Uhlobo E umbhobho wentsimbiyenziwe ngokuhambelana neI-ASTM A53kwaye iveliswa kusetyenziswa i-Electric-Resistance-Welding (ERW) inkqubo.

Lo mbhobho ngokuyintloko usetyenziselwa ukusetyenziswa koomatshini kunye noxinzelelo kodwa ukwafanelekile ukusetyenziswa njengemibhobho eqhelekileyo yokuthutha umphunga, amanzi, igesi kunye nomoya.

Iintlobo zemibhobho ye-ASTM A53

Kukho iintlobo ezintathu:Uhlobo F, Uhlobo E, kunye nohlobo S.

Phakathi kwabo, Uhlobo lwe-E yepayipi yensimbi yenziwa yinkqubo ye-ERW.

Ukuba ufuna ukwazi ngakumbi malungaI-ASTM A53, ungacofa apha.

Ukuhlelwa kweBanga

Uhlobo E lunamabanga amabini: iBakala A kunyeIBanga B.

Ubungakanani Uluhlu

Uluhlu lobungakanani beI-ASYM A53 yi-DN 6-650.

Uluhlu lwemveliso yeUhlobo E yi-DN 20-650 DN.

Iimitha zombhobho ngaphantsi kwe-DN 20 zincinci kakhulu ku-Type E. Ngenxa yezizathu zobugcisa akukho ndlela yokuvelisa, ngoko ke Uhlobo lwe-S, oluyiinkqubo yokuvelisa engenamthungo, isetyenziswa ngokuqhelekileyo.

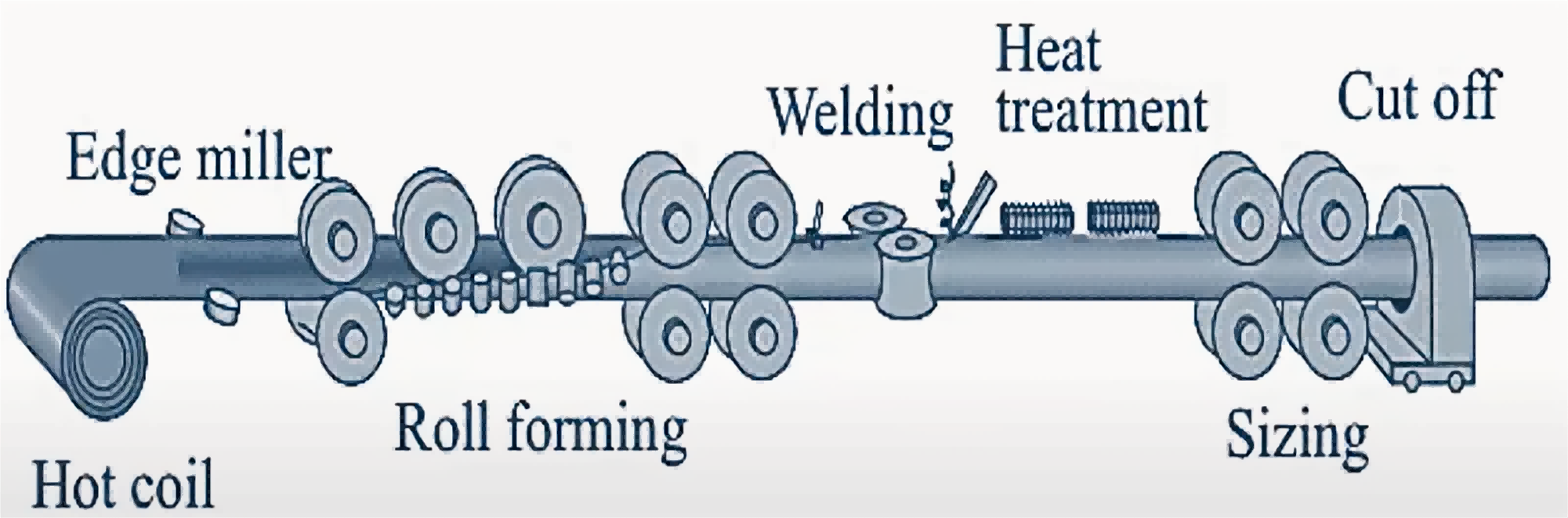

Inkqubo yokuVelisa ye-ASTM A53 Uhlobo E

Inkqubo yemveliso ibandakanya ukwenza iikhoyili zentsimbi ngokusebenzisa imiqulu, imiphetho ye-welding ngokufudumeza okuxhathisayo, i-welds deburring, kunye nokulinganisa kunye nokulungelelanisa ukwenza iityhubhu.

