I-JIS G 3444 ipayipi yentsimbingumbhobho we-carbon steel wesakhiwo owenziwe yinkqubo engenamthungo okanye edityanisiweyo, esetyenziswa ikakhulu kubunjineli bombutho kunye nokwakhiwa.

Amaqhosha okukhangela

Ubungakanani Uluhlu

Ukuhlelwa kweBanga

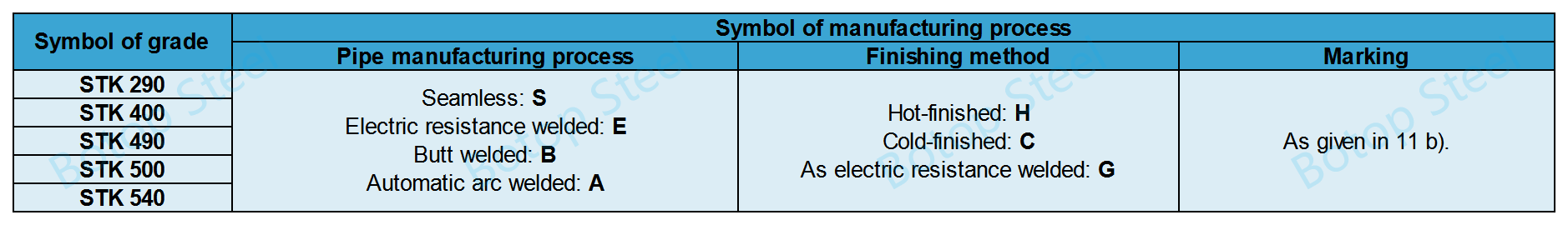

I-JIS G 3444 Iinkqubo zokuVelisa

Tube End Type

Ukubunjwa kwemichiza ye-JIS G 3444

IPropati yeMechanical ye-JIS G 3444

Ukuchasa ukunyangwa

Bend Test

Olunye Uvavanyo

Umbhobho Weight Table of JIS G 3444

Ukunyamezelwa koMda kwe-JIS G 3444

Imbonakalo

Ukumakisha

JIS G 3444 Isicelo

Imigangatho Eyeleleneyo

Izinto Eziluncedo Zethu

Ubungakanani Uluhlu

Injongo ngokubanzi Idayimitha yangaphandle: 21.7-1016.0mm;

Iimfumba zesiseko kunye neemfumba zokucutha ukudilika komhlaba OD: ngaphantsi kwe-318.5mm.

Ukuhlelwa kweBanga

Iityhubhu zohlulwe ngokwamabakala ama-5.

STK 290,I-STK 400, STK 490, STK 500, STK 540.

I-JIS G 3444 Iinkqubo zokuVelisa

Iibhubhu ziyakwenziwa ngokudibanisa indlela yokuvelisa i-tube kunye nendlela yokugqiba ebonakalisiweyo.

Imibhobho inokunyangwa ngokufanelekileyo ubushushu xa ifunwa.

Ukuba ifunwa nguMthengi, umbhobho unokwenziwa kwiphepha lentsimbi eligqunyiweyo okanye intsimbi edityanisiweyo. Kule meko, uhlobo lokugquma kunye nomgangatho womgangatho uya kuhambelana neemfuno ze-JIS G 3444, iSihlomelo A.

Iindidi zokugquma ezinokuthi zifakwe i-hot-dip zinc coating, i-electrolytic zinc coating, i-hot-dip aluminium yokugqoka, i-hot-dip zinc-5% i-aluminium alloy coating, i-hot-dip 55% ye-aluminium-zinc alloy coating, okanye i-hot-dip zinc-magnesium alloy coating.

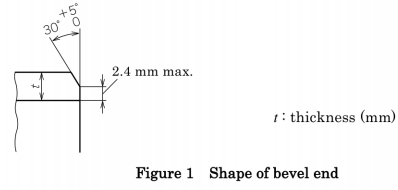

Tube End Type

Iziphelo zemibhobho yentsimbi ziya kuba mcaba.

