ASTM A501 intsimbiyityhubhu emnyama neshushu editshiweyo eyenziwe ngesinyithi eshushu-eyenziweyo edityanisiweyo kunye neseamless carbon steel structural tubhing ukulungiselela iibhulorho, izakhiwo, kunye nezinye iinjongo zolwakhiwo jikelele.

Amaqhosha okukhangela

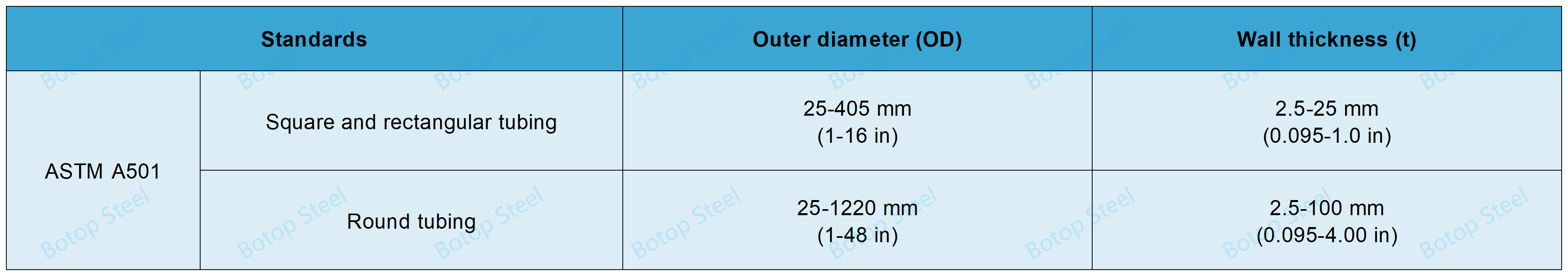

ASTM A501 Ubungakanani Range

Ukuhlelwa kwamaBanga

Iimilo zeCandelo eliHoli

Iimpahla ezingekasilwa

Iinkqubo Zokuvelisa

Ukuqulunqwa kwemichiza ye-ASTM A501

IiPropati zoomatshini ze-ASTM A501

Ukunyamezelwa komda kwe-ASTM A501

Ukugalela

Imbonakalo

Ukumakisha

Imigangatho Efanelekileyo

Usetyenziso

Izinto Eziluncedo Zethu

ASTM A501 Ubungakanani Range

Ukuhlelwa kwamaBanga

I-ASTM A501 ihlelwe ngokwamabakala amathathu, iBakala A, iBakala B, neBakala C.

Iimilo zeCandelo eliHoli

Isikwere, ingqukuva, uxande, okanye iimilo ezikhethekileyo.

Iimpahla ezingekasilwa

Intsimbi iya kwenziwa yi-basic-oxygen okanye i-electric-arc-furnace-steel-making process.

Intsimbi inokuphoswa kwiingothi okanye iphoswe ngomsonto.

Iinkqubo Zokuvelisa

Ityhubhu iya kwenziwa ngenye yezi nkqubo zilandelayo:engenamthungo; i-furnace-butt-welding (i-welding eqhubekayo);ukuwelda ukumelana nombane (ERW)okanye i-arc welding ephantsi kwamanzi (i-SAW) ilandelwa ngokutshisa kwakhona kwi-cross-section kunye nokutshisa ukubunjwa ngokunciphisa okanye ukubunjwa kwenkqubo, okanye zombini.

Ukubunjwa kokugqibela kobume kuya kwenziwa ngenkqubo yokubumba eshushu.

Kuya kuvunyelwa ukongeza unyango oluqhelekileyo lobushushu kwityhubhu enobunzima bodonga olukhulu kune-13mm [1/2 in].