Iimpawu ze-ASTM A53 Uhlobo lwePipe yentsimbi ye-E

Ineempundu ezimbini ze-longitudinal welds ngaphakathi nangaphandle.Amaphethelo amacwecwe ensimbi ahlanganiswe ngaphakathi nangaphandle kombhobho ngexesha lenkqubo yokuvelisa ukuqinisekisa amandla kunye nokutywinwa.

I-welds yangaphakathi nangaphandle ayibonakali.I-welds yangaphakathi nangaphandle ihlanjululwa malunga nobude obufanayo nombhobho ngexesha lemveliso, enegalelo kwinkangeleko yonke kunye neepropati ezinokwenzeka ze-hydrodynamic zombhobho.

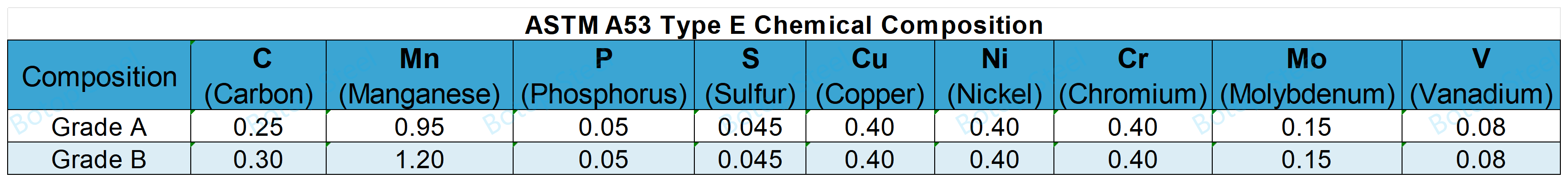

I-ASTM A53 Uhlobo lwe-E Izahlulo zeMichiza

Kunciphiso ngalunye lwe-0.01 % ngaphantsi kobuninzi bekhabhoni echaziweyo, ukonyuka kwe-0.06 % yemanganese ngaphezu kobuninzi obuchaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.65 %.

I-Cu, i-Ni, i-Cr, i-Mo, kunye ne-V, ziziqalelo ezintlanu kunye azidluli kwi-1.00%.

I-ASTM A53 Uhlobo lwe-E yeePropati zoomatshini

Uvavanyo loxinzelelo

Imibhobho edityanisiweyo yokumelana ne-DN ≥ 200 iya kuvavanywa kusetyenziswa iisampuli ezimbini ezinqamlezayo, enye ngapha kwe-weld kwaye enye ichasene ne-weld.

| Uluhlu | ukuhlelwa | IBanga A | IBanga B |

| Amandla okuqina, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Amandla esivuno, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Ubude kwi-50 mm (2 ngaphakathi) | Phawula | A, B | A, B |

Qaphela A: Obona buncinane bobude kwisi-2 kwi[50 mm] buya kuba bobo bugqitywe yile nxaki ilandelayo:

e = 625000 [1940] A0.2/U0.9

e = ubuncinci bobude kwi-2 kwi-50 mm okanye i-50 mm ngepesenti, isondezwe kwipesenti ekufutshane

A = ngaphantsi kwe-0.75 ngo2[500 mm2] kunye nommandla onqamlezileyo wovavanyo lovavanyo loxinzelelo, olubalwe kusetyenziswa idayamitha yangaphandle echaziweyo yombhobho, okanye ububanzi begama lovavanyo lovavanyo loxinzelelo kunye nobukhulu bodonga obuchaziweyo bombhobho, ngexabiso elibaliweyo lijikelezwe kwi-0.01 ekufutshane2 [1 mm2].