Ukuba umbhobho kufuneka uqhutywe kwi-beveled end, i-angle ye-bevel yi-30-35 °, ububanzi be-bevel bombhobho wepayipi yensimbi: i-max 2.4mm.

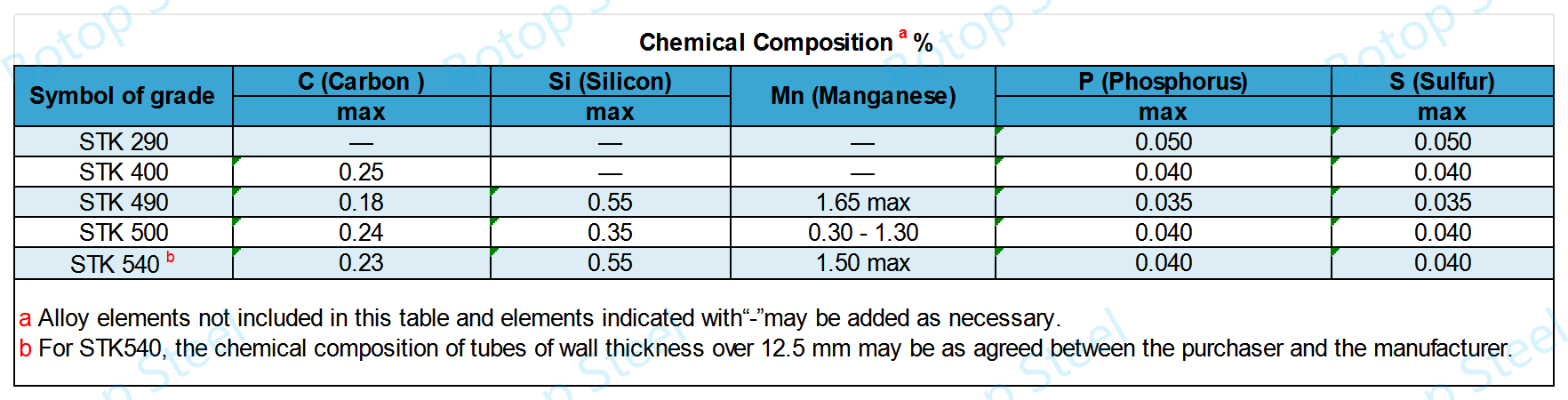

Ukubunjwa kwemichiza ye-JIS G 3444

Iindlela zokuhlalutya i-thermal ziya kuhambelana neemfuno kwi-JIS G 0320.

Indlela yohlalutyo lwemveliso iya kuhambelana neemfuno kwi-JIS G 0321.

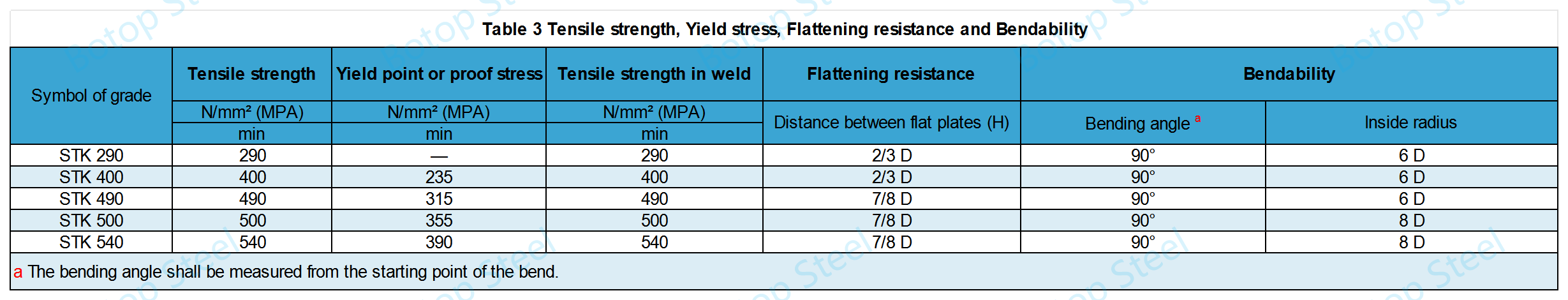

IPropati yeMechanical ye-JIS G 3444

Iimfuno jikelele zovavanyo lomatshini ziya kuhambelana neCandelo lesi-7 nele-9 le-JIS G 0404.

