Umbhobho wentsimbi yekhabhoningumbhobho owenziwe nge-carbon steel kunye nokwakhiwa kweekhemikhali, xa uhlalutya i-thermal, ungadluli umda ophezulu we-2.00% we-carbon kunye ne-1.65% ye-manganese.

Umbhobho wentsimbi yeCarbon yinto eqhelekileyo yokubhobhoza esetyenziswa ngokubanzi kwishishini ukuthutha ulwelo kunye neegesi.

Amaqhosha okukhangela

Ukuhlelwa kweCarbon Steel Pipe

Carbon Steel Pipe Ubungakanani Range

ImiGangatho yesiGqeba esiQhelekileyo soMbhobho wentsimbi yeCarbon

IiParameters eziphambili zeCarbon Steel Pipe

ICarbon Steel Pipe Surface Coating

Izinto eziluncedo zeCarbon Steel Pipe

Ububi beCarbon Steel Pipe

Ukusetyenziswa kweCarbon Steel Pipe

Indlela yokukhetha uMboneleli weMibhobho yentsimbi yeCarbon ethembekileyo

Ngathi

Ukuhlelwa kweCarbon Steel Pipe

Ukuhlelwa ngokweNjongo

Imibhobho yesakhiwo: isetyenziswa ikakhulu kwizakhiwo zokwakha, ezifana nezixhaso zezakhiwo, iibhulorho, kunye nezakhiwo zemizi-mveliso.

Imibhobho yezothutho: Le mibhobho yentsimbi yekhabhoni isetyenziselwa ukuthutha ulwelo olufana neoyile, igesi, namanzi.

Imibhobho yoomatshini: Isetyenziswa koomatshini kunye ne-automation apho imilinganiselo echanekileyo kunye neempawu ezithile zoomatshini zifuneka.

Imibhobho yeBhola: Ezizodwa kubushushu obuphezulu kunye neendawo ezinoxinzelelo oluphezulu, ezinje ngeebhoyila kwizikhululo zamandla kunye neendawo zokucoca ioyile.

I-oyile kunye ne-gas well tubing: isetyenziswe kwi-oyile kunye ne-gas extraction, ekufuneka ikwazi ukumelana noxinzelelo olunzulu kunye nokubola kweekhemikhali.

