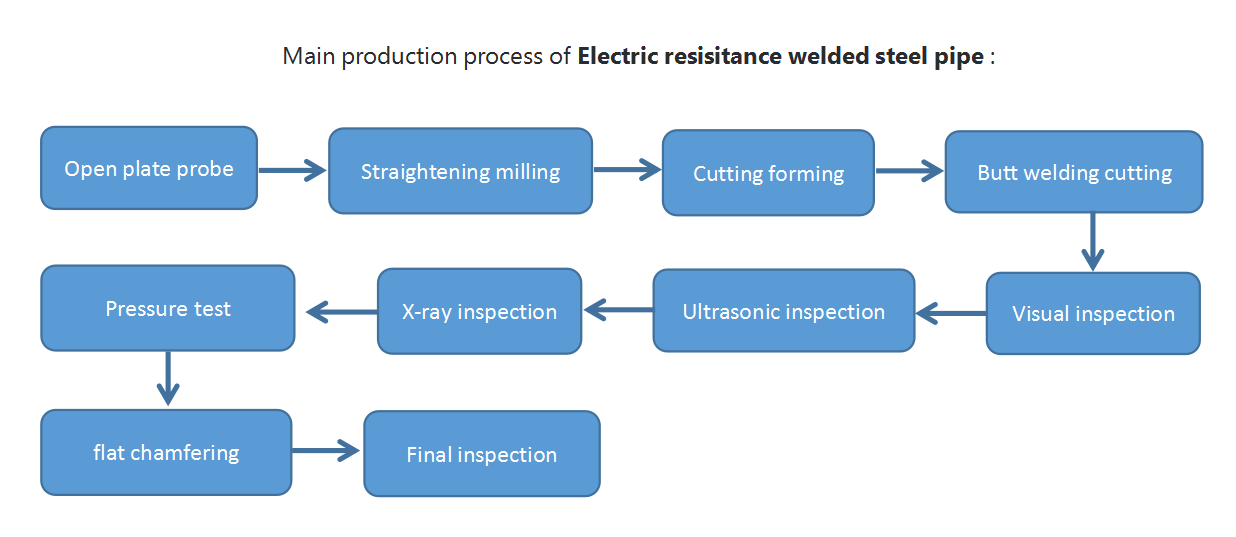

Inkqubo yokuVelisa

Imveliso egqityiweyo yecandelo elinomngxuma iya kwenziwa yinkqubo yokwenza ukubanda kunye nokusetyenziswaukuchaswa kombane (ERW)ubuchule bokudibanisa imiphetho yomcu.

I-weld seam kufuneka ibe yi-longitudinal kwaye iya kususwa ukuphazamiseka kwangaphandle.

Akusayi kubakho unyango olupheleleyo lobushushu kwimveliso egqityiweyo.

