ASTM A519tubing yoo wa ni ti ṣelọpọ nipasẹ awọn iran ilana ati ki o yoo wa ni gbona-pari tabi tutu-pari bi pato.

Fun awọn tubes yika pẹlu iwọn ila opin ita ti ko kọja 12 3/4 in (325 mm).

Ọpọn irin le tun ṣe ni onigun mẹrin, onigun mẹrin, tabi awọn apẹrẹ miiran bi o ṣe nilo.

ASTM A519 le jẹ ipin gẹgẹbi ohun elo ti irin:Erogba Irinati Alloy Irin.

Erogba irinti pin siErogba kekere MT(Ẹ̀rọ Ìdánilẹ́gbẹ́),Ga Erogba IrinatiDesulfurized tabi Rephosphorized, tabi awọn mejeejiErogba Irin, lati baamu awọn iwulo ile-iṣẹ oriṣiriṣi ati awọn oju iṣẹlẹ ohun elo.

Nigbati ko si ite ti wa ni pato, awọn olupese ni aṣayan ti ẹbọMT1015 tabi MTX1020awọn onipò.

Ita opin: 13.7 - 325 mm;

Odi sisanra: 2-100mm.

Irin le ṣee ṣe nipasẹ eyikeyi ilana.

Irin le jẹ simẹnti sinu ingots tabi o le jẹ simẹnti okun.

Awọn tubes yoo ṣee ṣe nipasẹ alaisiyonu ilanayoo si jẹ boya gbona-pari tabi tutu-pari, bi pato.

Awọn tubes irin ti ko ni ailabawọn jẹ awọn tubes ti ko ni awọn okun ti a fi welded jakejado.

Tutu-pari tubesti wa ni niyanju fun ga wáà lori onisẹpo yiye ati dada didara.

Ibakcdun akọkọ jẹ ṣiṣe idiyele ati lile ohun elo,gbona-pari irin pipele jẹ kan diẹ dara wun.

Nigbamii ni ilana iṣelọpọ ti paipu irin ti ko ni iyipo ti o gbona.

Olupese irin yoo ṣe itupalẹ ooru ti irin kọọkan lati pinnu ipin ogorun awọn eroja pato.

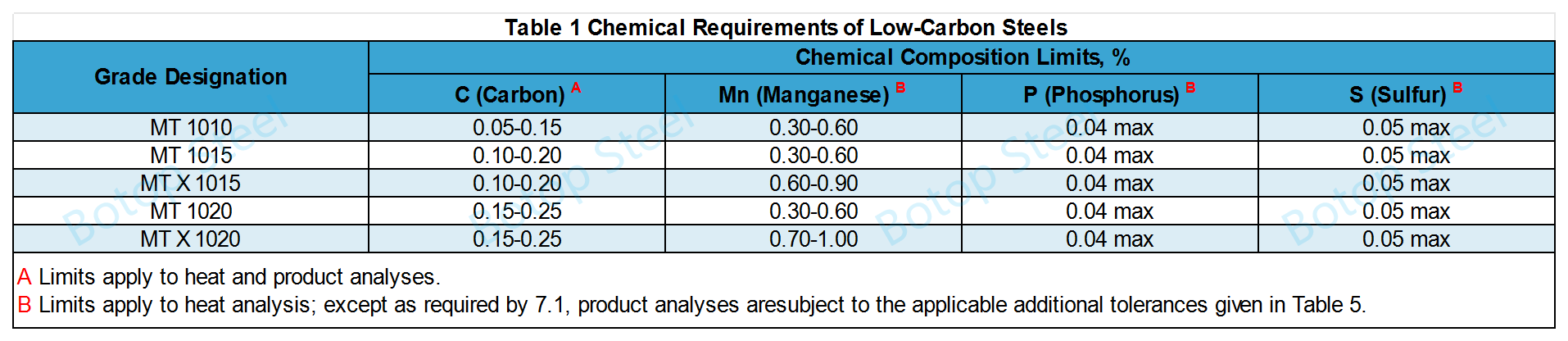

Tabili 1 Awọn ibeere Kemikali ti Awọn irin-irin Kekere

Irin kekere jẹ irin pẹlu akoonu erogba nigbagbogbo ko kọja 0.25%. Nitori awọn oniwe-kekere erogba akoonu, irin yi ni o ni dara ductility ati malleability ati ki o jẹ kere lile ati ki o lagbara akawe si ga-erogba irin.

