ASTM A513 intsimbingumbhobho we-carbon kunye ne-alloy steel pipe kunye ne-tube eyenziwe kwintsimbi eshushu-eshushu okanye epholileyo njengento ekrwada ngenkqubo yokumelana nombane (ERW), esetyenziswa ngokubanzi kuzo zonke iintlobo zezakhiwo zomatshini.

Amaqhosha okukhangela

Iindidi kunye neeMeko zoThermal ze-ASTM A513

Ukuhlelwa kweBanga

ASTM A513 Ubungakanani Range

Imilo yeCandelo eliHoli

Iimpahla ezingekasilwa

Iinkqubo zokwenziwa kwe-ASTM A513

Unyango olushushu

Ukuphatha i-Welding Seam

Ukuqulunqwa kwemichiza ye-ASTM A513

IiPropati zoomatshini ze-ASTM A513

Uvavanyo lobulukhuni

Uvavanyo lokucaba

Uvavanyo oluvuthayo

Uvavanyo lwe-Hydrostatic Round Tubing

Uvavanyo loMbane olungonakaliyo

Ukunyamezelwa koBume beMibhobho eRound

Ukunyamezela kweSikwere kunye neRectangular Tube Dimensions

Imbonakalo

Ukwaleka

Ukumakisha

Usetyenziso lwe-ASTM A513

Izinto Eziluncedo Zethu

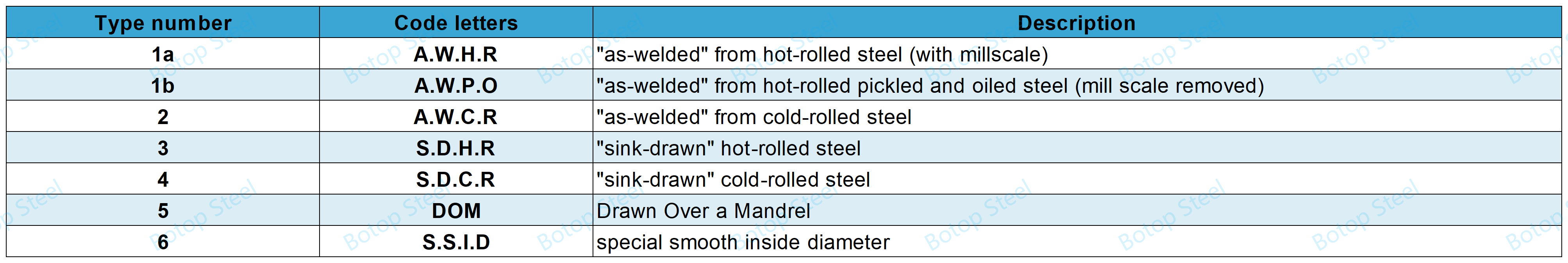

Iindidi kunye neeMeko zoThermal ze-ASTM A513

Ukwahlula kusekelwe kwiimeko ezahlukeneyo okanye iinkqubo zombhobho wensimbi.

Ukuhlelwa kweBanga

I-ASTM A513 ingaba yi-carbon okanye i-alloy steel, kuxhomekeke kwisicelo sangempela.

Intsimbi yeCarbon

MT 1010, MT 1015, MT X 1015, MT 1020, MT X 1020.

1006, 1008, 1009, 1010, 1012, 1015, 1016, 1017, 1018, 1019, 1020, 1021, 1022, 1023, 1024, 1026, 1025,1 1033, 1035, 1040, 1050, 1060, 1524.

Iintsimbi zentsimbi

1340, 4118, 4130, 4140, 5130, 8620, 8630.