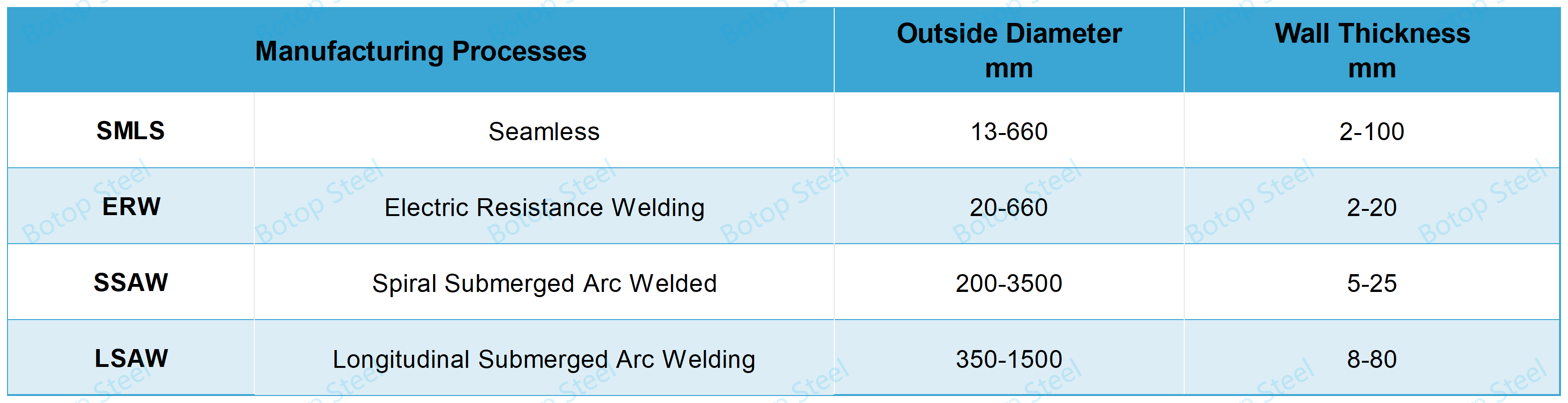

Ukuhlelwa ngokweNkqubo yokuVelisa

Umbhobho wentsimbi ongenamthungo: umbhobho wensimbi owenziwe ngokutshisa okutshisa okanye inkqubo yokugqiba ebandayo, akukho mthungo odibeneyo, osetyenziswa ngokuqhelekileyo ngexesha loxinzelelo oluphezulu.

Umbhobho wentsimbi odityanisiweyo: yenziwe kwipleyiti yensimbi okanye i-coil strip ibe ityhubhu, ngokusebenzisa indlela ye-welding yokucubungula ukubunjwa.

Umbhobho wentsimbi odityanisiweyo ungahlelwa ngokwenkqubo yokuwelda:

Ukumelana nombhobho wentsimbi odityanisiweyo (ERW): Umbhobho owenziwe nge-welded roll-formed by high-frequency resistance resistance, ukuveliswa kombhobho we-carbon steel kunye nobukhulu obuncinci kunye nesantya sokuvelisa ngokukhawuleza.

Umbhobho oDidiweyo we-Arc (SAW): isebenzisa inkqubo yokudibanisa i-arc ezenzekelayo ephantsi kwamanzi ukuvelisa imibhobho yentsimbi ye-carbon ene-diameters enkulu okanye ubukhulu bodonga.

SAWumbhobho wentsimbi nawo unokwahlulwa ubeLSAW(I-Longitudinal Submerged Arc Welding) kunyeSSAW(Spiral Submerged Arc Welded) ngokwendlela ye-weld seam.

Ukuba ufuna ukwazi umahlukophakathi kwe-SMLS,ERW,LSAW,SSAW, ungacofa ukuyijonga.

Carbon Steel Pipe Ubungakanani Range

ImiGangatho yesiGqeba esiQhelekileyo soMbhobho wentsimbi yeCarbon

I-ASTM A106: Umbhobho we-carbon steel ongenamthungo kwinkonzo yobushushu obuphezulu.

I-ASTM A53: Iityhubhu zentsimbi ezidityanisiweyo kunye nezingenamthungo zenkonzo eqhelekileyo kunye noxinzelelo.

I-ASTM A333: Umbhobho wentsimbi ongenamthungo kunye ne-welded yenkonzo yobushushu obuphantsi.

API 5L: Ukucaciswa kwemibhobho yentsimbi kwiinkqubo zothutho lwemibhobho esetyenziswa kwishishini leoli negesi.

DIN 2440: Iityhubhu zentsimbi zekhabhoni ezinobunzima obuphakathi kwizakhiwo jikelele kunye neenjongo zoxinzelelo lokusebenza.

EN 10210: Iityhubhu zentsimbi ezakhiwe ngokushushu ezilungiselelwe iinjongo zesakhiwo.

EN 10219: Imibhobho yentsimbi edityanisiweyo epholileyo ngeenjongo zokwakha.

I-JIS G3452: Imibhobho yentsimbi yeCarbon yombhobho jikelele.

I-JIS G3454: Imibhobho yentsimbi yeCarbon yoxinzelelo lwemibhobho.

AS/NZS 1163: Iityhubhu zentsimbi ezakhiwe ngokubanda kunye namacandelo angenanto kwiimveliso zesakhiwo kunye neenkqubo zemibhobho yesakhiwo.

IiParameters eziphambili zeCarbon Steel Pipe

Ubungakanani bombhobho

Iiparameters ze-dimensional ze-carbon steel pipe zibalulekile ekuqinisekiseni ukufakela okufanelekileyo kunye nokusebenza kwenkqubo yokubhobhoza.