U=ubuncinane obuchaziweyo bamandla etensile, psi [MPa].

Qaphela B: Jonga kwiTheyibhile X4.1 okanye iTheyibhile X4.2, nokuba yeyiphi esebenzayo, kubuncinane bamaxabiso obude obufunekayo kwindibaniselwano eyahlukahlukeneyo yomzekelo wovavanyo loxinzelelo kunye namandla achaziweyo asezantsi etensile.

Bend Test

Umbhobho, i-DN ≤50, ubude obaneleyo bombhobho buya kukwazi ukugoba kubanda nge-90 ° malunga ne-cylindrical mandrel, ububanzi obuphindwe kalishumi elinambini kububanzi obuchazwe ngaphandle kombhobho, ngaphandle kokuphuhlisa iintanda nakweyiphi na indawo kwaye ngaphandle kokuvula i-weld.

Umbhobho ophindwe kabini owomeleleyo ngaphezu kwe-DN 32 akufuneki ubekwe phantsi kovavanyo lokugoba.

"I-Double-yongeziweyo-yomelele", ihlala ibizwa ngokuba yi-XXSngumbhobho onodonga oluqiniswe ngokukodwa, olusetyenziswa ngokuqhelekileyo kwizicelo zemizi-mveliso ukumelana noxinzelelo oluphezulu kunye neendawo ezinzima. Ubunzima bodonga lwalo mbhobho bukhulu kakhulu kunombhobho oqhelekileyo, ngoko ke unika amandla amaninzi kunye nokuqina okungcono.

Uvavanyo lokucaba

Uvavanyo lokucaba luya kwenziwa kumbhobho odityanisiweyo ngaphezulu kwe-DN 50 kubunzima obungaphezulu ebomeleleyo (XS) okanye ukhaphukhaphu.

Le nkqubo yovavanyo ilandelayo isebenza kuHlobo E, kumaBanga A no-B.

Ngethuba lokucinezela i-flat, i-weld kufuneka ibekwe kwi-0 ° okanye i-90 ° ukuya kumgca wolwalathiso lwamandla, kuxhomekeke kwiimfuno ezithile.

Inyathelo loku-1: Vavanya i-ductility ye-weld. Akufuneki kubekho iintanda okanye ukuphuka kwiindawo zangaphakathi okanye zangaphandle ze-weld kude kube umgama phakathi kweeplati ezicwebileyo ungaphantsi kwesibini kwisithathu sobubanzi obungaphandle bombhobho.

Inyathelo lesi-2: Qhubeka ucinezela i-flat kwaye uvavanye i-ductility kwindawo engaphandle kwe-weld. Akufuneki kubekho iintanda okanye ukuphuka ngaphakathi okanye ngaphandle kwendawo yombhobho ngaphaya kwe-weld kude kube umgama phakathi kweeplati ezicwebileyo ungaphantsi kwesahlulo sesithathu sobubanzi obungaphandle bombhobho, kodwa ungabi ngaphantsi kwesihlanu ubukhulu bodonga lombhobho.

Inyathelo lesi-3: Vavanya ingqibelelo yezinto ngokuqhubeka ucinezela i-flat de umfuziselo wovavanyo uqhawuke okanye iindonga zombhobho zidibane. Oku kusetyenziselwa ukuvavanya imathiriyeli kwiingxaki ezinje ngeemaleko eziqhekekileyo, ukungazinzi, okanye iiwelds ezingaphelelanga.

Uvavanyo lweHydrostatic

Uvavanyo lwe-hydrostatic luya kusetyenziswa, ngaphandle kokuvuza ngomthungo we-weld okanye umzimba wombhobho.

Umbhobho ongenasiphelo uya kuvavanywa nge-hydrostatically kuxinzelelo olusebenzayo olunikezwe kwiThebhile X2.2,

umbhobho othungelweyo kunye nodityanisiweyo uya kuvavanywa nge-hydrostatically kuxinzelelo olusebenzayo olunikwe kwiThebhile X2.3.