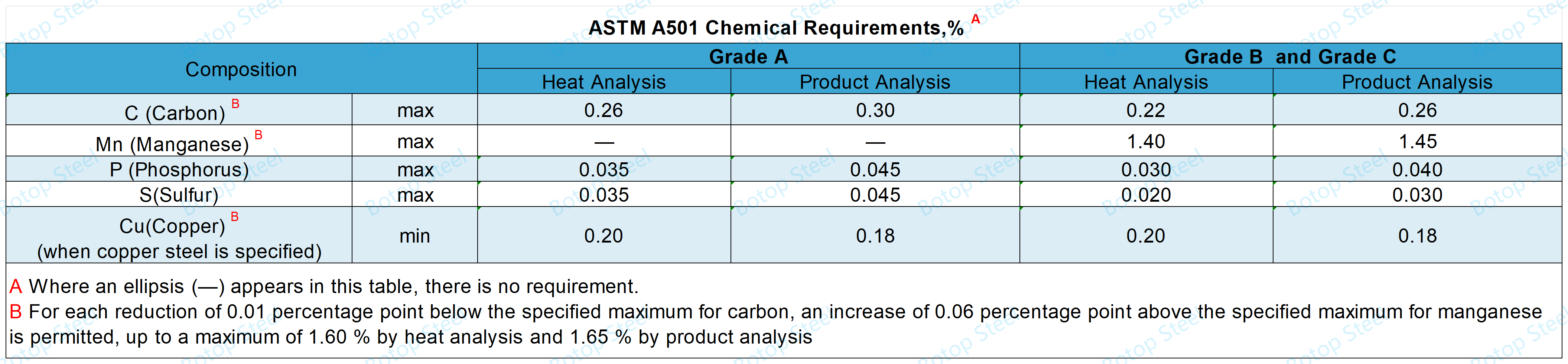

Ukuqulunqwa kwemichiza ye-ASTM A501

Indlela yoVavanyo: ASTM A751.

Kwinqanaba le-ASTM A501, kukho iindlela ezimbini zokuhlalutya ukwakheka kweekhemikhali zensimbi: uhlalutyo lwe-thermal kunye nohlalutyo lwemveliso.

Uhlalutyo lwe-thermal lwenziwa ngexesha lokunyibilika kwentsimbi. Injongo yalo kukuqinisekisa ukuba ukubunjwa kweekhemikhali zentsimbi kuhlangabezana neemfuno zomgangatho othile.

Uhlalutyo lwemveliso, ngakolunye uhlangothi, lwenziwa emva kokuba insimbi sele yenziwe imveliso. Le ndlela yokuhlalutya isetyenziselwa ukuqinisekisa ukuba ukubunjwa kweekhemikhali zemveliso yokugqibela ihlangabezana neemfuno ezichaziweyo.

