ASTM A500 intsimbiyi-welded welded kunye ne-seamless carbon steel structural tubing ye-welded, riveted, okanye iibhulorho eziboshiweyo kunye nezakhiwo zokwakha kunye neenjongo zesakhiwo ngokubanzi.

Amaqhosha okukhangela

Imilo yeCandelo eliHoli

Ukuhlelwa kweBanga

Ubungakanani Uluhlu

Iimpahla ezingekasilwa

Iindlela Zokuvelisa

Tube End Type

Unyango lobushushu

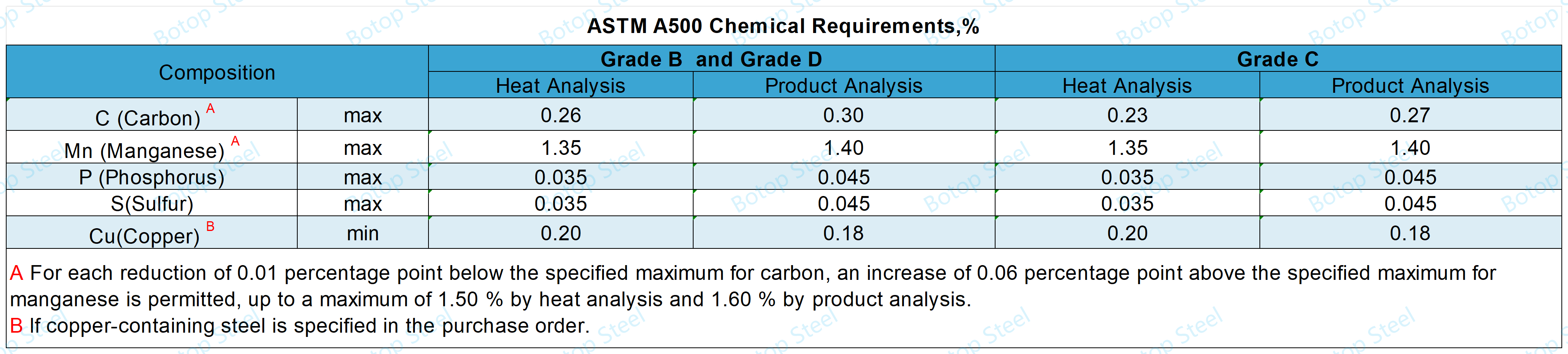

Ukuqulunqwa kwemichiza ye-ASTM A500

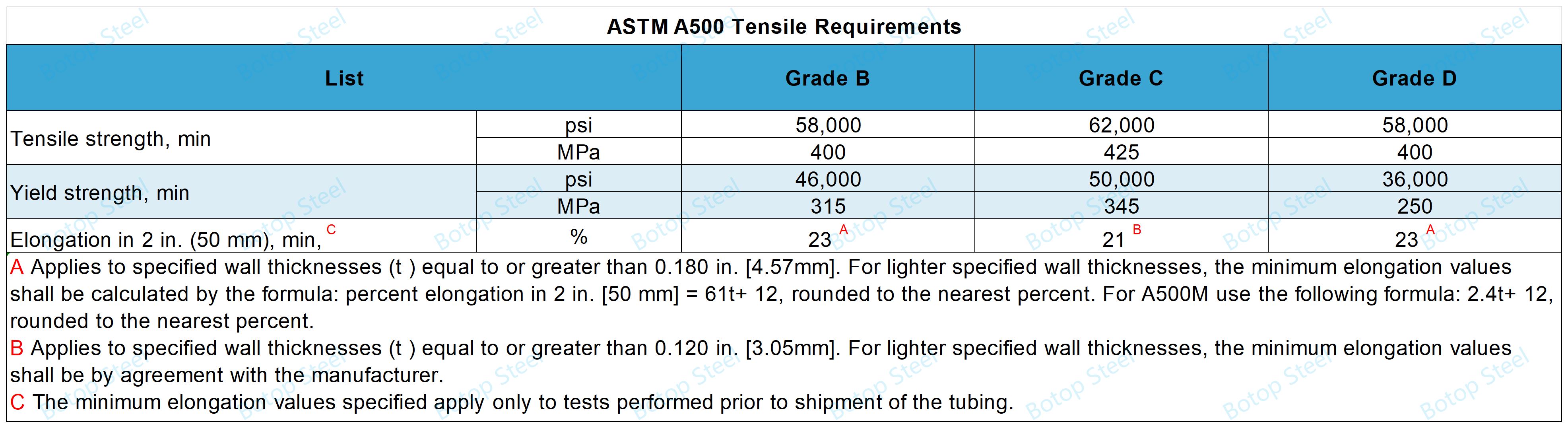

IiMfuno zeTensile ze-ASTM A500

Uvavanyo lokucaba

Uvavanyo oluvuthayo

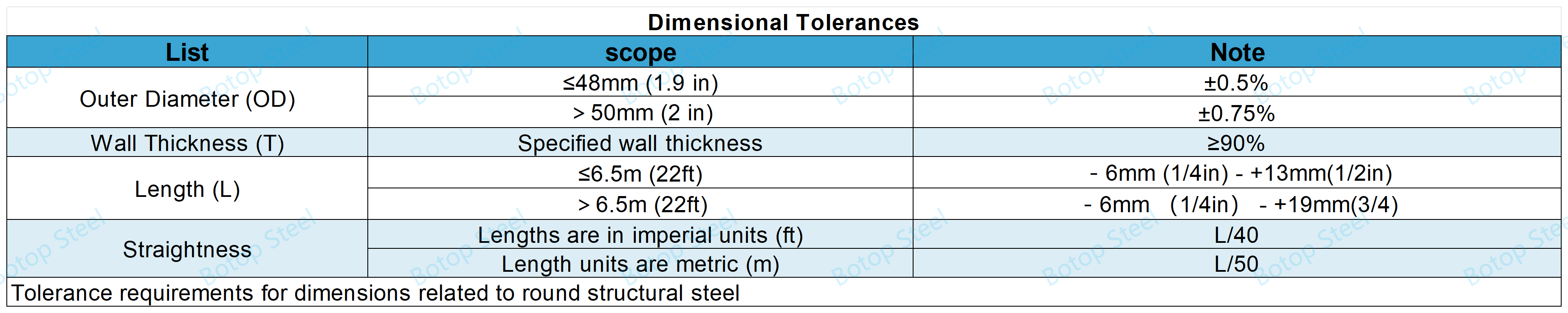

Unyamezelo lweDimensional ye-ASTM A500

Ukumakishwa kweThubhu

Usetyenziso lwe-ASTM A500

Izinto ezizezinye ze-ASTM A500

Iimveliso zethu ezinxulumeneyo

Imilo yeCandelo eliHoli

Inokuba njaloingqukuva, isikwere, uxande, okanye ezinye iimilo ezikhethekileyo zesakhiwo.

Eli nqaku lijolise kwiimfuno ze-ASTM A500 zentsimbi yesakhiwo esijikelezayo.

Ukuhlelwa kweBanga

I-ASTM A500 ihlela umbhobho wentsimbi ngokwamanqanaba amathathu,iBanga B, ibakala C, kunye nebakala D.

Kuyaphawuleka ukuba iinguqulelo zangaphambili ze-ASTM A500 nazo zineBanga A, elasuswa kuhlobo lwamva nje luka-2023.

Ubungakanani Uluhlu

Kwiityhubhu ezinobubanzi obungaphandle ≤ 2235mm [88in] kunye nobukhulu bodonga ≤ 25.4mm [1in].

Iimpahla ezingekasilwa

Intsimbi iya kwenziwa yinye okanye ngaphezulu kwezi nkqubo zilandelayo:i-oksijeni esisiseko okanye isithando somlilo sombane.

