I-JIS G 3455 ipayipi yentsimbiuveliswa nguumbhobho wentsimbi ongenamthungoinkqubo yokuvelisa, ikakhulu esetyenziselwa carbon steel umbhobho ngeubushushu obusebenzayo bungaphantsi kwe-350 ℃ kokusingqongileyo, ikakhulu isetyenziselwa amalungu oomatshini.

Amaqhosha okukhangela

Ubungakanani Uluhlu

Ukuhlelwa kweBanga

Iinkqubo Zokuvelisa

Unyango lobushushu

Uhlobo lokuphela kombhobho

Amacandelo eMichiza ye-JIS G 3455

IPropati yoomatshini ye-JIS G 3455

Uvavanyo lweHydrostatic okanye uvavanyo olungonakalisiyo

I-JIS G 3455 Itshathi yobunzima boMbhobho wentsimbi kunye neeShedyuli zemibhobho

I-JIS G 3455 Ukunyamezelwa kweDimensional

Imbonakalo

Ukumakisha

Ukusetyenziswa kwe-JIS G 3455 yePipe yentsimbi

I-JIS G 3455 Imigangatho Elinganayo

Iimveliso zethu ezinxulumeneyo

Ubungakanani Uluhlu

Umbhobho ngaphandle ubukhulu: 10.5-660.4mm (6-650A) (1/8-26B)

A=DN;B=NPS.

Ukuhlelwa kweBanga

I-JIS G 3455 inamabakala amathathu ngokobuncinane bokuqina kombhobho, oko kukuthiSTS370, STS410, kwayeSTS480.

Iinkqubo Zokuvelisa

Imibhobho kufuneka yenziwe ngaphandle komthungo ngentsimbi ebuleweyo.

Ukubunjwa kokugqibela kwahlulwe kwiindidi ezimbini, ezishushu-ezigqityiweyo kwaye zibandayo, kuxhomekeke kububanzi obungaphandle kunye nobukhulu bodonga.

| Uphawu lwebakala | Uphawu lwenkqubo yokuvelisa | |

| Inkqubo yokwenziwa kwemibhobho | Indlela yokugqiba | |

| STS370 STS410 STS480 | Ngaphandle komthungo: S | Igqityiwe ngokushushu: H Kubanda kugqityiwe: C |

Unyango lobushushu

| Uphawu lwebakala | Ishushu-igqityiwe umbhobho wentsimbi ongenamthungo | Kubanda-kugqityiwe umbhobho wentsimbi ongenamthungo |

| STS370 STS410 | Njengoko yenziwe. Nangona kunjalo, i-annealing yobushushu obuphantsi okanye i-normalizing ingasetyenziswa njengoko kuyimfuneko. | Ubushushu obuphantsi bufakwe okanye buqhelekile |

| STS480 | Ubushushu obuphantsi bufakwe okanye buqhelekile | |

Unyango lobushushu ngaphandle kwalolo lunikiweyo kwitheyibhile lunokwenziwa ngesivumelwano phakathi komthengi nomvelisi.

Uhlobo lokuphela kombhobho

Imibhobho iya kugqitywa ngeziphelo ezisicaba.

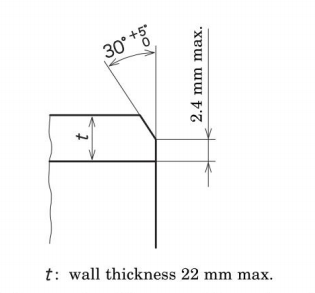

Ukuba isiphelo se-beveled sicacisiwe, i-tapered end shape yemibhobho enobunzima bodonga ≤ 22 mm iya kuhambelana ne-30-35 °, kunye nobubanzi be-bevel bombhobho wentsimbi bukhulu be-2.4mm.

Amacandelo eMichiza ye-JIS G 3455

Uhlalutyo lobushushu luya kuhambelana ne-JIS G 0320. Uhlalutyo lwemveliso luya kuhambelana ne-JIS G 0321.

