API (Aṣewadii Ile-iṣẹ Epo ilẹ Amẹrika) 5L jẹ boṣewa agbaye fun paipu irin ti a lo ninu awọn ọna gbigbe irinna.

API 5L ni wiwa paipu irin fun ọpọlọpọ awọn ohun elo fun gbigbe ti gaasi adayeba, epo, ati awọn olomi miiran.Ọjọ imuṣiṣẹ ti ikede 46th: ti o ṣiṣẹ ni Oṣu kọkanla ọjọ 1, ọdun 2018.

Ti o ba kan fẹ lati ni imọran gbogbogbo ti API 5L, jọwọ tẹAPI 5L Pipe Specification Akopọ.

Awọn bọtini lilọ kiri

Ohun ti a ti ni imudojuiwọn ni API 5L 46th

Oti ti API 5L PSL

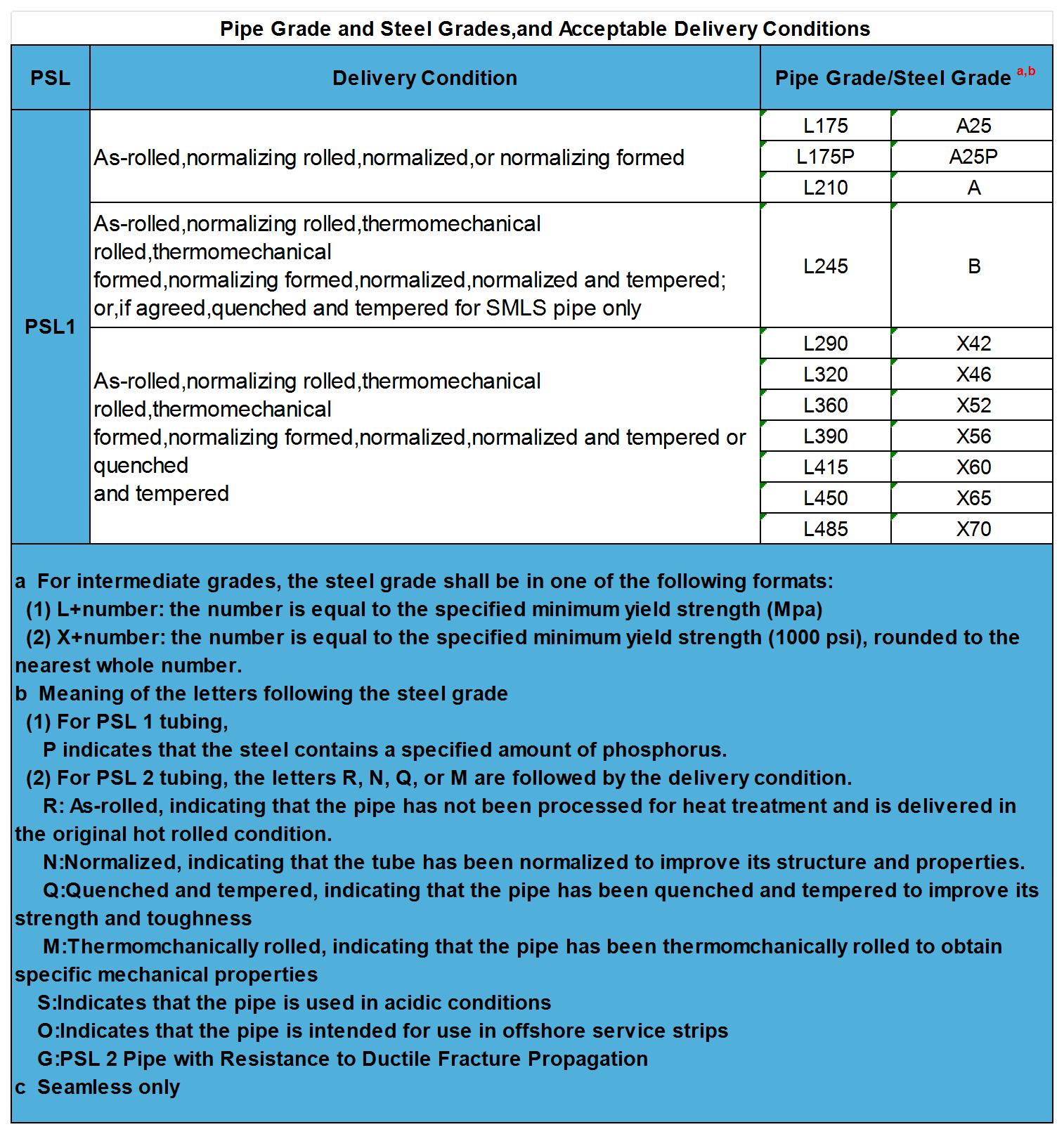

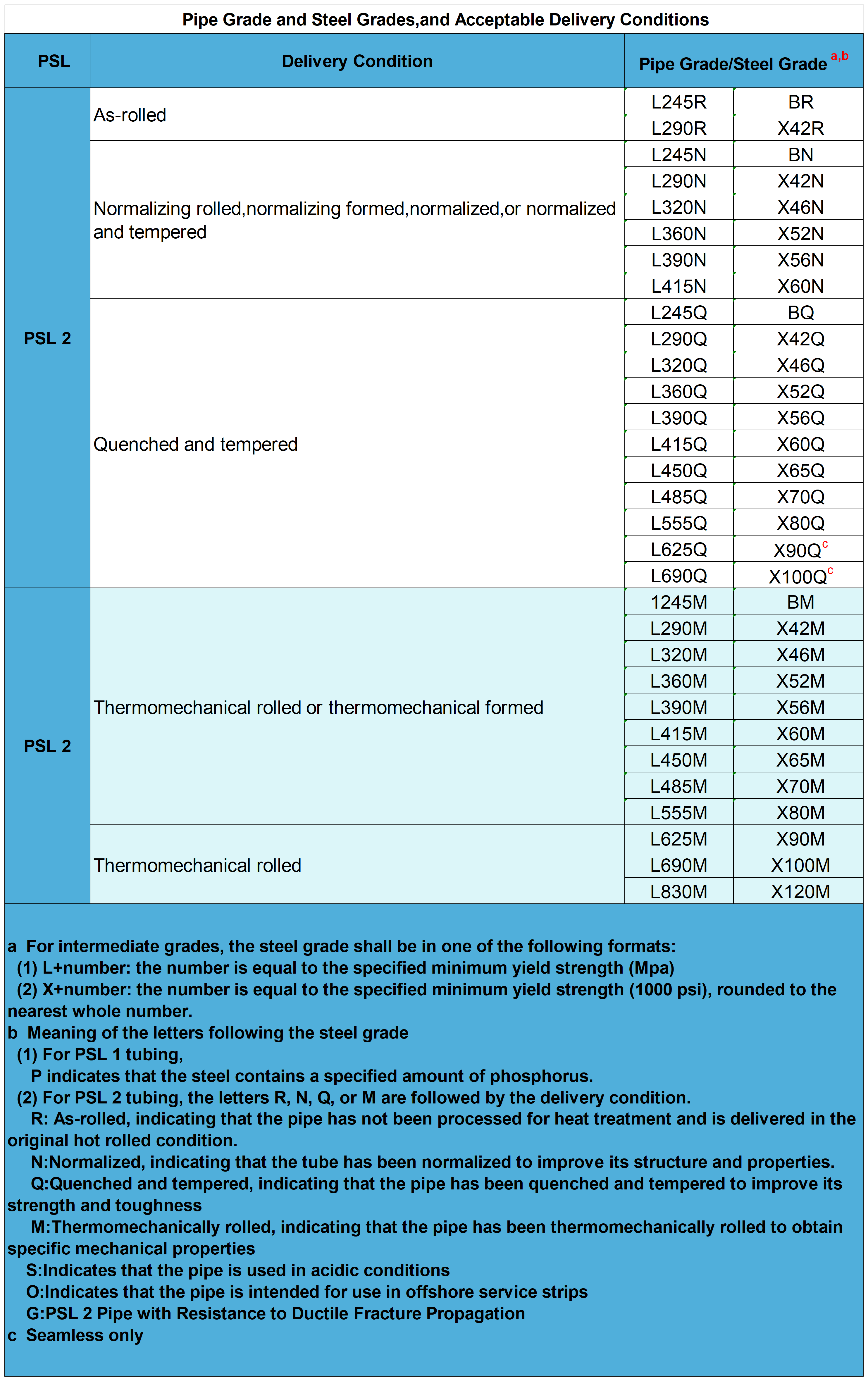

Isọri ti Irin onipò ati Pipe onipò

Itewogba Ifijiṣẹ States

Aise Awọn ohun elo fun Irin Pipes

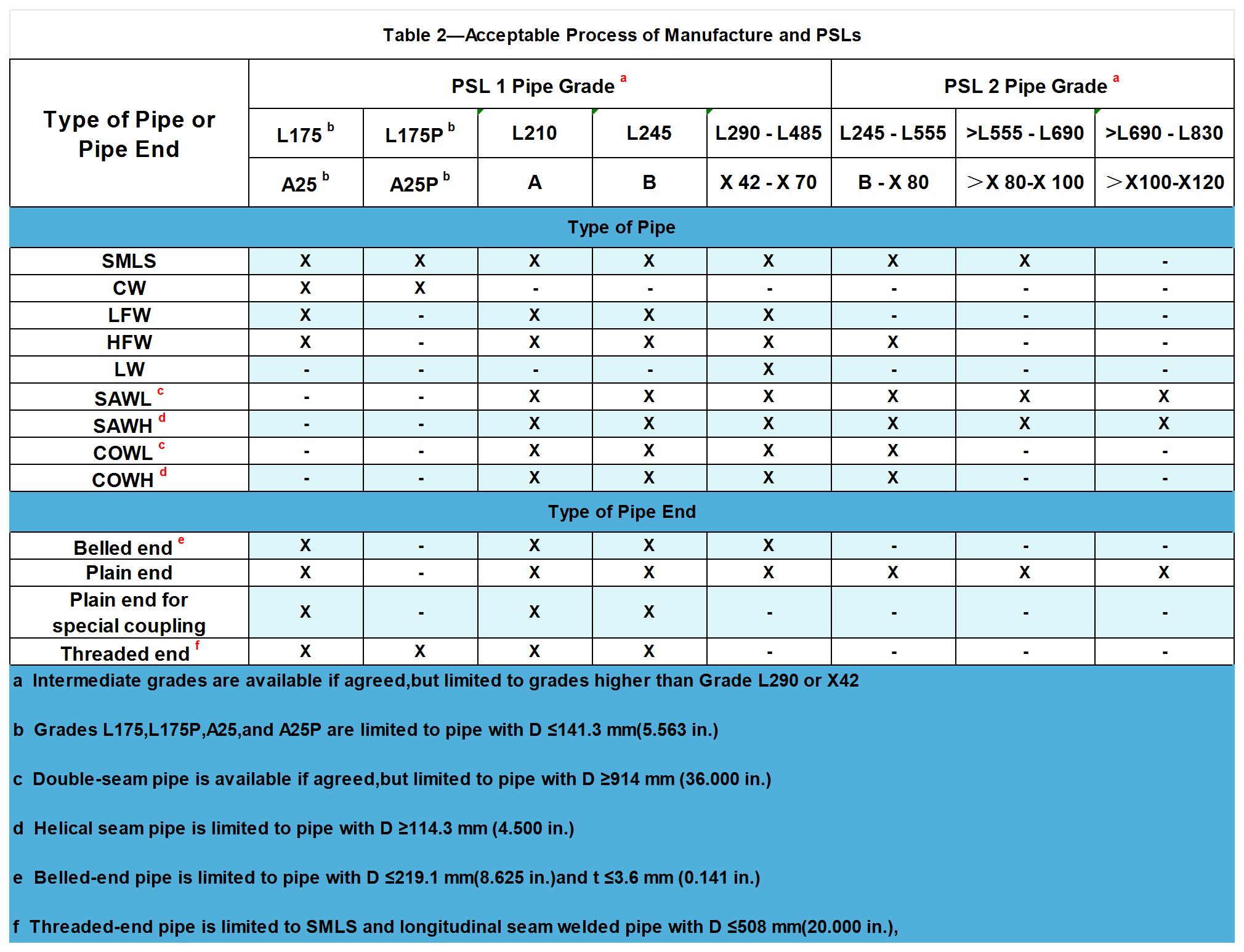