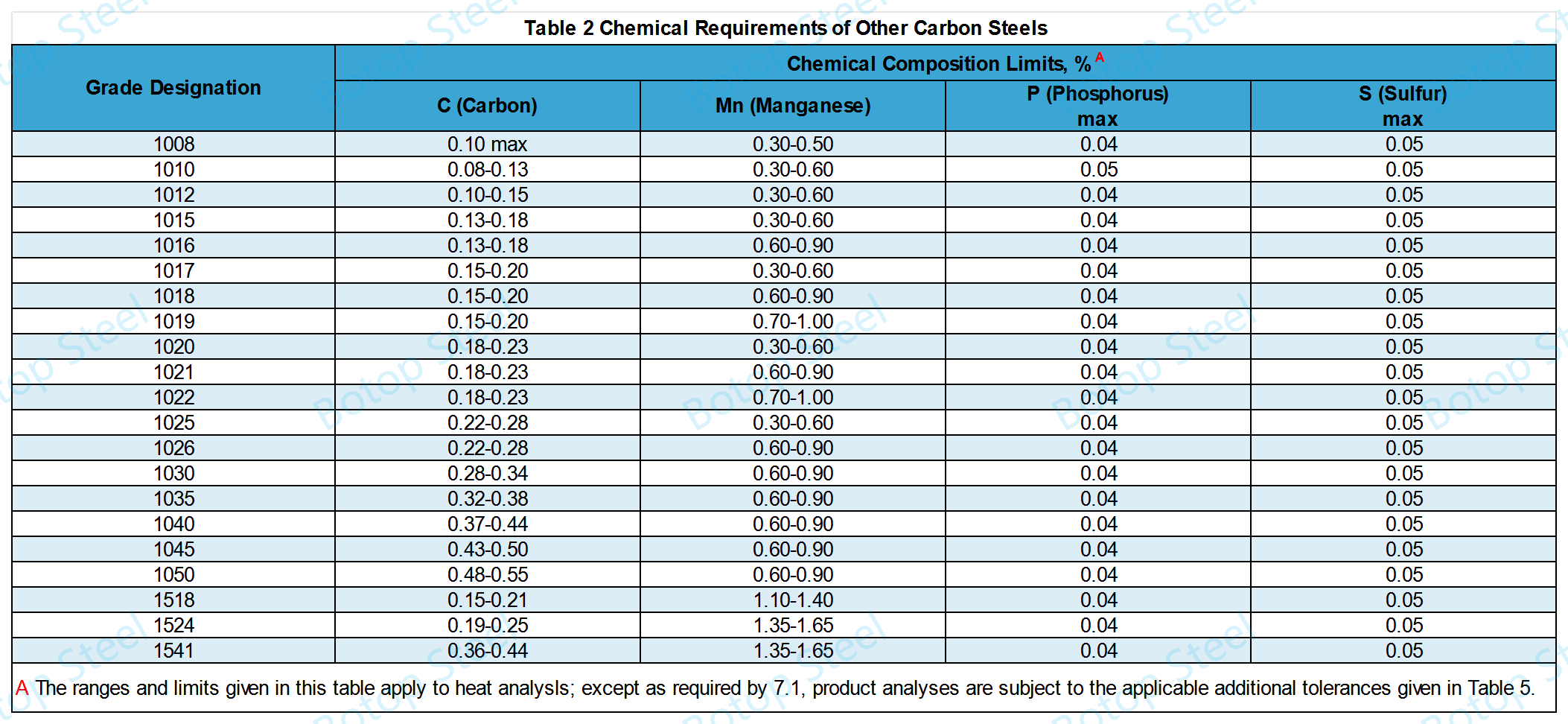

Tabili 2 Awọn ibeere Kemikali ti Awọn irin Erogba miiran

Awọn irin erogba alabọde: Ti o ni laarin 0.25% ati 0.60% erogba, wọn pese lile ati agbara ti o ga julọ ati nilo itọju ooru lati mu awọn ohun-ini dara sii.

Ga erogba, irin: Ni laarin 0.60% ati 1.0% tabi diẹ ẹ sii erogba, ati ki o pese gidigidi ga líle ati agbara, sugbon kekere toughness.

