I-ASTM A672ngumbhobho wentsimbi owenziwe kwipleyiti yomgangatho wenqanawa yoxinzelelo,Ukuhlanganiswa koMbane-oWelded (EFW)kwinkonzo yoxinzelelo oluphezulu kumaqondo obushushu aphakathi.

Amaqhosha okukhangela

UHlelo lweBanga le-ASTM A672

ASTM A672 Class Ukuhlelwa

ASTM A672 Ubungakanani Uluhlu

Ukhuseleko lweWelding

Unyango lobushushu

Amacandelo eMichiza

Uvavanyo loxinzelelo

Uvavanyo lwe-Transverse-Guided-Weld-Bend

Uvavanyo loxinzelelo

Uviwo lweRadiographic

Ukunyamezelwa komgangatho we-ASTM A672

ASTM A672 Imbonakalo

Iziphene kunye noLungiso

Ukumakishwa kwe-ASTM A672

Ukusetyenziswa kwe-ASTM A672 yentsimbi yombhobho

Iimveliso zethu ezinxulumeneyo

UHlelo lweBanga le-ASTM A672

Ihlelwe ngokohlobo lwepleyiti esetyenziselwa ukuvelisa iityhubhu zentsimbi.

Amabakala ahlukeneyo amele ukubunjwa kweekhemikhali ezahlukeneyo kunye neempawu zomatshini zoxinzelelo oluhlukeneyo kunye neemeko zokushisa.

| IBanga lombhobho | Uhlobo lweNsimbi | Ukucaciswa kwe-ASTM | |

| Hayi. | IBanga | ||

| A45 | ikhabhoni ecacileyo | A285 / A285M | A |

| A50 | ikhabhoni ecacileyo | A285 / A285M | B |

| A55 | ikhabhoni ecacileyo | A285 / A285M | C |

| B 60 | ikhabhoni ecacileyo, ibulewe | A515 / A515M | 60 |

| B 65 | ikhabhoni ecacileyo, ibulewe | A515 / A515M | 65 |

| B 70 | ikhabhoni ecacileyo, ibulewe | A515 / A515M | 70 |

| C 55 | ikhabhoni ecacileyo, ibulewe, ingqolowa entle | A516 / A516M | 55 |

| C 60 | ikhabhoni ecacileyo, ibulewe, ingqolowa entle | A516 / A516M | 60 |

| C 65 | ikhabhoni ecacileyo, ibulewe, ingqolowa entle | A516 / A516M | 65 |

| C70 | ikhabhoni ecacileyo, ibulewe, ingqolowa entle | A516 / A516M | 70 |

| D 70 | manganese-silicon, eqhelekileyo | A537 / A537M | 1 |

| D 80 | manganese-silicon, Q&TA | A537 / A537M | 2 |

| H 75 | manganese-molybdenum, eqhelekileyo | A302 / A302M | A |

| H80 | manganese-molybdenum, eqhelekileyo | A302 / A302M | B, C, okanye D |

| J 80 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-1B |

| J 90 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-2B |

| J 100 | manganese-molybdenum, Q&TA | A533 / A533M | Cl-3B |

| L 65 | molybdenum | A204 / A204M | A |

| L 70 | molybdenum | A204 / A204M | B |

| L 75 | molybdenum | A204 / A204M | C |

| N 75 | manganese-silicon | A299 / A299M | A |

AQ & T = ucinywe kwaye unomsindo.

ВNaliphi na ibakala linokunikwa.

Sinokuqala ngokumisela uhlobo lombhobho wensimbi ngeeleta kwibakala.

Amabanga aqala ngoonobumba A, B, no-C adla ngokubonisaumbhobho wentsimbi yekhabhoni.

Amabanga aqala ngoonobumba D, H, J, L, no-N abonisaumbhobho wentsimbi yengxubevange.