Nangona kunjalo, indlela yesampulu yovavanyo lomatshini iya kuhambelana neemfuno zeKlasi A amalungiselelo kwiCandelo 7.6 le-JIS G 0404.

Amandla e-Tensile kunye neNqanaba lokuZivuza okanye ubungqina boxinzelelo

Amandla okuqina kunye nenqaku lesivuno okanye uxinzelelo lobungqina kunye namandla okuqina kwi-weld aya kwanelisa amaxabiso achazwe kwiThebhile 3.

Amandla okuqina e-weld asebenza kwi-arc welded tubes ngokuzenzekelayo.

Amandla e-weld afana nalawo afunekayo kumzimba wombhobho. Inxalenye edibeneyo idla ngokuba likhonkco elibuthathaka kwisakhiwo, ngoko ke ukuba namandla afanayo okuqina kuqinisekisa ukuthembeka kwesakhiwo esidibeneyo.

Itheyibhile ye-3 iqulethe iimfuno zomgama wokuchasana kwe-Flattening kunye neemfuno ze-angle bend kunye ne-bend radius ekupheleni kokugoba.

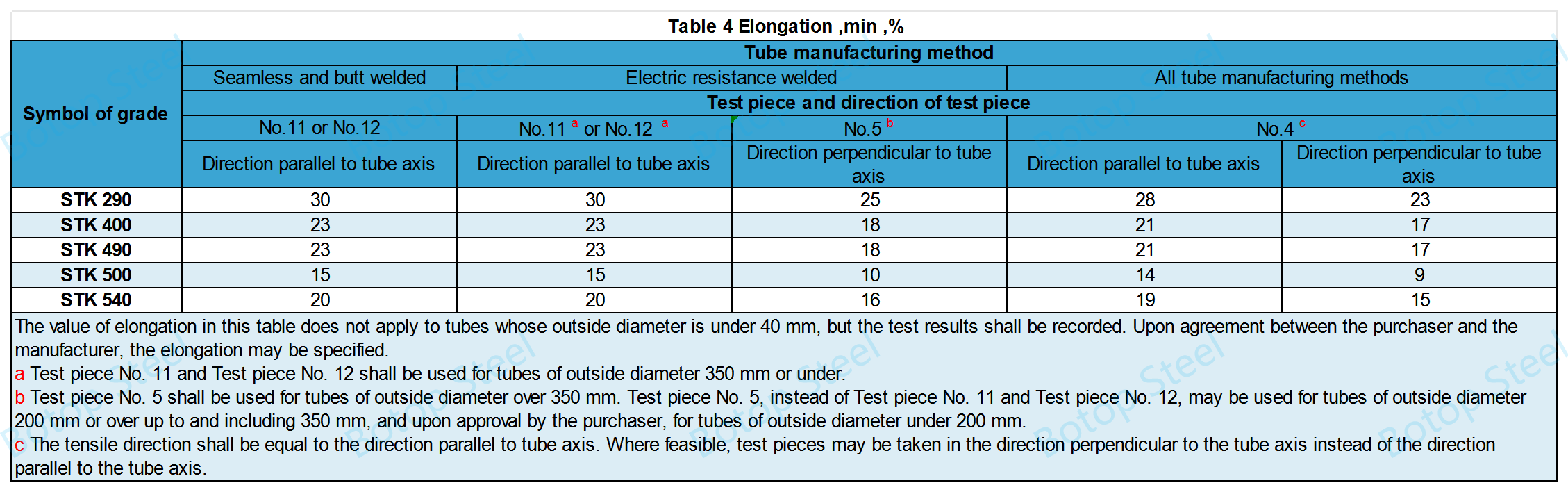

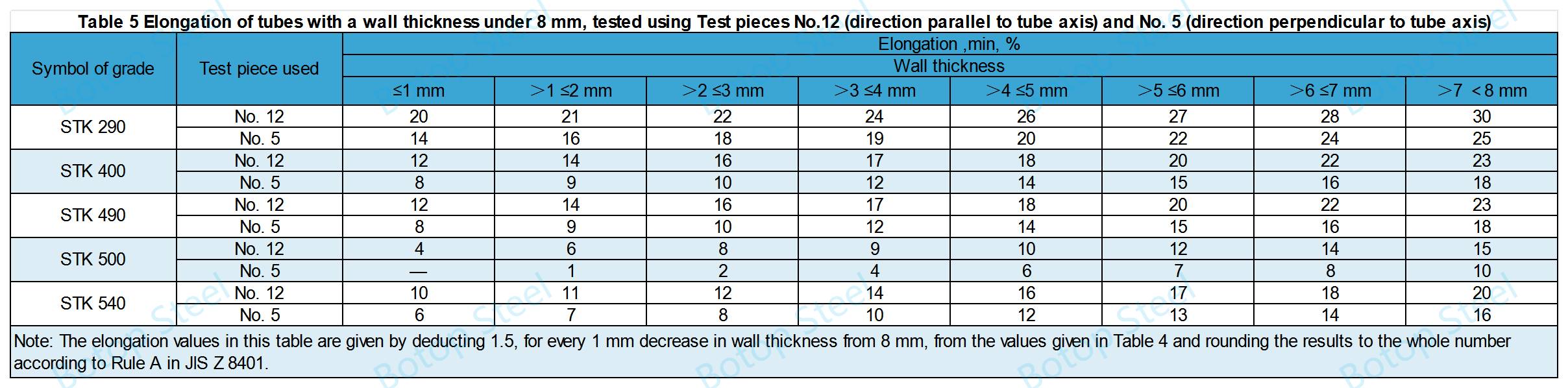

Elongation

Ukwandiswa okuhambelana nendlela yokuvelisa ityhubhu kuboniswe kwiThebhile 4.