Amaxabiso ohlalutyo lwe-thermal aya kuhambelana nezi mfuno zilandelayo:

| Uphawu lwebakala | C (iKhabhoni) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| max | max | max | |||

| STS370 | 0.25% | 0.10-0.35% | 0.30-1.10% | 0.35% | 0.35% |

| STS410 | 0.30% | 0.10-0.35% | 0.30-1.40% | 0.35% | 0.35% |

| STS480 | 0.33% | 0.10-0.35% | 0.30-1.50% | 0.35% | 0.35% |

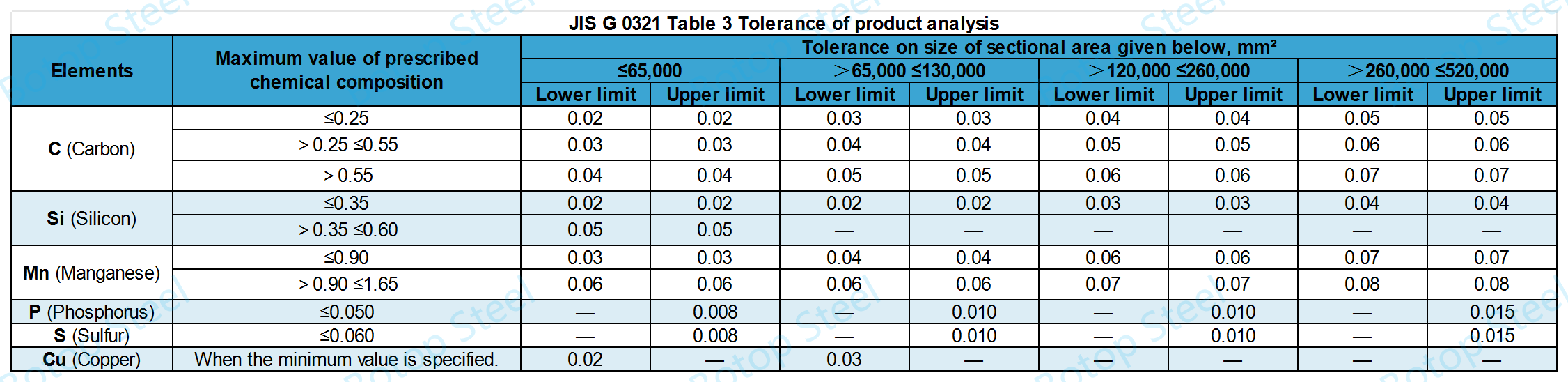

Amaxabiso ahlalutyiweyo emveliso akufanele ahlangabezane namaxabiso kwitheyibhile kuphela, kodwa uluhlu lonyamezelo lwento nganye kufuneka luhambelane neemfuno zeThebhile 3 ye-JIS G 3021.

IPropati yoomatshini ye-JIS G 3455

Iimfuno jikelele zovavanyo lomatshini ziya kuhambelana nesolotya lesi-7 nelesi-9 le-JIS G 0404. Iindlela zesampulu zovavanyo lomatshini ziya kuhambelana neKlasi A ye-JIS G 0404, iGatya 7.6.