Awọn oriṣi ti Paipu Irin ati Awọn ipari tube Ti a bo nipasẹ API 5L

Awọn ilana iṣelọpọ itẹwọgba fun PSL2 Irin Tubing

Ṣiṣayẹwo ifarahan ati awọn abawọn ti o wọpọ ti API 5L

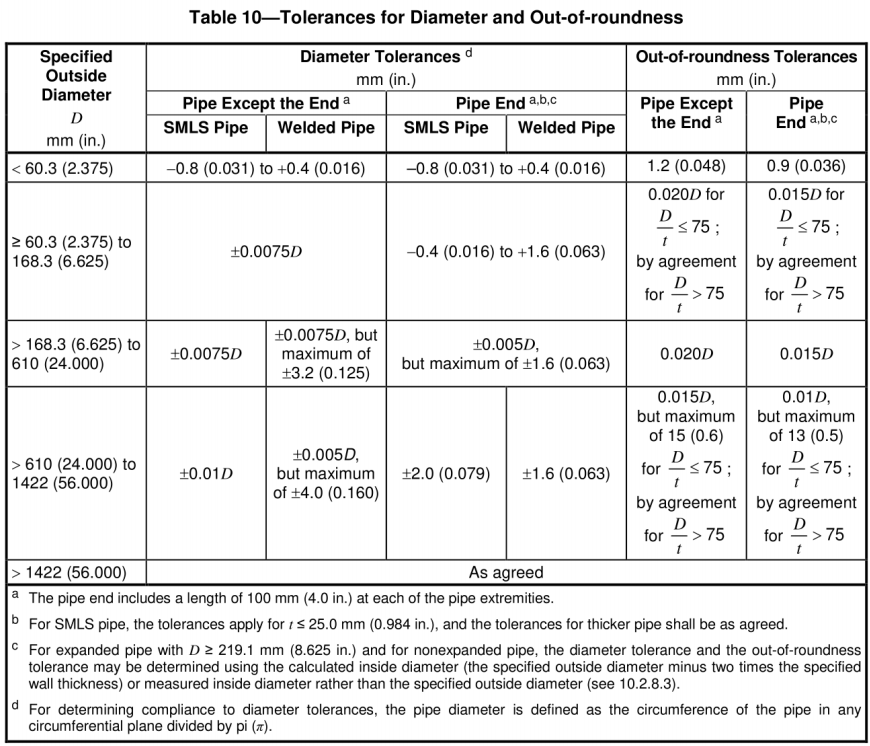

Ayẹwo Onisẹpo (Awọn Iyatọ Oniwọn)

API 5L Igbeyewo Awọn ohun

Paipu Siṣamisi ati Location

Iwọn deede

Awọn ọja ibatan wa

Ohun ti a ti ni imudojuiwọn ni API 5L 46th

Awọn imudojuiwọn

Imudojuiwọn ati ti fẹ awọn ibeere fun milled isẹpo;

Awọn ibeere imudojuiwọn fun paipu opin perpendicularity;

Awọn ibeere idanwo líle ti a ṣe imudojuiwọn fun API 5LPSL 2 paipu fun awọn agbegbe ekan ati API 5L PSL 2 paipu fun awọn agbegbe ita;

Tuntun

API 5L PSL 2 paipu fun awọn ohun elo ti o nilo agbara igara ṣiṣu gigun.