AS / NZS 1163 Ukwakhiwa kweMichiza

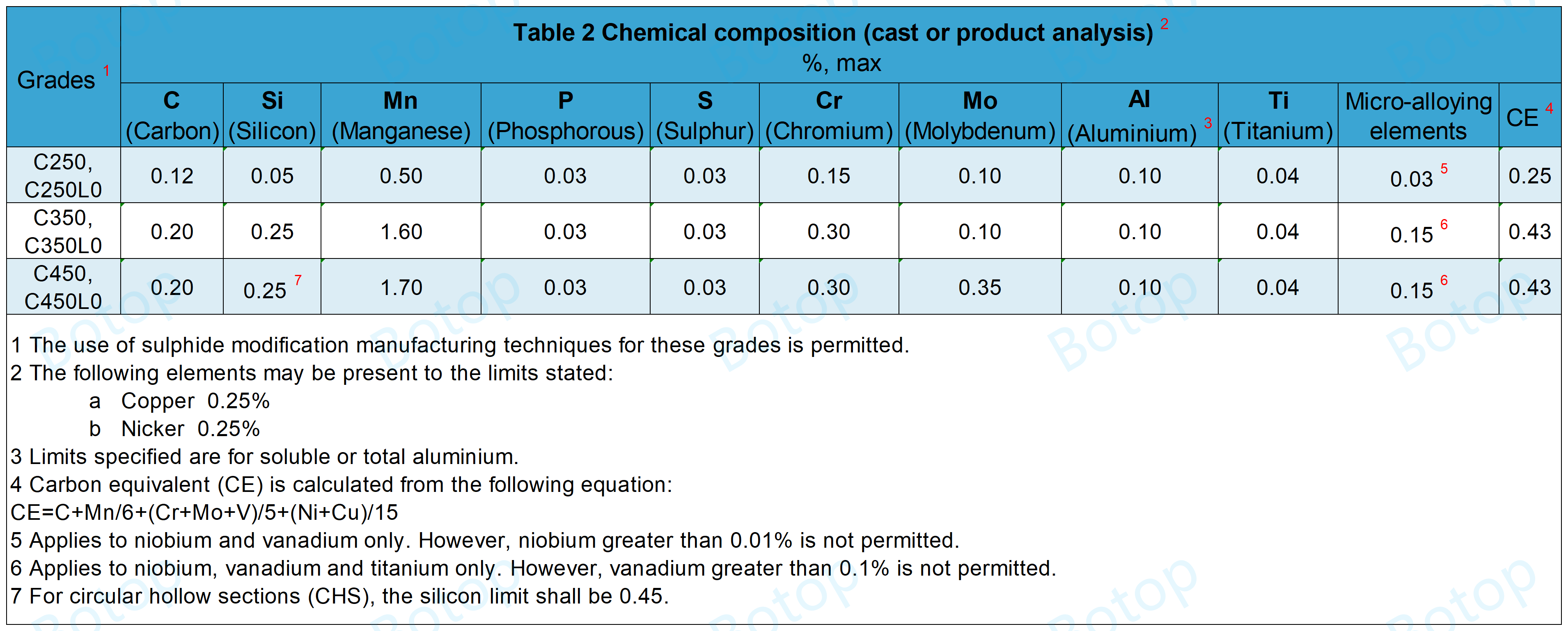

I-AS/NZS 1163 kuvavanyo lokwakheka kweekhemikhali yahlulwe ngamatyala amabini:

Imeko enye yimathiriyeli ekrwada yovavanyo lokwakheka kweekhemikhali,

enye igqityiwe ukuhlolwa kombhobho wentsimbi.

Ukuphosa Uhlalutyo lweNsimbi

Uhlalutyo olutyhidiweyo lwentsimbi luya kwenziwa kwiqondo lokushisa ngalinye ukumisela umlinganiselo wezinto ezichaziweyo.

Kwiimeko apho kungenakwenzeka ukufumana iisampulu kwintsimbi engamanzi, uhlalutyo kwiisampuli zovavanyo ezithathwe ngokuhambelana ne-AS/NZS 1050.1 okanye i-ISO 14284 inokuchazwa njengohlalutyo lokuphoswa.

Uhlalutyo olutyhidiweyo lwentsimbi luya kuhambelana nemida yebakala elifanelekileyo elinikezelweyoItheyibhile 2.

Uhlalutyo lweMichiza yeMveliso egqityiweyo

AS/NZS 1163ayigunyazisi ukuvavanywa kokwakheka kweekhemikhali kwimveliso yokugqibela.

Ukuba uvavanyo luyenziwa, kufuneka luhambelane nemida enikiweyoUluhlu lwesi-2kunye nokunyamezelana okunikezelweyoItheyibhile 3.

