I-arc welding ephantsi kwamanzi ifanelekile kwimibhobho, iinqanawa zoxinzelelo kunye neetanki, ukuveliswa kwesitimela kunye nezicelo ezinkulu zokwakha, kunye nefom ye-monofilament elula, i-double wire structure, i-tandem i-wire double structure kunye ne-multi-filament structure.

I-arc welding ephantsi kwamanzi inokunceda abasebenzisi kwizicelo ezininzi ze-welding. Ukusuka ekwandiseni imveliso, ekuphuculeni indawo yokusebenza, ukuya ekuqinisekiseni umgangatho ongaguqukiyo nokunye. Abaqulunqi besinyithi abaqwalasela utshintsho kwinkqubo ye-arc welding ephantsi kwamanzi kufuneka bacinge ukuba banokufumana inzuzo eninzi kule nkqubo.

Ulwazi olusisiseko lwe-arc welding ephantsi kwamanzi

Inkqubo ye-arc welding ephantsi kwamanzi iyimfuneko efanelekileyo kwizicelo ezinzima zoshishino ezifana nemibhobho, iinqanawa zoxinzelelo kunye namatanki, ukwakhiwa kwe-locomotive, ukwakhiwa okunzima / ukumba. Ilungele amashishini afuna imveliso ephezulu, ngakumbi xa kuziwa ekudibaniseni izinto ezityebileyo, zininzi izibonelelo ezizuzwa kwinkqubo ye-arc ye-welding ephantsi kwamanzi.

Isantya esiphezulu sokubeka kunye nesantya sokuhamba sinokuba nefuthe elibonakalayo kwimveliso yabasebenzi, ukusebenza kakuhle kunye neendleko zokuvelisa, enye yeenzuzo eziphambili zenkqubo ye-arc welding ye-arc.

Olunye uncedo lubandakanya: Ukwakheka kweekhemikhali okugqwesileyo kunye neempawu zoomatshini be-weld, ukubonakala okuncinci kwe-arc kunye nomsi we-welding ophantsi, ukuphuculwa kokuthuthuzela kwendawo yokusebenza, kunye nokumila okuhle kwe-weld kunye nomgca weenzwane.

I-arc welding ephantsi kwamanzi yindlela yokutya yocingo esebenzisa i-granular flux ukwahlula i-arc emoyeni, njengoko igama libonisa, i-arc ingcwatywe kwi-flux, oku kuthetha ukuba xa iiparitha zisetwa, i-arc ayibonakali kunye nokuphuma koluhlu lwe-flux. Ucingo lokuwelda lutyiswa ngokuqhubekayo yitotshi ehamba ecaleni kweweld.

Ukufudumeza kwe-Arc kunyibilika icandelo locingo, inxalenye ye-flux kunye nesiseko sesinyithi, senza i-pool etyhidiweyo, edibanisayo ukuze yenze i-weld ehlanganiswe ngoluhlu lwe-welding slag. Uluhlu olutyebileyo lwezixhobo zokuwelda luyi-1/16 "-3/4", lunokuba yi-100% ye-welding yokungena nge-welding enye, ukuba ubukhulu bodonga alunamda, i-welding ye-multi-pass ingenziwa, kwaye i-weld iqhutywe ngokufanelekileyo kwaye ikhethwe, kwaye i-welding wire flux idibanisa ngokufanelekileyo ikhethiwe.

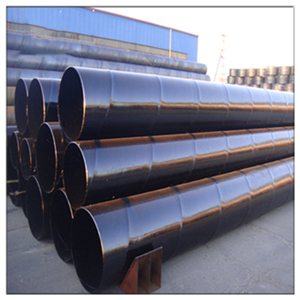

LSAW

ERW

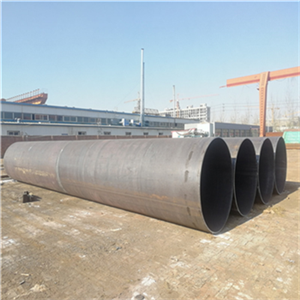

SSAW

Ukukhethwa kwe-flux kunye ne-welding wire

Ukukhetha i-flux efanelekileyo kunye nocingo lwenkqubo ethile ye-arc welding ye-arc ibaluleke kakhulu ekufezekiseni iziphumo ezilungileyo ngokusebenzisa inkqubo. Ngelixa iinkqubo ze-arc welding eziphantsi kwamanzi zodwa zisebenza kakuhle, imveliso kunye nokusebenza kakuhle kunokunyuswa ngokusekwe kwi-welding wire kunye ne-flux esetyenzisiweyo.