Nangona kunjalo, xa uvavanyo lwe-tensile lwenziwa kwi-Test Piece No.

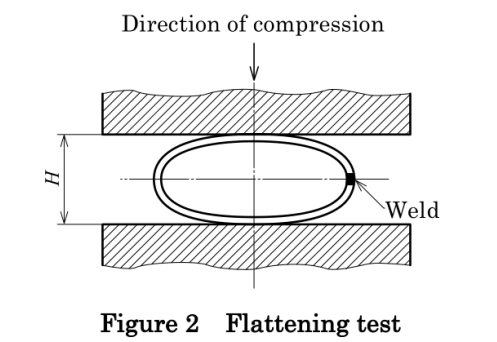

Ukuchasa ukunyangwa

Beka isiqwenga sovavanyo kwiqondo lobushushu eliqhelekileyo (5 °C ukuya ku-35 °C) phakathi kweepleyiti ezimbini ezisicaba kwaye ucinezele ukuze ucande de umgama phakathi kwamacwecwe H ulingana okanye uncinci kunexabiso elichazwe kwiThebhile 3, emva koko uhlolisise iintanda kwisiqwenga sovavanyo.

Beka i-welds yokumelana ne-weld yentsimbi yombhobho kunye ne-butt weld welding yentsimbi ukwenzela ukuba umgca phakathi kombindi wombhobho kunye ne-weld i-perpendicular ukuya kwicala loxinzelelo.

Bend Test

Goba isiqwenga sovavanyo malunga ne-cylinder kwiqondo lobushushu eliqhelekileyo (5 °C ukuya kwi-35 °C) kwi-engile yokugoba engekho ngaphantsi kwe-engile yokugoba encinci echazwe kwiThebhile 3, kunye ne-radius yangaphakathi engekho ngaphezu kobuninzi be-radius yangaphakathi echazwe kwiThebhile 3, kwaye uhlolisise isiqwenga sovavanyo lweentanda.

