I-ASTM A106 iBanga B yipayipi yensimbi ye-carbon engenamthungo esekelwe kumgangatho we-ASTM A106 kwaye yenzelwe ukujamelana nokushisa okuphezulu kunye neendawo zoxinzelelo.

Isetyenziswa ikakhulu kumashishini e-oyile, erhasi, nakumashishini ekhemikhali ekwakheni imibhobho kunye nezixhobo ezinxulumeneyo.

Amaqhosha okukhangela

IBanga le-ASTM A106

I-ASTM A106 yinkcazo esemgangathweni yombhobho wentsimbi ye-carbon engenamthungo kwizicelo zobushushu obuphezulu obuphuhliswe yi-ASTM International. Inkcazo ichaza amabakala amathathu e-seamless carbon steel pipe, iBanga A, iBanga B, kunye neBanga C. Kulawa, iBakala B lelona lisetyenziswa ngokuqhelekileyo.

IBakala "B" limele ukwakheka kweekhemikhali ezithile kunye nenqanaba lepropathi yomatshini wezinto ezisetyenziswayo kumaqondo obushushu athile kunye noxinzelelo.

Ukuba ufuna ukwazi ngakumbi nge-ASTM A106 ungacofa:Ithetha ukuthini iASTM A106?

Ezona mpawu

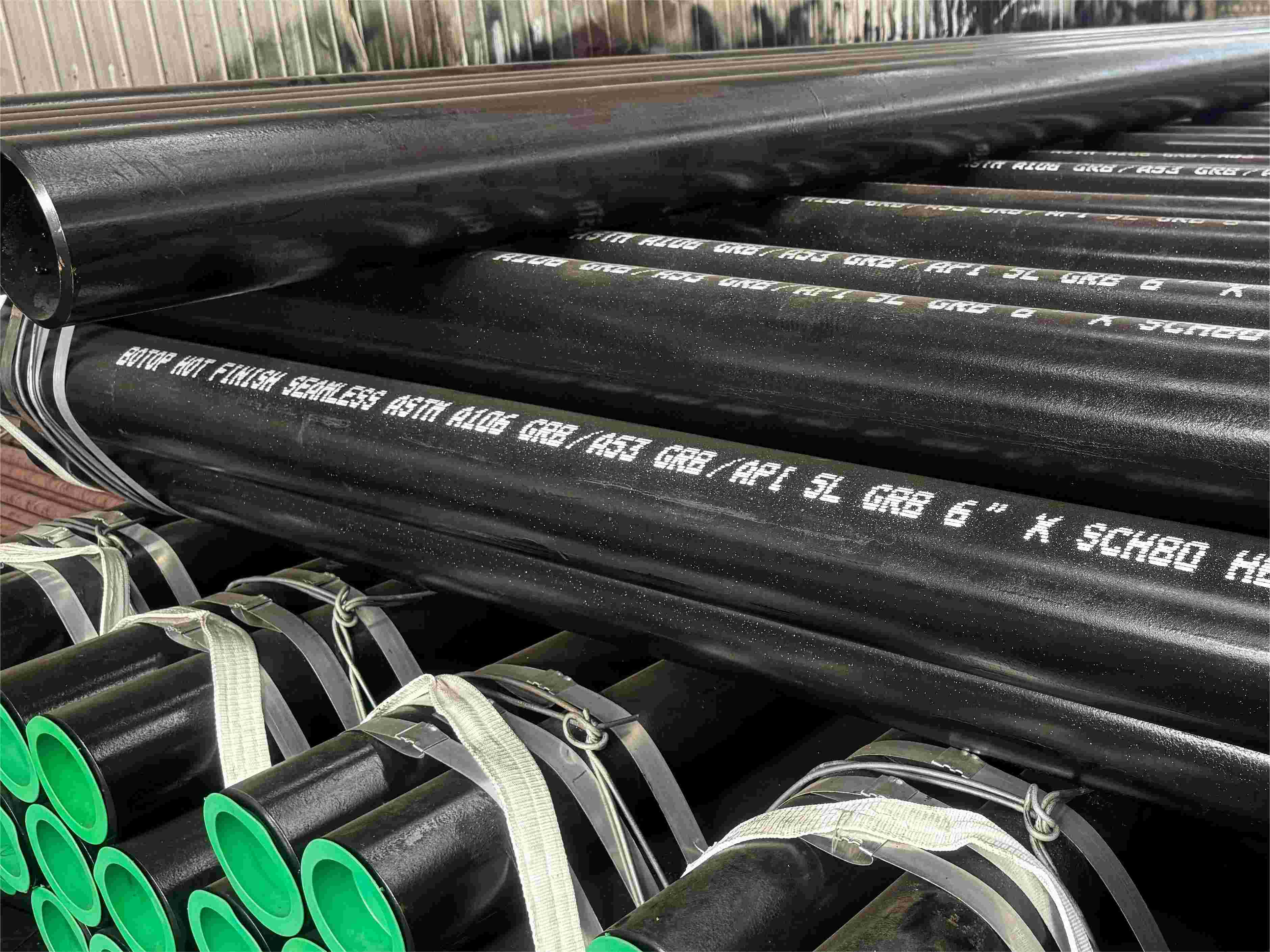

Uveliso olungenamthungo

Ityhubhu ye-ASTM A106 yeBanga B iveliswa ngenkqubo yokuvelisa engenamthungo eqinisekisa ukufana kunye namandla okusetyenziswa kwiindawo eziphantsi koxinzelelo oluphezulu.

Ubushushu bokusebenza obuphezulu

Lo mbhobho ulungele ukusebenza kwiindawo eziphezulu zobushushu, njengeenkqubo zombhobho kwizikhululo zamandla, iindawo zokucoca, kunye nezityalo zekhemikhali.

Ukuqulunqwa kwemichiza