| ULUHLU 3 Ukunyamezela uhlalutyo lwemveliso kumabakala anikwe kwiThebhile yesi-2 | |

| Isiqalelo | Ukunyamezelana ngaphezu komda ophezulu |

| C(Ikhabhoni) | 0.02 |

| Si(Isilicon) | 0.05 |

| Mn(Manganese) | 0.1 |

| P(Phosphorous) | 0.005 |

| S(Sulphur) | 0.005 |

| Cr(Chromium) | 0.05 |

| Ni(Nickel) | 0.05 |

| Mo(Molybdenum) | 0.03 |

| Cu(Ubhedu) | 0.04 |

| AI(iAluminiyam) (iyonke) | -0.005 |

| Izinto ze-Micro-alloying (i-niobium kunye ne-vanadium kuphela) yeAmabanga C250, C250L0 | 0.06 kunye ne-niobium engekho ngaphezulu kwe-0.020 |

| I-Micro-alloying elements (i-niobium, i-vanadium, kunye ne-titanium kuphela) kumaBangaC350, C350L0, C450, C450L0 | 0.19 kunye ne-vanadium engekho ngaphezulu kwe-0.12 |

AS/NZS 1163 Tensile Test

Indlela yovavanyo: AS 1391.

Ngaphambi kovavanyo lwe-tensile, i-specimen iya kufudunyezwa kubushushu obungekho ngaphantsi kwe-15 min ngokufudumeza kubushushu obuphakathi kwe-150 ° C kunye ne-200 ° C.

| IBanga | Ubuncinane Yima kancinci amandla | Ubuncinane ukuqina amandla | Ubuncinane bobude njengomlinganiselo yobude begeyiji eyi-5.65√S0 | ||

| yenza/t | |||||

| ≤ 15 | >15 ≤30 | >30 | |||

| IMPA | IMPA | % | |||

| C250, C250L0 | 250 | 320 | 18 | 20 | 22 |

| C350, C350L0 | 350 | 430 | 16 | 18 | 20 |

| C450, C450L0 | 450 | 500 | 12 | 14 | 16 |

AS/NZS 1163 Uvavanyo lweMpembelelo

Indlela yovavanyo: kwi-0 ° C ngokwe-AS 1544.2.

Ngaphambi kovavanyo lwempembelelo, umzekelo uya kufudunyezwa ngokufudumeza phakathi kwe-150 ° C kunye ne-200 ° C engekho ngaphantsi kwe-15 min.

| IBanga | Uvavanyo lobushushu | Ubuncinci bamandla afunxayo, uJ | |||||

| Ubungakanani beqhekeza lovavanyo | |||||||

| 10mm×10mm | 10mm×7.5mm | 10mm×5mm | |||||

| I-avareji yeemvavanyo ezi-3 | Umntu ngamnye uvavanyo | I-avareji yeemvavanyo ezi-3 | Umntu ngamnye uvavanyo | I-avareji yeemvavanyo ezi-3 | Umntu ngamnye uvavanyo | ||

| C250L0 C350L0 C450L0 | 0℃ | 27 | 20 | 22 | 16 | 18 | 13 |

Uvavanyo olubandayo lokucaba

Isiqwenga sovavanyo siya kunyanzeliswa kude kube ngumgama phakathi kwemigangatho yi-0.75 yenza okanye ngaphantsi.

Ingabonisi zimpawu zeentanda okanye iziphene.

Uviwo olungonakalisi

Njengento enganyanzelwanga, i-welds kumacandelo angenanto yezakhiwo ezidibeneyo zinokuthi zibe phantsi koviwo olungonakalisi (NDE).

Ukunyamezela kwiMilo kunye neMisa

| Uhlobo | Uluhlu | Ukunyamezelana |

| Uphawu | - | Amacandelo ajikelezayo angenanto |

| imilinganiselo yangaphandle(yenza) | - | ±1%, ubuncinane ±0.5 mm kunye nobuninzi ±10 mm |

| Ukutyeba (t) | yenza≤406,4 mm | 土10% |

| ukuya >406.4 mm | ±10% kunye nobukhulu ±2 mm | |

| Ngaphandle kokujikeleza (o) | Idayamitha yangaphandle(bo)/ubukhulu bodonga(t)≤100 | ±2% |

| Ukuthe tye | ubude bubonke | 0.20% |

| Ubunzima (m) | ubunzima obuchaziweyo | ≥96% |

Ukutyeba:

Ubukhulu (t) buya kulinganiswa kwindawo engekho ngaphantsi kwe-2t (Intsingiselo ye-2x yodonga ubukhulu) okanye i-25 mm, nokuba yeyiphi encinci, ukusuka kwi-weld seam.

ngaphandle kokujikeleza:

Ukungaphandle komjikelo (o) kunikwa ngu:o=(yenzamax-yenzaimiz)/yenza×100

Ukunyamezela Ubude

| Uhlobo lobude | Uluhlu m | Ukunyamezelana |

| Ubude obungacwangciswanga | 4m ukuya 16m nge uluhlu lwe-2m nganye iodolo into | I-10% yamacandelo anikezelweyo anokuba ngaphantsi kobuncinane boluhlu oluodolweyo kodwa lungabi ngaphantsi kwe-75% yobuncinane |

| ubude obungachazwanga | ZONKE | 0-+100mm |

| Ubude obuchanekileyo | ≤ 6m | 0-+5mm |

| >6m ≤10m | 0-+15mm | |

| >10m | 0-+(5+1mm/m)mm |

I-AS/NZS 1163 SSHS Uluhlu lobungakanani boMbhobho kunye neTayibhile zobunzima zibandakanyiwe

Kwi-AS/NZS 1163, kubonelelwe ngoluhlu lwamacandelo aqhelekileyo olwakhiwo olunomngxuma oluqhelekileyo (SSHS) e-Australia naseNew Zealand.

Olu luhlu lubonelela ngamagama amacandelo, ubungakanani obufanelekileyo begama, iimpawu zecandelo, kunye neempawu.

| Ngaphandle Ububanzi | Ukutyeba | Masperunitlength | Ngaphandle indawo ephezulu | Umlinganiselo | |