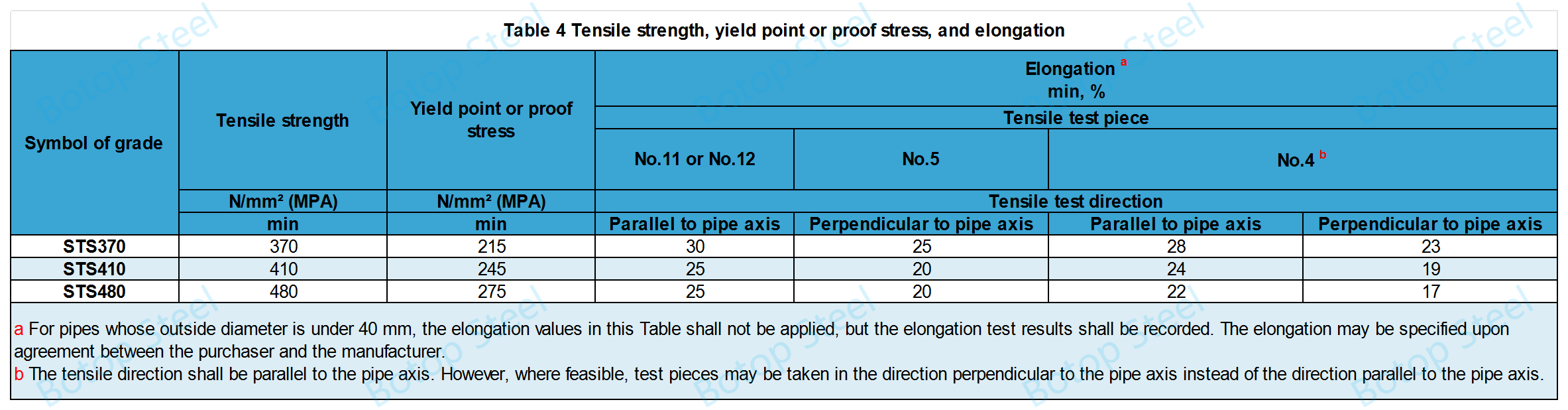

Amandla okuqina, iNqaku lokuZivuza okanye uQinisekiso loQinisekiso, kunye nokwandiswa

Indlela yokuvavanya iya kuhambelana nemigangatho ye-JIS Z 2241.

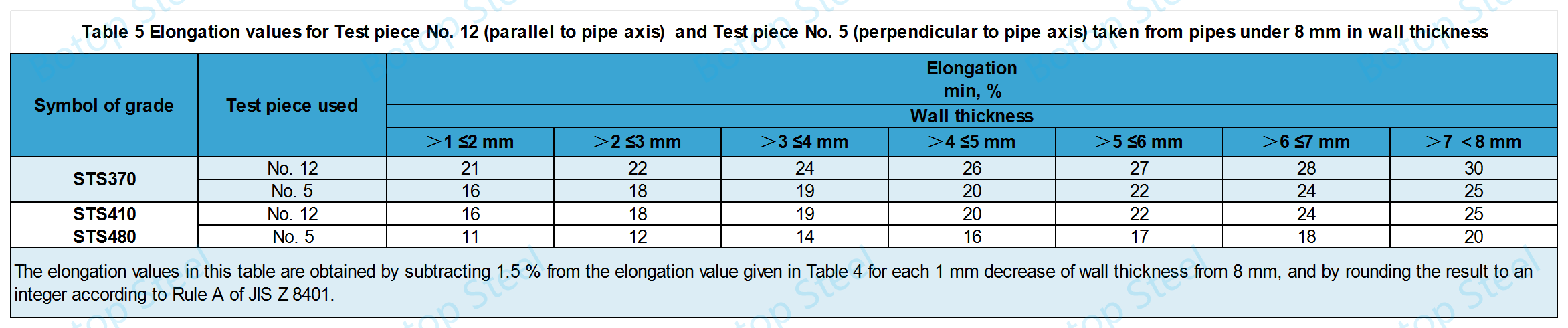

Kwimibhobho ephantsi kovavanyo lwe-tensile usebenzisa i-specimen ye-12 okanye i-No.

Ukunyanzeliswa kokuchasa

Uvavanyo lunokushiywa ngokubona komenzi ukuba nje imibhobho iyanelisa ukuxhathisa okucacisiweyo.

I-specimen ifakwe phakathi kweeplatifomu ezimbini kwaye ifakwe kwi-compression de umgama H phakathi kwamaqonga ufikelele kwixabiso elichaziweyo.Lo mzekelo ujongwa ukuba awunazo iintanda.