I-flux ayikhuseli kuphela i-weld pool, kodwa igalelo ekuphuculeni iimpawu zomatshini kunye nemveliso ye-weld. Ukuqulunqwa kwee-fluxes kunempembelelo enkulu kule miba, echaphazela ukuthwala kwangoku kunye nokukhululwa kwe-slag.

Umthamo wangoku wokuthwala uthetha ukuba obona buchule buphezulu bokubekwa kunye neprofayile yeweld ekumgangatho ophezulu inokufumaneka.

Ukukhutshwa kwe-slag kwi-flux ethile kuchaphazela ukhetho lwe-flux kuba ezinye ii-fluxes zifanelekile ngakumbi kuyilo oluthile lwe-solder kunabanye.

Izinketho zokukhetha i-Flux ye-arc soldering ephantsi kwamanzi ibandakanya iintlobo ezisebenzayo kunye nezingathathi hlangothi ze-welds. Umahluko osisiseko kukuba i-flux esebenzayo itshintsha i-chemistry ye-weld, ngelixa i-neutral flux ayifuni.

I-fluxes esebenzayo ibonakaliswe ngokubandakanywa kwe-silicon kunye ne-manganese. Ezi zinto zinceda ukugcina amandla okuqina e-weld kwigalelo lobushushu obuphezulu, ukunceda ukugcina i-weld igudile kwaye igudileyo kwizantya eziphezulu zokuhamba kunye nokubonelela ngokukhululwa kwe-slag elungileyo. Ngokubanzi, ii-fluxes ezisebenzayo zinokunceda ukunciphisa umngcipheko womgangatho ophantsi we-solder, kunye nokucoca emva kwe-weld kunye nokusebenza kwakhona. Gcina ukhumbula, nangona kunjalo, ukuba ii-fluxes ezisebenzayo zihlala zifaneleka kakhulu kwi-soldering enye okanye kabini.

Ii-fluxes ezingathathi hlangothi zingcono kwii-solders ezinkulu ze-multipass kuba zinceda ukuphepha ukubunjwa kwe-brittle, i-weld-sensitive welds.

Kukho iintlobo ezininzi zokhetho lwe-welding ye-welding malunga ne-arc welding ephantsi kwamanzi, nganye inenzuzo kunye nokungalunganga. Ezinye iingcingo zenzelwe i-welding kumagalelo aphezulu obushushu, ngelixa ezinye ziyilelwe ngokukodwa ukuba zibe ne-alloys ezinceda ukucoca ukwenza i-welding.

Qaphela ukuba iipropati zeekhemikhali kunye nokusebenzisana kwegalelo lobushushu kwi-welding wire ichaphazela i-mechanical properties of the weld. Imveliso inokunyuswa kakhulu ngokukhethwa kwentsimbi yokuzalisa.

Umzekelo, ukusebenzisa ucingo olungundoqo lwentsimbi kunye nenkqubo ye-arc ye-welding ephantsi kwamanzi kunokunyusa ukusebenza kakuhle kwe-deposition nge-15% ukuya kwi-30% xa kuthelekiswa nokusebenzisa ucingo oluqinileyo, ngelixa ibonelela ngeprofayili yokungena ebanzi kunye nengekho nzulu.

Ngenxa yesantya esiphezulu sokuhamba, iingcingo ezingundoqo zentsimbi nazo zinciphisa igalelo lobushushu ukuze kuncitshiswe umngcipheko we-welding deformation kunye nokutshiswa.

Kuzo zonke iintsimbi, i-austenitic stainless steels ineyona ndawo isezantsi yesivuno. Ngoko ke, ngokweempawu zemishini, i-austenitic stainless steel ayiyona nto ibhetele kwi-valve stem, kuba ukuqinisekisa amandla athile, ububanzi be-valve stem buya kwanda. Inqaku lesivuno alinakunyuswa ngonyango lobushushu, kodwa linokunyuswa ngokubumba okubandayo.

Siyi-stockist yekhabhoni kunye nombhobho wensimbi ongenamthungo, wamkelekile nayiphi na imibuzo, siya kuyinikezela okokuqala!

Ixesha lokuposa: Jan-30-2023