ASTM A672 Class Ukuhlelwa

Iityhubhu zihlelwa ngokohlobo lonyango lobushushu abalufumanayo ngexesha lenkqubo yokuvelisa kunye nokuba ngaba bahlolwe nge-radiographical kunye noxinzelelo.

| Iklasi | Unyango lobushushu kumbhobho | Iradiyografi, jonga inqaku: | Uvavanyo loxinzelelo, jonga inqaku: |

| 10 | akukho nanye | akukho nanye | akukho nanye |

| 11 | akukho nanye | 9 | akukho nanye |

| 12 | akukho nanye | 9 | 8.3 |

| 13 | akukho nanye | akukho nanye | 8.3 |

| 20 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | akukho nanye | akukho nanye |

| 21 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | 9 | akukho nanye |

| 22 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | 9 | 8.3 |

| 23 | kuthotyiwe uxinzelelo, jonga ku-5.3.1 | akukho nanye | 8.3 |

| 30 | iqhelekile, jonga ku-5.3.2 | akukho nanye | akukho nanye |

| 31 | iqhelekile, jonga ku-5.3.2 | 9 | akukho nanye |

| 32 | iqhelekile, jonga ku-5.3.2 | 9 | 8.3 |

| 33 | iqhelekile, jonga ku-5.3.2 | akukho nanye | 8.3 |

| 40 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | akukho nanye | akukho nanye |

| 41 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | 9 | akukho nanye |

| 42 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | 9 | 8.3 |

| 43 | iqhelekile kwaye inomsindo, jonga ku-5.3.3 | akukho nanye | 8.3 |

| 50 | ucime wacaphuka, jonga ku-5.3.4 | akukho nanye | akukho nanye |

| 51 | ucime wacaphuka, jonga ku-5.3.4 | 9 | akukho nanye |

| 52 | ucime wacaphuka, jonga ku-5.3.4 | 9 | 8.3 |

| 53 | ucime wacaphuka, jonga ku-5.3.4 | akukho nanye | 8.3 |

Ingqwalasela ekhethekileyo kufuneka ihlawulwe kwiqondo lokushisa elilindelekileyo xa ukhetha iklasi yezinto ezifanelekileyo.Jonga kwiinkcukacha ze-ASTM A20/A20M.

ASTM A672 Ubungakanani Uluhlu

Uluhlu lwesayizi olucetyiswayo: DN≥400mm[16 in] kunye ne-WT≤75mm[3 kwi].

Ngobunye ubungakanani bombhobho, ngaphandle kokuba ihlangabezana nazo zonke ezinye iimfuno zolu luhlu, ingasetyenziswa kwakhona.

Ukhuseleko lweWelding

Ii-seams ziyakudityaniswa kabini, zingene ngokuzeleyo.

I-welds iya kwenziwa ngesandla okanye ngokuzenzekelayo ngenkqubo yombane ebandakanya ukubekwa kwesinyithi.

Iiwelds zinokuhlolwa kusetyenziswa iradiography kwaye kufuneka zilandele izibonelelo ezikwiCandelo VII UW-51 le-ASME Boiler kunye neKhowudi yeVessel yoxinzelelo.

Ubude be-weld abuyi kudlula i-3 mm [1/8 in].