Ukwakhiwa kweekhemikhali zeBanga B kuyilelwe ukunika ukuxhathisa ubushushu kunye nokuqhubekeka. Ngokuqhelekileyo iqulethe umxholo wekhabhoni ephantsi kunye nemilinganiselo ephakathi ye-manganese, i-phosphorus, isulfure, kunye ne-silicon.

Iipropati zoomatshini

Umbhobho wensimbi we-ASTM A106 weBanga B unika amandla agqwesileyo okuqina kunye namandla esivuno esihle kwizicelo ezifuna iipropati ezilungileyo zoomatshini.

Uluhlu olubanzi lwezicelo

Ngenxa yokumelana nobushushu kunye neempawu zemishini, i-ASTM A106 yeBanga B i-tubing isetyenziselwa uluhlu olubanzi lwezicelo ezifana neoli kunye negesi, i-petrochemicals, i-boilers, kunye nokutshintsha ubushushu.

Ukuqulunqwa kwemichiza

| Ukuqamba | C (Ikhabhoni) | Mn (Manganese) | P (Phosphorus) | S (Sulfure) | Si (Isilicon) | Cr (Chromium) | Cu (Ubhedu) | Mo (Molybdenum) | Ni (Nickel) | V (Vanadium) |

| max | - | max | max | imiz | max | max | max | max | max | |

| ubungakanani obuqulethwe | 0.30 % | 0.29 - 1.06 % | 0.035 % | 0.035 % | 0.10 % | 0.40 % | 0.40 % | 0.15 % | 0.40 % | 0.08 % |

Ngaphandle kokuba kucaciswe ngenye indlela ngumthengi, kunciphiso ngalunye lwe-0.01 % ngaphantsi kobuninzi bekhabhoni obuchaziweyo, ukwanda kwe-0.06% yemanganese ngaphezu kobuninzi obuchaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.65 %.

I-Cr, i-Cu, i-Mo, i-Ni, kunye ne-V: i-totali yezi zinto zintlanu aziyi kuba ngaphezu kwe-1%.