Inkqubo ye-Oxygen esisiseko: Le yindlela yanamhlanje ekhawulezayo yokuveliswa kwentsimbi, enciphisa umxholo wekhabhoni ngokuvuthela ioksijini kwintsimbi yehagu etyhidiweyo, ngelixa isusa ezinye izinto ezingafunekiyo ezifana nesulfure kunye nephosphorus. Kufanelekile ukuveliswa ngokukhawuleza kwezinto ezininzi zetsimbi.

Inkqubo yesithando soMbane: Inkqubo yeSithando soMbane isebenzisa i-arc yombane ephezulu yokushisa ukunyibilikisa i-scrap kunye nokunciphisa ngokuthe ngqo isinyithi, kwaye iluncedo ngokukhethekileyo ekuveliseni amabakala akhethekileyo kunye nokulawula iingoma ze-alloy, kunye nokuveliswa kwebhetshi encinci.

Iindlela Zokuvelisa

Inkqubo engenamthungo okanye i-welding.

I-Welded tubing iya kwenziwa kwi-flat-rolled steel ngenkqubo ye-electric-resistance-welding (ERW). I-weld seam kufuneka idityaniswe ukuze kuqinisekiswe amandla ombhobho.

Imibhobho eveliswa yinkqubo ye-welding ngokuqhelekileyo ayinayo i-weld yangaphakathi isuswe.

Tube End Type

Ukuba ayifunwa ngokuthe ngqo, iityhubhu zesakhiwo kufuneka zibeiphelilekwaye ucocekile kwii-burrs.

Unyango lobushushu

IBanga B kunye neBanga C

Inokukhutshwa okanye ithotywe uxinzelelo.

I-Anealing ifezekiswa ngokufudumeza ityhubhu kwiqondo lobushushu eliphezulu kwaye emva koko uyipholise kancinci. I-Annealing iphinda ihlengahlengise i-microstructure yezinto zokuphucula ukuqina kwayo kunye nokufana.

Ukunciphisa uxinzelelo ngokuqhelekileyo kwenziwa ngokufudumeza imathiriyeli kwiqondo lobushushu elisezantsi (elihlala lingaphantsi kunelo lokucoca) emva koko uyibambe ixesha elithile kwaye emva koko uyipholise. Oku kunceda ukuthintela ukuphazamiseka okanye ukuphuka kwezinto ngexesha lemisebenzi elandelayo efana ne-welding okanye ukusika.

IBanga D

Unyango lobushushu luyafuneka.

Kufuneka kwenziwe kwiqondo lobushushu ubuncinaneI-1100 ° F (590 ° C) ngeyure enye nge-25 mm ubukhulu bodonga.

Ukuqulunqwa kwemichiza ye-ASTM A500

Indlela yovavanyo: ASTM A751.

IiMfuno zeTensile ze-ASTM A500

Imizekelo iya kuhlangabezana neemfuno ezisebenzayo ze-ASTM A370, iSihlomelo A2.

Uvavanyo lokucaba

IMibhobho yeZakhiwo eDidiyelweyo

WeldduncedotEst: Ukusebenzisa i-specimen ubuncinane i-intshi ezi-4 (i-100 mm) ubude, thambisa umboniso nge-weld kwi-90 ° ukuya kwicala lokulayisha kude kube umgama phakathi kwamacwecwe ungaphantsi kwe-2/3 yobubanzi obungaphandle bombhobho. umfuziselo awuyi kuqhekeka okanye wophuke ngaphakathi okanye ngaphandle komphezulu ngexesha lenkqubo.

Uvavanyo lwe-ductility yombhobho: qhubeka uhlambulule i-specimen kude kube umgama phakathi kwamacwecwe ungaphantsi kwe-1/2 ye-diameter yangaphandle yombhobho. ngeli xesha, umbhobho akufanele ube nokuqhekeka okanye ukuphuka kwiindawo zangaphakathi nangaphandle.

