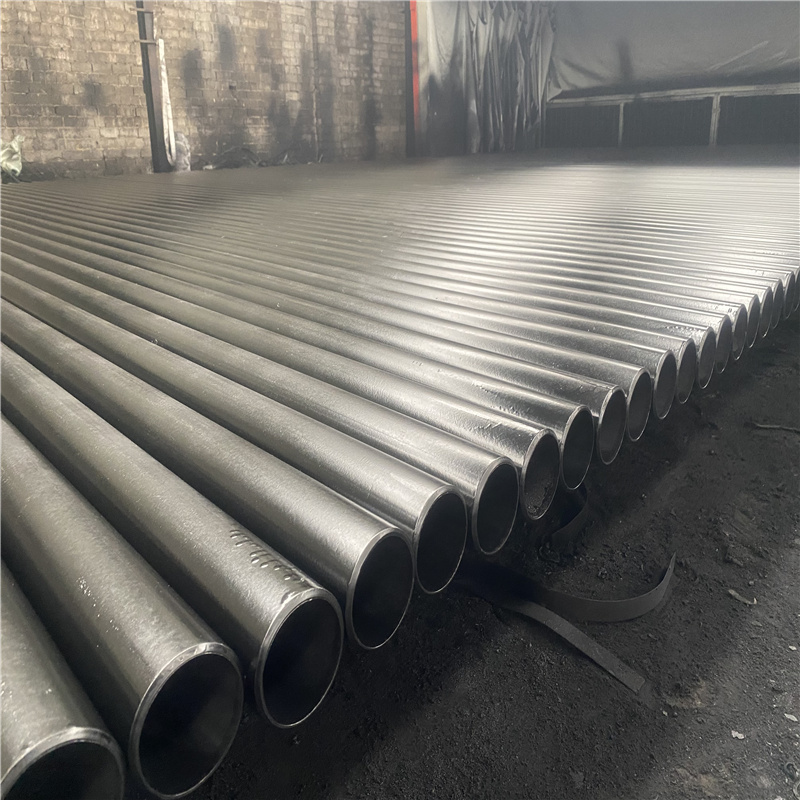

I-ASTM A192:Inkcazo esemgangathweni yeeThubhu zeBoiler zentsimbi yeCarbon engenamthungo kwiNkonzo yoxinzelelo oluphezulu.

Le nkcazo igubungela ubuncinci bodonga lobunzima, ibhoyila yentsimbi yekhabhoni engenamthungo, kunye neetyhubhu zeheater enkulu yenkonzo yoxinzelelo oluphezulu.

Amaqhosha okukhangela

ASTM A192 Ubungakanani Range

Ububanzi obungaphandle: 12.7-177.8mm1/2-7 ngaphakathi.]

Ubuncinane obukhulu bodonga: 2.2-25.4mm [0.085 -1in.]

Iityhubhu ezinomnye umlinganiselo zinokunikezelwa, ngaphandle kokuba iityhubhu ezinjalo zithobelana nazo zonke ezinye iimfuno zolu nkcukacha.

Ukwenziwa

Iityhubhu azinamthungo kwaye zishushu okanye zibandayo zisetyenzwe njengoko kusenziwa iNkqubo.

I-ASTM A192 zimbini iindlela eziphambili zokuvelisa umbhobho wentsimbi ongenamthungo: utsalwa ngokubanda kwaye ushushu uqengqiwe.

Unyango lobushushu

Ubushushu bunyangwa kwi-1200℉ [650℃] okanye ngaphezulu emva kwepaseji yokufunxa ebandayo yokugqibela.

Ukunyamezelwa kweDimensional

Izixhobo ezibonelelweyo ziya kuhlangabezana neemfuno ezifanelekileyo ze-ASTM A450.