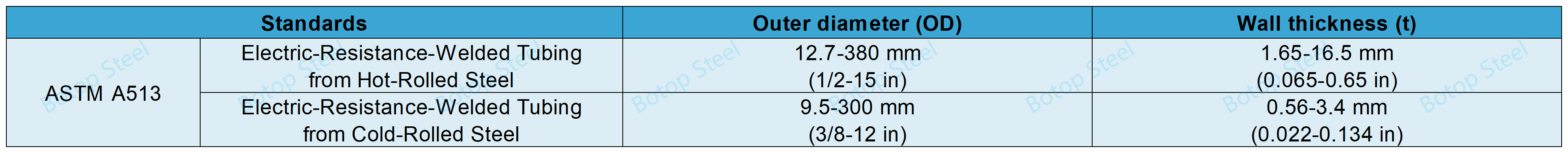

ASTM A513 Ubungakanani Range

Imilo yeCandelo eliHoli

Umjikelo

Isikwere okanye uxande

Ezinye iimilo

ezifana ne-streamlined, i-hexagonal, i-octagonal, ingqukuva ngaphakathi kunye ne-hexagonal okanye i-octagonal ngaphandle, i-ribbed ngaphakathi okanye ngaphandle, i-triangular, i-rectangular engqukuva kunye neemilo zika-D.

Iimpahla ezingekasilwa

Intsimbi inokwenziwa ngayo nayiphi na inkqubo.

Ukunyibilika okuphambili kunokubandakanya ukuchithwa kwegesi okwahlukileyo okanye ukucocwa kwaye kunokulandelwa kukunyibilika kwesibini, njenge-electro slag okanye i-vacuum-arc remelting.

Intsimbi inokuphoswa kwiingothi okanye iphoswe ngomsonto.

Iinkqubo zokwenziwa kwe-ASTM A513

Iityhubhu ziya kwenziwa yiUkumelana nombane (ERW)inkqubo kwaye iya kwenziwa kwintsimbi eshushu-eshushu okanye ebandayo njengoko kuchaziwe.

Umbhobho we-ERW yinkqubo yokwenza i-weld ngokudibanisa izinto zetsimbi kwi-cylinder kunye nokusebenzisa ukuxhathisa kunye noxinzelelo kunye nobude bayo.

Intsimbi eQithiweyo: Kwinkqubo yokuvelisa, insimbi eshushu ishushu iqala ukushisa kwiqondo lokushisa eliphezulu, ivumela ukuba insimbi ifakwe kwisimo seplastiki, okwenza kube lula ukutshintsha imilo kunye nobukhulu bentsimbi. Ekupheleni kwenkqubo eshushu yokuqengqeleka, izinto eziphathekayo zidla ngokulinganiswa kwaye zikhubazeke.

Intsimbi eBanda-Rolwe: Intsimbi epholileyo iqengqeleka ngakumbi emva kokuba izinto zipholile ukufezekisa ubungakanani obufunwayo kunye nemilo. Le nkqubo idla ngokuqhutyelwa kwiqondo lokushisa legumbi kwaye ibangele intsimbi enomgangatho ongcono wendawo kunye nemilinganiselo echanekileyo.

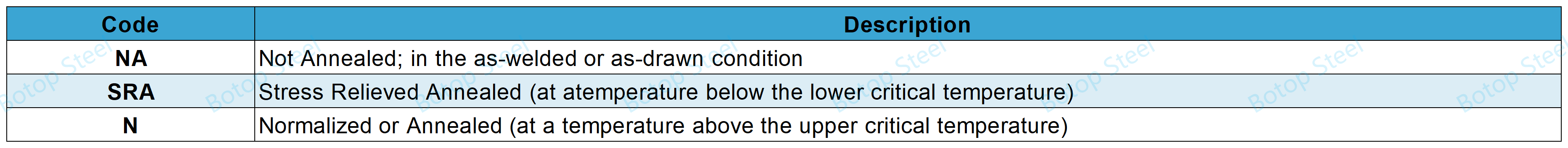

Unyango olushushu

Xa imeko ye-thermal ingachazwanga, ityhubhu inokunikezelwa kwimeko ye-NA.

Xa unyango lokugqibela lwe-thermal lucacisiwe, i-oxide eqinile iyinto eqhelekileyo.

Xa i-oxide-free surface icacisiwe, ityhubhu inokugqama i-annealed okanye i-pickled kwinketho yomenzi.

Ukuphatha i-Welding Seam

Iiwelds zangaphandle kufuneka zicocwe

Iiwelds zangaphakathi ziya kuba neemfuneko zobude obuhlukeneyo ngokuxhomekeke kuHlobo.