H=(1+e)t/(e+t/D)

H: umgama phakathi kweeplatens (mm)

t: Ubukhulu bodonga lombhobho (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

е: rhoqo kuchazwe kwibakala ngalinye lombhobho: 0.08 ye-STS370, 0.07 ye-STS410 kunye ne-STS480.

Uvavanyo lokuBendability

Isebenza kwimibhobho ene-diameter yangaphandle ≤50 mm njengoko kuchazwe ngumthengi.

I-specimen iya kukhululeka kwiintanda xa igobile kwi-angle ye-90 ° kunye nobubanzi bangaphakathi be-6 amaxesha angaphandle kombhobho.I-angle yokugoba iya kulinganiswa ekuqaleni kokugoba.

Uvavanyo lweHydrostatic okanye uvavanyo olungonakalisiyo

Uvavanyo lwe-hydrostatic okanye olungonakalisi luya kwenziwa kumbhobho ngamnye.

Uvavanyo lweHydrostatic

Bamba umbhobho ongekho ngaphantsi kobuncinci obuchaziweyo bovavanyo lwe-hydrostatic ubuncinane imizuzwana emi-5 kwaye ukhangele ukuba umbhobho unokumelana noxinzelelo ngaphandle kokuvuza.

Xa uMthengi engakhankanyi uxinzelelo lovavanyo, kwaye xa umbhobho uphantsi koxinzelelo oluncinci lovavanyo lwe-hydrostatic olunikiweyo, umbhobho uya kukwazi ukumelana nawo ngaphandle kokuvuza.

| Ubukhulu bodonga lwegama | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Ubuncinci boxinzelelo lovavanyo lwe-hydraulic, iMpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Xa ubukhulu bodonga lobubanzi obungaphandle bombhobho wensimbi abukho ixabiso eliqhelekileyo kwitheyibhile yobunzima bombhobho wensimbi, kuyimfuneko ukusebenzisa ifomula ukubala ixabiso loxinzelelo.

P=2st/D

P: uxinzelelo lovavanyo (MPa)

t: Ubukhulu bodonga lombhobho (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

s: 60 % yexabiso elincinci lenqaku lesivuno okanye ubungqina boxinzelelo olunikiweyo.

Xa ubuncinci boxinzelelo lovavanyo lwe-hydrostatic lwenani lesicwangciso esikhethiweyo lidlula uxinzelelo lovavanyo lwe-P olufunyenwe yifomula, uxinzelelo lwe-P luya kusetyenziswa njengoxinzelelo oluncinci lovavanyo lwe-hydrostatic endaweni yokukhetha olona xinzelelo luphantsi lovavanyo lwe-hydrostatic kwitheyibhile engentla.

Uvavanyo olungonakalisi

Umbhobho uya kuhlolwa ngokufunyaniswa kwe-ultrasonic okanye ukufunyanwa kwe-eddy yangoku.

Kwiimpawu zokufumanisa i-ultrasonic, izibonakaliso zeesampulu zereferensi eziqulethe imigangatho yereferensi yeklasi ye-UD echazwe kwi-JIS G 0582 iya kuthathwa njengenqanaba le-alamu, kwaye akukho signali elingana okanye enkulu kunenqanaba le-alamu liya kubakho.

Kwiimpawu ze-eddy zangoku zokubona, umqondiso wesampulu yereferensi equlethe umgangatho wesalathiso weklasi ye-EY njengoko kucacisiwe kwi-JIS G 0583 iya kuthathwa njengenqanaba le-alamu, kwaye akukho signali elingana okanye enkulu kunenqanaba le-alamu liya kubakho.

