I-JIS G 3456 iMibhobho yentsimbiziityhubhu zentsimbi zekhabhoni zifaneleke ikakhulu ukusetyenziswa kwindawo zenkonzo ezinobubanzi obungaphandle phakathi kwe-10.5 mm kunye ne-660.4 mm kumaqondo obushushu angaphezu kwama-350℃.

Amaqhosha okukhangela

I-JIS G 3456 yoHlelo lweBanga

Iimpahla ezingekasilwa

I-JIS G 3456 Iinkqubo zokuVelisa

Ukuphela kombhobho

Unyango olushushu

Amacandelo emichiza ye-JIS G 3456

Uvavanyo lwe-Tensile ye-JIS G 3456

Ukuzama ukuThwalaza

Uvavanyo lokuBendability

Uvavanyo lweHydraulic okanye uvavanyo olungonakalisi (NDT)

Itshathi yobunzima bombhobho kunye neeShedyuli zemibhobho ye-JIS G 3456

Ukunyamezelwa kweDimensional

Imbonakalo

JIS G 3456 Ukumakisha

I-JIS G 3456 Izicelo zemibhobho yentsimbi

Imigangatho eNxulumene ne-JIS G 3456

Iimveliso zethu ezinxulumeneyo

I-JIS G 3456 yoHlelo lweBanga

Umgangatho we-JIS G 3456 unamabakala amathathu ngokokuqina kombhobho.

I-STPT370,STPT410 kunye ne-STPT480

Bamele iityhubhu ezinobuncinci bokuqina be-370, 410, kunye ne-480 N/mm² (MPa) ngokulandelelanayo.

Iimpahla ezingekasilwa

Imibhobho iya kwenziwa ngentsimbi ebuleweyo.

Insimbi ebuleweyo luhlobo olukhethekileyo lwensimbi olubonakaliswe ngokongezwa kwezinto ezithile, ezifana ne-aluminium kunye ne-silicon, ngexesha lenkqubo yokunyibilika ukufunxa nokubopha i-oksijini kunye nezinye izinto ezinobungozi kwintsimbi.

Le nkqubo isusa ngokufanelekileyo iigesi kunye nokungcola, ngaloo ndlela iphucula ukucoceka kunye nokufana kwentsimbi.

I-JIS G 3456 Iinkqubo zokuVelisa

Iveliswe ngokusebenzisa inhlanganisela efanelekileyo yeenkqubo zokuvelisa i-tube kunye neendlela zokugqiba.

| Uphawu lwebakala | Uphawu lwenkqubo yokuvelisa | ||

| Inkqubo yokwenziwa kwemibhobho | Indlela yokugqiba | Ukumakisha | |

| STPT370 STPT410 STPT480 | Ingenamthungo:S | Kugqityiwe:H Kubanda-kugqityiwe:C | Njengoko kunikwe kwi-13 b). |

| Ukuxhathisa kombane okudityanisiweyo:E Impundu idityanisiwe:B | Kugqityiwe:H Kubanda-kugqityiwe:C Njengoko ukuxhathisa umbane welding:G | ||

KubaSTPT 480umbhobho womgangatho, kuphela umbhobho wentsimbi ongenamthungo oya kusetyenziswa.

Ukuba i-welding ye-resistance isetyenzisiweyo, i-welds kwindawo yangaphakathi nangaphandle yombhobho iya kususwa ukuze ifumane i-weld egudileyo.