Iimfuno ezicacileyo zinokufumaneka kwi-ASTM A513, icandelo 12.3.

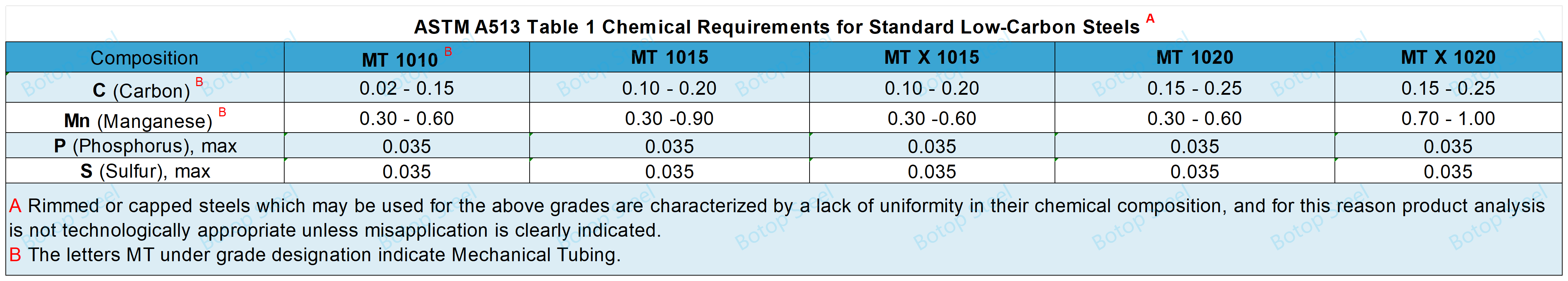

Ukuqulunqwa kwemichiza ye-ASTM A513

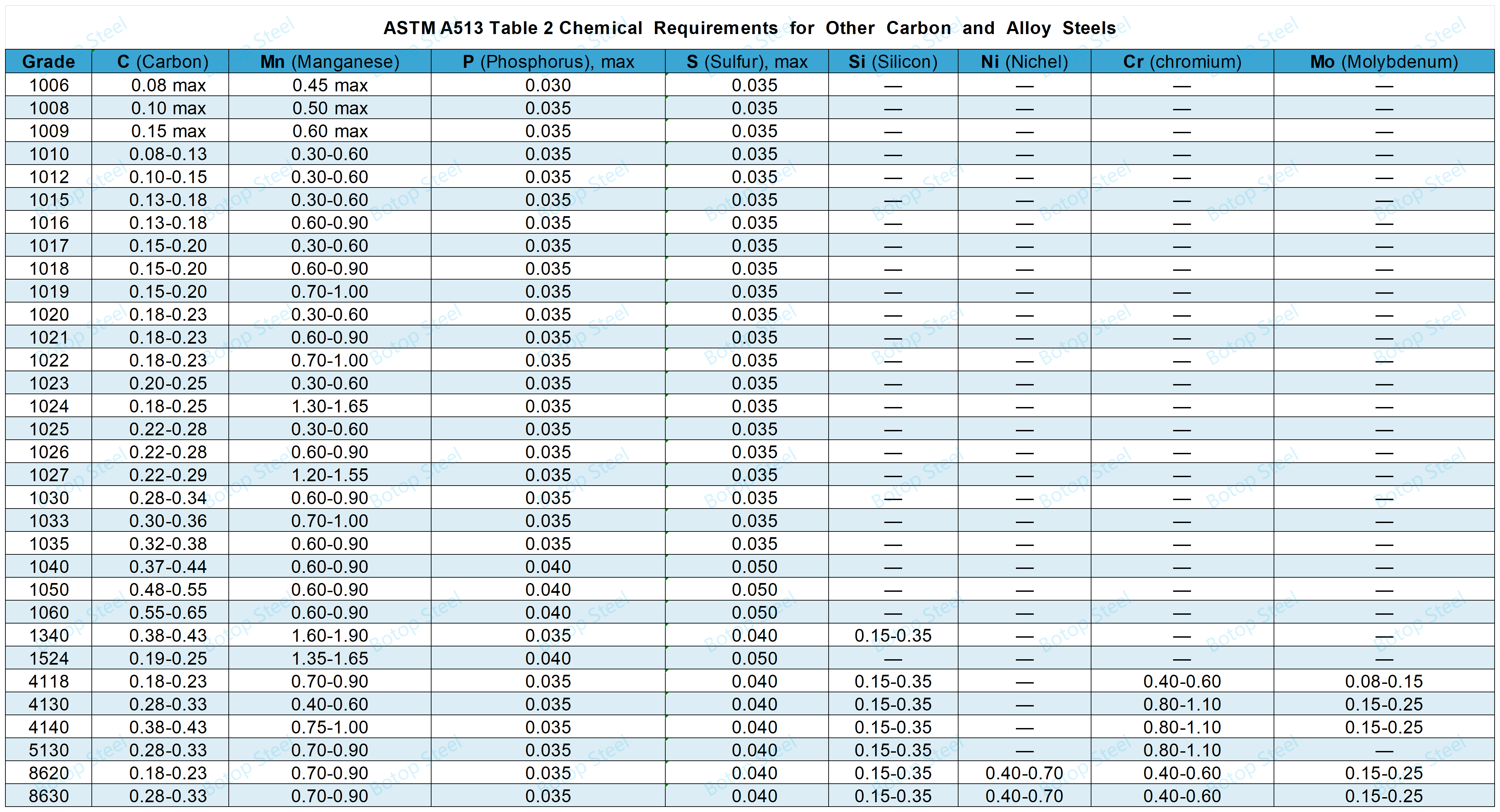

Intsimbi iya kuhambelana neemfuno zokwakheka kweekhemikhali ezichazwe kwiThebhile 1 okanye kwiTheyibhile 2.

Xa amabakala e-carbon steel ayala ukusuka kumgangatho, akuvumelekanga ukubonelela ngamabakala e-alloy abiza ngokukodwa ukongezwa kwayo nayiphi na into ngaphandle kwalawo adweliswe kwiTables I kunye ne-2.

Ukuba akukho bakala lichaziweyo, amabakala MT 1010 ukuya kuMT 1020 ayafumaneka.

IiPropati zoomatshini ze-ASTM A513

Uvavanyo lokuqina luya kwenziwa kube kanye ngeqashiso ngalinye.