IngqibelelotEst: Qhubeka uthambisa umfuziselo de kwenzeke ukwaphuka okanye de iimfuno zobunzima bodonga zihlangatyezwe. Ukuba ubungqina be-ply peeling, izinto ezingazinzanga, okanye i-welds engaphelelanga ifunyenwe ngexesha lovavanyo lwe-flattening, i-specimen iya kugwetywa ngokunganelisiyo.

Imibhobho yoLwakhiwo eRound engenamthungo

Ubude boMfanekiso: Ubude bomzekelo osetyenziselwa uvavanyo abuyi kuba ngaphantsi kwe-2 1/2 kwi-(65 mm).

Uvavanyo lweDuctility: Ngaphandle kokuqhekeka okanye ukuqhekeka, i-specimen iyancipha phakathi kwamacwecwe ahambelanayo de umgama phakathi kwamacwecwe ungaphantsi kwexabiso elithi "H" elibalwe ngolu hlobo lulandelayo:

H=(1+e)t/(e+t/D)

H = umgama phakathi kweepleyiti ezicaba, ngaphakathi [mm],

e= deformation ngobude beyunithi nganye (ngokuqhubekayo kwibakala elinikiweyo lentsimbi, 0.07 kwiBanga B, kunye no-0.06 kwiBanga C),

t= ubukhulu bodonga obuchaziweyo betyhubhu, ngaphakathi. [mm],

D = icaciswe ngaphandle kwedayamitha yetyhubhu, ngaphakathi [mm].

IngqibelelotEst: Qhubeka ucoca isampuli de isampuli iphuke okanye iindonga ezichaseneyo zesampulu zihlangane.

Ukusilelacriteria: I-laminar peeling okanye izinto ezibuthathaka ezifunyenwe kulo lonke uvavanyo oluthe tyaba luya kuba zizizathu zokukhatywa.

Uvavanyo oluvuthayo

Uvavanyo oluvuthayo luyafumaneka kwiityhubhu ezijikelezayo ≤ 254 mm (10 in) ububanzi, kodwa akunyanzelekanga.

Unyamezelo lweDimensional ye-ASTM A500

Ukumakishwa kweThubhu

Olu lwazi lulandelayo kufuneka lubandakanywe:

Igama lomenzi: Oku kunokuba ligama elipheleleyo lomenzi okanye isifinyezo.

Uphawu okanye uphawu loRhwebo: Igama lebrendi okanye uphawu lwentengiso olusetyenziswa ngumenzi ukwahlula iimveliso zalo.

Iinkcukacha zoMyili: ASTM A500, ekungafunekiyo iquke unyaka wokupapashwa.

Ileta yeBanga: B, C okanye ibakala D.

Kwiityhubhu zesakhiwo ≤ 100mm (4in) ububanzi, iilebula zingasetyenziselwa ukuphawula ulwazi lokuchongwa ngokucacileyo.

Usetyenziso lwe-ASTM A500

Ngenxa yeempawu zayo ezigqwesileyo zoomatshini kunye ne-weldability, umbhobho wensimbi we-ASTM A500 usetyenziswa kwiintlobo ngeentlobo zezakhiwo apho kufuneka ukuqina kunye namandla.

Ukwakhiwa: Isetyenziselwa ukuxhasa izakhiwo zokwakha ezifana neenkqubo zokumisa, izakhiwo zophahla, izakhi zoyilo lwe-arch, kunye neentsika ezingqukuva.

Ukwakhiwa kwebhulorho: Kwizinto zesakhiwo seebhulorho, ezifana nesetyhula iikholomu ezithwele umthwalo kunye neetrasi zeebhulorho.

Iziseko zemizi-mveliso: Kwizakhiwo ezinkulu zoshishino ezifana nezixhobo ze-oyile kunye negesi, izityalo zekhemikhali, kunye nezixhobo zetsimbi, iityhubhu zetsimbi ezijikelezayo zisetyenziselwa ukwakha izakhiwo zenkxaso kunye nemibhobho yokuhambisa.

Iinkqubo zothutho: Ngeendawo zeempawu zendlela, iipali zokukhanya, kunye neenqwelo zokugada.