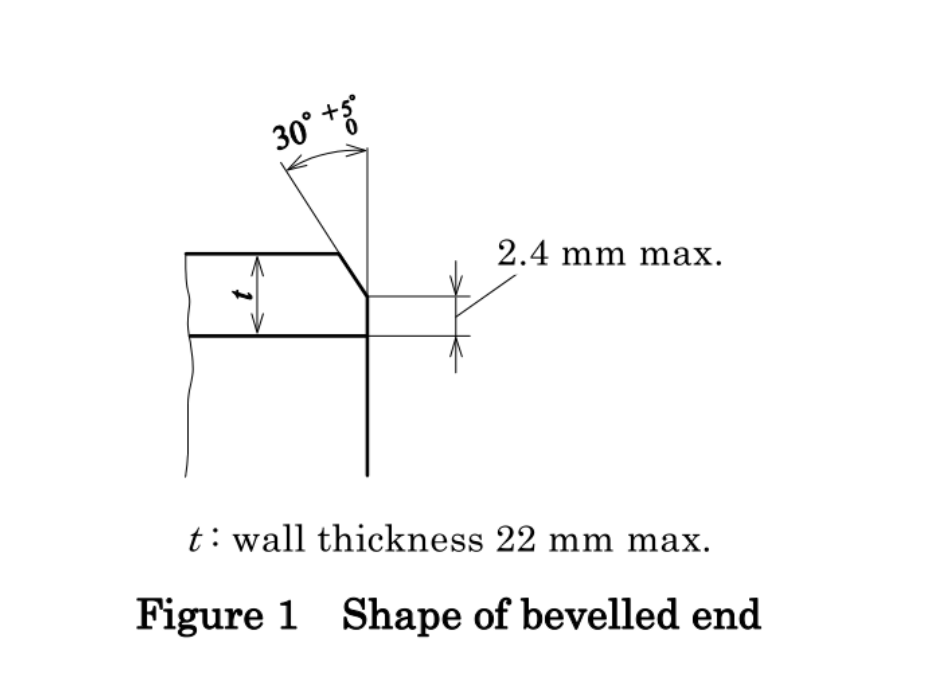

Ukuphela kombhobho

Umbhobho kufuneka ubeisiphelo esicaba.

Ukuba umbhobho kufuneka uqhutywe kwi-beveled end, ngenxa yobunzima bodonga ≤ 22mm umbhobho wensimbi, i-angle ye-bevel yi-30-35 °, ububanzi be-bevel bombhobho wensimbi yensimbi: max 2.4mm.

Ubukhulu bodonga olungaphezulu kwe-22mm yentsimbi yombhobho othambekileyo ekupheleni, ngokubanzi kusetyenzwa njenge-bevel edibeneyo, ukuphunyezwa kwemigangatho kunokubhekisela kwiimfuno ezifanelekileyo ze-ASME B36.19.

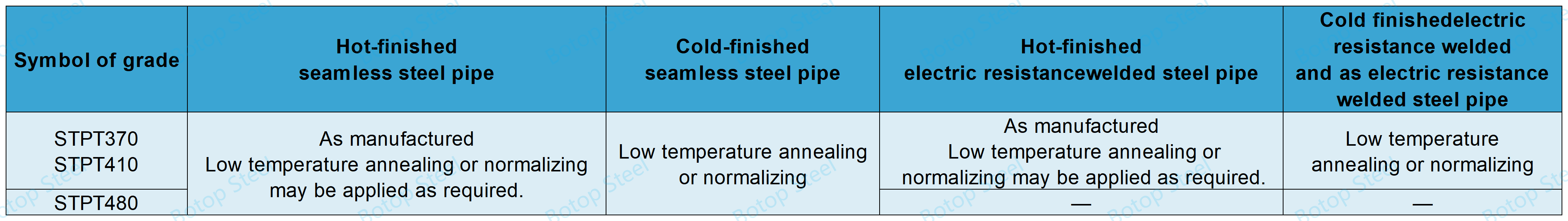

Unyango olushushu

Khetha inkqubo efanelekileyo yonyango lobushushu ngokwebakala kunye nenkqubo yokuvelisa.

Amacandelo emichiza ye-JIS G 3456

UVavanyo lokuBumba kweMichiza

Indlela yohlalutyo lobushushu iya kuhambelana ne-JIS G 0320.

Indlela yohlalutyo lwemveliso iya kuhambelana ne-JIS G 0321.

| Uphawu lwebakala | C(Ikhabhoni) | Si(Isilicon) | Mn(Manganese) | P(Phosphorus) | S(Sulfure) |

| max | max | max | |||

| STPT370 | 0.25% | 0.10-0.35% | 0.30-0.90% | 0.035% | 0.035% |

| STPT410 | 0.30% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

| STPT480 | 0.33% | 0.10-0.35% | 0.30-1.00% | 0.035% | 0.035% |

Ukunyamezela ukuBunjwa kweMichiza

Imibhobho yentsimbi engenamthungo iya kuba phantsi konyamezelo kwiThebhile 3 ye-JIS G 0321.

Imibhobho yentsimbi echasayo iya kuba phantsi kokunyamezelana kwiThebhile 2 ye-JIS G 0321.

