I-API 5L X70 yibakala le-API ye-5L yezinto zombhobho womgca kunye namandla amancinci e-70,000 psi.Isetyenziselwa ikakhulu ukuthuthwa koxinzelelo oluphezulu lwerhasi yendalo, ioyile kunye namanzi.

Ukufunda ngakumbi malunga ne-API 5L-46th, unakoCofa apha!

Amaqhosha okukhangela

Iimpawu ze-API 5L X70

Amandla aphezulu esivuno: Ubuncinci bamandla esivuno se-70,000 psi (malunga ne-485 MPa), ilungele uxinzelelo oluphezulu lwangaphakathi.

Ukuqina okuhle: kugcina ukusebenza kumaqondo obushushu aphantsi kwimimandla ebandayo kunye nosetyenziso lolwandle olunzulu.

I-weldability egqwesileyo: Amandla aphezulu ngelixa igcina i-weldability elungileyo, kunye ne-welds ehambelana neempawu zesiseko sesinyithi.

Ukumelana nokukhula: kunokongezwa ngokulawulwa kokwakheka kweekhemikhali kunye nonyango lwasemva konyango (umzekelo, i-coatings), ilungele indawo ekude nonxweme kunye neendawo ezidliwayo.

Ukufaneleka kokusiNgqongileyo: Inokuyilwa ukuze isetyenziswe kumhlaba osemgangathweni, kude nonxweme, nakwiindawo zenkonzo yeasidi.

Uzinzo: Ukuncitshiswa kwempembelelo yokusingqongileyo kunye nokuphuculwa kosulelo njengemathiriyeli enokurisayikilishwa.

API 5L X70 Classifications

Uhlobo lombhobho: Umbhobho wentsimbi odityanisiweyo kunye nongenamthungo

Ibakala lokucaciswa kwemveliso: API 5L X70 PSL1 kunye ne-API 5L X70 PSL2

Inkqubo yokwenziwa kwemibhobho: SMLS, LFW, HFW, LW, SAWL, SAWH, COWL, COWH

Uhlobo lokuphela kombhobho: Isiphelo seBelled, Isiphelo esingenanto

Iimpahla ezingekasilwa

Iingothi, iibhilithi, iibhilidi, imicu (iikhoyili), okanye iipleyiti njengento ekrwada yokwenza imibhobho yentsimbi.

Imathiriyeli ekrwada ye-PSL2 yentsimbi yombhobho iya kuba yintsimbi ecolekileyo yentlenga.

Ngaphezu koko, umtya wentsimbi (ikhoyili) okanye ipleyiti esetyenziselwa ukwenziwa kombhobho wentsimbi wePSL2 awuyi kuthwala naziphi na iiwelds zokuzalisa.

I-API 5L X70 Inkqubo yokuVelisa uMbhobho

| Uhlobo loMbhobho | I-SMLS | LFW | HFW | LW | SAWLc | SAWHd | INKOMOc | COWHd |

| API 5L X70 PSL1 | X | X | X | X | X | X | X | X |

| API 5L X70 PSL2 | X | - | X | - | X | X | X | X |

cUmbhobho wokuthunga kabini uyafumaneka ukuba kuvunyelwene, kodwa ukhawulelwe kumbhobho one-D ≥ 914 mm.

dUmbhobho we-Helical we-seam ukhawulelwe kumbhobho nge-D ≥ 114.3 mm.

Iindidi zokuphela kombhobho we-API 5L X70

| Ukuphela kombhobho | Belled ende | Isiphelo esicacileyo |

| API 5L X70 PSL1 | X | X |

| API 5L X70 PSL2 | - | X |

eUmbhobho we-Belled-end ukhawulelwe kumbhobho kunye ne-D ≤219.1 mm kunye ne-t≤ 3.6 mm.