Iipropati zoomatshini

| Uluhlu | Amandla okuqina, min | Amandla esivuno, min | ||

| ukuhlelwa | psi | MPa | psi | MPa |

| I-ASTM A106 IBanga b | 60,000 | 415 | 35,000 | 240 |

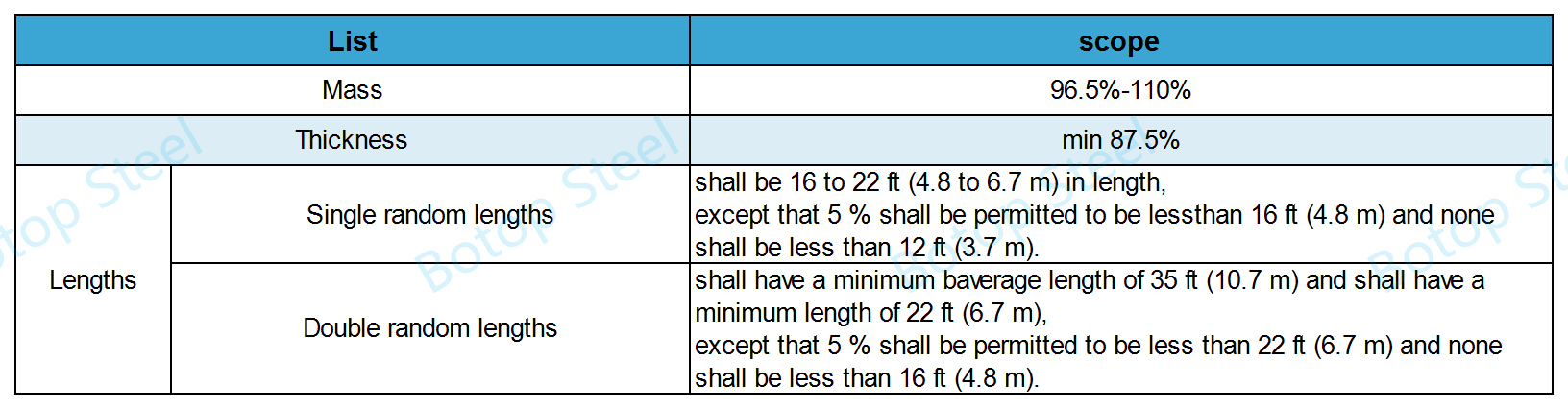

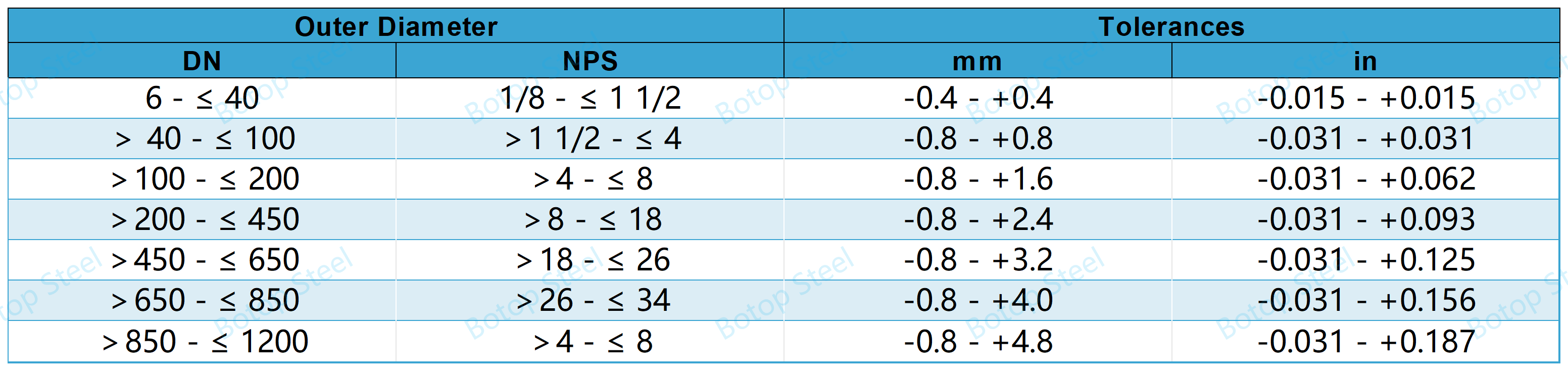

Ukunyamezelwa kweDimensional

Ubunzima, Ukutyeba, kunye noBude

Ububanzi bangaphandle

Uvavanyo kunye neSiqinisekiso

Uhlalutyo lokuBumba kweMichiza

Ukugqiba ukubunjwa kweekhemikhali zombhobho, kuquka i-carbon, i-manganese, i-phosphorus, isulfure, kunye ne-silicon ukuqinisekisa ukuba izinto eziphathekayo zihlangabezana neemfuno zokwakheka kweekhemikhali ezichazwe kumgangatho.