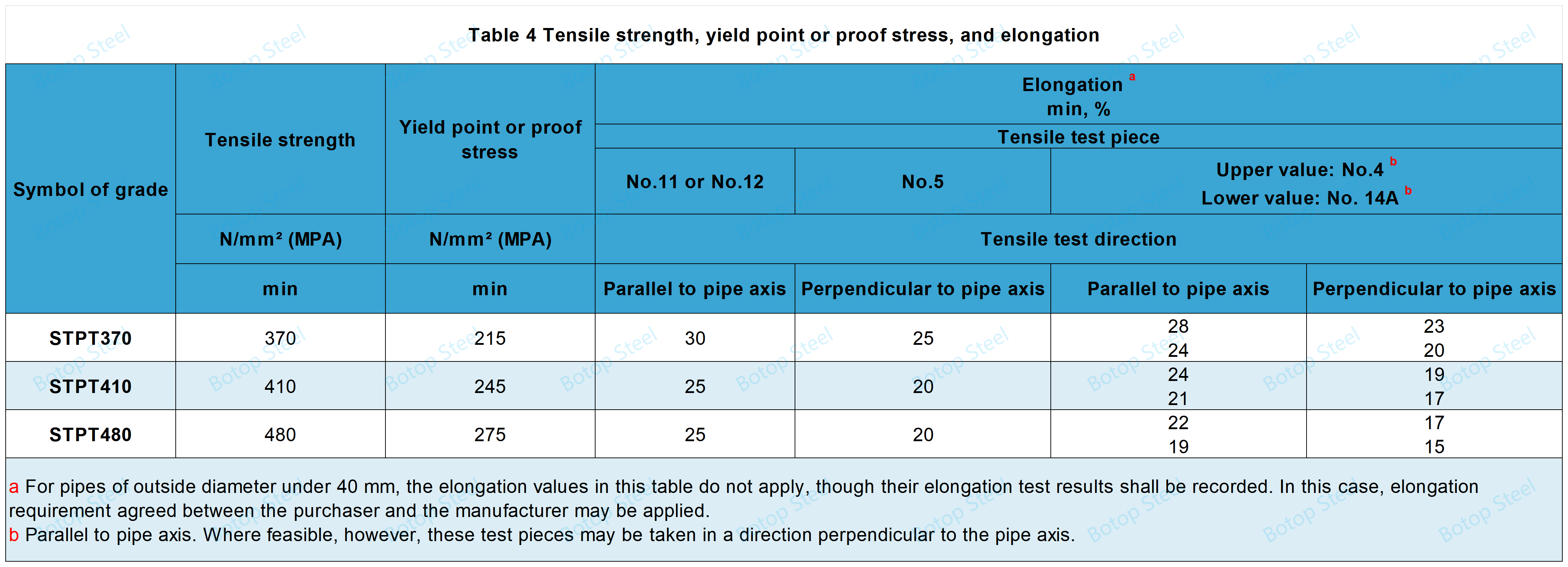

Uvavanyo lwe-Tensile ye-JIS G 3456

Iindlela zovavanyo: Iindlela zovavanyo ziya kuhambelana nemigangatho ekwi-JIS Z.2241.

Umbhobho uya kuhlangabezana neemfuno ezinikwe kwiThebhile 4 zokuqina kokuqina, amandla esivuno, kunye nobude.

Isiqwenga sovavanyo esisetyenzisiweyo siya kuba seNombolo ye-11, iNo.

I-diameter ye-Test piece No. 4 iya kuba yi-14 mm (ubude be-gauge 50 mm).

Iziqwenga zovavanyo ze-11 kunye neNombolo ye-12 ziya kuthathwa ngokuhambelana ne-axis yombhobho,

Iziqwenga zovavanyo No. 14A kunye no.

kunye nesiqwenga soVavanyo lwe-5, kwi-perpendicular kwi-axis yombhobho.

Isiqwenga sovavanyo lwe-12 okanye iNombolo ye-5 ethathwe kwi-electric resistance welded steel pipe ayiyi kuba ne-weld.