Ubume boNikezo bokugqibela

I-API 5L X70 yelizwe lokugqibela lonikezelo (unyango lokugqibela lobushushu lombhobho wentsimbi ogqityiweyo) lunokwahlulwa lube: ukuqengqeleka, ukuqengqeleka okuqhelekileyo, ukuqengqeleka kwe-thermo-mechanical, ukubunjwa kwe-thermo-mechanical, ukubunjwa okuqhelekileyo, ukuqhelanisa, ukuqheleka kunye nokuqukumbela okanye ukucima kunye nokuthambisa.

| PSL | Unikezelo lwemeko | IBanga lombhobho/iBanga leNsimbi | |

| PSL1 | Njenge-rolled, normalizing rolled, thermomechanical rolled, thermomechanical kwakheka, ukuqhelanisa ukubunjwa, ukuqheleka, ukuqheleka kunye nobushushu okanye ukucinywa kwaye unomsindo | X70 | L485 |

| PSL 2 | Ucinywe kwaye unomsindo | X70Q | I-L485Q |

| I-Thermomechanical rolled okanye i-thermomechanical yenziwe | X70M | I-L485M | |

Ezi zizwe zokuhanjiswa ziqinisekisa ukuba i-API 5L X70 ityhubhu iqhuba kakuhle kwiinkqubo ezahlukeneyo ezahlukeneyo, ezifana nokusetyenziswa kuxinzelelo oluphezulu, ubushushu obuphantsi, okanye kwiindawo ezinobungozi.

Ukuqulunqwa kwemichiza

I-API 5L X70 PSL1 Ukwakhiwa kweMichiza

Ukubunjwa kweekhemikhali ze-API 5L X70 PSL1 ipayipi yensimbi iquka i-carbon ephantsi, amanani aphakathi kwe-manganese, kunye neemali ezincinci ze-phosphorus, isulfure kunye ne-silicon.Ukongeza, izinto ezidityanisiweyo ezinje ngechromium, nickel kunye nobhedu zongezwa ukomeleza amandla kunye nokumelana nomhlwa.Izinto ze-Micro-alloying ezifana ne-vanadium, i-molybdenum kunye ne-titanium ziqhubela phambili ukuqina kunye neempawu zesivuno, ziqinisekisa ukusebenza kwiindawo ezinomngeni.

| Ukuqulunqwa kwemichiza ye-PSL 1 Umbhobho one-t≤25.0 mm (0.984 in.) | |||||||||

| IBanga leNsimbi (Igama lentsimbi) | Iqhekeza leMass, ngokuSekwe kubushushu kunye noHlalutya lweMvelisoag % | ||||||||

| C | Mn | P | S | V | Nb | Ti | |||

| maxb | maxb | imiz | max | max | max | max | max | ||

| Umbhobho ongenamthungo | |||||||||

| L485 | X70 | 0.28 | 1.40 | - | 0.03 | 0.03 | f | f | f |

| Umbhobho odityanisiweyo | |||||||||

| L485 | X70 | 0.26e | 1.65e | - | 0.03 | 0.03 | f | f | f |

| a Cu≤0.50 %;Ni≤0.50%;Cr≤0.50 %kunye neMo≤0.15%. b Kunciphiso ngalunye lwe-0.01% ngaphantsi kogxininiso oluphezulu oluchaziweyo lwekhabhoni, ukwanda kwe I-0.05% ngaphezu kogxininiso oluphezulu oluchaziweyo lwe-Mn luvumelekile, ukuya kutsho kubukhulu be-1.65 % kumabakala ≥L245 okanye B, kodwa ≤L360 okanye X52;ukuya kuthi ga kubuninzi be-1.75 % kumabakala>L360 okanye X52, kodwa ukuya kutsho kwi-2.00 % kwiBakala L485 okanye X70. e Ngaphandle kokuba kuvunyelwene ngenye indlela f Ngaphandle kokuba kuvunyelwene ngenye indlela, Nb+V+Ti≤0.15 %. g Akukho kongezwe ngabom ku-B kuvunyelwe kwaye intsalela ye-B≤0.001 %. | |||||||||