Ukuvavanya ukuxhathisa kombane ityhubhu yentsimbi edityanisiweyo kunye netyhubhu yentsimbi ene-butt-welded, beka isiqwenga sovavanyo ukuze i-weld ibe ngama-90 ° C ukusuka kwindawo engaphandle yokugoba.

Olunye Uvavanyo

Uvavanyo lwe-Hydrostatic, iimvavanyo ezingonakalisi ze-welds, okanye ezinye iimvavanyo ziya kuvunyelwana kwangaphambili kwiimfuno ezifanelekileyo.

Umbhobho Weight Table of JIS G 3444

Ifomula yokubala ubunzima kombhobho wentsimbi

W=0.02466 t (Dt)

W: Ubunzima beyunithi yetyhubhu (kg/m)

t: Ubukhulu bodonga lwetyhubhu (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

0.02466: iyunithi yokuguqula into yokufumana i-W

Ifomula isekelwe kwinto yokuba ubuninzi bentsimbi yi-7.85 g/cm³.

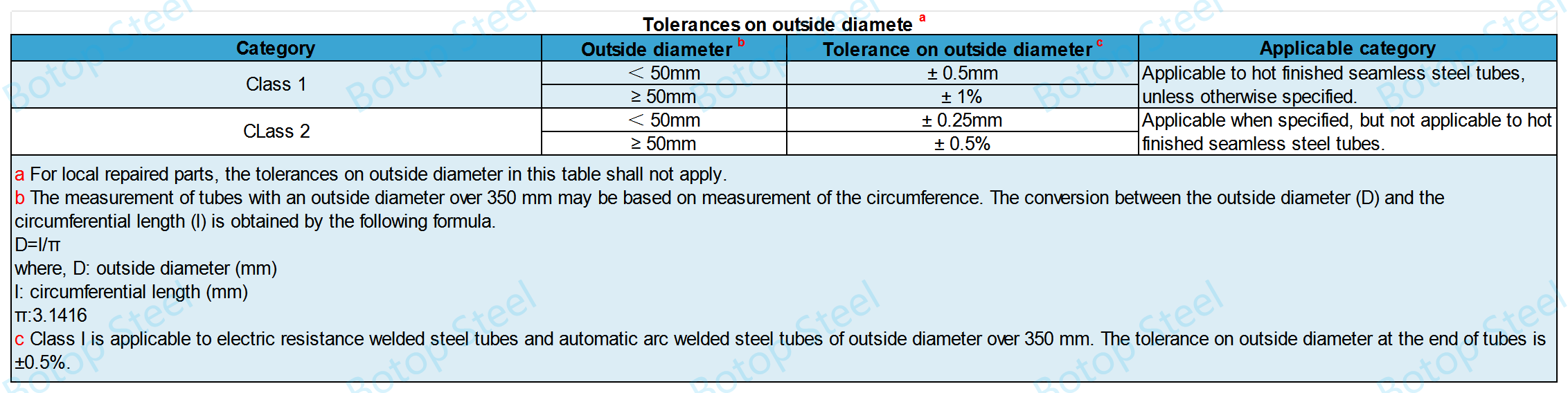

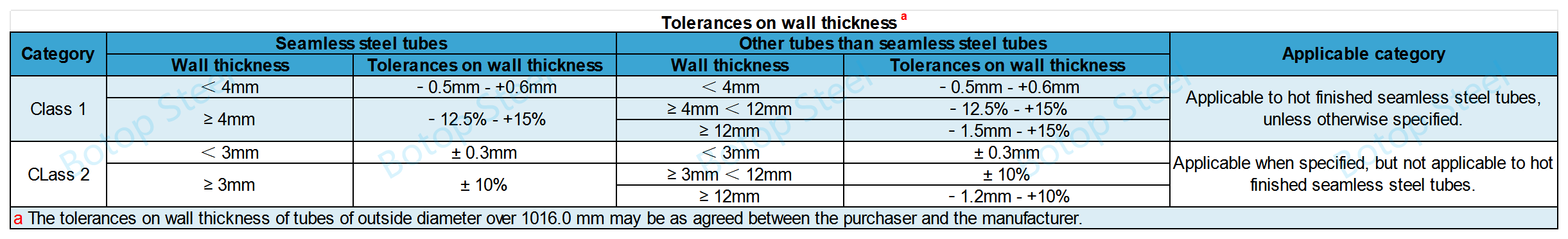

Ukunyamezelwa koMda kwe-JIS G 3444

Unyamezelo lweDiameter yangaphandle

Unyamezelo lokutyeba kodonga

Ukunyamezela Ubude

Ukunyamezela ubude bombhobho wensimbi, ukunyamezela okungalunganga ku-zero, ukunyamezela okulungileyo akufuneki ngokucacileyo, umthengi kunye nomenzi banqume ngesivumelwano esifanayo.

Imbonakalo

Ubuso bangaphakathi nangaphandle bombhobho wensimbi buya kuba bushelelezi kwaye bukhululekile kwiziphene ezingathandekiyo ukusetyenziswa.

Iingubo ezichasene ne-corrosion ezifana ne-zinc-rich rich, i-epoxy coatings, iipeyinti zepeyinti, njl.

Ukumakisha

Umbhobho ngamnye wentsimbi uya kubhalwa ngolu lwazi lulandelayo.

a)Uphawu lwebakala.

b) Uphawu lwendlela yokuvelisa.Isimboli yendlela yokuvelisa iya kuba ngolu hlobo lulandelayo. Isikhewu sinokutshintshwa kungabi nanto.

I-1) I-tube yensimbi engenamthungo eshushu egqityiweyo: -SH

2) I-tube yensimbi engenamthungo ebandayo egqityiweyo: -SC

3) Njengokumelana nombane ityhubhu yentsimbi edityanisiweyo: -EG