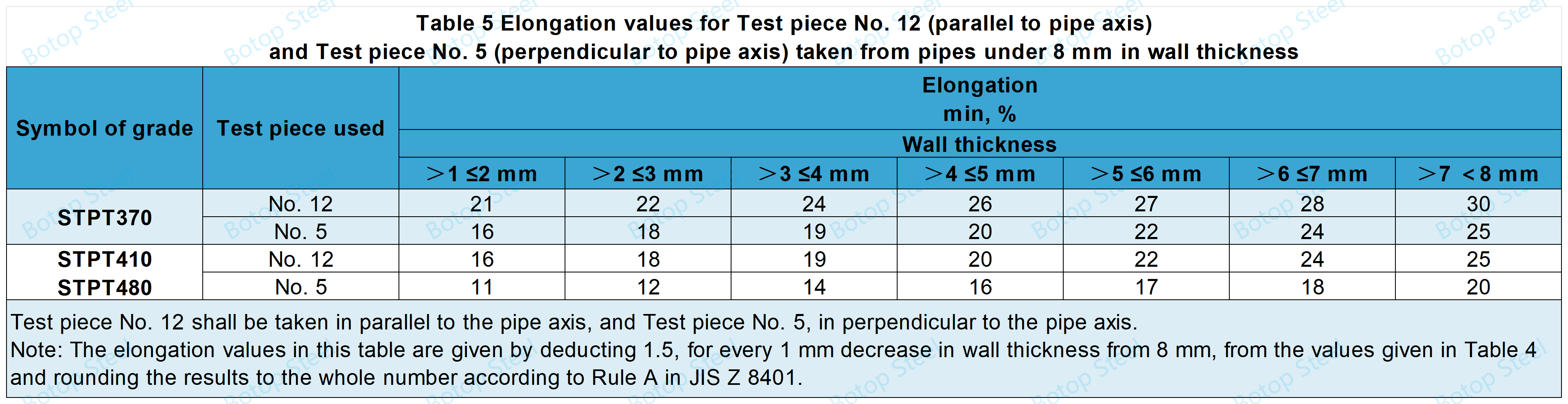

Kuvavanyo lwe-tensile lwemibhobho engaphantsi kwe-8 mm ubukhulu obuqhutywe kusetyenziswa isiqwenga soVavanyo esinguNombolo 12 okanye isiqwenga soVavanyo esinguNombolo 5, imfuneko yobude obunikwe kwiThebhile yesi-5 iya kusebenza.

Ukuzama ukuThwalaza

Kwiqondo lokushisa lokushisa (5 ° C - 35 ° C), thambisa i-specimen phakathi kwamaqonga amabini kude kubeumgama (H) phakathi kwabo ufikelela kwixabiso elichaziweyo kwaye emva koko ukhangele iintanda.

H=(1+e)t/(e+t/D)

н: umgama phakathi kweeplatens (mm)

t: ubukhulu bodonga lombhobho (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

е: kuchaziwe rhoqo kwibakala ngalinye lombhobho:

0.08 ye STPT370,

0.07 ye-STPT410 kunye ne-STPT480

Uvavanyo lokuBendability

I-Bendability isetyenziswa kwiibhobho ezinobubanzi obungaphandle be-60.5 mm okanye ngaphantsi.

Indlela yokuvavanya Kwiqondo lobushushu (5 ° C ukuya ku-35 ° C), bend iqhekeza lovavanyo malunga ne-mandrel de i-radius yangaphakathi ibe ngamaxesha angama-6 ububanzi obungaphandle bombhobho kwaye ukhangele iintanda. Kolu vavanyo, i-weld kufuneka ibekwe malunga ne-90 ° ukusuka kwindawo engaphandle ye-bend.

Uvavanyo lwe-Bendability lunokuthi luqhutywe ngokuhambelana nemfuno yokuba i-radius yangaphakathi iphindwe kane ububanzi bangaphandle bombhobho kunye ne-angle yokugoba yi-180 °.

Uvavanyo lweHydraulic okanye uvavanyo olungonakalisi (NDT)

Uvavanyo lwehydraulic okanye uvavanyo olungonakalisi luya kwenziwa kumbhobho ngamnye.

Uvavanyo lweHydraulic

Bamba umbhobho ubuncinane ubuncinane bexinzelelo lovavanyo lwe-hydraulic oluchazwe ubuncinane imizuzwana emi-5 kwaye uqaphele ukuba umbhobho uyakwazi ukumelana noxinzelelo ngaphandle kokuvuza.