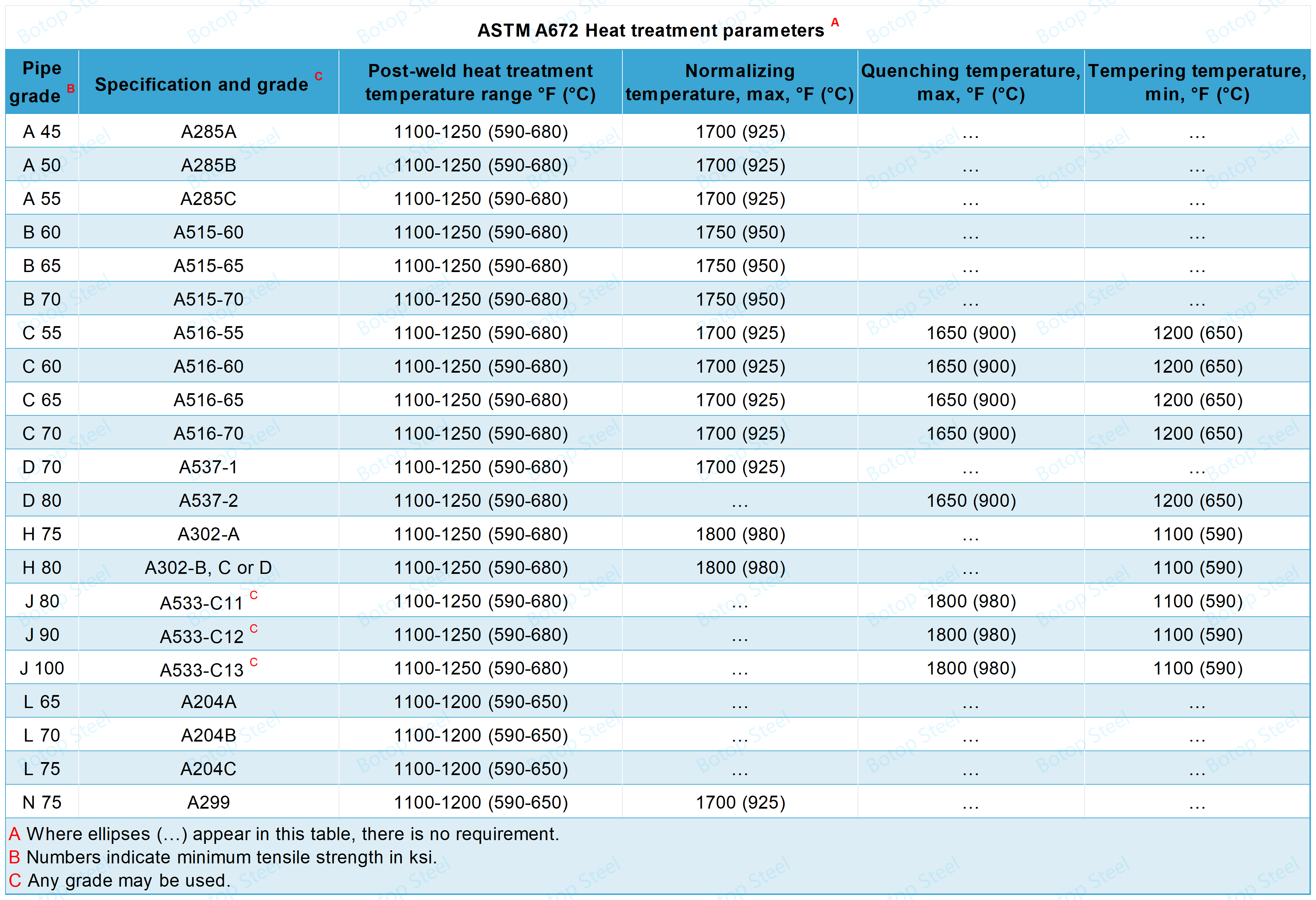

Unyango lobushushu

Zonke iiklasi ngaphandle kwe-10, 11, 12, kunye ne-13 ziya kunyangwa ubushushu kwiziko elilawulwa ukuya ku-±25 °F[± 15°C]:

Iiklasi 20, 21, 22, kunye 23

Umbhobho uya kufudunyezwa ngokufanayo kwiqondo lokushisa emva kwe-weld eliboniswe kwiThebhile 2 ubuncinane be-1 h / ngo.[0.4 h/cm] ubukhulu okanye i-1 h, nayiphi na enkulu.

Iiklasi 30, 31, 32, kunye nama-33

Umbhobho uya kutshiswa ngokufanayo kwiqondo lokushisa kwi-austenitizing range kwaye ungadluli ubushushu obuqhelekileyo obuqhelekileyo obuboniswe kwiThebhile 2 kwaye emva koko ipholile emoyeni kwiqondo lokushisa.

Iiklasi 40, 41, 42, kunye nama-43

Umbhobho uya kuba yinto eqhelekileyo.

Umbhobho uza kufudunyezwa kwakhona kwiqondo lobushushu elibonakaliswe kwiTheyibhile 2 njengobuncinane kwaye ugcinwe kwiqondo lobushushu ubuncinane be-0.5 h/in.[0.2 h/cm] ubukhulu okanye ngenxa1/2h, nokuba yeyiphi enkulu, kwaye ipholiswe ngumoya.

Iiklasi 50, 51, 52, kunye nama-53

Umbhobho uya kutshiswa ngokufanayo kumaqondo obushushu ngaphakathi koluhlu lwe-austenitizing kwaye ungagqithisi ubushushu bokucima ubuninzi obuboniswe kwiThebhile 2.