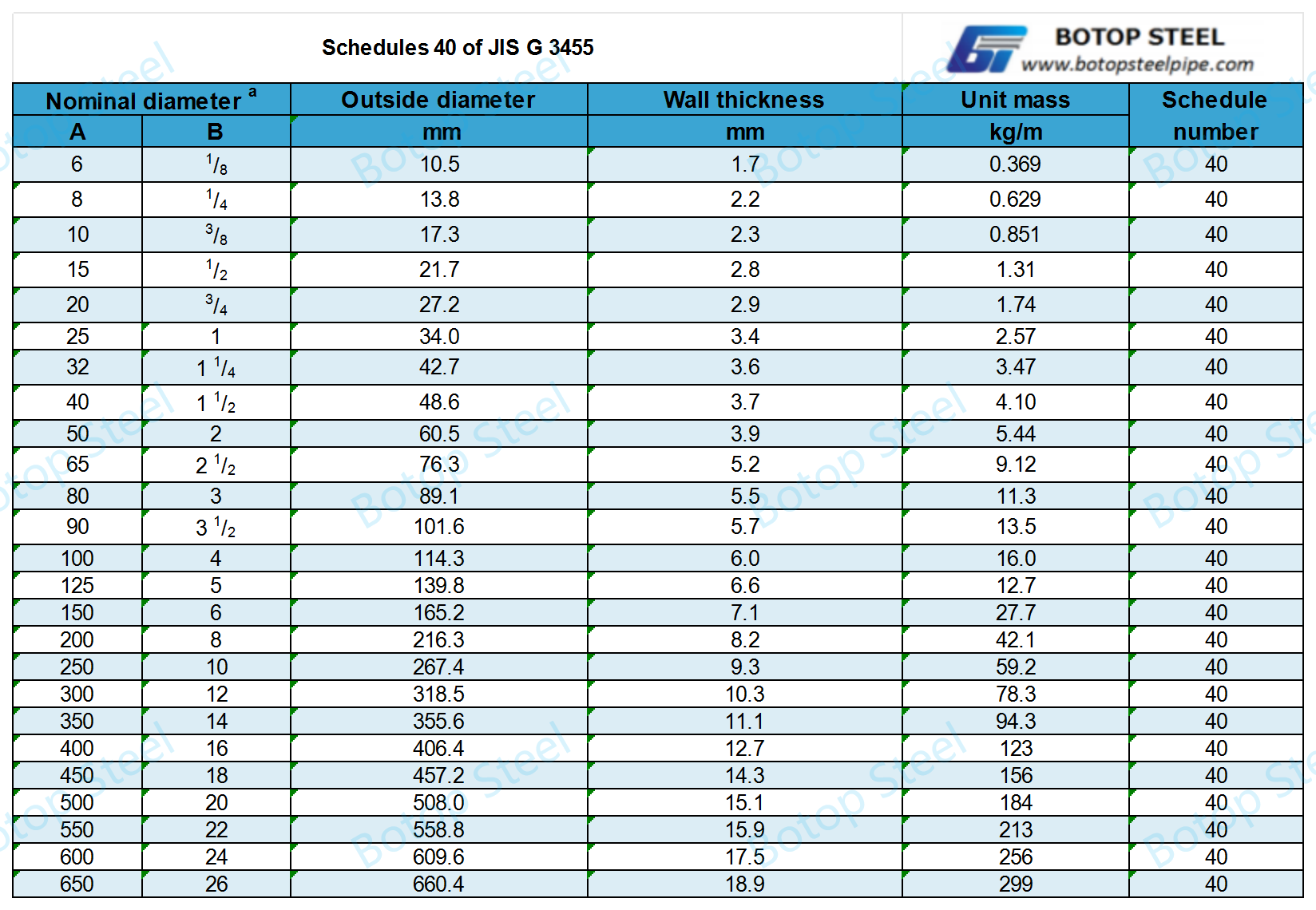

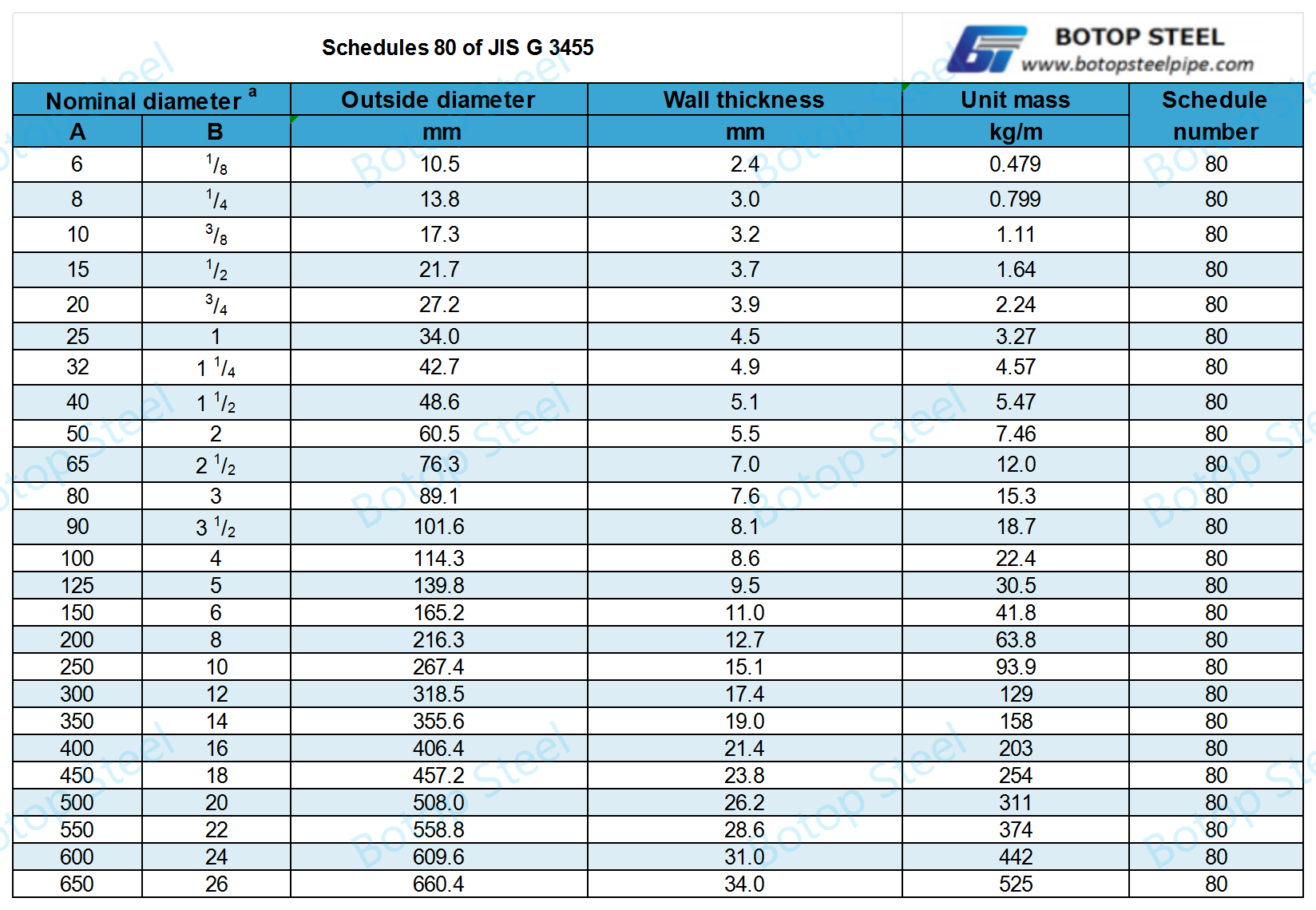

I-JIS G 3455 Itshathi yobunzima boMbhobho wentsimbi kunye neeShedyuli zemibhobho

Itshathi yobunzima bombhobho wentsimbi

Kwimeko yemilinganiselo engachazwanga kwiitafile zobunzima bombhobho, ifomyula ingasetyenziselwa ukubala.