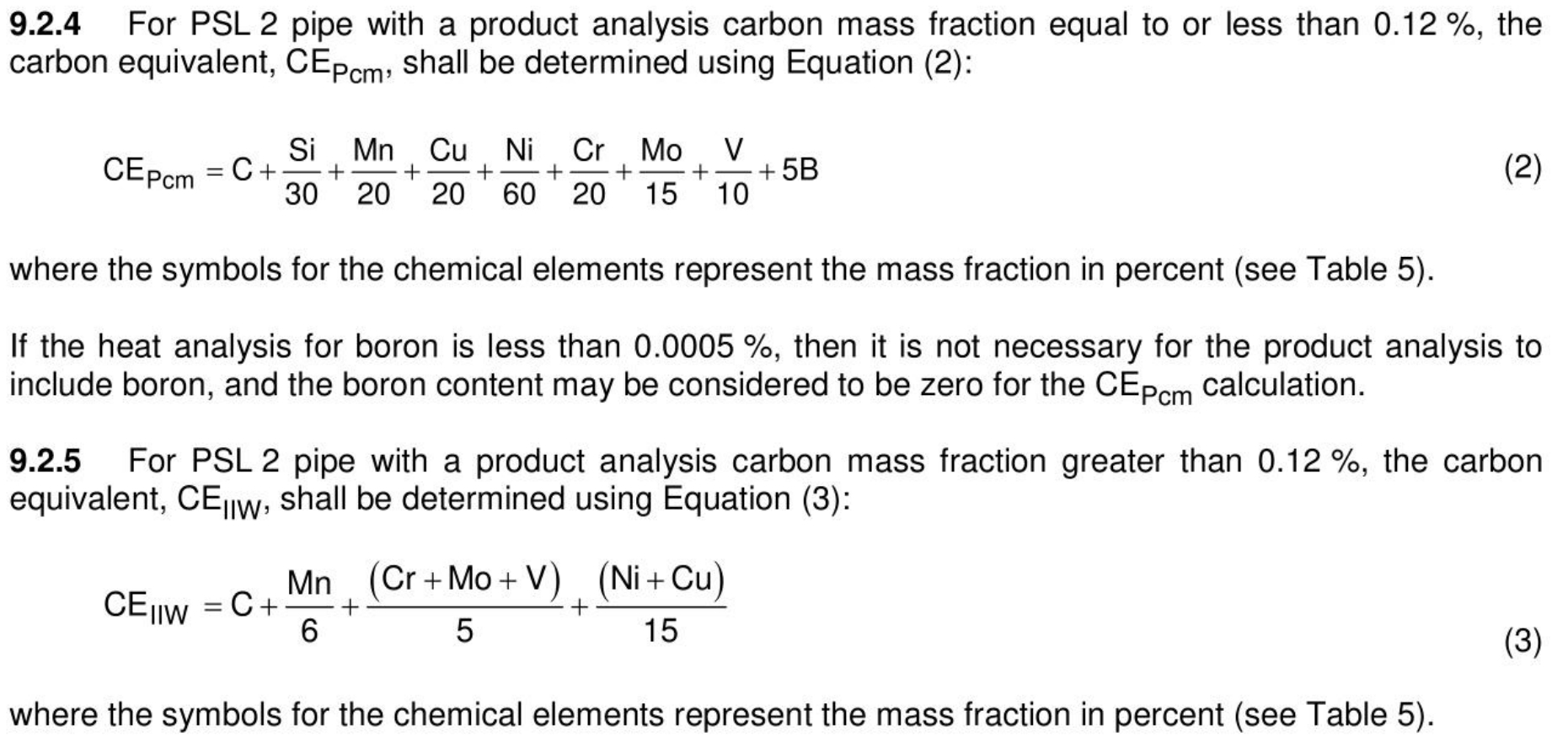

I-API 5L X70 PSL2 Ukwakhiwa kweMichiza

Ukwakhiwa kweekhemikhali ze-API 5L X70 PSL2 ibandakanya ngokuchanekileyo i-carbon elawulwayo, i-manganese, isulfure, kunye ne-phosphorus, kunye nomlinganiselo ofanelekileyo we-silicon, i-chromium, i-nickel kunye nobhedu.Ulawulo olungqongqo lwe-elemental alugcini nje ukwandisa amandla esivuno kunye nokuqina kombhobho kodwa kuphucula ukuxhathisa ukubola phantsi kweemeko ezinzima.Ukongeza, ukulandelela izinto ezifana ne-vanadium, i-molybdenum, kunye ne-titanium zilungelelaniswe ukuqhubela phambili ukusebenza, okwenza i-X70 PSL2 ilungele ukujongana neendawo ezinomngcipheko ophezulu.