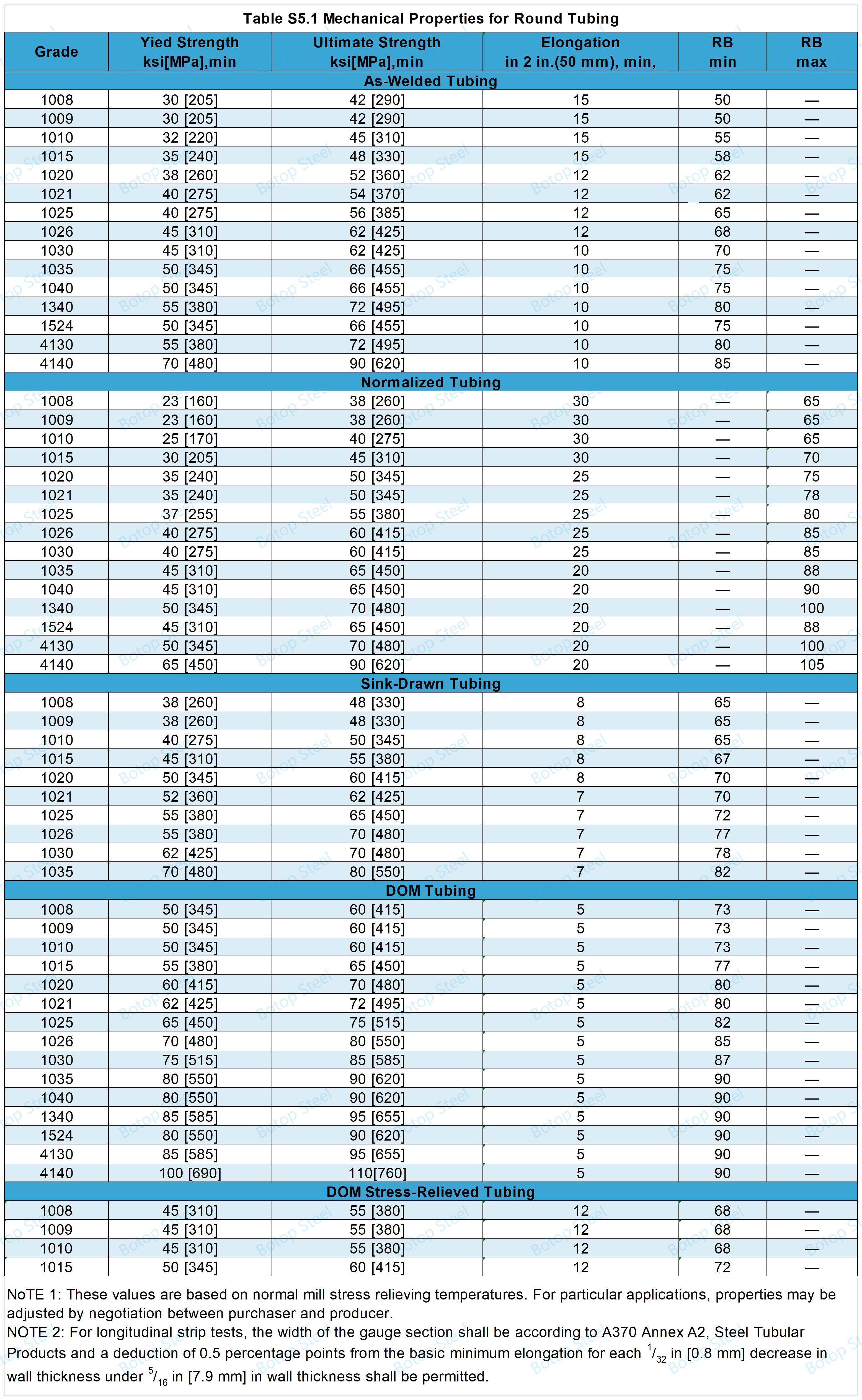

Xa "IiPropati eziFunekayo zokuqina" zichazwe kuMyalelo wokuThenga, iityhubhu engqukuva iya kuhambelana neemfuno zokuqina kwaye hayi ngokuyimfuneko kwimida yobulukhuni eboniswe kwiThebhile 5.

Uvavanyo lobulukhuni

I-1% yazo zonke iibhubhu kwiqashiso ngalinye kwaye ingabi ngaphantsi kweetyhubhu ezi-5.

Uvavanyo lokucaba

Iityhubhu ezingqukuva kunye neetyhubhu ezenza ezinye iimilo xa zingqukuva ziyasebenza.

Akukho kuvuleka kwi-weld kuya kwenzeka de umgama phakathi kweepleyiti ube ngaphantsi kwesibini esithathwini sedayamitha yangaphandle yangaphandle yetyhubhu.

Akukho zintanda okanye ukuqhekeka kwisiseko sesinyithi kuya kwenzeka kude kube umgama phakathi kweepleyiti ungaphantsi kwesinye kwisithathu sedayamitha yangaphandle ye-tubing kodwa akukho meko ingaphantsi kwamahlanu ubukhulu bodonga lwe-tubing.

Ubungqina bezinto ezitshisiweyo okanye ezitshisiweyo aziyi kuphuhliswa ngexesha lenkqubo yokuthambisa, kwaye i-weld ayiyi kubonakalisa iziphene ezilimazayo.

Qaphela: Xa ityhubhu ephantsi ye-D-to-t ivavanywa, ngenxa yokuba ubunzima obubekwe ngenxa yejometri buphezulu ngokungekho ngqiqweni kumphezulu wangaphakathi kwindawo yesithandathu neyeshumi elinesibini, iintanda kwezi ndawo aziyi kuba yimbangela yokwaliwa ukuba umlinganiselo we-D-to-t ungaphantsi kwe-10.