| Ukunyamezelwa komgangatho | ||

| Uluhlu | uhlobo | ububanzi |

| IMisa | DN≤38.1mm[NPS 11/2] | +12% |

| DN>38.1mm[NPS 11/2] | +13% | |

| Ububanzi | DN≤38.1mm[NPS 11/2] | +20% |

| DN>38.1mm[NPS 11/2] | + 22% | |

| Ubude | DN<50.8mm[NPS 2] | +5mm[NPS 3/16] |

| DN≥50.8mm[NPS 2] | +3mm[NPS 1/8] | |

| Ukuthe tye kwaye Gqiba | Iityhubhu ezigqityiweyo ziya kuthi nkqo ngokufanelekileyo kwaye zibe neziphelo ezigudileyo ezingenazo iibhara. | |

| Ukuphatha isiphene | Nakuphi na ukungaqhubeki okanye ukunganyaniseki okufunyenwe kwityhubhu kunokususwa ngokusila, ngaphandle kokuba indawo egudileyo egobileyo igcinwe, kwaye ubuninzi bodonga abuncitshiswanga bube bungaphantsi kokuvunyelwa yile nto okanye inkcazo yemveliso. | |

Ubunzima boMbhobho we-ASTM A192 wokubala

Ifomula yobunzima yile:

M=(DT)×T×C

Mbubunzima ngeyunithi yobude;

Dyi-diameter yangaphandle echaziweyo, echazwe ngeemilimitha (ii-intshi);

T ubukhulu bodonga obuchaziweyo, bubonakaliswe ngeemilimitha (ii-intshi);

Cyi 0.0246615 ukubala kwiiyunithi SI kunye 10.69 ukubala kwiiyunithi USC.

Ukuba ufuna ukwazi ngakumbi malunga nentsimbiitshathi yobunzima bombhobhokwayeishedyuli yombhobho, Cofa apha!

Uvavanyo lwe-ASTM A192

Imigangatho yokuphumeza yovavanyo

| Uvavanyo | Umgangatho |

| Amacandelo eMichiza | I-ASTM A450 Icandelo le-6 |

| Iimvavanyo zoomatshini | I-ASTM A450 Icandelo le-7 |

| Uvavanyo lokucaba | I-ASTM A450 Icandelo le-19 |

| Uvavanyo lomlilo | I-ASTM A450 Icandelo le-21 |

| Uvavanyo lobulukhuni | I-ASTM A450 Icandelo le-23 |

| Uvavanyo loxinzelelo lwe-hydraulic | I-ASTM A450 Icandelo le-24 |

| Uviwo Olungonakalisi | I-ASTM A450, iCandelo lama-26 |

Lo mgangatho uneemfuno ezithile zokwakheka kweekhemikhali kunye neempawu zoomatshini: ezinye iimvavanyo zibhekisa kwi-ASTM A450.

Amacandelo eMichiza

| Amacandelo eMichiza | |

| C(Ikhabhoni) | 0.06-0.18 |

| Mn(Manganese) | 0.27-0.63 |

| P(Phosphorus) | ≤0.035 |

| S(Sulfure) | ≤0.035 |

| Si(Isilicon) | ≤0.25 |

| Akuvumelekanga ukubonelela ngamabakala e-alloy acela ngokucacileyo ukuba kongezwe nayiphi na into ngaphandle kwezi zidweliswe ngasentla. | |

Iipropati ze-Tensile

| IiMfuno zeTensile | |||

| Uluhlu | ukuhlelwa | ixabiso | |

| Tensile strength, umz | ksi | 47 | |

| MPa | 325 | ||

| Unikeze Amandla, umz | ksi | 26 | |

| MPa | 180 | ||

| Elongation kwi-50mm (2 ngaphakathi), min | % | 35 | |

Imiba engundoqo yokuMakisha

Iya kuphawulwa ngokucacileyo:

igama lomenzi okanye uphawu

inombolo yenkcazo,ibakala

igama kunye nenombolo ye-odolo yomthengi

kushushu okanye kubanda.

Qaphela: Ukumakishwa akufuneki kuquke umhla wonyaka wolu luhlu.

Ngeityhubhu ezingaphantsi ko-11/4ngaphakathi [31.8 mm] ububanzi kunye neetyhubhu ezingaphantsi kwe-3 ft [1 m] ubude, ulwazi olufunekayo lunokuphawulwa kwithegi eqhotyoshelwe ngokukhuselekileyo kwi-bundle okanye ibhokisi apho iityhubhu zithunyelwa khona.

ULungiselelo olongezelelweyo

Xa kuthengwa kwaye kusetyenziswa umbhobho we-ASTM A192, indawo yokusetyenziswa kokuphela kunye neemfuno ezithile zomsebenzisi zinokufuna ukuqhutyelwa phambili okongezelelweyo:

Ipeyinti okanye iCoating

Ipeyinti engangenwa ngumhlwa okanye ezinye izinto zokukhusela zingafakwa kumphezulu. Ezi zambatho zibonelela ngokhuseleko oluthile ekudlekeni, ngakumbi ukuba ityhubhu yebhoyila ibonakaliswe kukufuma.