| Ukuqulunqwa kweMichiza ye-PSL 2 Ipayipi ene-t ≤ 25.0 mm (0.984 in.) | ||||||||||||

| IBanga leNsimbi (Igama lentsimbi) | Iqhekeza leMass, ngokuSekwe kubushushu kunye noHlalutya lweMveliso % max | Ikhabhoni Iyalinganaa % ubuninzi | ||||||||||

| c b | Si | Mn b | P | S | V | Nb | Ti | Okunye | CEllw | CEpcm | ||

| Umbhobho ongenamthungo kunye neWelded | ||||||||||||

| I-L485Q | X70Q | 0.18f | 0.45 f | 1.80f | 0.025 | 0.015 | g | g | g | Mholo | 0.43 | 0.25 |

| Umbhobho odityanisiweyo | ||||||||||||

| I-L485M | X70M | 0.12 f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | Mholo | 0.43 | |

| a Ngokusekelwe kuhlalutyo lwemveliso, kumbhobho ongenamthungo one-t>20.0 mm (0.787 in.), imida yeCE iya kuba njengoko kuvunyelwene;imida yeCEllw iyasebenza ukuba C>0.12 %, kwaye imida yeCEpcm iyasebenza ukuba C≤0.12 %. b Kucutho ngalunye lwe-0.01 % ngaphantsi kobuninzi obuchaziweyo kwi-C, ukwanda nge-0.05 % ngaphezu kobuninzi obuchaziweyo kuMn ongavumelekanga, ukuya kutsho kubuninzi be-1.65 % kumabakala≥L245 okanye B, kodwa≤L360 okanye X52;ukuya kutsho kubuninzi be-1.75 % kumabakala > L360 okanye X52, kodwaL555 okanye X80. c Ngaphandle kokuba kuvunyelwene ngenye indlela, Nb+V≤0.06 %. d Nb+V+Ti≤0.15%. e Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu≤0.50 %;Ni≤0.30 %;Cr≤0.30 %kunye neMo≤0.15%. f Ngaphandle kokuba kuvunyelwene ngenye indlela. g Ngaphandle kokuba kuvunyelwene ngenye indlela, Nb+V+Ti≤0.15 %. h Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu≤0.50%;Ni≤0.50%;Cr≤0.50% kunye ne-Mo≤0.50%. i Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu≤0.50 %;Ni≤1.00%;Cr≤0.50%kunye neMo≤0.50%. j B≤0.004 %. k Ngaphandle kokuba kuvunyelwene ngenye indlela, Cu≤0.50 %;Ni≤1.00 %;Cr≤0.55 % kunye ne-Mo≤0.80 %. l Kwi-PSL 2 amabakala emibhobho ngaphandle kwaloo mabanga esele esebenza umbhalo osemazantsi j), oku kulandelayo kuyasebenza: ngaphandle kokuba kuvunyelwene ngenye indlela, ukongezwa kwe-nointional ku-B kuvumelekile kwaye intsalela engu-B≤0.001 %. | ||||||||||||

Ubume beMichiza yeeMeko zeNkonzo ezimuncu API 5L X70 PSL2

Iimeko zenkonzo ezimuncu zibhekisela ikakhulu ekusebenziseni imibhobho kwiindawo ezine-hydrogen sulfide (H₂S), enokukhokelela kwi-hydrogen sulfide stress corrosion cracking (HIC) kunye ne-sulfide stress corrosion cracking (SSCC).

Ukulungelelaniswa kokwakheka kweekhemikhali: Ngaphantsi kwezi meko, ukubunjwa kweekhemikhali zeentsimbi zemibhobho kufuneka zilungiswe ngokufanelekileyo ukuphucula ukuxhathisa ukubola.Ngokuqhelekileyo, oku kubandakanya ukunciphisa umxholo wekhabhoni wezinto eziphathekayo kunye nokongeza izinto ze-alloying ezifana ne-molybdenum (Mo) kunye ne-nickel (Ni), eyandisa ukuxhatshazwa kwe-corrosion kunye nobunzima bezinto eziphathekayo.