Oti ti API 5L PSL

PSL: Pipeline Specification Level abbreviation;

Pipin si: API 5L PSL 1 ati API 5L PSL 2.

Isọri ti Irin onipò ati Pipe onipò

L + nọmba(Lẹta L ni atẹle nipasẹ agbara ikore ti o kere ju ni MPa):

L175,L175P,L210,L245,L290,L320,L360,L390,L415,L450,L485,L555,L625,L680,L690.

X + nọmba(Nọmba ti o tẹle lẹta X sọ pato agbara ikore ti o kere julọ ni 1000 psi):

X42,X46,X52,X56,X60,X65,X70,X80,X90,X100,X120.

Ati ite a ati ite b.Ite A=L210 Ite B=L 2459

Awọn ipinlẹ ifijiṣẹ itẹwọgba

Akiyesi: L415/X60 tabi awọn ipele ti o ga julọ ko yẹ ki o lo ni aaye L360/X52 tabi awọn ipele kekere laisi adehun ti olura.

Aise Awọn ohun elo fun Irin Pipes

Ingot, billet, billet, rinhoho (okun) tabi awo.

Akiyesi:

1. Awọn aise ohun elo funAPI 5L PSL2irin paipu yoo jẹ itanran-ọkà sedimented, irin.

2. Steel strip (coil) tabi awo ti a lo fun iṣelọpọ API 5L PSL2 paipu irin ko ni ru eyikeyi tack welds.

Awọn oriṣi ti Paipu Irin ati Awọn ipari tube Ti a bo nipasẹ API 5L

Welded Irin Pipe

CW Pipe:Ilana ti dida okun kan nipa alapapo adikala naa ni ileru kan ati ni titẹ ọna ẹrọ ti a ṣẹda papọ, ninu eyiti awọn coils ti o tẹle ti rinhoho naa ti darapọ mọ papọ lati pese ṣiṣan lilọsiwaju ti rinhoho fun ọlọ alurinmorin.

COWHPipe:Ọja Tubular ti o ni okun helical kan ti a ṣe nipasẹ apapọ ti aaki irin gaasi ati alurinmorin aaki submerged, ninu eyiti gaasi irin aaki weld ileke ko ni yọkuro patapata nipasẹ alurinmorin arc submerged.

Màlúù Paipu:Ọja Tubular ti o ni awọn okun gigun kan tabi meji ti a ṣe nipasẹ apapọ ti arc irin gaasi ati alurinmorin aaki submerged, ninu eyiti gaasi irin aaki weld ileke ko ni yọkuro patapata nipasẹ alurinmorin arc submerged.

EW Pipe:Ọja Tubular ti o ni okun gigun gigun kan ti a ṣelọpọ nipasẹ alurinmorin itanna-kekere tabi giga-igbohunsafẹfẹ.

HFW Pipe:EWpipe ti a ṣe pẹlu igbohunsafẹfẹ lọwọlọwọ alurinmorin ti o dọgba si tabi tobi ju 70 kHz.

Pipe LFW:EW paipu jẹ iṣelọpọ pẹlu igbohunsafẹfẹ lọwọlọwọ alurinmorin ti o kere ju 70 kHz.

LW Pipe:Ọja Tubular nini okun gigun kan ti a ṣe nipasẹ alurinmorin laser.

Pipe SAWH:Ọja Tubular nini okun helical kan ti a ṣe nipasẹ ilana alurinmorin arc submerged.