Amayeza okulwa nomhlwa

Ukongeza kwipeyinti, ezinye iindlela zonyango ezichasene ne-corrosion ezifana ne-galvanizing, i-aluminizing, okanye i-coating kunye nezinye izinto ezichasene ne-corrosion zingasetyenziswa ukunceda ukwandisa ukuqina kombhobho kwiindawo ezinzima.

Unyango lobushushu

Nangona i-ASTM A192 ichaza iimfuno zokwenziwa kunye novavanyo lombhobho, kwezinye izicelo unyango olongezelelweyo lobushushu (umzekelo, ukunyanzeliswa, ukufakwa kwe-annealing) kunokufuneka ukuphumeza iipropati ezithile zoomatshini okanye ukuphucula i-microstructure yombhobho.

Umphezulu wangaphakathi nowangaphandle uyaGqibela

Umphezulu wangaphakathi nangaphandle weityhubhu zebhoyila unokufuna ukugutywa, ukukhazimliswa, okanye ukucocwa ukuze kuphuculwe iimpawu zokuqukuqela kwamanzi okanye ucoceko.

Ukuphelisa oomatshini

Ngokuxhomekeke kwiimfuno zofakelo kunye noqhagamshelo, iziphelo zeetyhubhu zebhoyila zingadinga ukuxutyushwa, i-chamfered, okanye ngenye indlela umatshini ukuququzelela ukufakwa.

Uhlolo olongezelelweyo

Ukuqinisekisa ukuba iibhubhu ziyahlangabezana ne-ASTM A192 kunye neemfuno ezikhethekileyo kumthengi, uhlolo olongezelelweyo lunokwenziwa. Ngokomzekelo, uvavanyo lwe-ultrasonic, uvavanyo lwe-X-ray, njl.

Isicelo esikhethekileyo

Ubuchwephesha kwibhoyila yentsimbi yekhabhoni engenamthungo kunye neetyhubhu zeheater. Ezi zityhubhu zisetyenziselwa kakhulu iinkonzo zoxinzelelo oluphezulu ezifana ne-boilers yoxinzelelo oluphezulu, i-ultra-high-pressure boilers, kunye nezixhobo ezisebenza kwiindawo eziphezulu zokushisa kunye noxinzelelo oluphezulu.

Oku kulandelayo kusetyenziswa umbhobho wentsimbi we-ASTM A192 ekusebenzeni:

Iibhoyili zoxinzelelo oluphezulu

Iityhubhu ze-ASTM A192 ezingenamthungo zifaneleke ngokukodwa ukwenza iityhubhu ze-superheater, iityhubhu zebhoyila yamanzi ashushu, ii-conduits zomphunga, iityhubhu ezinkulu zeflue, njl. Ngokuqhelekileyo zisetyenziswa kwizikhululo zamandla, izityalo zoshishino kunye nemigodi kunye nezixhobo zekhemikhali, ezisetyenziselwa ukuvelisa ukushisa okuphezulu kunye noxinzelelo oluphezulu lwe-steam.

Iibhoyili zoxinzelelo oluphezulu

Iityhubhu ze-ASTM A192 zisetyenziswa ngokubanzi kwi-ultra-high-pressure (edla ngokubizwa ngokuba ngamabhoyili aneengcinezelo zokusebenza ngaphezu kwe-9.8 MPa) izicelo. Ezi bhoyila zidla ngokusetyenziswa kwizikhululo zamandla amakhulu.

Izifudumezi eziphezulu kunye nezifudumezi

Ezi zixhobo eziphambili zebhoyili kwaye zisetyenziselwa ukunyusa izinga lokushisa lomphunga, okwandisa ukufudumala kwenkqubo yonke.

Izitshintshi zobushushu

Nangona i-ASTM A192 isetyenziselwa ubukhulu becala kwiityhubhu zebhoyila, ingasetyenziselwa ukutshintshiselana kobushushu apho iipropati ezifanelekileyo zokutshintshwa kobushushu zifunekayo, ngakumbi kwiindawo eziphakamileyo zokushisa, eziphakamileyo.