| Itheyibhile H.1—Ubume beKhemikhali boMbhobho one-t≤25.0 mm (0.984 in.) | |||||||||||

| IBanga leNsimbi | Iqhekeza leMisa eliSekwe kubushushu kunye noHlalutya lweMveliso% max | Ikhabhoni Iyalinganaa % max | |||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Okunyec,d | CEllw | CEpcm | |

| I-SMLS kunye ne-Welded Pipe | |||||||||||

| I-L485QS okanye i-X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.003e | 0.09 | 0.05 | 0.06 | g, mna, k | 0.42 | 0.22h |

| Umbhobho odityanisiweyo | |||||||||||

| L485MS okanye X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002e | 0.10 | 0.08 | 0.06 | g, mna,j | - | 0.22 |

Iinkcukacha ezithe vetshe zinokufumaneka kwi-API 5L kwiSihlomelo H.

Ukwakhiwa kwemichiza ye-API 5L X70 PSL2 yeeMeko zeNkonzo ye-Offshore

Iimeko zenkonzo ye-offshore ziquka imo engqongileyo yaselwandle, kubandakanywa nokuvezwa kwamanzi anetyuwa kunye neemeko zemozulu ezibi kakhulu.Ezi meko zifuna imibhobho enokumelana nomhlwa kunye nokuqina okwaneleyo ukuxhathisa ukubola kwamanzi anetyuwa kunye neempembelelo ezisezantsi zobushushu.

Ukulungelelaniswa kokwakheka kweekhemikhali: Kwinkonzo ye-offshore, i-alloy yombhobho idla ngokunyuswa kwi-chromium (Cr), i-nickel (Ni) kunye ne-molybdenum (Mo) ukunyusa ukuxhathisa kwayo kwi-corrosion yamanzi olwandle.Ubungakanani bezinto ezincinci ze-micro-alloying ezifana ne-vanadium (V) kunye ne-niobium (Nb) nazo zingalungiswa ukuze kulungiswe ukuqina kumaqondo aphantsi.

| Itheyibhile J.1—Ukwakheka kweChemical kuMbhobho one-t≤25.0 mm (0.984 in.) | ||||||||||||

| IBanga leNsimbi | Iqhekeza leMisa eliSekwe kubushushu kunye noHlalutya lweMveliso max % | Ikhabhoni Equivalenta max % | ||||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Okunyec | CEllw | CEPcm | ||

| I-SMLS kunye ne-Welded Pipe | ||||||||||||

| L485QO | X70QO | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | e,h | 0.42 | 0.23g |

| Umbhobho odityanisiweyo | ||||||||||||

| I-L485MO | X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 | e,h | - | 0.22 |

Iinkcukacha ezithe vetshe zinokufumaneka kwi-API 5L kwiSihlomelo J.

Ukongezelela, ukubunjwa kweekhemikhali zombhobho wensimbi kwiimeko zenkonzo ye-offshore kwi-API 5L X70 PSL2 iyafana neemfuno zombhobho wezicelo ezifuna umthamo weplastiki ye-longitudinal.Amaqela anomdla angajonga i-API 5L yeSihlomelo N.

Iipropati zoomatshini

API 5L X70 PSL1 Mechanical Properties

| Itheyibhile 6-IiMfuno zeziphumo zovavanyo lwe-Tensile ye-PSL 1 iPipe | ||||

| IBanga lombhobho | Umzimba wombhobho wePipe engenamthungo kunye neWelded | I-Weld Seam ye-EW, I-LW, i-SAW, kunye ne-COW Pipe | ||

| Unikeze Amandlaa Rukuya.5 MPa(psi) | Tensile strengtha Rm MPa(psi) | Ukwandisa (kwi-50 mm okanye 2 ngaphakathi.) Af % | Tensile strengthb Rm MPa(psi) | |

| imiz | imiz | imiz | imiz | |

| L485 okanye X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Iiparamitha ezithile zinokujongwa kwi-API 5L Itheyibhile yesi-6.