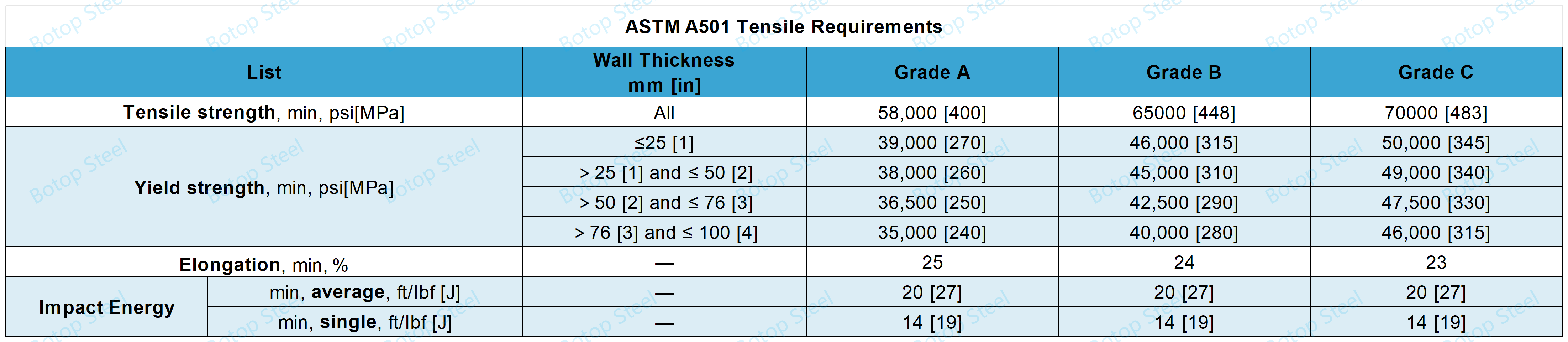

IiPropati zoomatshini ze-ASTM A501

Iindlela zovavanyo kunye neenkcazo zihambelana neemfuno ezifanelekileyo ze-ASTM A370.

Ubunzima beendonga ≤ 6.3mm [0.25in] ayifuni uvavanyo lwempembelelo.

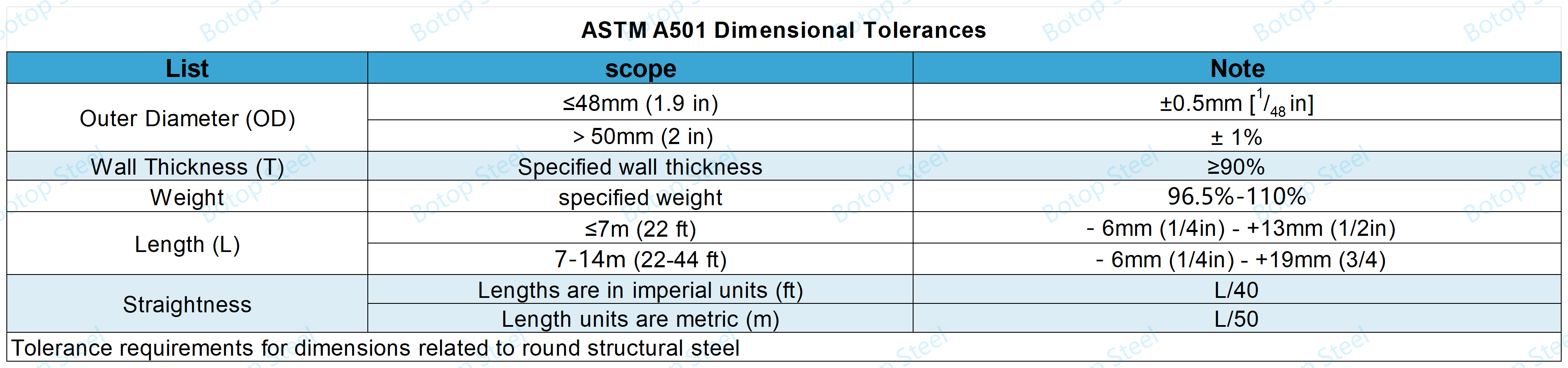

Ukunyamezelwa komda kwe-ASTM A501

Ukugalela

Ukuze iityhubhu zesakhiwo zibe shushu-dip zenziwe ngegalvanized, le ngubo iyakuhlangabezana neemfuno ze-Specification A53/A53M.

Ukulinganisa ixabiso lokugquma kumphezulu wangaphandle wombhobho ukumisela ubunzima bokugquma / ukutyeba.

Imbonakalo

Iityhubhu zesakhiwo aziyi kuba naziphene kwaye zibe nomphezulu ogudileyo ngexesha lokwenziwa kwe-hot rolling.

Iziphene zomphezulu ziya kuhlelwa ngolu hlobo xa ubunzulu besiphako somphezulu bungaphezulu kwe-10% yobukhulu bodonga oluqhelekileyo.

Iziphene ezifuna ukulungiswa ziya kupheliswa ngokupheleleyo ngokusika okanye ukugaya ngaphambi kwe-welding.

Ukumakisha

Ukumakishwa kwe-ASTM A501 kufuneka kube nale ngcaciso ilandelayo ubuncinane:

Igama lomenzi

Uphawu okanye uphawu lwentengiso

Ubungakanani

Igama lomgangatho (unyaka wokupapashwa awufunwa)

IBanga

Ubude betyhubhu yolwakhiwo ngalunye kufuneka buphawulwe ngendlela efanelekileyo, njengokuqengqeleka, isitampu, isitampu, okanye ukupeyinta.