Idayimitha yangaphandle (OD): Ububanzi bomphandle wombhobho, buhambelana ngokuthe ngqo nokudibanisa kombhobho kunye nokuhlelwa.

Idayimitha yangaphakathi (ID): ububanzi bengaphakathi lombhobho, oluchaphazela izinga lokuhamba kunye nokuhamba kwamanzi.

Ubunzima bodonga (WT): ubukhulu bodonga lombhobho, olubaluleke kakhulu ekunyamezelweni koxinzelelo kunye nokuqina kombhobho.

Ubude (L): Umbhobho unokuba nobude obusisigxina okanye obungahleliweyo.

Ukujikeleza kunye nokuthe tye: misela umgangatho wofakelo lombhobho kunye nokutywinwa koqhagamshelwano.

Uhlobo lwesiphelo setyhubhu: Isiphelo sombhobho sinokuba sicaba, sibevelelwe, okanye sifakwe umsonto ukulungiselela iintlobo ezahlukeneyo zonxibelelwano.

Ukuqulunqwa kwemichiza

Ukwakhiwa kweekhemikhali zombhobho we-carbon steel umisela ukuqina kwawo, amandla, ukuqina, kunye nokuxhathisa ukubola.

Ikhabhoni (C): kwandisa ubulukhuni kunye namandla, kodwa kakhulu kunciphisa ukuqina.

IManganese (Mn): kwandisa amandla kunye nokunxiba ukuxhathisa ngelixa ugcina ukuqina okulungileyo.

Isilicon (Si): kwandisa ukuqina kunye nokumelana nobushushu.

Isulfure (S)kwayeiphosphorus (P): zidla ngokuthathwa njengokungcola kwaye zifuna ukugcinwa kumanqanaba aphantsi njengoko zinciphisa ukuqina kunye ne-weldability.

Ezinye izinto zokudibanisa(umzekelo, i-chromium, i-nickel, i-molybdenum): inokuphucula iimpawu ezithile zoomatshini kunye nokumelana nomhlwa.

Iipropati zoomatshini

Iiparamitha zepropathi zomatshini zichaphazela ngokuthe ngqo ukuzinza kombhobho we-carbon steel phantsi kweemeko zenkonzo.

Tensile strength: ukukwazi kwezinto eziphathekayo ukuxhathisa ukuphuka kwingxabano.

Unikeze Amandla: olona xinzelelo luphezulu apho izinto ziphantsi kwayo ngaphambi kokuba ziqale ukonakala ngokusisigxina.

Elongation: Isalathiso sokukwazi kwempahla ukonakala ngokweplastiki, ubungakanani bobude obunokwelula phambi kokwaphuka.

Ukuqina: Isakhono semathiriyeli ukuxhathisa ukufakwa kwendawo, edla ngokulinganiswa ngoBrinell, Rockwell, okanye Vickers uvavanyo lobulukhuni.

Uvavanyo lwempembelelo: Uvavanyo lwempembelelo olwenziwa kwiqondo lobushushu elithile ukuvavanya ukuqina kwesixhobo.

Xa ukhetha iibhubhu zensimbi zekhabhoni, ezi pharamitha eziphambili kufuneka zihambelane neemfuno ezithile zesicelo kunye nemigangatho ehambelanayo.

ICarbon Steel Pipe Surface Coating

Ukukhuselwa komgangatho wombhobho we-carbon steel yindlela ebalulekileyo yokuthintela ukubola kunye nokwandisa ubomi bombhobho. Iindidi ezahlukeneyo zeengubo zibonelela ngamanqanaba ahlukeneyo okukhusela kwaye zifanelekile kwiindawo ezahlukeneyo zokusebenza kunye neemeko.

Ezi zilandelayo zezinye iindidi eziqhelekileyo zokugquma komhlaba kumbhobho wentsimbi yekhabhoni:

Iingubo ze-epoxy: ukubonelela ngokubambelela kakuhle kunye nokuchasana kweekhemikhali kwaye ziqhelekileyo zisetyenziselwa ukuthintela ukubola kunye nezicelo ezingaphantsi kwamanzi.