Ixesha le-Hydraulic lichazwe ngokweShedyuli yepayipi yensimbi.

| Itheyibhile 6 Ubuncinci boxinzelelo lovavanyo lwehydraulic | ||||||||||

| Ubukhulu bodonga lwegama | Inombolo yeShedyuli: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Ubuncinci boxinzelelo lovavanyo lwe-hydraulic, iMpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Uvavanyo olungonakalisi

Ukuba ukuhlolwa kwe-ultrasonic kusetyenziswa, iimpawu ezivela kwiisampuli zereferensi eziqulethe imigangatho yereferensi yohlobo lwe-UD, njengoko kuchazwe kwi-JIS G 0582, iya kusetyenziswa njengamanqanaba e-alamu; naluphi na uphawu olusuka kumbhobho olulingana okanye olukhulu kunomgangatho we-alam luya kwaliwa. Ukongezelela, ubunzulu obuncinci beendawo zokuhlala zesikwere zokuvavanya imibhobho, ngaphandle kokugqiba okubandayo, kuya kuba ngu-0.3 mm.

Ukuba uhlolo lwangoku lwe-eddy luyasetyenziswa, iimpawu ezisuka kumgangatho wesalathiso wohlobo lwe-EY njengoko kuchaziwe kwi-JIS G 0583 ziya kusetyenziswa njengenqanaba le-alam; naluphi na uphawu olusuka kumbhobho olulingana okanye olukhulu kunomgangatho we-alam luya kuba sisizathu sokukhatywa.