Uvavanyo oluvuthayo

Iityhubhu ezingqukuva kunye neetyhubhu ezenza ezinye iimilo xa zingqukuva ziyasebenza.

Icandelo letyhubhu elimalunga ne-4 ku-.[100 mm] ubude liya kuma livutha ngesixhobo esine-angle engama-60 equkiweyo de umbhobho osemlonyeni wedangatya lonwenwe nge-15 % yobubanzi obungaphakathi, ngaphandle kokuqhekeka okanye ukubonisa iziphene.

Uvavanyo lwe-Hydrostatic Round Tubing

Zonke iityhubhu ziya kunikwa uvavanyo lwe-hydrostatic.

Gcina ubuncinci boxinzelelo lwe-hydro test ungekho ngaphantsi kwe-5s.

Uxinzelelo lubalwa ngolu hlobo:

P=2St/D

P= ubuncinci boxinzelelo lovavanyo lwe-hydrostatic, i-psi okanye iMPa,

S= uxinzelelo lwefiber oluvumelekileyo lwe-14,000 psi okanye i-96.5 MPa,

t= ubukhulu bodonga obuchaziweyo, ngaphakathi okanye mm,

D= icaciswe ngaphandle kwedayamitha, ngaphakathi okanye mm.

Uvavanyo loMbane olungonakaliyo

Yinjongo yolu vavanyo ukugatya iityhubhu ezineziphene eziyingozi.

ityhubhu nganye iya kuvavanywa ngovavanyo lombane olungonakalisiyo ngokuhambelana ne-Practice E213, Practice E273, Practice E309, or Practice E570.

Ukunyamezelwa koBume beMibhobho eRound

Ngolwazi oluthe kratya, nceda ubone itafile ehambelanayo kumgangatho.

Ububanzi bangaphandle

Uluhlu lwesi-4Unyamezelo lweDayimitha yoHlobo lwe-I (AWHR) i-Round Tubing

Uluhlu 5Ukunyamezelwa kweDiameter kwiintlobo ze-3, 4, 5, kunye ne-6 (SDHR, SDCR, DOM, kunye ne-SSID) i-Round Tubing

Uluhlu lwe-10Ukunyamezelwa kweDiameter ye-Type ye-2 (AWCR) i-Round Tubing

Ukutyeba kweendonga

Uluhlu 6Unyamezelo loButyenene beDonga kuHlobo loku-I (AWHR) lweTubhing eRound (Iintshi zeeYunithi)

Uluhlu 7Unyamezelo loButyenene beDonga kuHlobo loku-I (AWHR) lweMibhobho eRound (iiYunithi ze-SI)

Uluhlu lwesi-8Ukunyamezelwa koDonga lweeNdidi ze-5 kunye ne-6 (i-DOM kunye ne-SSID) i-Round Tubing (ii-Inch Units)

ULUHLU 9Ukunyamezelwa koDonga lweeNdidi ze-5 kunye ne-6 (i-DOM kunye ne-SSID) i-Round Tubing (iiyunithi ze-SI)

Uluhlu 11Unyamezelo lokutyeba kweDonga kuHlobo lwesi-2 (AWCR) lweTubhing eRound (Iiyunithi ze-intshi)

Uluhlu 12Unyamezelo lokutyeba kweDonga kuHlobo lwesi-2 (AWCR) lweMibhobho eRound (iiYunithi zeSI)

Ubude

Uluhlu 13Ukunyamezelwa koBunde bokuSika kwi-Lathe-Cut Round Tubing

Uluhlu 14Ukunyamezela Ubude bePunch-, Saw-, okanye Disc-Sika Round Tubing

Squareness

Uluhlu lwe-15Ukunyamezelana (i-intshi) ye-Squareness of Cut (Nayiphi na isiphelo) Xa icacisiwe kwi-Round Tubing

Ukunyamezela kweSikwere kunye neRectangular Tube Dimensions

Ngolwazi oluthe kratya, nceda ubone itafile ehambelanayo kumgangatho.