Table 3 Kemikali ibeere fun Alloy Irin

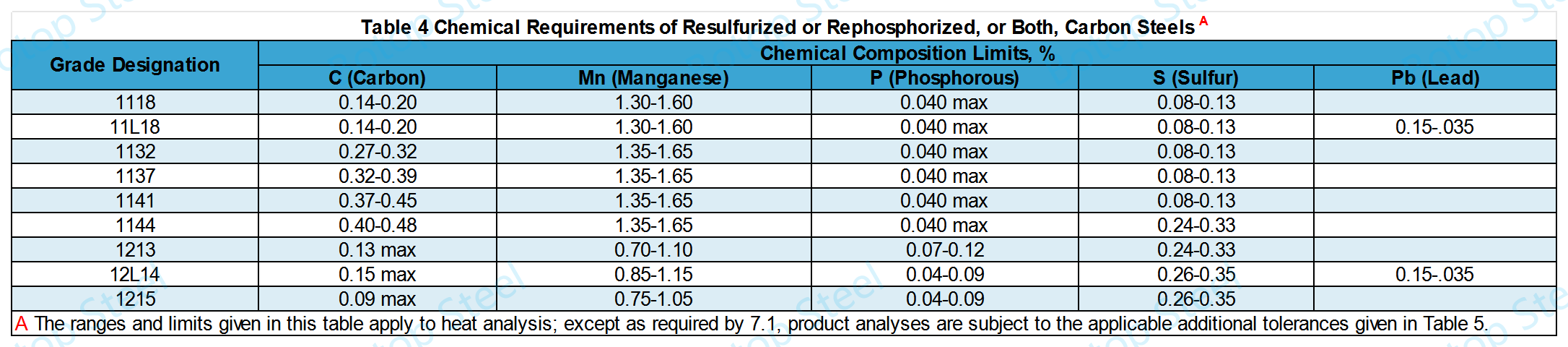

Tabili 4 Awọn ibeere Kemikali ti Resulfurized tabi Rephosphorized, tabi Mejeeji, Awọn irin Erogba

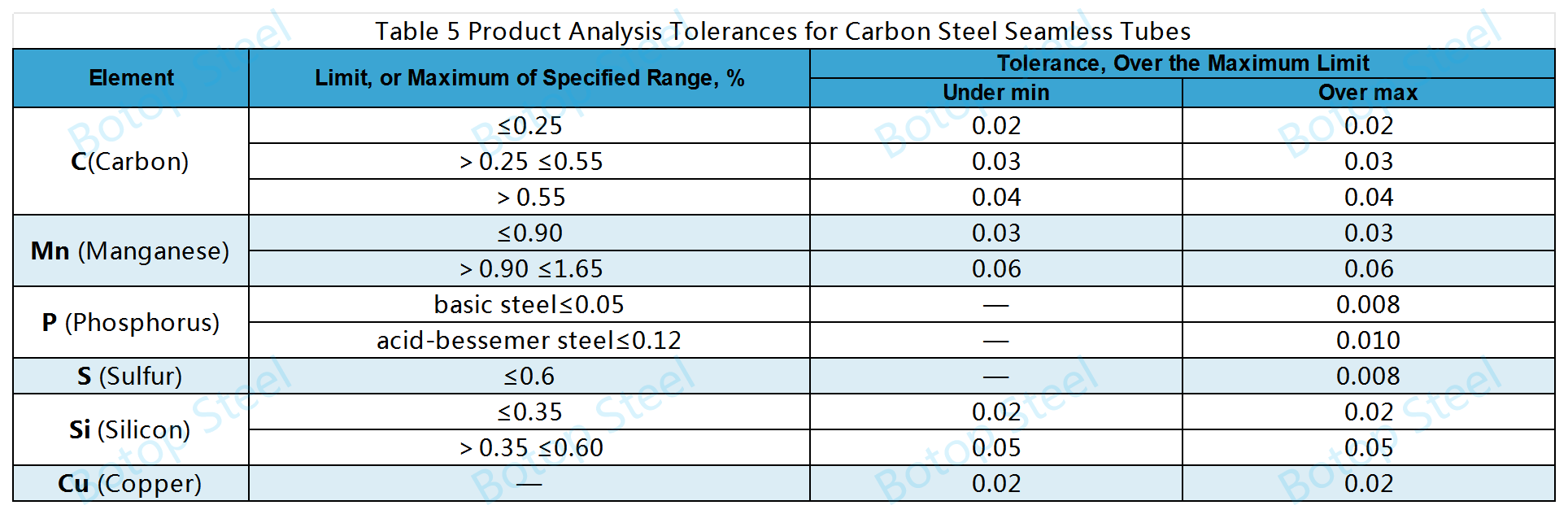

TABLE 5 Awọn ifarada Onínọmbà Ọja Lori tabi Labẹ Ibiti pato tabi Idiwọn

Olupese yẹ ki o beere nikan lati ṣe itupalẹ ọja ti o ba nilo nipasẹ aṣẹ naa.