| do | t | ngobude beyunithi nganye | ubunzima beyunithi nganye | ||

| mm | mm | kg/m | m²/m | m²/t | yenza/t |

| 610.0 | 12.7CHS | 187 | 1.92 | 10.2 | 48.0 |

| 610.0 | 9.5CHS | 141 | 1.92 | 13.6 | 64.2 |

| 610.0 | 6.4CHS | 95.3 | 1.92 | 20.1 | 95.3 |

| 508.0 | 12.7CHS | 155 | 1.60 | 10.3 | 40.0 |

| 508.0 | 9.5CHS | 117 | 1.60 | 13.7 | 53.5 |

| 508.0 | 6.4CHS | 79.2 | 1.60 | 20.2 | 79.4 |

| 457.0 | 12.7CHS | 139 | 1.44 | 10.3 | 36.0 |

| 457.0 | 9.5CHS | 105 | 1.44 | 13.7 | 48.1 |

| 457.0 | 6.4CHS | 71.1 | 1.44 | 20.2 | 71.4 |

| 406.4 | 12.7CHS | 123 | 1.28 | 10.4 | 32.0 |

| 406.4 | 9.5CHS | 93.0 | 1.28 | 13.7 | 42.8 |

| 406.4 | 6.4CHS | 63.1 | 1.28 | 20.2 | 63.5 |

| 355.6 | 12.7CHS | 107 | 1.12 | 10.4 | 28.0 |

| 355.6 | 9.5CHS | 81.1 | 1.12 | 13.8 | 37.4 |

| 355.6 | 6.4CHS | 55.1 | 1.12 | 20.3 | 55.6 |

| 323.9 | 2.7CHS | 97.5 | 1.02 | 10.4 | 25.5 |

| 323.9 | 9.5CHS | 73.7 | 1.02 | 13.8 | 34.1 |

| 323.9 | 6.4CHS | 50.1 | 1.02 | 20.3 | 50.6 |

| 273.1 | 9.3CHS | 60.5 | 0.858 | 14.2 | 29.4 |

| 273.1 | 6.4CHS | 42.1 | 0.858 | 20.4 | 42.7 |

| 273.1 | 4.8CHS | 31.8 | 0.858 | 27.0 | 56.9 |

| 219.1 | 8.2CHS | 42.6 | 0.688 | 16.1 | 26.7 |

| 219.1 | 6.4CHS | 33.6 | 0.688 | 20.5 | 34.2 |

| 219.1 | 4.8CHS | 25.4 | 0.688 | 27.1 | 45.6 |

| 168.3 | 71CHS | 28.2 | 0.529 | 18.7 | 23.7 |

| 168.3 | 6.4CHS | 25.6 | 0.529 | 20.7 | 26.3 |

| 168.3 | 4.8CHS | 19.4 | 0.529 | 27.3 | 35.1 |

| 165.1 | 5.4CHS | 21.3 | 0.519 | 24.4 | 30.6 |

| 165.1 | 5.0CHS | 19.7 | 0.519 | 26.3 | 33.0 |

| 165.1 | 3.5CHS | 13.9 | 0.519 | 37.2 | 47.2 |

| 165.1 | 3.0CHS | 12.0 | 0.519 | 43.2 | 55.0 |

| 139.7 | 5.4CHS | 17.9 | 0.439 | 24.5 | 25.9 |

| 139.7 | 5.0CHS | 16.6 | 0.439 | 26.4 | 27.9 |

| 139.7 | 3.5CHS | 11.8 | 0.439 | 37.3 | 39.9 |

| 139.7 | 3.0CHS | 10.1 | 0.439 | 43.4 | 46.6 |

| 114.3 | 6.0CHS | 16.0 | 0.359 | 22.4 | 19.1 |

| 114.3 | 5.4CHS | 14.5 | 0.359 | 24.8 | 21.2 |

| 114.3 | 4.8CHS | 13.0 | 0.359 | 27.7 | 23.8 |

| 114.3 | 4.5CHS | 12.2 | 0.359 | 29.5 | 25.4 |

| 114.3 | 3.6CHS | 9.83 | 0.359 | 36.5 | 31.8 |

| 114.3 | 3.2CHS | 8.77 | 0.359 | 41.0 | 35.7 |

| 101.6 | 5.0CHS | 11.9 | 0.319 | 26.8 | 20.3 |

| 101.6 | 4.0CHS | 9.63 | 0.319 | 33.2 | 25.4 |

| 101.6 | 3.2CHS | 7.77 | 0.319 | 41.1 | 31.8 |

| 101.6 | 2.6CHS | 6.35 | 0.319 | 50.3 | 39.1 |

| 88.9 | 5.9CHS | 12.1 | 0.279 | 23.1 | 15.1 |

| 88.9 | 5.0CHS | 10.3 | 0.279 | 27.0 | 17.8 |

| 88.9 | 5.5CHS | 11.3 | 0.279 | 24.7 | 16.2 |

| 88.9 | 4.8CHS | 9.96 | 0.279 | 28.1 | 18.5 |

| 88.9 | 4.0CHS | 8.38 | 0.279 | 33.3 | 22.2 |

| 88.9 | 3.2CHS | 6.76 | 0.279 | 41.3 | 27.8 |

| 88.9 | 2.6CHS | 5.53 | 0.279 | 50.5 | 34.2 |

| 76.1 | 5.9CHS | 10.2 | 0.239 | 23.4 | 12.9 |

| 76.1 | 4.5CHS | 7.95 | 0.239 | 30.1 | 16.9 |

| 76.1 | 3.6CHS | 6.44 | 0.239 | 37.1 | 21.1 |

| 76.1 | 3.2CHS | 5.75 | 0.239 | 41.6 | 23.8 |

| 76.1 | 2.3CHS | 4.19 | 0.239 | 57.1 | 33.1 |