Kwimibhobho yensimbi ene-DN ≤ 80, uxinzelelo lovavanyo aluyi kudlula i-17.2MPa;

Kwimibhobho yensimbi ene-DN>80, uxinzelelo lovavanyo aluyi kudlula i-19.3MPa;

Uvavanyo loMbane olungonakaliyo

Ngohlobo lwe-E kunye noHlobo lwe-F ye-Class B imibhobho ye-DN ≥ 50, i-welds kufuneka ifakwe kuvavanyo lombane olungonakaliyo.

Uvavanyo lombane olungonakaliyo luya kwenziwa ngokuhambelana neNgcaciso ye-E213, E273, E309 okanye i-E570.

Ukuba uvavanyo lombane olungonakaliyo lwenziwe, umbhobho uya kumakishwa "NDE".

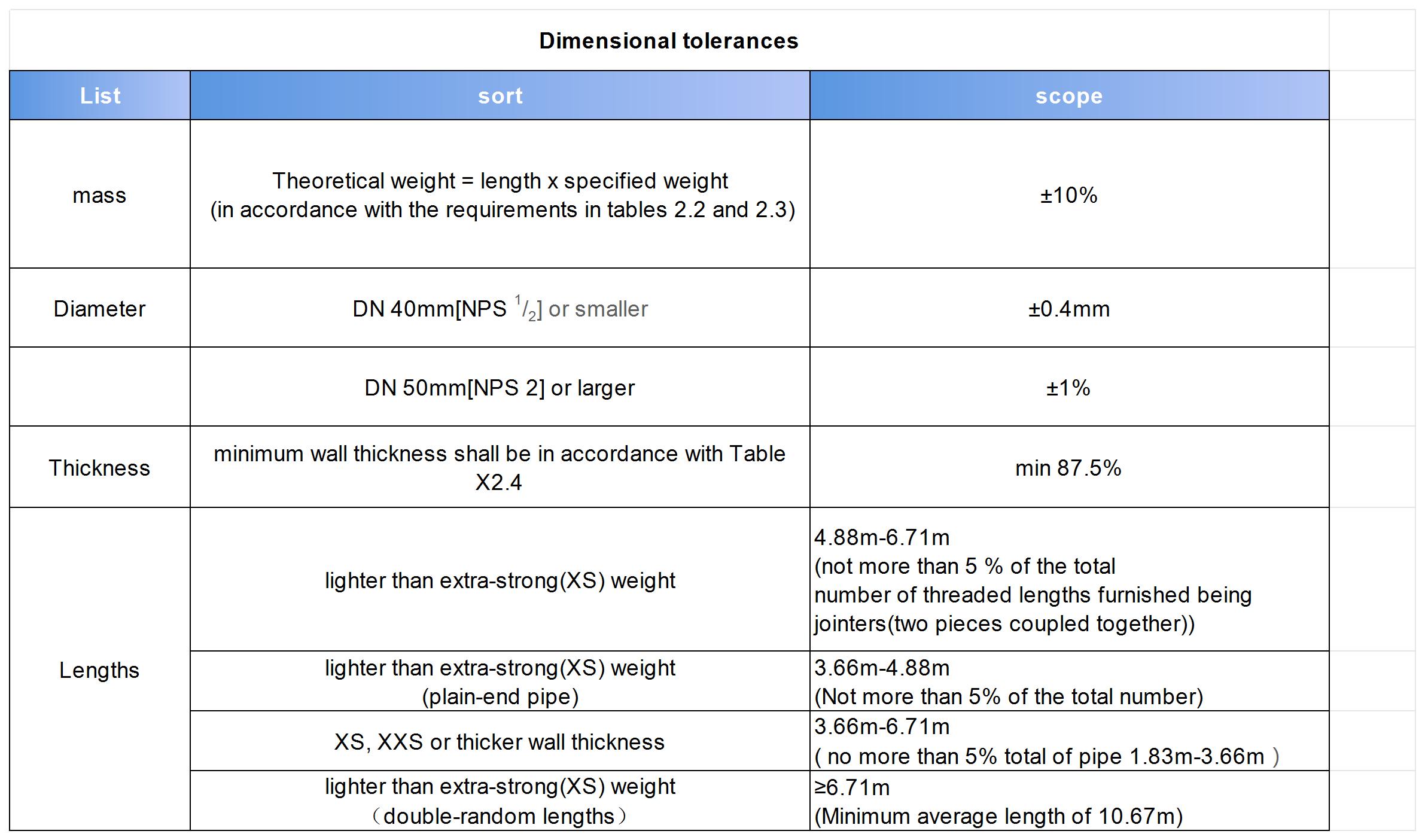

I-ASTM A53 yoNyamezelo oluDimensional

Iitshathi zobunzima bombhobho kunye neeShedyuli zemibhobho

Izinto ezilungileyo ze-ASTM A53 Uhlobo lwe-E Pipe

I-Resistance welding yindlela ye-welding ephantsi kwexabiso eliphantsi, okwenza iityhubhu ze-E zingabizi kakhulu ukuvelisa kwaye zilungele imveliso yobuninzi.

Inkqubo yokumelana ne-welding ikhawuleza kwaye inokuveliswa ngokuqhubekayo, eyandisa imveliso kunye nokunciphisa amaxesha okukhokela.

Ngenxa yeempawu zayo ezintle zoomatshini kunye nokumelana nokubola, olu hlobo lombhobho lusetyenziswa ngokubanzi kwiinkqubo ezahlukeneyo zokuthutha ulwelo, njengamanzi, igesi kunye nomphunga.

I-welds inokwenziwa ingabonakali ngokucokisekileyo unyango lwe-welds, engaphuculi nje ukubonakala kombhobho kodwa inokunciphisa ukuchasana nokuhamba kwamanzi okubangelwa yi-welds..

Usetyenziso lwe-ASTM A53 Uhlobo lwePipe yentsimbi ye-E

Ukusetyenziswa kolwakhiwo: Ekwakhiweni, umbhobho wensimbi we-A53 Uhlobo lwe-E lusetyenziswa njengamacandelo ezakhiwo ezifana nezakhiwo ezixhasayo kunye neenkqubo ze-truss.