ASTM A519 bo awọn nkan idanwo wọnyi:

Idanwo Lile; Idanwo ẹdọfu; Idanwo ti ko ni iparun; Idanwo igbona; Irin Cleanliness ati Hardenability.

| Ipe yiyan | Pipe Iru | Ipo | Agbara to wulo | Agbara Ikore | Ilọsiwaju ni 2in.[50mm],% | Rockwell, Lile B Asekale | ||

| ksi | Mpa | ksi | Mpa | |||||

| 1020 | Erogba Irin | HR | 50 | 345 | 32 | 220 | 25 | 55 |

| CW | 70 | 485 | 60 | 415 | 5 | 75 | ||

| SR | 65 | 450 | 50 | 345 | 10 | 72 | ||

| A | 48 | 330 | 28 | 195 | 30 | 50 | ||

| N | 55 | 380 | 34 | 235 | 22 | 60 | ||

| 1025 | Erogba Irin | HR | 55 | 380 | 35 | 240 | 25 | 60 |

| CW | 75 | 515 | 65 | 450 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 53 | 365 | 30 | 205 | 25 | 57 | ||

| N | 55 | 380 | 35 | 250 | 22 | 60 | ||

| 1035 | Erogba Irin | HR | 65 | 450 | 40 | 275 | 20 | 72 |

| CW | 85 | 585 | 75 | 515 | 5 | 88 | ||

| SR | 75 | 515 | 65 | 450 | 8 | 80 | ||

| A | 60 | 415 | 33 | 230 | 25 | 67 | ||

| N | 65 | 450 | 40 | 275 | 20 | 72 | ||

| 1045 | Erogba Irin | HR | 75 | 515 | 45 | 310 | 15 | 80 |

| CW | 90 | 620 | 80 | 550 | 5 | 90 | ||

| SR | 80 | 550 | 70 | 485 | 8 | 85 | ||

| A | 65 | 450 | 35 | 240 | 20 | 72 | ||

| N | 75 | 515 | 48 | 330 | 15 | 80 | ||

| 1050 | Erogba Irin | HR | 80 | 550 | 50 | 345 | 10 | 85 |

| SR | 82 | 565 | 70 | 485 | 6 | 86 | ||

| A | 68 | 470 | 38 | 260 | 18 | 74 | ||

| N | 75 | 540 | 50 | 345 | 12 | 82 | ||

| 1118 | Resulfurized tabi tun ṣe atunṣe, tabi Mejeeji, Erogba Irin | HR | 50 | 345 | 35 | 240 | 25 | 55 |

| CW | 75 | 515 | 60 | 415 | 5 | 80 | ||

| SR | 70 | 485 | 55 | 380 | 8 | 75 | ||

| A | 80 | 345 | 30 | 205 | 25 | 55 | ||

| N | 55 | 380 | 35 | 240 | 20 | 60 | ||

| 1137 | Resulfurized tabi tun ṣe atunṣe, tabi Mejeeji, Erogba Irin | HR | 70 | 485 | 40 | 275 | 20 | 75 |

| CW | 80 | 550 | 65 | 450 | 5 | 85 | ||

| SR | 75 | 515 | 60 | 415 | 8 | 80 | ||

| A | 65 | 450 | 35 | 240 | 22 | 72 | ||

| N | 70 | 485 | 43 | 295 | 15 | 75 | ||

| 4130 | Alloy Irin | HR | 90 | 620 | 70 | 485 | 20 | 89 |

| SR | 105 | 725 | 85 | 585 | 10 | 95 | ||

| A | 75 | 515 | 55 | 380 | 30 | 81 | ||

| N | 90 | 620 | 60 | 415 | 20 | 89 | ||

| 4140 | Alloy Irin | HR | 120 | 825 | 90 | 620 | 15 | 100 |

| SR | 120 | 825 | 100 | 690 | 10 | 100 | ||

| A | 80 | 550 | 60 | 415 | 25 | 85 | ||

| N | 120 | 825 | 90 | 620 | 20 | 100 | ||

HR-gbona ti yiyi, CW-tutu ṣiṣẹ, SR-wahala Relieved, A-Annealed ati N-Normalized.