API 5L X70 PSL2 iimpawu mechanical

Iityhubhu ze-PSL2 zezicelo ezikhethekileyo zilungelelaniswa ikakhulu kukwakheka kweekhemikhali, kodwa iimfuno zeempawu zoomatshini ziyafana.

| Itheyibhile 7-IiMfuneko zeziphumo zovavanyo lwe-Tensile ye-PSL 2 Pipe | |||||||

| IBanga lombhobho | Umzimba wombhobho wePipe engenamthungo kunye neWelded | Weld Seam yeHFW SAW kunye Umbhobho weNkomo | |||||

| Unikeze Amandlaa Rukuya.5 MPa(psi) | Tensile strengtha Rm MPa (psi) | Umlinganiseloac Rt0.5/Rm | Ukwandisa (kwi-50 mm okanye 2 ngaphakathi.) Af % | Ukuqina Amandlad Rm MPa (psi) | |||

| imiz | max | imiz | max | max | imiz | imiz | |

| L485Q okanye X70Q L485M okanye X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

Iiparamitha ezithile zinokujongwa kwi-API 5L Itheyibhile yesi-7.

Iindlela zokuLinga

| Uluhlu lovavanyo | Indlela yoVavanyo |

| Ukuqulunqwa kwemichiza | ISO 9769 okanye ASTM A751 |

| Iipropati zoomatshini | ISO 6892-1 okanye ASTM A370 |

| Uvavanyo lweHydrostatic | API 5L 10.2.6 |

| Uviwo Olungonakalisi | API 5L Isihlomelo E |

| Ukugoba uvavanyo | ISO 8491 okanye ASTM A370 |

| Uvavanyo lwe-Bend ekhokelwayo | ISO 5173 okanye ASTM A370 |

| Uvavanyo lokucaba | ISO 8492 okanye ASTM A370 |

| Uvavanyo lweMpembelelo yeCVN(PLS2) | I-ASTM A370 |

| Uvavanyo lwe-DWT(PSL2) | API 5L3 |

Usetyenziso lwe-API 5L X70

Imibhobho yeoli: isetyenziselwa ukuthutha i-oyile ekrwada okanye iimveliso ezisulungekisiweyo, ngakumbi kuthutho lomgama omde ukunqumla imimandla yejografi okanye ngaphantsi kwamanzi.

Imibhobho yerhasi: ukuqokelela kunye nokusasazwa kwerhasi yendalo, kubandakanywa nokuthuthwa komgama omde kunye neendawo ezinoxinzelelo oluphezulu.

Ukusetyenziswa kwezakhiwo: I-API 5L X70 ipayipi yensimbi iphinda isetyenziswe kwiiprojekthi ezikhethekileyo ezifana namaqonga ase-offshore okanye izakhiwo zenkxaso ephezulu.

Ukusetyenziswa kwemizi-mveliso: Iinkqubo zokuthutha ulwelo kwizityalo zekhemikhali, iindawo zokucoca, njl.

Iimeko ezikhethekileyo zokusetyenziswa: Ukuxhatshazwa kwe-corrosion ye-API 5L X70 ipayipi yensimbi yenza ukuba ilungele ukusetyenziswa kwiindawo ezahlukeneyo ezikhethekileyo, ngokukodwa kwiimeko ezinobungozi kunye ne-offshore.

Iimveliso zethu ezinxulumeneyo

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Umbhobho wentsimbi yeCarbon

I-Pipe End Processing

Ukusika imibhobho

Iingubo ezichasene ne-corrosion: i-galvanized, painted, 3PE, FBE, njl.

Singomnye wemibhobho yentsimbi yekhabhoni ehamba phambili kunye nabavelisi bemibhobho yentsimbi engenamthungo kunye nabanikezeli abavela eChina, kunye noluhlu olubanzi lwemibhobho yentsimbi ephezulu kwisitokhwe, sizimisele ukukunika uluhlu olupheleleyo lwezisombululo zemibhobho yentsimbi.Ukufumana iinkcukacha ezithe kratya zemveliso, nceda ukhululeke ukudibana nathi, sijonge phambili ekuncedeni ukuba ufumane iinketho ezingcono kakhulu zemibhobho yentsimbi kwiimfuno zakho!

Iithegi: X70, API 5l x70, ai 5l, ababoneleli, abavelisi, iifektri, abagcini bempahla, iinkampani, ihoseyili, thenga, ixabiso, ucaphulo, isambuku, intengiso, ixabiso.

Ixesha lokuposa: Apr-14-2024