Imibhobho yamanzi: Isetyenziswa kwiinkqubo zokubonelela ngamanzi kwizakhiwo, kubandakanywa neenkqubo zokutshiza umlilo.

Iinkqubo zomphunga: Kwiindawo zoshishino, lo mbhobho wensimbi usetyenziswa ngokuqhelekileyo kwiinkqubo zokuhanjiswa kwe-steam, ngokukodwa kwizicelo eziphantsi koxinzelelo.

Ukuhanjiswa kwerhasi: Isetyenziselwa ukuthutha igesi yendalo okanye ezinye, ngakumbi kwiinkqubo zokubonelela ngegesi kamasipala kunye nendawo yokuhlala.

Izityalo zemichiza: ukuhambisa umphunga woxinzelelo oluphantsi, amanzi, kunye nezinye iikhemikhali.

Iimveliso zephepha kunye neswekile: ukuhambisa izinto eziluhlaza kunye neemveliso ezigqityiweyo, kunye nokulahla inkunkuma yenkqubo.

Iinkqubo zokufudumeza kunye nokupholisa: Isetyenziselwa kakhulu imibhobho kwiinkqubo zokufudumeza, ukungena komoya, kunye ne-air conditioning (HVAC).

Ukucocwa kwamanzi amdaka: Ukuhambisa amanzi amdaka okanye acociweyo.

Iinkqubo zokunkcenkceshela: Imibhobho yamanzi esetyenziselwa ukunkcenkceshela umhlaba wezolimo.

Ukwembiwa kwemigodi: Isetyenziselwa ukuthutha amanzi kunye negesi emigodini.

Iimveliso zethu ezinxulumeneyo

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi.

Inkampani ibonelela ngeendidi zemibhobho yentsimbi yekhabhoni kunye neemveliso ezinxulumeneyo,

kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kombhobho kunye neeflange.

Iimveliso zayo ezikhethekileyo zikwabandakanya iialloys zodidi oluphezulu kunye neentsimbi ze-austenitic stainless, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zemibhobho.

Iithegi: ASTM a53, uhlobo e, ibakala a, ibakala b, erw.

Ixesha lokuposa: May-12-2024