Emva koko, cima emanzini okanye ngeoli.Emva kokucima, umbhobho uya kuhlaziywa kwiqondo lokushisa elincinci eliboniswe kwiThebhile 2 kwaye ligcinwe apho.

iqondo lobushushu ubuncinane be-0.5 h/intshi [0.2 h/cm] ubukhulu okanye i-0.5 h, leliphi na elikhulu ngakumbi, nelipholiswe ngumoya.

Amacandelo eMichiza

Kuya kuba noxanduva lomenzi ukuvavanya ukubunjwa kweekhemikhali zepleyiti kunye ne-welds ukuthotyelwa kweemfuno zenkcazo yepleyiti yezinto eziyalelweyo kunye nenkqubo ye-welding yokufaka i-weld metal, ngokulandelanayo.

Uvavanyo loxinzelelo

Ukuphindaphindwa kovavanyo: umzekelo omnye kwiqashiso ngalinye.

Indlela yoVavanyo: Imizekelo yovavanyo iya kwenziwa ngokuhambelana ne-QW-150 kwiCandelo le-IX le-ASME yeBoiler kunye neKhowudi yeVessel yoxinzelelo.Iisampulu ziya kuvavanywa kwiqondo lobushushu begumbi ngokuhambelana neeNdlela zoVavanyo kunye neNgcaciso ye-A370.

Ukongeza kwiBanga le-Dxx, i-Hxx, i-Jxx, kunye ne-Nxx kwiiKlasi ze-3x, i-4x, kunye ne-5x yeepropati ezinqamlezayo ze-base plate, ziya kumiselwa kwiisampuli ezisikwe kumbhobho ophethwe ukushisa.

Iimfuno zeziphumo: Iipropati ezinqamlezileyo zobunzima bomdibaniso odityanisiweyo ziya kuhlangabezana nezona mfuno zisezantsi zokuqina kokugqibela kwemathiriyeli yepleyiti echaziweyo.

Uvavanyo lwe-Transverse-Guided-Weld-Bend

Inani leemvavanyo: Ubuninzi bovavanyo: kube kanye kwibhetshi nganye, imizekelo emibini

Indlela yovavanyo: Iimfuno zovavanyo lweeNdlela zoVavanyo kunye neeNkcazo ze-A370, umhlathi A2.5.1.7 ziya kuhlangatyezwa.

Kuba ubukhulu bodonga ngaphezulu3/ 8ngaphakathi [10 mm] kodwa ngaphantsi kwe3/4in [19 mm] iimvavanyo ze-Side-bend zinokwenziwa endaweni yovavanyo lobuso kunye neengcambu.

Ngobunzima bodonga3/4ngaphakathi [19 mm] nangaphezulu kwemizekelo yomibini iya kufakwa kuvavanyo lwe-side-bend.

Iimfuno zeziphumo: Uvavanyo lokugoba luya kwamkeleka ukuba akukho zintanda okanye ezinye iziphene ezidlulayo1/8in. [3 mm] kulo naliphi na icala zikhona kwintsimbi edibeneyo okanye phakathi kwentsimbi kunye nesiseko sesinyithi emva kokugoba.

Iintanda ezivela ecaleni komfanekiso ngexesha lovavanyo, kwaye ezingaphantsi1/4ngo. [6 mm] ilinganiswe kulo naliphi na icala ayisayi kuqwalaselwa.

Uvavanyo loxinzelelo

Iiklasi X2 kunye X3 umbhobho ziya kuvavanywa ngokuhambelana Specification A530/A530M, Hydrostatic Test Requirements.

Uviwo lweRadiographic

Ubude obupheleleyo beweld nganye yeeKlasi X1 kunye ne-X2 buya kujongwa ngeradiographically ngokuhambelana kwaye kuhlangabezene neemfuno ze-ASME Boiler kunye neKhowudi yeVessel yoxinzelelo, iCandelo VIII, umhlathi UW-51.

Uvavanyo lwe-radiographic lunokwenziwa ngaphambi konyango lobushushu.