Iibhoyila zeoyile ezishushu

Kolu hlobo lwebhoyila, amandla ashushu ahanjiswa ngokufudumeza ioyile eshushu, esetyenziswa ngokuqhelekileyo kwimichiza, ekusetyenzweni kokutya, nakwimizi-mveliso yelaphu. I-astm a192 tubing ilungele ubushushu obuphezulu, iimeko zoxinzelelo oluphezulu ezifumaneka kwezi zicelo.

Imigangatho Efanelekileyo

I-ASTM A192: Kwimibhobho yebhoyila yentsimbi yekhabhoni engenamthungo yeebhoyila zoxinzelelo oluphezulu.

I-ASTM A179: Umthungo ongenamthungo opholileyo wokutshintshiselana kobushushu bentsimbi kunye neetyhubhu zecondenser kwiimeko zobushushu obuphantsi.

I-ASTM A210: Umthungo ophakathi kwibhoyila yentsimbi yekhabhoni kunye neetyhubhu zokufudumeza.

I-ASTM A213: Ibhoyila yensimbi engenamthungo ye-ferritic kunye ne-austenitic alloy steel, iheater enkulu, kunye neetyhubhu zokutshintsha ubushushu.

I-ASTM A106: Iityhubhu zentsimbi zekhabhoni ezingenamthungo zenkonzo yobushushu obuphezulu.

I-ASTM A335: Iityhubhu zentsimbi ze-ferritic ezingenamthungo kunye ne-austenitic alloy kunye nemibhobho yenkonzo yobushushu obuphezulu, umz. izikhululo zamandla.

I-ASTM A516: Izinto zeplate yentsimbi yeCarbon ezifanelekileyo kwiinqanawa zoxinzelelo oluphakathi kunye nobushushu obuphantsi.

I-ASTM A285: Ipleyiti yentsimbi yeCarbon ifanelekile kwiinqanawa eziphantsi ukuya kweziphakathi.

I-ASTM A387: I-alloy steel plate esetyenziselwa ukuveliswa kweebhoyili ezidityanisiweyo kunye neenqanawa zoxinzelelo, ngakumbi apho kufuneka ukuxhatshazwa kobushushu.

I-ASTM A53: Umthungo kunye ne-welded ezimnyama kunye ne-hot-dip yentsimbi yeetyhubhu zentsimbi yezakhiwo eziqhelekileyo kunye nezomatshini.

Ngokudibeneyo, le migangatho igubungela iipropathi zemathiriyeli, ukunyamezelwa komda, iipropathi zoomatshini, kunye nokwakheka kweekhemikhali ezifunekayo ukuze zisetyenziswe kwiibhoyila, iinqanawa zoxinzelelo, ii-heaters, njl., kumaqondo obushushu ahlukeneyo, uxinzelelo kunye neemeko zenkonzo.

Iimveliso zethu ezinxulumeneyo

I-ASTM ye-A192 yeBoiler ye-Carbon Steel Iityhubhu zoxinzelelo oluphezulu.

I-ASTM A179 Umtshintshisi wobushushu ongenamthungo weMibhobho yentsimbi

I-ASTM A 106 Black Carbon Umbhobho wentsimbi engenamthungo kwiNkonzo yoBubushushu obuphezulu

I-ASTM A53 Gr.A &Gr. B Umbhobho weNtsimbi weKhabhoni ongenaMthungo weOli kunye neGesi

I-Botop Steel yi-China yobuGcisa iWelded Carbon Steel Pipes uMvelisi & nababoneleli abangaphezulu kweminyaka eli-16 kunye ne-8000+ yeeToni zombhobho womgca ongenamthungo kwisitokhwe kwiNyanga nganye. Ukuba ufuna ukwazi ngakumbi malunga neemveliso zethu zentsimbi yombhobho, ungaqhagamshelana nathi ukuze sikunike iimveliso kunye neenkonzo ezikumgangatho ophezulu!

tags:astm a192, carbon steel pipe, Boiler Tubes, ababoneleli, abavelisi, iifektri, abagcini bempahla, iinkampani, ihoseyili, thenga, ixabiso, ixabiso, ixabiso, ubuninzi, ukuthengiswa, ixabiso.

Ixesha lokuposa: Apr-01-2024