Iingubo zepolyurethane: Ukubonelela ngemozulu egqwesileyo kunye nokuxhathisa kwe-abrasion kwaye zisetyenziswa kwiindawo ezivezwe ngaphandle.

Iingubo ezityebileyo zeZinc: Iqulethe ipesenti ephezulu ye-zinc powder, ibonelela ngokukhuselwa kwe-cathodic kwaye ifanelekile kwiindawo zaselwandle kunye nezoshishino.

Ukugalela: Ibonelela ngokukhuselwa kwe-cathodic ngokutshisa i-zinc okanye i-electroplating zinc kwaye yindlela yendabuko yokuthintela ukubola.

Ukufakwa kweAluminiyam: ibonelela ngokhuseleko oluphezulu kwi-galvanizing phantsi kweemeko ezithile, ngakumbi kwiindawo ezinobushushu obuphezulu.

Polyethylene (PE) ukutyabeka: Ibonelela ngekhemikhali elungileyo kunye nokuchasana kwempembelelo kwaye iqhele ukusetyenziselwa imibhobho engaphantsi komhlaba.

Polypropylene (PP) ukutyabeka: ifana ne-PE coating kodwa inika ukusebenza okungcono kumaqondo okushisa aphezulu.

Ukwenziwa kodaka lwesamente: Ilungele imibhobho yogutyulo kunye nonikezelo lwamanzi ukuthintela ukubola kwangaphakathi kunye nokungcoliseka kwamanzi.

Umgca werabha: Ibonelela ngokhuseleko lomzimba kwaye inciphisa umhlwa kunye nokukrala okubangelwa lulwelo.

Uhlobo ngalunye lokugquma lunemeko yokusetyenziswa kwayo, iingenelo, kunye nokungalungi. Izinto ezahlukeneyo ezibandakanya iindleko, iimeko zokwakha, ubude bokuphila, impembelelo yokusingqongileyo, kunye neemfuno zokulondolozwa kufuneka ziqwalaselwe xa kukhethwa isambatho esifanelekileyo.

Izinto eziluncedo zeCarbon Steel Pipe

Umbhobho wentsimbi yeCarbon unikezela ngeenzuzo ezahlukeneyo ezenza kube yinto ekhethiweyo kwizicelo ezininzi zoshishino.

1.Iinzuzo zexabiso: Ixabiso eliphantsi kunensimbi engenasici okanye i-alloy steel, iyona nto ikhethekileyo kwiiprojekthi ezinkulu kunye nemibhobho emide.

2. Amandla omatshini: Zineempawu ezilungileyo zoomatshini, kubandakanywa amandla aphezulu kunye nokuchasana kwempembelelo. Oku kuthetha ukuba inokumelana noxinzelelo oluphezulu kunye neendawo zokusebenza ezinzima.

3. Ukwenziwa lula: Kulula ukusika, ukuwelda, kunye nokumila kofakelo nokugcinwa kamva.

4. Ukuqhuba kakuhle kwe-thermal: I-Carbon steel yi-conductor efanelekileyo yokushisa kwaye ifanelekile kwizicelo ezifana nokutshintsha ubushushu kunye neenkqubo zokufudumeza apho kufuneka ukuhanjiswa kokushisa okufanelekileyo.

5. Ukumelana nobushushu obuphezulu: Igcina iimpawu zayo ezibonakalayo kumaqondo aphezulu kwaye ifanelekile kwiindawo ezifuna ukushisa okuphezulu okusebenzayo, njengeenkqubo ze-steam.

6. Ukurisayikilisha: Yinto enokuphinda isetyenziswe enokuthi ibuyiselwe kwiziko ukuze isetyenziswe kwakhona ekupheleni kweveki yokusetyenziswa.