SAWLPaipu:Ọja Tubular nini ọkan tabi meji awọn okun gigun gigun ti a ṣe nipasẹ alurinmorin aaki submerged.

Ailokun Irin Pipe

paipu SMLS:Gbona paipu irin alailẹgbẹ ti yiyi ati paipu irin ti o tutu, awọn ọna ṣiṣe miiran wa, gẹgẹbi iyaworan tutu, iyaworan tutu, ayederu, ati bẹbẹ lọ.

API 5L PSL2 Pipe orisi fun pataki awọn ohun elo

Atako si Itankadi Pigugu Ductile (G)

Ekan Service Pipe (S)

Ipò Iṣẹ́ Òkè Òkun (O)

Nbeere Longitudinal Ṣiṣu igara Agbara Pipe

Pipe Ipari Orisi

Socket Ipari, Alapin Ipari, Special Dimole Flat Ipari, Asapo Ipari.

Akiyesi:

1. Socket pari, paipu pari fun pataki clamps, ati asapo paipu pari ni o wa fun API 5L PSL1 nikan.

2. L175 P / A25 P steel grade API 5L PSL1 paipu irin yoo wa ni ẹrọ pẹlu awọn opin ti o tẹle, ati API 5L PSL1 paipu irin ti awọn ipele irin miiran yoo jẹ ẹrọ pẹlu awọn opin fifẹ.

3. API 5L PSL 2 tubes yoo wa ni jišẹ pẹlu alapin opin.

Awọn ilana iṣelọpọ itẹwọgba fun PSL2 Irin Tubing

| Table 3-Itewogba Awọn ipa ọna iṣelọpọ fun PSL 2 Pipe | ||||

| Iru Pipe | Ibẹrẹ Ohun elo | Pipe Lara | Pipe Ooru Itọju | Ifijiṣẹ Ipo |

| SMLS | Ingot, Bloom, tabi billet | Bi-yiyi | - | R |

| Normalizing lara | - | N | ||

| Gbona lara | Deede | N | ||

| Quenching ati tempering | Q | |||

| Gbona lara ati ki o tutu ipari | Deede | N | ||

| Quenching ati tempering | Q | |||

| HFW | Nkan ti yiyi deede | Igba otutu | Ooru atọjua ti agbegbe weld nikan | N |

| Thermomechanical-yiyi okun | Igba otutu | Ooru atọjua ti agbegbe weld nikan | M | |

| Ooru atọjua ti agbegbe weld ati idinku wahala ti paipu gbogbo | M | |||

| Bi-yiyi tabi thermomechanical-yiyi okun | Igba otutu | Deede | N | |

| Quenching ati tempering | Q | |||

| Tutu lara atẹle nipa gbona idinku labẹ iṣakoso otutu Abajade ni ipo deede | - | N | ||

| Cold lara atẹle nipa thermomechanical lara ti paipu | - | M | ||

| SAW tabi MALU | Ti ṣe deede tabi ṣe deede - yiyi okun tabi awo | Igba otutu | - | N |

| Bi-yiyi thermomechanical-yiyi normalizing-yiyi, tabi deede | Igba otutu | Deede | N | |

| Thermomechanical-yiyi okun tabi awo | Igba otutu | - | M | |

| Paná ati ibinu awo | Igba otutu | - | Q | |

| Bi-yiyi thermomechanical-yiyi normalizing-yiyi, tabi deede okun tabi awo | Igba otutu | Quenching ati tempering | Q | |

| Bi-yiyi thermomechanical-yiyi normalizing-yiyi, tabi deede okun tabi awo | Normalizing lara | - | N | |

| aWo ISO 5L 8.8 fun awọn itọju ooru to wulo | ||||

Ṣiṣayẹwo ifarahan ati awọn abawọn ti o wọpọ ti API 5L

Awọn ifarahan

Oju ita ti paipu yoo jẹ dan ati ofe lati awọn abawọn ti o le ni ipa lori agbara ati awọn ohun-ini edidi ti paipu naa.