Ukunyamezelwa komgangatho we-ASTM A672

| Ezemidlalo | Ukunyamezela Ixabiso | Phawula |

| Ngaphandle Ububanzi | ±0.5% | Ngokusekelwe kumlinganiselo ojikelezayo |

| Ngaphandle kwe-Roundness | 1%. | Umahluko phakathi kweedayamitha ezinkulu nezincinci zangaphandle |

| Ulungelelwaniso | 1/8 ngaphakathi [3 mm] | Ukusebenzisa i-10 ft [3 yeemitha] edge ethe tye ebekwe ukuze iziphelo zombini zidibane nombhobho |

| Ukutyeba | 0.01 ngaphakathi [0.3 mm] | Ubuncinane bobunzima bodonga bungaphantsi kobungqingqwa obuxeliweyo |

| Ubude | 0-+0.5in [0-+13mm] | iziphelo ezingenakwenziwa |

ASTM A672 Imbonakalo

Umbhobho ogqityiweyo awuyi kuba neziphene ezinobungozi kwaye uya kuba nesiphelo esifana nomsebenzi.

Iimfuno ezifanayo njengakwingcaciso ye-ASTM A20/A20M yokugqitywa komphezulu weepleyiti zentsimbi.

Iziphene kunye noLungiso

Ukuzimisela Kwesiphene

Umgangatho we-ASTM A672 awukhankanyi imigangatho eyamkelekileyo yeziphene kunye neendlela zokumisela imibhobho kwaye idla ngokubhekisa kwimigangatho efanelekileyo yobunjineli kunye nezenzo zeshishini.

Iziphene zangaphakathi: Iziphene zangaphakathi zingabandakanya i-porosity, i-slag, i-inclusions, njl.

Iziphene zangaphandle: Iziphene zangaphandle zingabandakanya iintanda, izibonda, imikrwelo, njl.

Ukususwa ngokuRegrinding

Iziphene zobuso zingasuswa ngokugrumba okanye ngomatshini kunye nobukhulu obushiyekileyo obungekho ngaphantsi kwe-0.3 mm ngaphantsi kobukhulu obuqhelekileyo.

I-regrind depression kufuneka idityaniswe ngokulinganayo kwindawo ejikelezileyo.

Ukulungiswa kweWelding

Iziphene ziya kususwa ngeendlela ezifanelekileyo zokusika okanye ukusika i-thermal okanye iidicing kwaye zilungiselelwe ukulungisa imigodi edibeneyo.

kunye nokuhlolwa ngemitha ngokuhambelana ne-ASME Boiler kunye neKhowudi yeVessel yoxinzelelo, iCandelo VIII, umhlathi UW-51.

Ubude obupheleleyo bombhobho olungisiweyo buya kunyangwa ngobushushu emva kokulungiswa ngokuhambelana neemfuno zombhobho ochaziweyo.

Ukumakishwa kwe-ASTM A672

Ukumakishwa kufuneka kuqulathe oku kulandelayo:

Isazisi somvelisi, esifana nophawu okanye ilogo.

Ukucaciswa kombhobho (ubungakanani, ubukhulu bodonga, njl.).

Ibakala lezinto eziphathekayo okanye uhlobo lombhobho.Umzekelo: C60-22 (isifinyezo sebakala: C60 kunye neklasi 22).

Umgangatho wokwenziwa kombhobho yi-ASTM A672.

Umhla wemveliso okanye inombolo yecandelo lemveliso.

Ukusetyenziswa kwe-ASTM A672 yentsimbi yombhobho

Kwishishini lamandla ombane, i-ASTM A672 Electric Welded Steel Pipe isetyenziswa ngokuqhelekileyo ukuhambisa umphunga kwiinkqubo zebhoyila.

Kwishishini lemichiza, i-ASTM A672 i-welded yentsimbi yombhobho idla ngokusetyenziselwa ukuthutha iikhemikhali ezahlukeneyo, i-asidi, kunye nezisombululo zealkali, kunye nezinye imidiya.

Kwishishini leoli kunye negesi, i-ASTM A672 yentsimbi edityanisiweyo yombhobho iqhele ukusetyenziselwa ukuthutha i-oyile ekrwada, igesi yendalo, kunye nolunye ulwelo okanye iigesi.

Singumvelisi wemibhobho yentsimbi yekhabhoni ekumgangatho ophezulu odityanisiweyo kunye nomthengisi ovela eChina, kunye nesitokhwe semibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Tags: ASTM a672, efw, carbon steel pipe, ibakala.

Ixesha lokuposa: Apr-23-2024