7. Ukuxhathisa i-abrasion: Ubunzima obuhle buvumela ukuxhathisa okulungileyo kwe-abrasion xa uhambisa izinto ezixubileyo kwaye, ngokomzekelo, zisetyenziselwa ukuhanjiswa kwezinto kwimigodi kunye ne-powder handling industry.

8. Ukuhambelana: Iyahambelana neendidi ezininzi ezahlukeneyo zeqhagamshelo kunye nokufakelwa, kunye noluhlu olubanzi lwezixhobo kunye nokufunyanwa lula.

Ububi beCarbon Steel Pipe

Nangona iibhobho zentsimbi zekhabhoni zisetyenziswa ngokubanzi kwizicelo ezininzi zemizi-mveliso ngenxa yeenzuzo zazo ezininzi, zikwanazo nezingeloncedo okanye imida.

1. Kulula ukubola: Ingakumbi kwindawo emanzi okanye enomhlwa. I-Corrosion inokunciphisa ubuninzi bodonga lombhobho wensimbi, okwandisa umngcipheko wokugqabhuka kwaye ekugqibeleni kukhokelela ekuvuzeni okanye ekungaphumeleli.

2. Iindleko zokugcina: Ukuze uxhathise i-corrosion kunye nokwandisa ubomi babo benkonzo, iipayipi zensimbi zekhabhoni zingadinga amanyathelo angakumbi okukhusela afana neengubo, ii-linings, okanye iinkqubo zokukhusela i-cathodic. Ukugcinwa rhoqo kunye nokuhlolwa kuyadingeka kubo bonke ubomi bombhobho, okongeza kwiindleko ezipheleleyo.

3. Ayifanelekanga ukusetyenziswa kunye neekhemikhali ezithile: Intsimbi yeCarbon inovelwano kwiikhemikhali ezithile kwaye inokonakala ngokukhawuleza phantsi kwempembelelo yale michiza. Ngokomzekelo, i-carbon steel ichaphazeleka kuxinzelelo lwe-corrosion cracking kwiindawo ezinoxinzelelo oluphezulu lwe-hydrogen sulfide.

4. Unyino lobushushu: Nangona i-carbon steels inokumelana noluhlu lwamaqondo okushisa aphezulu, iipropati ze-mechanical zensimbi ziyancipha kwiqondo lokushisa eliphezulu kakhulu, okubangela ukunciphisa amandla ezinto eziphathekayo kunye ne-creep (i-deformation ukusuka ekuvezweni kwexesha elide kwimithwalo ephezulu).

5. I-embrittlement yobushushu obuphantsi: Kwiqondo lokushisa eliphantsi, zombini ukuqina kunye nokuqina kuyancitshiswa, okukhokelela ekuqhekekeni kwe-brittle phantsi kwempembelelo.

6. Imiba yobunzima: Iibhobho zensimbi zeCarbon zinzima kunezinye izinto, ezifana neeplastiki, kwaye zingabangela iimfuno ezongezelelweyo kunye neendleko zokunyuka kunye nezakhiwo ezixhasayo.

7. Ukwandiswa kwe-thermal: Ukwandiswa kwe-thermal okwenzeka ngexesha lokutshintsha kweqondo lokushisa, ngokukodwa kwimibhobho yomgama omde. Oku kufuneka kuthathelwe ingqalelo kuyilo kunye nokufakwa kwemibhobho ukuphepha uxinzelelo kunye nokuguqulwa okubangelwa utshintsho lweqondo lokushisa.

Ukukhetha umbhobho ofanelekileyo kwiimfuno zesicelo esithile kunye / okanye ukuthatha amanyathelo okukhusela afanelekileyo ngundoqo ekuqinisekiseni impumelelo.

Ukusetyenziswa kweCarbon Steel Pipe

1. Ishishini leoli negesi:Isetyenziswa kakhulu ekuthuthweni kwe-oyile ekrwada, igesi yendalo, kunye nezinye iimveliso zepetroleum, kwiinkqubo zothutho lwemibhobho emide nakwimibhobho yokomba neoyile.