Ububanzi bangaphandle

Uluhlu 16Ukunyamezelwa, iMilinganiselo yangaphandle yesikwere kunye neTubing exande

IRadii yeekona

Uluhlu 17I-Radii yeeKona zoMbane-Ukumelana-i-Welded Square kunye ne-Rectangular Tubing

Ubude

Uluhlu lwe-18Ukunyamezelwa koBude-Isikwere kunye neTubing yeRectangular

Ukujija Ukunyamezela

Uluhlu lwe-19Ukunyamezelwa kwe-Twist-Resistance-Welded for Square kunye neRectangular-Mechanical Tubing

Imbonakalo

Ityhubhu mayingabi naziphene kwaye iya kuba nesiphelo esifana nomsebenzi.

Ukwaleka

Iityhubhu ziya kugqunywa ngefilim yeoli phambi kokuba ithunyelwe ngenqanawa ukunqanda umhlwa.

Ikhusela umhlwa ukuba ungenzeki ngexesha elifutshane.

Ukuba umyalelo uchaza ukuba iityhubhu ithunyelwe ngenqanawa ngaphandle kwe-oyile ebambe umhlwa, ifilimu yee-oyile ezenziweyo iya kuhlala phezu komhlaba.

Ukumakisha

Umphezulu wentsimbi uphawulwe ngokusebenzisa indlela efanelekileyo kwaye iqulethe ulwazi olulandelayo:

Igama lomenzi okanyeuphawu

Ubungakanani obuchaziweyo

Uhlobo

inombolo yeodolo yomthengi,

Inombolo yomgangatho, ASTM A513.

Iikhowudi zebhakhowudi zingasetyenziswa njengendlela yokuchonga ehambelanayo.

Usetyenziso lwe-ASTM A513

Ushishino lweemoto: Isetyenziswa kwiifreyimu zezihlalo zeemoto, izinto zokunqunyanyiswa, iikholamu zokuqhuba, izibiyeli, kunye nezinye izinto zesakhiwo sesithuthi.

Ishishini lokwakha: njengezinto ezixhasayo kwizakhiwo zokwakha, ezifana neetyhubhu ze-scaffolding, i-guardrails, i-railings, njl.

Oomatshinimukuvelisa: Isetyenziselwa ukuveliswa kwamacandelo ahlukeneyo omatshini, njengamasilinda e-hydraulic system, iindawo ezijikelezayo, iibheringi, njalo njalo.

Izixhobo zezolimo: Kwimveliso yoomatshini bezolimo, abasetyenziselwa ukwenza iinxalenye zesakhiwo sezixhobo zokulima, iinkqubo zokuhambisa, njl.

Ukwenziwa kweFenitshala: Isetyenziselwa ukuveliswa kwefenitshala yentsimbi eyahlukeneyo, njengamathala eencwadi, iifreyimu zesitulo, iibhedi zebhedi, njalo njalo.

Izixhobo zezemidlalo: kumaziko ezemidlalo kunye nokuveliswa kwezixhobo, ezisetyenziswa njengeentsimbi zentsimbi, njengezixhobo zokufaneleka, iinjongo ze-basketball, iinjongo zebhola, njl.

Izibonelelo zemizi-mveliso: isetyenziswe ekwenzeni amabhanti okuhambisa, iirola, iitanki, kunye nezinye izixhobo zemizi-mveliso.

Izinto Eziluncedo Zethu

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo yayo egqwesileyo, iimveliso ezikumgangatho ophezulu kunye nezisombululo ezibanzi. Uluhlu olubanzi lwemveliso yenkampani lubandakanya i-seamless, i-ERW, i-LSAW, kunye nemibhobho yentsimbi ye-SSAW, kunye nokufakelwa kwemibhobho, ii-flanges, kunye neentsimbi ezizodwa.

Ngokuzibophezela okuqinileyo kumgangatho, iBotop Steel isebenzisa ulawulo olungqongqo kunye neemvavanyo zokuqinisekisa ukuthembeka kweemveliso zayo. Iqela layo elinamava libonelela ngezisombululo zobuqu kunye nenkxaso yeengcali, kugxilwe ekwanelisekeni kwabathengi.

Iithegi: ASTM A513, carbon steel, uhlobo 5, uhlobo 1, dom.

Ixesha lokuposa: May-07-2024