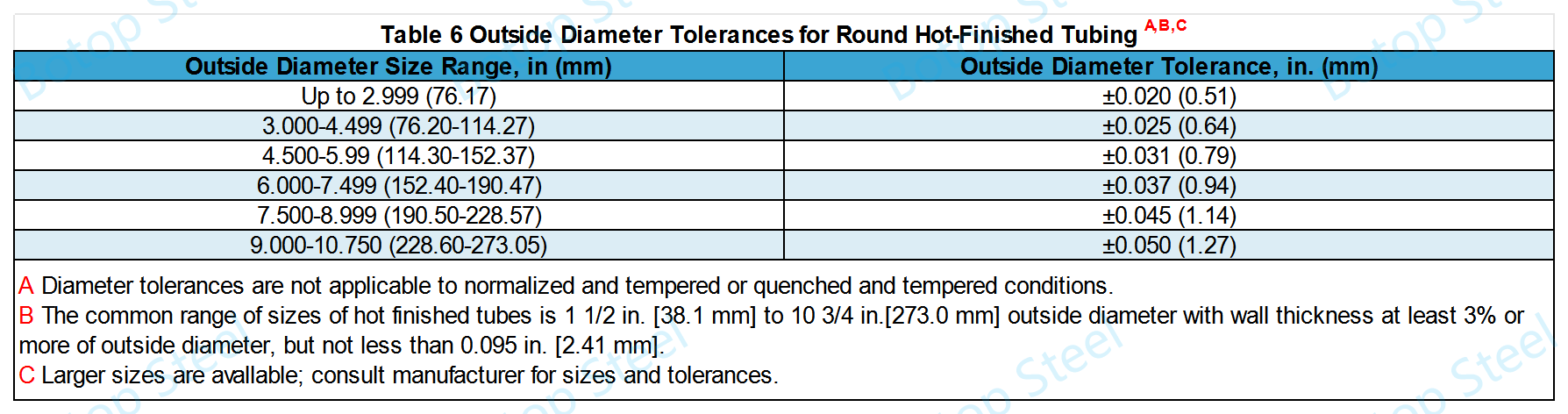

Ita Diamita ifarada

Table 6 Ita dimeter Tolerancesfun Yika Gbona-Pari ọpọn

Table 12 Ita dimeter Tolerances funIlẹ Seamless Tubing

| Iwọn Ita Iwọn, ninu [mm] | Awọn ifarada ita fun Awọn iwọn ati Awọn Gigun Ti a Fifunni, ni. [mm] | |||

| Pari | Labẹ | Pari | Labẹ | |

| OD≤1 1/4 [31.8] | 0.003 [0.08] nigbati L≤16ft[4.9m] | 0.000 | 0.004 [0.10] nigbati L = 16ft[4.9m] | 0.000 |

| 1 1/4 [31.8] OD ≤2[50.8] | 0.005 [0.13] nigbati L≤16ft[4.9m] | 0.000 | 0.006 [0.15] nigbati L = 16ft[4.9m] | 0.000 |

| 2 [50.8] | OD ≤3 [76.2] | 0.005 [0.13] nigbati L≤12ft[3.7m] | 0.000 | 0.006 [0.15] nigbati L≤16ft[4.9m] | 0.000 |

| 3 [76.2] | OD ≤4 [101.6] | 0.006 [0.15] nigbati L≤12ft[3.7m] | 0.000 | 0.006 [0.15] nigbati L≤16ft[4.9m] | 0.000 |

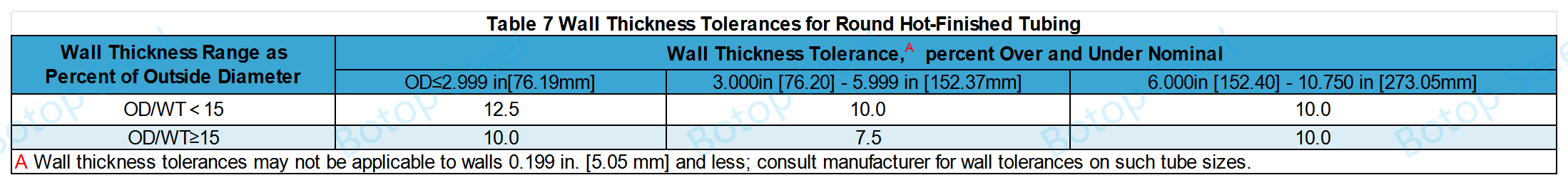

Ifarada Odi Sisanra

Table 7 Odi Sisanra Tolerancesfun Yika Gbona-Pari ọpọn

Table 10 Odi Sisanra Tolerancesfun Yika Tubing-ṣiṣẹ

| Awọn sakani Sisanra odi bi Ogorun ti Ita opin | Ifarada Sisanra Odi Lori ati Labẹ Orukọ,% | |