2. Amashishini ekhemikhali kunye nepetrochemical: La mashishini afuna imibhobho ekwazi ukumelana nokushisa okuphezulu kunye noxinzelelo lokuthutha iikhemikhali kunye nolwelo kwaye ngoko kaninzi zisebenzisa imibhobho ye-carbon steel ephathwe ngokukodwa.

3. Ukwenziwa kwemveliso: Ingasetyenziselwa ukwenza amacandelo oomatshini kunye nezixhobo, i-exhaust ducts, njl.

4. Ukwakha nokwakha: Kwintsimi yolwakhiwo, zisetyenziselwa njenge-skeleton yezakhiwo zokwakha ezifana nemiqadi, iikholomu, kunye nezinye izakhiwo ezixhasayo. Ikwasetyenziswa ekwenzeni isikafula kunye nezinye izakhiwo zethutyana.

5. Amanzi kunye nogutyulo: Isetyenziswe ngokubanzi kwiinkqubo zokuhambisa amanzi kunye nokuthuthwa kwamanzi amdaka, iipayipi zensimbi zihlala zifakwe ngaphakathi ngaphakathi kunye noluhlu olufanelekileyo lokugquma, olusetyenziselwa ukukhusela imibhobho ekungcoleni kunye nokwandisa ubomi babo benkonzo.

6. Ishishini lamandla: Kwizityalo zamandla, zisetyenziselwa ukuthutha ubushushu obuphezulu, umphunga ophezulu woxinzelelo. Zingasetyenziselwa ukwenza iibhoyili kunye nokutshintsha ubushushu.

7. Iinkqubo zokufudumeza kunye nokupholisa: Ukuhambisa imidiya okanye umphunga kwiinkqubo zokufudumeza kunye ne-air conditioning systems.

8. Ushishino lwaselwandle: Isetyenziselwa ukwakhiwa kweenqanawa kwizakhiwo zesakhelo, iinkqubo zokuhambisa amanzi, kunye nezinye iinkqubo ezahlukeneyo.

9. Izikhululo zamandla ezishushu: Ukuhambisa umphunga kunye namanzi kwizikhululo zamandla ezishushu.

10. Izakhiwo kunye nobunjineli: Idla ngokusetyenziselwa ukuxhasa izakhiwo zeebhulorho, iitonela, iindlela zikaloliwe ezingaphantsi komhlaba, kunye nezibonelelo ezinkulu zikawonke-wonke.

Iibhobho zensimbi zeCarbon zihlala zikhethwa ngokusekelwe kububanzi bazo, ubukhulu bodonga, ubude, inkqubo yokuvelisa, kunye nokuba iingubo ezongezelelweyo okanye i-linings ziyafuneka ukuxhathisa ukubola. Xa uzisebenzisa, kubalulekile ukuqwalasela ubushushu, uxinzelelo, kunye nodidi lwemidiya kwindawo yokusebenza.

Indlela yokukhetha uMboneleli weMibhobho yentsimbi yeCarbon ethembekileyo

1. Iziqinisekiso kunye noqinisekiso:Khangela ukuba iimveliso zomthengisi ziyahambelana nemigangatho yoshishino lwamazwe ngamazwe kunye nelizwe kwaye unesiqinisekiso senkqubo yolawulo lomgangatho (umz., ISO 9001).

2. Umgangatho wemveliso: Ngaba umthengisi ubonelela ngeengxelo zovavanyo malunga nokwakheka kweekhemikhali kunye neempawu zoomatshini bemathiriyeli ekrwada kunye neemveliso ezigqityiweyo. Kwaye uqonde amanyathelo okuqinisekisa umgangatho, kubandakanywa ukuhlolwa, ukuvavanywa, kunye nokulawula umgangatho ngexesha lenkqubo yokuvelisa.

3. Umthamo wemveliso: Ukuvavanya ukuba ubungakanani bomboneleli kunye nomthamo wemveliso unokuhlangabezana neemfuno zomyalelo. Jonga ukuba ngaba ubuchule bemveliso kunye nezixhobo ezisetyenziswa ngumthengisi ziphuculwe ngoku ukuqinisekisa umgangatho wemveliso.