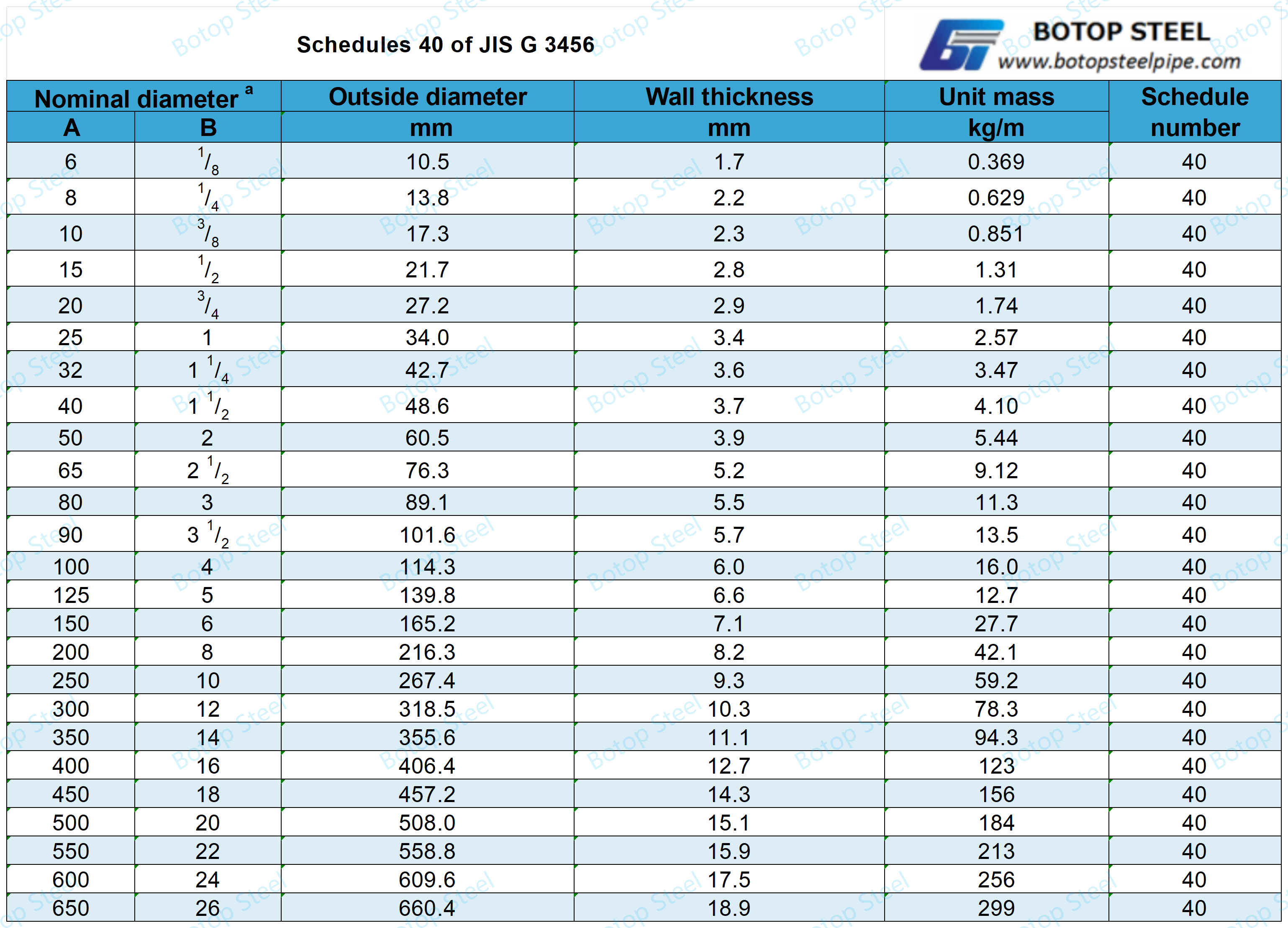

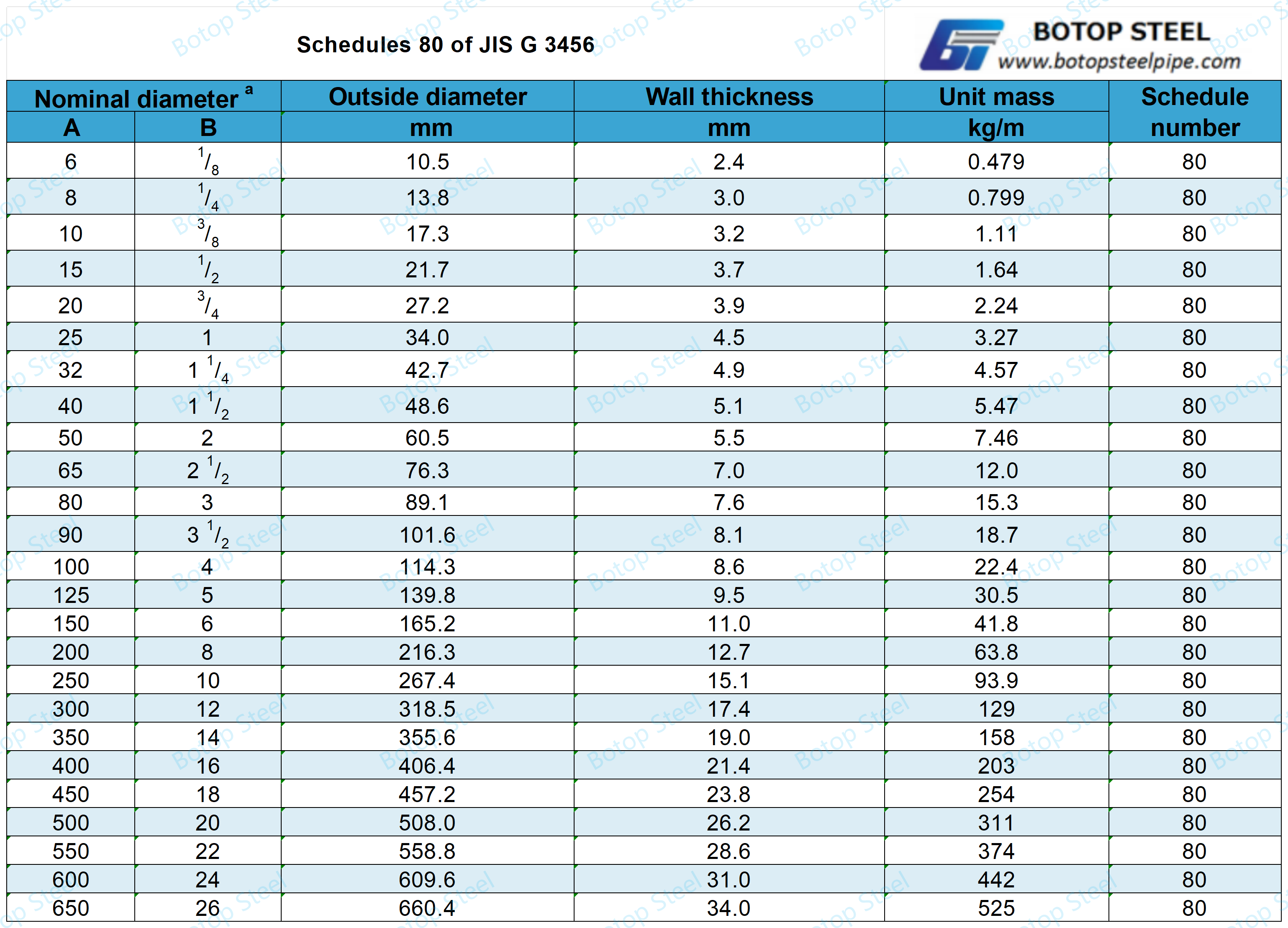

Itshathi yobunzima bombhobho kunye neeShedyuli zemibhobho ye-JIS G 3456

Steel Pipe Weight Calculation Formula

Qikelela ukuxinana kwe-7.85 g/cm³ kwityhubhu yentsimbi kwaye ujikeleze umphumo ukuya kumanani amathathu abalulekileyo.