| 60.3 | 5.4CHS | 7.31 | 0.189 | 25.9 | 11.2 |

| 60.3 | 4.5CHS | 6.19 | 0.189 | 30.6 | 13.4 |

| 60.3 | 3.6CHS | 5.03 | 0.189 | 37.6 | 16.8 |

| 48.3 | 5.4CHS | 5.71 | 0.152 | 26.6 | 8.9 |

| 48.3 | 4.0CHS | 4.37 | 0.152 | 34.7 | 12.1 |

| 48.3 | 3.2CHS | 3.56 | 0.152 | 42.6 | 15.1 |

| 42.4 | 4.9CHS | 4.53 | 0.133 | 29.4 | 8.7 |

| 42.4 | 4.0CHS | 3.79 | 0.133 | 35.2 | 10.6 |

| 42.4 | 3.2CHS | 3.09 | 0.133 | 43.1 | 13.3 |

Ukulungiswa kweZiphene zangaPhandle kunye nezoKuthambisa

Imbonakalo

Imveliso egqityiweyo ayinaziphene ezinobungozi kwingqibelelo yesakhiwo sezinto eziphathekayo.

Ukususwa kweziphene zoMphezulu

Xa iziphene ezingaphezulu zisuswa ngokusasaza, indawo enesanti iya kuba nenguqu elungileyo.

Ubunzima bodonga oluseleyo kwindawo enesanti abuyi kuba ngaphantsi kwe-90% yobukhulu obuqhelekileyo.

Ukulungiswa kweWeld yeziphene zoMphezulu

Iiwelds ziya kuvakala, i-weld idityaniswe ngokucokisekileyo ngaphandle kokusikwa ngaphantsi okanye ukuwelana.

Intsimbi ye-weld iya kuvelisa ubuncinci be-1.5 mm ngaphezu kwendawo eqengqelekayo kwaye isinyithi esibonakalayo siya kususwa ngokugungxula ngokugungxulwa komphezulu oqengqelekayo.

Iigalvanized

Amacandelo ajikelezileyo ajikelezileyo ajikelezileyo kunye nedayamitha yangaphandle ye ≤ 60.3 mm kunye namanye amacandelo amile anomgongxo wemilinganiselo elinganayo iya kukwazi ukumelana ne-90 ° bend malunga ne-grooved mandrel.

Utyatyazo lwegalvanized aluyi kubonakalisa iimpawu zokuqhekeka okanye iziphene emva komsebenzi wokugoba.

AS/NZS 1163 Ukumakisha

Oku kulandelayo kubonakala ubuncinane kanye kumbhobho wentsimbi wokumakisha.

(a) Igama lomenzi okanye uphawu, okanye zombini.

(b) Indawo yomenzi okanye isazisi sokusila, okanye zombini.

(c) Uchongo lwesicatshulwa esisodwa, esilandelekayo, esiya kuba ngenye okanye zombini kwezi ndlela zilandelayo:

(i) Ixesha kunye nomhla wokwenziwa kwemveliso.

(ii) Inombolo yesazisi elandelelanayo yolawulo lomgangatho/uqinisekiso kunye neenjongo zokulandelelwa.

Umzekelo:

BOTOP CHINA AS/NZS 1163-C350L0 457×12.7CHS×12000MM PIPE NO.001 HEAT NO.000001

Usetyenziso lwe-AS/NZS 1163

Ulwakhiwo lweZakhiwo zobuNjineli kunye nobuNjineli: Isetyenziswa kwizakhiwo zenkxaso yezakhiwo, ezifana nezakhiwo eziphakamileyo kunye namabala emidlalo.

IZibonelelo Zothutho: Zisetyenziswa ekwakhiweni kweebhulorho, iitonela, neziseko zikaloliwe.

I-oyile, irhasi, kunye nokwembiwa kwemigodi: isetyenziswa ekwakhiweni kwezixhobo zeoyile, izixhobo zemigodi, kunye neenkqubo ezinxulumeneyo zokuthutha.

Amanye amashishini anzima: kubandakanywa izakhiwo zesakhelo zezityalo zokuvelisa kunye noomatshini abanzima.

Iimveliso zethu ezinxulumeneyo

Singumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Tags: as/nzs 1163,chs, structural, erw, ababoneleli, abavelisi, iifektri, abagcini bempahla, iinkampani, ihoseyili, thenga, ixabiso, ikowuti, isambuku, intengiso, ixabiso.

Ixesha lokuposa: Apr-21-2024