| OD≤1.499ninu[38.07mm] | OD≥1.500 ninu [38.10mm] | |

| OD/WT≤25 | 10.0 | 7.5 |

| OD/WT:25 | 12.5 | 10.0 |

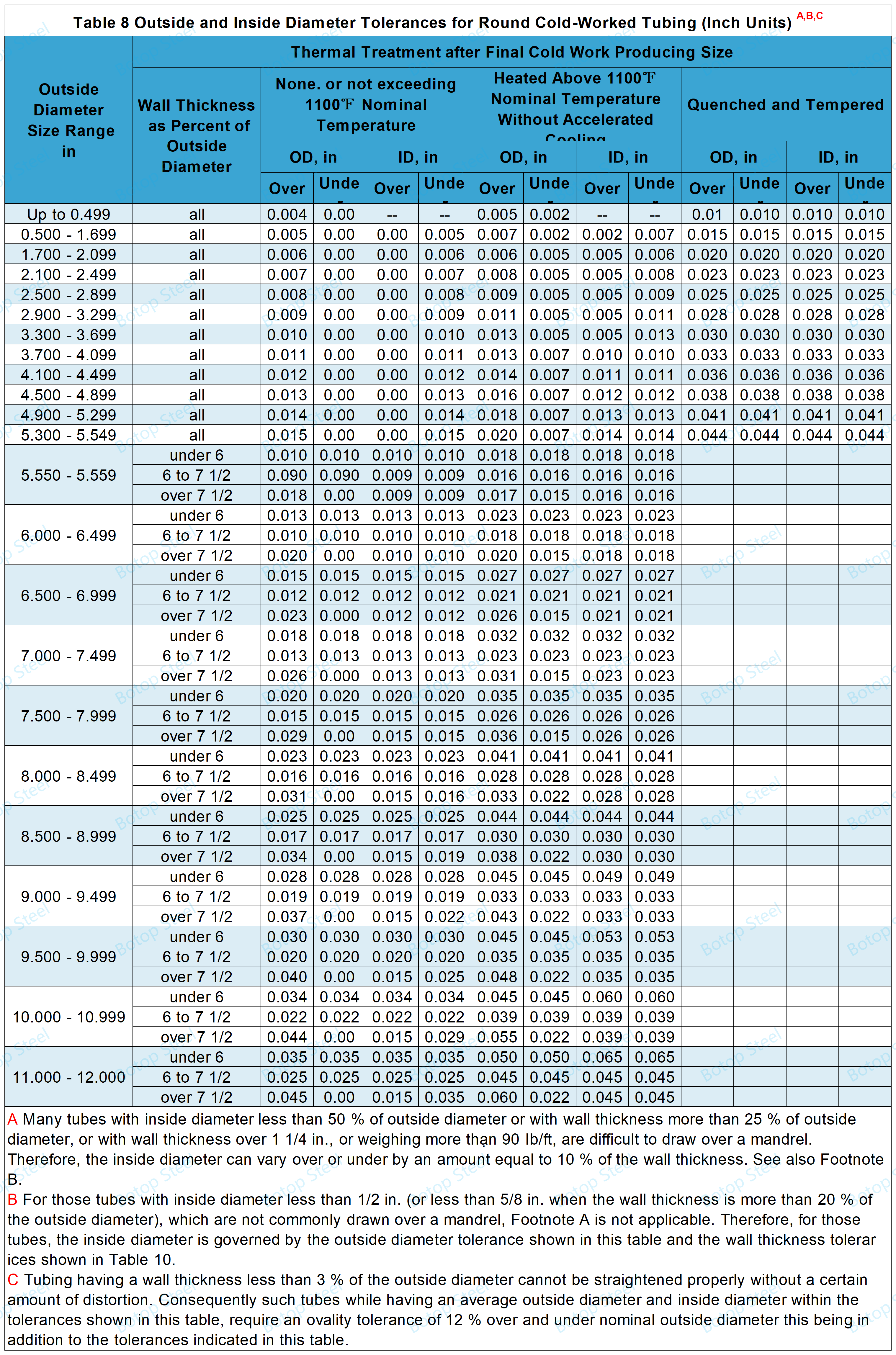

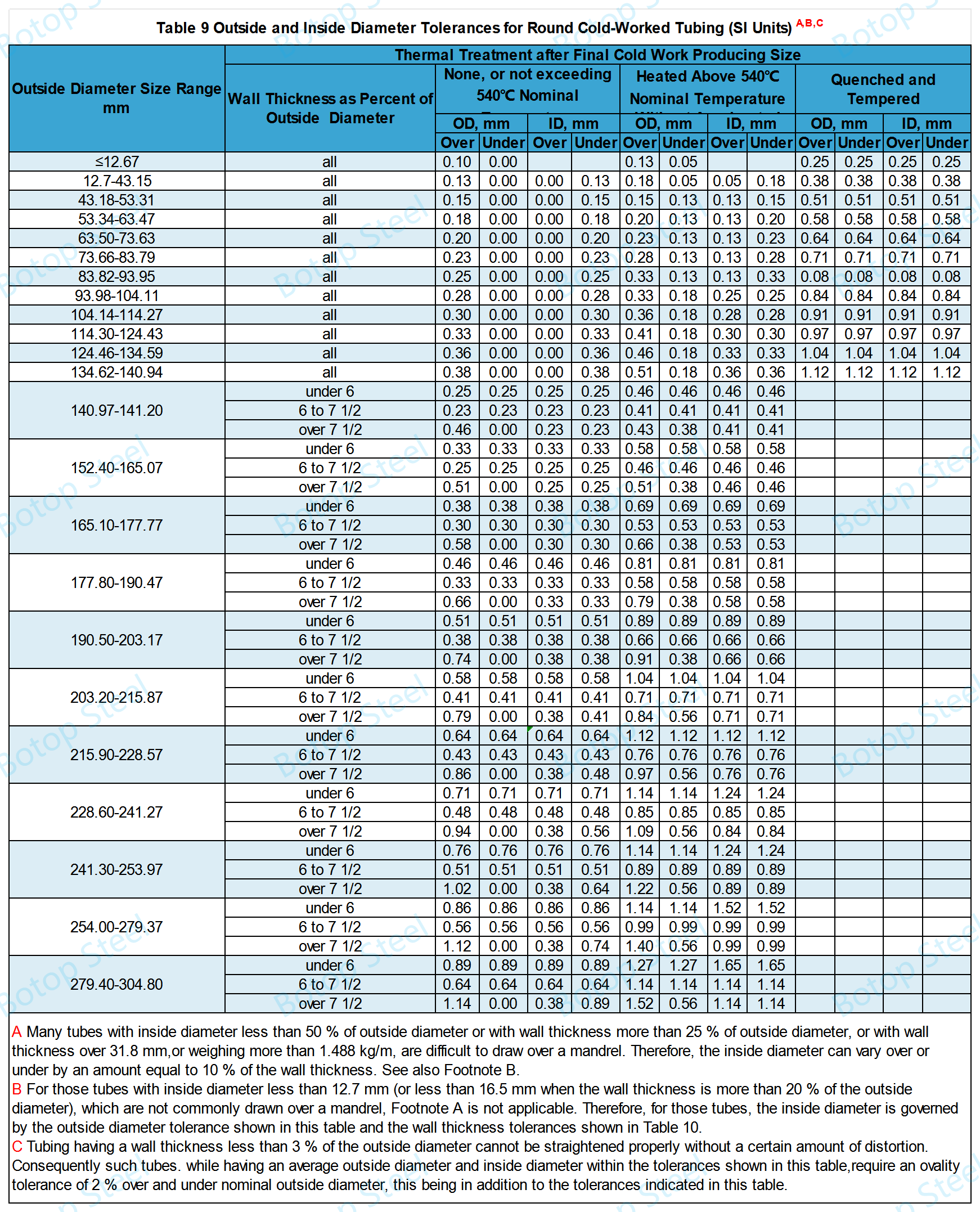

Ita ati Inu Ifarada Ifarada

Table 8 Ita ati Inu dimeter Tolerances funTubing Ti Ṣiṣẹ Yika (Awọn ẹya Inṣi)

Table 9 Ita ati Inu dimeter Tolerancesfun Tubing Ti nṣiṣẹ Yika (Awọn ẹya SI)