4. Udumo lwemarike: Qwalasela amava omthengisi kushishino lwekhabhoni yentsimbi yombhobho. Amava oshishino exesha elide adla ngokunxulunyaniswa nokuthembeka okuphezulu. Buza impendulo kunye nezimvo kubathengi abakhoyo, ngakumbi malunga nomgangatho wemveliso kunye nokwaneliseka kwenkonzo.

5. Inkonzo nenkxaso:Ngaba umthengisi ubonelela ngenkonzo elungileyo yabathengi, kubandakanya impendulo ekhawulezayo kunye nokusombulula iingxaki. Ingaba umthengisi unokubonelela ngenkxaso yobuchwephesha yobuchwephesha kwinkqubo yokukhethwa kwemveliso, inkcazo yokusebenza, kunye nofakelo.

6. Ixabiso kunye neendleko: Thelekisa iikowuteshini ezivela kubaboneleli abahlukeneyo ukuqinisekisa ukuba ixabiso lihambelana nenqanaba lemarike kunye nexabiso elisebenzayo. Zilumkele iindleko ezifihlakeleyo ezinokwenzeka ezivela kuthutho, ukupakisha, ukulibaziseka okunokwenzeka, njl.

7. Ixesha lokuhambisa:Ukuba ngaba abaniki-nkonzo bayakwazi ukuzibophelela kwaye bahlangabezane nemihla ebekiweyo yokuziswa kwempahla, vavanya uthungelwano lolungiselelo lomthengisi ukuqinisekisa ukuba iimveliso zinokuziswa ngokukhuselekileyo nangexesha.

8. Inkonzo emva kokuthengisa: Qonda umgaqo-nkqubo wenkonzo yomthengisi emva kokuthengisa, njengembuyekezo kunye notshintshiselwano, ukuphathwa kwenkcaso esemgangathweni, njl.

9. Uphando lweenkcukacha zenkampani: Sebenzisa izixhobo ze-intanethi ukufumana ulwazi olongezelelweyo. Umzekelo, iiwebhsayithi zenkampani, iiforam zeshishini, imidiya yoluntu, njl.

10. Ukutyelela indawo: Ukuba kuyenzeka, ungandwendwela umzi-mveliso womthengisi, kunye nezixhobo zokuvelisa ngokobuqu.

11. Uvavanyo lwesampula: Iisampulu zingacelwa ukuba zivavanywe ukuqinisekisa ukuba umgangatho wokwenyani wemveliso uyahlangabezana neemfuno.

Kuyo yonke inkqubo yokhetho, uvandlakanyo olubanzi kunye nokugweba ngobulumko ngundoqo. Qinisekisa ukuba umboneleli omkhethayo akakho phezulu nje ngokwexabiso, kodwa lolona khetho lulungileyo ngokwemigangatho, ukuthembeka, kunye nexabiso lilonke.

Ngathi

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo yayo egqwesileyo, iimveliso ezikumgangatho ophezulu kunye nezisombululo ezibanzi. Uluhlu olubanzi lwemveliso yenkampani lubandakanya i-seamless, i-ERW, i-LSAW, kunye nemibhobho yentsimbi ye-SSAW, kunye nokufakelwa kwemibhobho, ii-flanges, kunye neentsimbi ezizodwa.

Ngokuzibophezela okuqinileyo kumgangatho, iBotop Steel isebenzisa ulawulo olungqongqo kunye neemvavanyo zokuqinisekisa ukuthembeka kweemveliso zayo. Iqela layo elinamava libonelela ngezisombululo zobuqu kunye nenkxaso yeengcali, kugxilwe ekwanelisekeni kwabathengi.

Tags: carbon steel pipe, ababoneleli, abavelisi, iifektri, stockists, iinkampani, wholesale, thenga, ixabiso, ucaphulo, isambuku, intengiso, ixabiso.

Ixesha lokuposa: May-03-2024