W=0.02466t(Dt)

W: ubunzima beyunithi yombhobho (kg/m)

t: Ubukhulu bodonga lombhobho (mm)

D: ngaphandle kwedayamitha yombhobho (mm)

0.02466: into yokuguqula ukufumana iW

Qikelela ukuxinana kwe-7.85 g/cm³ kwityhubhu yentsimbi kwaye ujikeleze umphumo ukuya kumanani amathathu abalulekileyo.

Iishedyuli zombhobho

Umgangatho uxela iireyithingi ezintlanu zeShedyuli 40, 60, 80, 100, 120, kunye ne-160.

Ukwenzela lula, nantsi eyona shedyuli iqhele ukusetyenziswa 40 kunye neshedyuli 80.

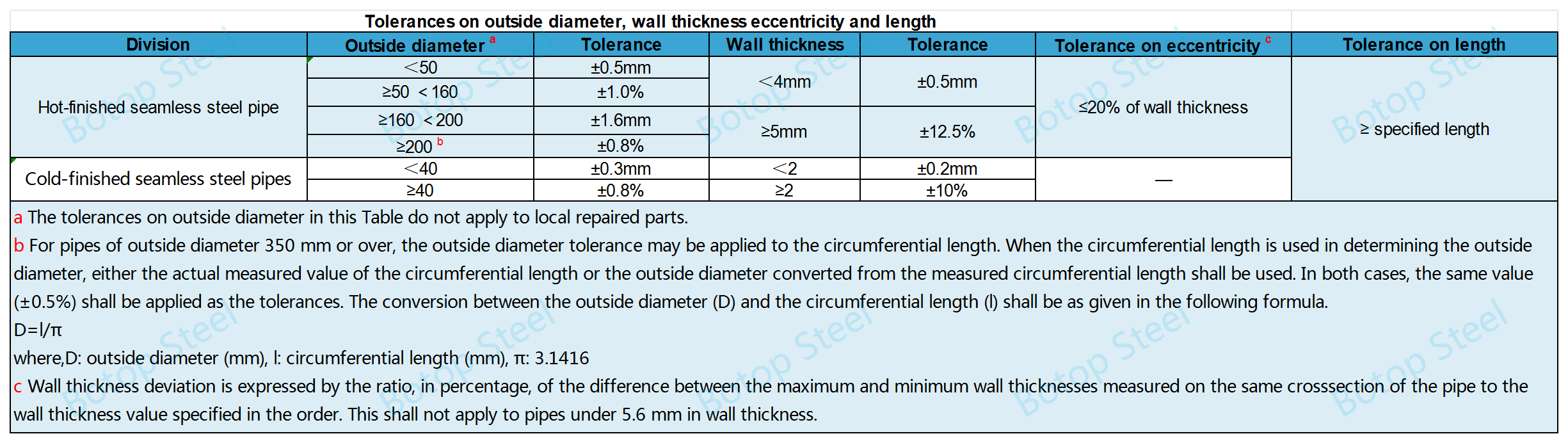

I-JIS G 3455 Ukunyamezelwa kweDimensional

Imbonakalo

Indawo yangaphakathi nangaphandle yombhobho iya kuba lula kwaye ikhululekile kwiziphene ezingathandekiyo ukuyisebenzisa.

Iziphelo zombhobho wensimbi ziya kuba kwii-angles ezichanekileyo kwi-axis yombhobho.

Ukumakisha

Ityhubhu nganye iya kubhalwa ngolu lwazi lulandelayo.

a) Uphawu lwebakala;

b) Uphawu lwendlela yokuvelisa;

Umbhobho wentsimbi ongenamthungo ogqityiweyo oshushu: -SH

Umbhobho wentsimbi ongenamthungo ogqityiweyo obandayo: -SC

c) ImilinganiseloUmzekelo 50AxSch80 okanye 60.5x5.5;

d) Igama lomenzi okanye uphawu lokuchonga.

Xa i-diameter yangaphandle yetyhubhu nganye incinci kwaye kunzima ukuphawula ityhubhu nganye, okanye xa umthengi efuna ukuba inyanda nganye yeetyhubhu imakishwe, inyanda nganye inokumakishwa ngendlela efanelekileyo.