Uvavanyo lwe-Tensile

Ukulinganisa amandla okuqina, amandla esivuno, kunye nobude bombhobho wentsimbi. Olu vavanyo lunceda ukuvavanya ukusebenza kwemathiriyeli kunye nokuqina phantsi koxinzelelo lwe-tensile.

Ukugoba uvavanyo

Iimvavanyo zokugoba zenziwa kumbhobho odityanisiweyo kunye nongenamthungo ukuvavanya umthamo weplastiki yoguquko kunye nokuthembeka kwamalungu adityanisiweyo.

Uvavanyo lokucaba

Uvavanyo lwe-flattening lwenziwa kwiityhubhu ukuvavanya i-deformation yabo kunye neempawu zokuqhawula phantsi koxinzelelo.

Uvavanyo lobulukhuni

Ukuqina kwesixhobo kuhlolwa ngovavanyo lobulukhuni be-Brinell okanye i-Rockwell. Olu vavanyo lubalulekile ekunqumeni ukusetyenzwa kunye neempawu zokusetyenziswa kwezinto eziphathekayo.

I-Hydrotesting

Umbhobho ngamnye kufuneka uvavanywe nge-hydrostatically ukuqinisekisa ukuba awuvuzi kuxinzelelo oluchaziweyo ukuqinisekisa ukuqina kunye nokhuseleko lwenkqubo yemibhobho.

Uvavanyo olungonakalisi

Kubandakanya uVavanyo lwe-Ultrasonic (UT), uVavanyo lweMagnetic Particle (MT) kunye / okanye uvavanyo lweRadiographic (RT) ukufumanisa iziphene zangaphakathi kunye nephezulu ezifana nokuqhekeka, ukufakwa kunye ne-porosity.

Uvavanyo lweMpembelelo (ngesicelo)

Kwezinye iimeko, uvavanyo lwempembelelo (umzekelo, uvavanyo lwe-Charpy V-notch) lunokufuneka ukuvavanya ukuqina kokwaphuka kwesixhobo kumaqondo obushushu aphantsi.

Usetyenziso oluphambili lwe-ASTM A106 iBanga B

Ukuthuthwa kweoyile negesi: kuxinzelelo oluphezulu kunye neendawo ezinobushushu obuphezulu.

Ukulungiswa kweekhemikhali: Kumhlwa kunye neenkqubo zemibhobho ekwazi ukumelana nobushushu obuphezulu.

Izikhululo zombane: kwimigca yomphunga kunye neendawo zokubilisa.

Imveliso yoShishino: kwimibhobho yoxinzelelo kunye nezixhobo zoxinzelelo oluphezulu.

Ukwakhiwa kunye nokwakhiwa kweenqanawa: Ukwakhiwa kweenkqubo zokufudumeza kunye nokupholisa kunye nebhoyila kunye neenkqubo zomphunga kwiinqanawa.

Ushishino lweemoto: kukwenziwa kweendawo zeemoto ezixhathisayo kumaqondo obushushu aphezulu kunye noxinzelelo.

Enye indawo kwi-ASTM A106 GR.B

Xa ukhetha izinto ezizezinye, kufuneka kuqwalaselwe kwiipropati zomatshini, ukuchasana nokushisa, ukunyanzeliswa koxinzelelo, kunye nokuxhatshazwa kwe-corrosion ye-corrosion ye-corrosion material ukuqinisekisa ukuthotyelwa kwezidingo ezithile zesicelo kunye nemimiselo kunye nemigangatho efanelekileyo.

| Igama eliqhelekileyo | Ubungakanani besicelo |

| I-ASTM A53 iBanga B | Uxinzelelo oluphantsi kunye nezicelo zeZakhiwo zoomatshini |

| API 5L iBanga B | Imibhobho yeoli kunye negesi |

| I-ASTM A333 iBanga lesi-6 | Ngenkonzo yobushushu obuphantsi |

| I-ASTM A335 P11 或 P22 | Kubushushu obuphezulu obufana neebhoyila kwizikhululo zamandla |

| I-ASTM A312 TP304 或 TP316 | Izicelo ezifuna ukuxhathisa kokutya okuphezulu |

| ASME SA106 | Ubushushu obuphezulu kunye neendawo ezinoxinzelelo oluphezulu |

| AS/NZS 1163 C350L0 | Iinjongo zesakhiwo kunye noomatshini |

| GB 3087 | Iityhubhu zentsimbi ezingenamthungo kwiibhoyili eziphantsi kunye neziphakathi |

| GB 5310 | Iityhubhu zentsimbi ezingenamthungo kwiibhoyili zoxinzelelo oluphezulu |

| GB 9948 | Iityhubhu zentsimbi ezingenamthungo zokuqhekeka kweoyile |

Ukugquma okuKhuselayo kwe-ASTM A106 GR.B

Iigalvanized

I-galvanizing yindlela yokubonelela ngokukhuselwa kwe-corrosion ngokusebenzisa i-zinc coating kumphezulu wentsimbi.