Ita Opin ati Ifarada Sisanra Odi

Table 11 Ita opin ati odi Tolerancesfun Ti o ni inira-Tan Seamless Irin ọpọn

| Pato Iwon Ita Ode, ninu [mm] | Ita Opin, ninu [mm] | Sisanra ogiri, % |

| 6 3/4 [171.4] | ± 0.005 [0.13] | ± 12.5 |

| 6 3/4 - 8 [171.4 - 203.2] | ± 0.010 [0.25] | ± 12.5 |

Ifarada Gigun

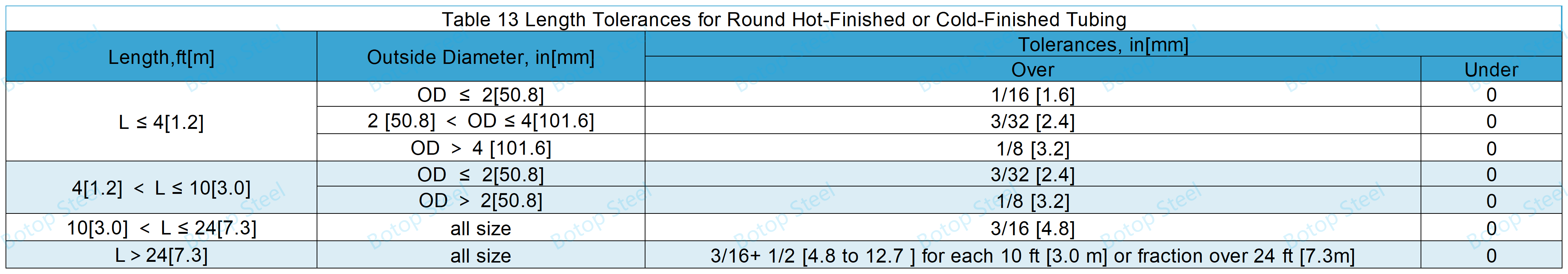

Table 13 Ipari Tolerancesfun Yika Gbona-Pari tabi Tubing-Pari

Ifarada Titọ

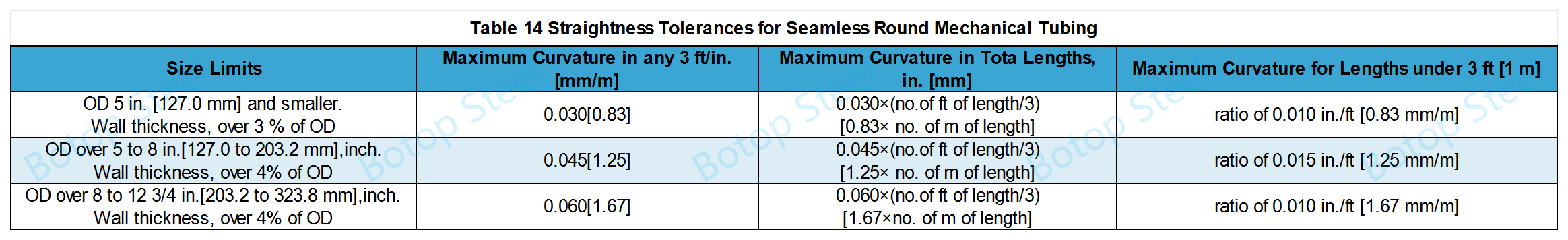

Table 14 Straightness Tolerancesfun Ailokun Yika Mechanical ọpọn

Awọn paipu yẹ ki o wa ni ti a bo pẹlu kan fiimu ti epo ṣaaju ki o to mọto lati se ipata.

Epo idena ipata le tun lo si inu ati ita ti paipu naa.

Ofurufu ati Aerospace: iṣelọpọ awọn paati to ṣe pataki gẹgẹbi awọn ẹrọ ọkọ ofurufu ati awọn eto atilẹyin ọkọ ofurufu.

Agbara ile ise: liluho ẹrọ ati ki o ga-titẹ igbomikana fifi ọpa ẹrọ.

Awọn ẹrọ ati ẹrọ iṣelọpọ: Awọn paati mojuto ti o jẹ ọpọlọpọ awọn ẹrọ ati ẹrọ ile-iṣẹ lọpọlọpọ.

Awọn ohun elo ere idaraya: Ṣiṣẹpọ awọn fireemu keke ti o ga julọ ati awọn ohun elo ere idaraya miiran.

Ilé ati ikole: awọn eroja atilẹyin igbekale fun awọn ile ati awọn ohun elo ni awọn agbegbe ti o ga-titẹ.

1. EN 10297-1: E355, 25CrMo4, 42CrMo4, bbl Awọn ohun elo wọnyi le jẹ deede ti diẹ ninu awọn erogba ati awọn irin alloy ni ASTM A519.

2. DIN 1629: St52, St37.4, bbl Nigbagbogbo a lo fun awọn ọna ẹrọ ati awọn idi-itumọ, iwọnyi jẹ iru si awọn onipò irin kekere ni ASTM A519.

3. JIS G3445: STKM13A, STKM13B, bbl Awọn wọnyi ni awọn tubes erogba ti a lo fun awọn ẹrọ ati awọn idi-itumọ.

4. BS 6323: CFS 3, CFS 4, CFS 8, bbl Awọn wọnyi ni awọn tubes irin ti a ko ni idọti ati ti a fiwe si fun ọkọ ayọkẹlẹ, ẹrọ, ati awọn idi-ẹrọ imọ-ẹrọ gbogbogbo.

5. GB/T 8162: 20 #, 45 #, 40Cr, 20CrMo, ati be be lo Awọn ọpọn irin ti ko ni ilọlẹ ati awọn paipu fun ipilẹ gbogbogbo ati ọna ẹrọ.

6. ISO 683-17: 100Cr6, ati bẹbẹ lọ, ti a lo ni iṣelọpọ ti nso, tun le rii ohun elo ni imọ-ẹrọ ẹrọ ati pe o ni awọn ohun elo kanna si awọn irin alloy kan ti ASTM A519.

Nigbati o ba yan ohun elo deede, o ṣe pataki lati tọka si akojọpọ kemikali alaye ati awọn pato ohun-ini ẹrọ lati rii daju pe ohun elo ti o yan yoo pade awọn ibeere iṣẹ ti ohun elo pato.

Niwon idasile rẹ ni 2014, Botop Steel ti di olutaja asiwaju ti paipu irin carbon ni Ariwa China, ti a mọ fun iṣẹ ti o dara julọ, awọn ọja ti o ga julọ, ati awọn iṣeduro okeerẹ. Ile-iṣẹ nfunni ni ọpọlọpọ awọn paipu irin erogba ati awọn ọja ti o jọmọ, pẹlu lainidi, ERW, LSAW, ati paipu irin SSAW, bakanna bi tito lẹsẹsẹ pipe ti awọn ohun elo pipe ati awọn flanges.

Awọn ọja pataki rẹ tun pẹlu awọn alloy-giga ati awọn irin alagbara austenitic, ti a ṣe deede lati pade awọn ibeere ti awọn iṣẹ akanṣe opo gigun ti epo pupọ.