Ukwenziwa koomatshini: Njengenxalenye yoomatshini kunye nezixhobo ezinzima, ezinje ngoomatshini bezolimo, izixhobo zemigodi, kunye noomatshini bokwakha.

Izinto eziluncedo: Isetyenziswe kwimibhobho yamanzi, igesi, iimveliso zepetroleum, njl., kunye nemibhobho yokukhusela ucingo kunye nentambo.

Amaziko ezemidlalo: Ekwakhiweni kweendawo zezemidlalo, iibhubhu zetsimbi ezijikelezayo zisetyenziselwa ukwenza i-bleachers, iinqaba zokukhanyisa, kunye nezinye izakhiwo zokuxhasa.

Ifenitshala kunye nokuhombisa: Iityhubhu zentsimbi ezijikelezayo zisetyenziselwa ukwenza ifenitshala yentsimbi, njengemilenze yeetafile kunye nezitulo, kunye nezinto zokuhombisa kuyilo lwangaphakathi lwangoku.

Iinkqubo zocingo kunye neziporo: Isetyenziswa njengezithuba zokubiyela kunye neenkqubo zomzila weziporo, ingakumbi apho amandla olwakhiwo kunye nokuqina kufuneka.

Izinto ezizezinye ze-ASTM A500

I-ASTM A501: Lo ngumgangatho wokutshisa i-carbon steel structural tubing, efana ne-ASTM A500, kodwa iyasebenza kwinkqubo yokuvelisa i-hot-forming process.

I-ASTM A252: Umgangatho wemibhobho yentsimbi yokusetyenziswa kwisiseko kunye nomsebenzi wokupakisha.

I-ASTM A106: Umbhobho we-carbon steel umthungo, osetyenziswa ngokuqhelekileyo kwiindawo ezinobushushu obuphezulu.

I-ASTM A53: Olunye uhlobo lwebhobho yensimbi ye-carbon yoxinzelelo kunye nezicelo zomatshini, ezisetyenziswa ngokubanzi kwiinkqubo zokudlulisa ulwelo.

EN 10210: EYurophu, umgangatho we-EN 10210 uchaza iimeko zokunikezelwa kobugcisa kumacandelo akhiweyo ashushu, aneendawo ezifanayo zesicelo kwi-ASTM A500.

CSA G40.21: Umgangatho waseKhanada obonelela ngoluhlu olubanzi lweentsimbi ezisemgangathweni kwimigangatho eyahlukeneyo yamandla angasetyenziselwa izicelo ezifanayo.

I-JIS G3466: IMigangatho yoShishino yaseJapan yesikwere kunye neetyhubhu ezixande zekhabhoni yentsimbi yokusetyenziswa kwesakhiwo ngokubanzi.

IS 4923: Umgangatho wamaNdiya wamacandelo angaphakathi adityanisiweyo okanye angenamthungo entsimbi yekhabhoni.

AS/NZS 1163: Imigangatho yase-Australia kunye neNew Zealand yeetyhubhu zentsimbi yesakhiwo kunye namacandelo angenalutho.

Iimveliso zethu ezinxulumeneyo

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo yayo egqwesileyo, iimveliso ezikumgangatho ophezulu kunye nezisombululo ezibanzi. Uluhlu olubanzi lwemveliso yenkampani lubandakanya i-seamless, i-ERW, i-LSAW, kunye nemibhobho yentsimbi ye-SSAW, kunye nokufakelwa kwemibhobho, ii-flanges, kunye neentsimbi ezizodwa.

Ngokuzibophezela okuqinileyo kumgangatho, iBotop Steel isebenzisa ulawulo olungqongqo kunye neemvavanyo zokuqinisekisa ukuthembeka kweemveliso zayo. Iqela layo elinamava libonelela ngezisombululo zobuqu kunye nenkxaso yeengcali, kugxilwe ekwanelisekeni kwabathengi.

Iithegi: astm a500, astm a500 grade b, astm a500 grade c, astm a500 grade d.

Ixesha lokuposa: May-04-2024