W=0.02466t(Dt)

W: ubunzima beyunithi yombhobho (kg/m)

t: Ubukhulu bodonga lombhobho (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

0.02466: into yokuguqula ukufumana iW

Itshathi yobunzima bombhobho

Iitheyibhile zobunzima bombhobho kunye neeshedyuli ziimbekiselo ezibalulekileyo ezisetyenziswa ngokuqhelekileyo kubunjineli bombhobho.

Iishedyuli zombhobho

Ishedyuli yindibaniselwano esemgangathweni yobunzima bodonga kunye nobukhulu obuqhelekileyo bombhobho.

IShedyuli ye-40 kunye neShedyuli ye-80 yeetyhubhu zetsimbi zisetyenziswa ngokubanzi kwishishini kunye nokwakhiwa. Ziyimibhobho yobungakanani obuqhelekileyo obunobunzima obuhlukeneyo bodonga kunye namandla kwiimeko ezahlukeneyo zesicelo.

Ukuba ufuna ukwazi ngakumbi malunga neitafile yobunzima bombhobho kunye neshedyuli yombhobhokumgangatho, ungacofa ukuyijonga!

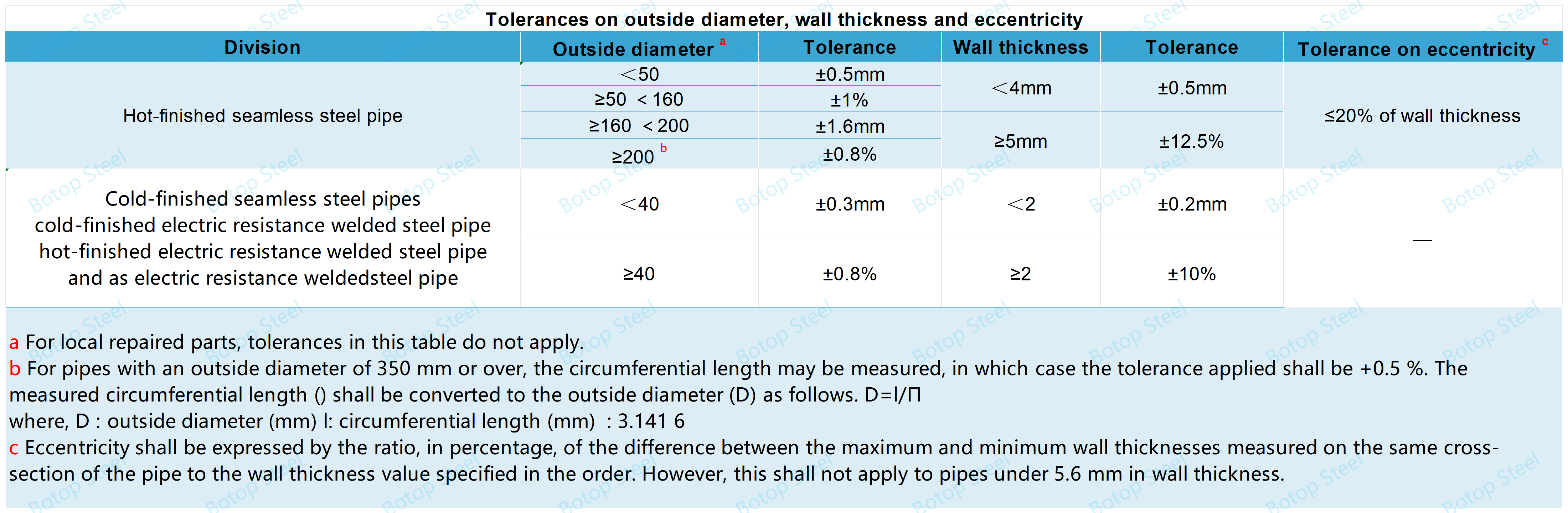

Ukunyamezelwa kweDimensional

Imbonakalo

Indawo yangaphakathi nangaphandle yombhobho iya kuba lula kwaye ikhululekile kwiziphene ezingathandekiyo ukuyisebenzisa.