Ukusetyenziswa kwe-JIS G 3455 yePipe yentsimbi

Ukwenziwa koomatshini: Ngenxa yokuqina kwayo okuphezulu kunye nokumelana nobushushu obuphezulu, isetyenziselwa ukwenziwa kwezinto ezahlukeneyo zomatshini, njengamacandelo eenkqubo ze-hydraulic kunye ne-high-pressure fuel injection systems.

Iinkqubo zemibhobho yoshishino: Isetyenziswa ngokubanzi kwizicelo zemizi-mveliso ezifuna umthamo woxinzelelo oluphezulu, njengemibhobho kwizityalo zekhemikhali, iindawo zokucokisa, kunye nezinye iiplanti zokulungisa.Bayakwazi ukuhambisa ngokukhuselekileyo umphunga, amanzi, ioli kunye nezinye iikhemikhali.

Izityalo zamandla: Isetyenziswe kumacandelo abalulekileyo afana neebhoyili kunye ne-superheaters eziphantsi kokushisa okuphezulu kunye neemeko zokusebenza zoxinzelelo oluphezulu.

Ukwakha nokwakha: Zingasetyenziselwa ukuxhasa izakhiwo okanye njengemibhobho yoxinzelelo, ngakumbi apho kufuneka amandla angaphezulu kunye nokuqina.

I-JIS G 3455 Imigangatho Elinganayo

I-ASTM A106 / ASME SA106: I-standard-defining seamless carbon steel tubes kwinkonzo yobushushu obuphezulu, ehlala isetyenziswa kwiindawo zokucoca, iibhoyili, kunye nokutshintsha ubushushu.

DIN 17175: Igubungela iibhubhu zetsimbi ezingenamthungo kunye nemibhobho yokusetyenziswa kwiimeko eziphakamileyo zokushisa kwaye iyasebenza kwizicelo ezichasene noxinzelelo oluphezulu olufana noshishino lwebhoyila.

EN 10216-2: Igubungela iibhubhu ezingenamthungo kunye nemibhobho yentsimbi engekho i-alloyed kunye ne-alloyed ukuze isetyenziswe kwiimeko eziphezulu zokushisa.

GB 5310: Umgangatho weetyhubhu zetsimbi ezingenamthungo kunye nemibhobho ye-boilers yoxinzelelo oluphezulu, kunye neemfuno zobuchwepheshe ezifana nezo ze-JIS G 3455, nazo zisebenza kwiindawo eziphakamileyo zokushisa kunye noxinzelelo oluphezulu.

API 5L: Isetyenziselwa ikakhulu kwimigca yokuhambisa ioli kunye negesi, iimfuno zayo eziphathekayo, kunye nokusetyenziswa kombhobho ongenamthungo phantsi kweemeko ezithile ezifanayo.

Iimveliso zethu ezinxulumeneyo

Ukususela ekusekweni kwayo kwi-2014, i-Botop Steel iye yaba ngumthengisi ohamba phambili we-carbon steel pipe eNyakatho ye-China, eyaziwa ngenkonzo egqwesileyo, iimveliso eziphezulu, kunye nezisombululo ezibanzi.

Inkampani inikezela ngeendidi zemibhobho ye-carbon steel kunye nemveliso ehambelana nayo, kubandakanywa i-seamless, i-ERW, i-LSAW, kunye ne-SSAW ipayipi yensimbi, kunye nomgca opheleleyo wokufakelwa kwemibhobho kunye neeflange.

Iimveliso zayo ezikhethekileyo zikwabandakanya iialloys zodidi oluphezulu kunye neentsimbi ze-austenitic stainless, ezenzelwe ukuhlangabezana neemfuno zeeprojekthi ezahlukeneyo zemibhobho.

Iithegi: I-JIS G 3455, umbhobho we-carbon steel, i-STS, ingenamthungo.

Ixesha lokuposa: May-14-2024