Obona buchule buxhaphakileyo bokwenza inkenteza kukugalela idiphu eshushu, apho umbhobho wentsimbi uthi nkxu kwi-zinc etyhidiweyo ukuze wenze umaleko oshinyeneyo we-zinc kumphezulu wawo.

Olu luhlu lwe-zinc alugcini nje ngokukhusela i-substrate yensimbi emoyeni nasemanzini, lukhusela i-oxidation, kodwa lunciphisa izinga le-corrosion yensimbi ngokukhuselwa kwe-anodic yedini (i-zinc isebenza ngakumbi kunentsimbi).

Umbhobho wentsimbi owenziwe ngesinyithi oshushu-dip ulungele ukusetyenziswa ngaphandle okanye kwiindawo ezimanzi, ezifana nezixhobo zokucocwa kwamanzi kunye nezakhiwo zangaphandle zokwakha.

Ukwaleka

I-Coating yindlela yokuthintela ukubola ngokufaka enye okanye ngaphezulu kweengqimba ze-anti-corrosion ye-coating ethile kumphezulu wepayipi yensimbi.

Ezi zambatho zinokuba yi-epoxy, i-polyurethane, i-polyethylene, okanye ezinye izinto zokwenziwa.

Iingubo ze-epoxy zisetyenziswa ngokubanzi kwimibhobho yemizi-mveliso ngenxa yozinzo olugqwesileyo lweekhemikhali kunye nokunamathela.

Umsebenzi oyintloko wokugquma kukuthintela umswakama kunye neekhemikhali ezitshabalalisayo, ukuthintela ukuba badibane ngqo nentsimbi. Ukunyangwa kwe-coating ifanelekile kuluhlu olubanzi lweendawo ezifana nezityalo zekhemikhali, iindawo zaselwandle kunye nothungelwano lwemibhobho yasezidolophini.

I-Lining Coating

Ukunyangwa kwe-lining kukusebenzisa umaleko wezinto ezichasene ne-corrosive, ezifana ne-epoxy resin, i-ceramics, okanye i-rubber, ngaphakathi kombhobho wentsimbi ukuthintela ukubola kwendlela yokuhambisa kudonga lwangaphakathi lombhobho wensimbi.

Le ndlela ifaneleke ngokukodwa ukuhambisa ulwelo oludlekayo (umz. iiasidi, iialkali, izinyibiliko zetyuwa, njl. njl.).

I-Epoxy resin lining inika umaleko oqinileyo wokuchasana nokonakala okwaziyo ukumelana nenqanaba elithile lokuhlaselwa kweekhemikhali kunye nokuqhawuka komzimba.

Ulwelo alunandisi nje kuphela ubomi bombhobho kodwa lukwagcina ukucoceka kolwelo nokuthintela ukungcoliseka.

Iimveliso zethu ezinxulumeneyo

Singomnye wemibhobho yentsimbi yekhabhoni ehamba phambili kunye nabavelisi bemibhobho yentsimbi engenamthungo kunye nabanikezeli abavela eChina, kunye noluhlu olubanzi lwemibhobho yentsimbi ephezulu kwisitokhwe, sizimisele ukukunika uluhlu olupheleleyo lwezisombululo zemibhobho yentsimbi. Ukufumana iinkcukacha ezithe kratya zemveliso, nceda ukhululeke ukudibana nathi, sijonge phambili ekuncedeni ukuba ufumane iinketho ezingcono kakhulu zemibhobho yentsimbi kwiimfuno zakho!

tags:a106 ibakala b, a106, ingenamthungo, ababoneleli, abavelisi, iifektri, abagcini bempahla, iinkampani, ihoseyili, thenga, ixabiso, ikowuti, isambuku, intengiso, ixabiso.

Ixesha lokuposa: Mar-01-2024