Umbhobho uya kuba ngokuthe tye, kunye neziphelo kwii-angles ezichanekileyo kwi-axis yombhobho.

Imibhobho inokulungiswa ngokusila, umatshini okanye ezinye iindlela, kodwa ubuninzi bodonga olulungisiweyo buya kuhlala ngaphakathi kokunyamezela okuchaziweyo kunye nokulungiswa kwendawo kuya kuba lula kwiprofayili.

Ubunzima bodonga lombhobho olungisiweyo buya kugcinwa ngaphakathi kokunyamezela okuchaziweyo kunye nomphezulu wombhobho olungisiweyo uya kuba lula kwiprofayili.

JIS G 3456 Ukumakisha

Umbhobho ngamnye odlula ukuhlolwa kufuneka ubhalwe ngolu lwazi lulandelayo. Iileyibhile zinokusetyenziswa kwiibhandle zemibhobho yobubanzi obuncinci.

a) Uphawu lwebakala

b) Uphawu lwenkqubo yokuvelisa

Isimboli yenkqubo yokwenziwa kwemveliso iya kuba ngolu hlobo lulandelayo. Udwi unokutshintshwa ngezithuba ezingenanto.

Umbhobho wentsimbi ongenamthungo ogqitywe kushushu:-SH

Umbhobho wentsimbi ongenamthungo ogqityiweyo obandayo: -SC

Njengoko ukuxhathisa ombane welding umbhobho wentsimbi: -EG

Umbhobho wentsimbi odityanisiweyo oshushu ogqityiweyo: -EH

Umbhobho wentsimbi odityanisiweyo ogqityiweyo obandayo: -EC

c) Imilinganiselo, ebonakaliswa ngedayamitha yegama × ubukhulu bodonga lwegama, okanye ngaphandle kwedayamitha × ubukhulu bodonga.

d) Igama lomenzi okanye uphawu lokuchonga

Umzekelo:BOTOP JIS G 3456 SH STPT370 50A×SHC40 HEAT NO.00001

I-JIS G 3456 Izicelo zemibhobho yentsimbi

I-JIS G 3456 yentsimbi yombhobho idla ngokusetyenziselwa izixhobo kunye neenkqubo zombhobho kwiindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu, njengamabhoyili, i-heat exchangers, i-high-pressure steam piping, izityalo zamandla ashushu, izityalo zekhemikhali, kunye nezixhobo zephepha.

Imigangatho eNxulumene ne-JIS G 3456

Le migangatho ilandelayo isetyenziswa yonke imibhobho kwindawo yobushushu obuphezulu kunye noxinzelelo oluphezulu kwaye ingasetyenziswa njengenye indlela ye-JIS G 3456.

I-ASTM A335 / A335M: esebenzayo kwimibhobho yentsimbi ye-alloy

I-DIN 17175: kwimibhobho yentsimbi engenamthungo

I-EN 10216-2: Imibhobho yentsimbi engenamthungo

I-GB 5310: esebenzayo kumbhobho wensimbi ongenamthungo

I-ASTM A106 / A106M: Iityhubhu zentsimbi zekhabhoni ezingenamthungo

I-ASTM A213/A213M: Iityhubhu ezingenamthungo kunye nemibhobho yentsimbi yealloyi kunye nentsimbi engatyiwayo.

I-TS EN 10217-2 Ilungele iityhubhu ezidityanisiweyo kunye nemibhobho

ISO 9329-2: Iityhubhu zentsimbi zekhabhoni kunye nealloy kunye nemibhobho engenamthungo

I-NFA 49-211: kwiityhubhu zentsimbi ezingenamthungo kunye nemibhobho

I-BS 3602-2: kwimibhobho yentsimbi yekhabhoni engenamthungo kunye nokufakelwa

Iimveliso zethu ezinxulumeneyo

Singumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi! Ukuba ufuna ukwazi ulwazi oluthe kratya malunga neemveliso zemibhobho yentsimbi, ungaqhagamshelana nathi.

Iithegi: JIS G 3456, SPTP370, STPT410, STPT480, STPT, ababoneleli, abavelisi, iifektri, ii-stockists, iinkampani, ihoseyili, thenga, ixabiso, ucaphulo, isambuku, intengiso, ixabiso.

Ixesha lokuposa: Apr-29-2024