Kwimibhobho yesakhiwo <50 mm [2 kwi] OD, kuvumelekile ukuphawula ulwazi lwensimbi kwilebula efakwe kwi-bundle nganye.

Imigangatho Efanelekileyo

I-ASTM A53/A53M: Ukucaciswa kwePipe, iNsimbi, iMnyama kunye neHot-Dipped, i-Zinc-Coated, i-Welded, kunye ne-Seamless.

I-ASTM A370: Iindlela zoVavanyo kunye neeNkcazo zoVavanyo lweMechanical yeeMveliso zetsimbi.

I-ASTM A700: Isikhokelo sokuPakisha, ukuMakisha, kunye neendlela zokuLayisha kwiiMveliso zeNtsimbi zoThutho.

I-ASTM A751: Iindlela zoVavanyo kunye neZiqhelo zokuHlalutywa kweMichiza yeeMveliso zeNtsimbi.

I-ASTM A941: Isigama esiNxulumana neNtsimbi, iNtsimbi engaGxili, ii-alloys eziNxulumeneyo, kunye neeFerroalloys.

Usetyenziso

Isetyenziswa ikakhulu kulwakhiwo kunye nobunjineli boluntu.

Ukwakhiwa kwebhulorho: ngenxa yeempawu zayo ezintle zoomatshini kunye namandla, ifanelekile kwiindawo ezibalulekileyo zezakhiwo zebhuloho, kubandakanywa amabhanti okuthwala imithwalo, i-bridge decks, kunye nezakhiwo ezixhasayo.

Ukwakhiwa kwesakhiwo: ingasetyenziselwa kwisakhiwo samathambo ezakhiwo, kubandakanywa iikholomu, imiqadi, iinkqubo zokuqulunqa, kunye nophahla kunye nokuxhasa umgangatho.

Ukusetyenziswa koLwakhiwo ngokubanzi: Ukongeza kwiibhulorho nezakhiwo, ikwafanelekile nakwezinye iiprojekthi ezifuna inkxaso yezakhiwo, njengokwakhiwa kwamabala emidlalo, iindawo zokupaka iimoto, izikolo nezinye iindawo ezinkulu zikawonke-wonke.

Izicelo zamashishini: Kwezinye izibonelelo zoshishino, ezifana neefektri kunye neendawo zokugcina iimpahla, le ntsimbi ingasetyenziselwa ukwakha izakhiwo zenkxaso, iifreyimu zephahla kunye nezinye izakhiwo zokuthwala umthwalo.

Iziseko zophuhliso: Le ntsimbi ingasetyenziswa kwiziseko ezingundoqo ezifana neempawu zendlela, ukukhanya, kunye neenqaba zonxibelelwano, umzekelo.

Izinto Eziluncedo Zethu

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo yayo egqwesileyo, iimveliso ezikumgangatho ophezulu kunye nezisombululo ezibanzi. Uluhlu olubanzi lwemveliso yenkampani lubandakanya i-seamless, i-ERW, i-LSAW, kunye nemibhobho yentsimbi ye-SSAW, kunye nokufakelwa kwemibhobho, ii-flanges, kunye neentsimbi ezizodwa.

Ngokuzibophezela okuqinileyo kumgangatho, iBotop Steel isebenzisa ulawulo olungqongqo kunye neemvavanyo zokuqinisekisa ukuthembeka kweemveliso zayo. Iqela layo elinamava libonelela ngezisombululo zobuqu kunye nenkxaso yeengcali, kugxilwe ekwanelisekeni kwabathengi.

Iithegi: ASTM a501, ibakala, ibakala b, ibakala c, ityhubhu yentsimbi, ityhubhu yentsimbi yesakhiwo.

Ixesha lokuposa: May-06-2024