4) Ukutshatyalaliswa kombane okutshisayo okugqityiweyo ityhubhu yentsimbi edibeneyo: -EH

5) Ukumelana nombane ogqityiweyo ogqityiweyo we-welded steel tube: -EC

6) Imibhobho yentsimbi ene-butt-welded -B

I-7) Iityhubhu zetsimbi ze-arc ezizenzekelayo ezidibeneyo -A

c) Imilinganiselo.Idayamitha yangaphandle kunye nobukhulu bodonga buya kuphawulwa.

d) Igama lomenzi okanye isifinyezo.

Xa ukumakishwa kwityhubhu kunzima ngenxa yokuba i-diameter yayo yangaphandle incinci okanye xa kucelwe njalo ngumthengi, ukumakishwa kunokunikwa kwi-bundle nganye yeetyhubhu ngendlela efanelekileyo.

Iindlela ezinjengokusetyenziswa kweelebhile, njl.

JIS G 3444 Isicelo

Zisetyenziselwa ubunjineli boluntu kunye nolwakhiwo olunje ngeenqaba zentsimbi, izikafula, iimfumba zeenyawo, iimfumba zesiseko, kunye neemfumba zokucinezelwa kokudilika komhlaba.

Imigangatho Eyeleleneyo

JIS G 3452: Icacisa iibhobho zensimbi zekhabhoni ngeenjongo eziqhelekileyo (zihluke kwiinjongo zesakhiwo kwaye zigxininise ngakumbi ekuthuthweni kolwelo okanye iigesi).

JIS G 3454: Ichaza imigangatho yeebhobho zentsimbi zekhabhoni zoxinzelelo lwemibhobho.

ASTM A500: ihlanganisa i-welded welded kunye ne-seamless carbon steel structural tubes kwaye ifana ne-JIS G 3444 kwezinye iimfuno zayo.

EN 10219: Igquma amacandelo aqinileyo adityanisiweyo ngeenjongo zolwakhiwo, kuquka iprofayili engqukuva, yesikwere, kunye noxande.

Izinto Eziluncedo Zethu

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange.

Iimveliso zayo ezikhethekileyo zikwabandakanya i-alloys ephezulu kunye ne-austenitic stainless steels, elungiselelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zepayipi.

Iithegi: jis g 3444, umbhobho we-carbon steel, stk, ityhubhu yensimbi, umbhobho wesakhiwo.

Ixesha lokuposa: May-10-2024