Awọn abawọn pataki

Awọn egbegbe ti a pa:Awọn egbegbe nibbled le dara julọ wa nipasẹ ayewo wiwo.

Arc jo:Arc Burs yoo wa ni dajo bi alebu awọn.

Arc Burns ni awọn nọmba kan ti etiile awọn abawọn abawọn akoso nipa yo ti awọn irin dada ṣẹlẹ nipasẹ awọn aaki laarin awọn elekiturodu tabi grounding elekiturodu ati awọn dada ti irin paipu.

Awọn aaye olubasọrọ jẹ awọn aaye ti o wa lainidii nitosi laini weld ti paipu EW kan, ti o fa nipasẹ olubasọrọ laarin elekiturodu ti n pese lọwọlọwọ alurinmorin ati oju paipu naa.

Iyasọtọ:Eyikeyi delamination tabi ifisi ti o gbooro lori dada paipu tabi oju beveled ati pe o jẹ> 6.4 mm (0.250 in) ni ipari yipo lori ayewo wiwo yoo jẹ abawọn.

Awọn iyapa jiometirika:Iyapa jiometirika (fun apẹẹrẹ, bulọọki alapin tabi pout, ati bẹbẹ lọ), miiran ju ọfin ju, ti o ṣẹlẹ nipasẹ ilana dida tube tabi iṣẹ iṣelọpọ.Awọn aaye laarin awọn iwọn ojuami ati awọn itẹsiwaju ti awọn deede elegbegbe ti awọn tube, ie, kan ijinle ti o tobi ju 3.2 mm (0.125 in), yẹ ki o wa ni kà a abawọn.

Awọn iho silẹ yoo jẹ ≤ 0.5 D ni eyikeyi itọsọna.

LileNigbati ayewo wiwo ba ṣafihan líle ti a fura si, oluyẹwo líle to ṣee gbe yoo ṣee lo lati ṣe idanwo lile, ati indentation kan-ojuami kan pẹlu iye líle ti o ju 35 HRC, 345 HV10, tabi 327 HBW lọ ni abawọn nigbati iwọn ba ti indentation jẹ tobi ju 50 mm (2.0 ni) ni eyikeyi itọsọna.

Imudani abawọn

Jọwọ tọka si awọn ibeere ti o yẹ ni API 5L Àfikún C fun mimu.

Ayẹwo Onisẹpo (Awọn Iyatọ Oniwọn)

Pipe iwuwo Chart ati iwuwo Iyapa

Agbekalẹ iwuwo

M=(DT)×T×C

M jẹ ibi-iwọn fun ipari ẹyọkan;

D jẹ iwọn ila opin ita ti a sọ pato, ti a fihan ni awọn milimita (inch);

T jẹ sisanra ogiri ti a sọ pato, ti a fihan ni millimeters (inches);

C jẹ 0.02466 fun awọn iṣiro ni awọn ẹya SI ati 10.69 fun awọn iṣiro ni awọn ẹya USC.

PIPE ÀWỌN SHAtti ati awọn iṣeto

awọn tabili iwuwo paipu ni API 5L ti tọka siISO 4200atiASME B36.10M, eyiti o fun awọn iye boṣewa fun paipu pẹlu iwọn ila opin ita pato ati sisanra ogiri pato.

Iṣeto 40 ati Eto 80ti wa ni asopọ ni isalẹ, ti o ba fẹ lati wo iṣeto pipe pipe,jọwọ tẹ nibi!

Iyapa iwuwo

Didara ti paipu kọọkan ni ibatan si imọran: iwuwo: 95% ≤ iwuwo imọ-jinlẹ ≤ 110;

Iyapa ati afikun-tinrin sipesifikesonu tubes: 5% ≤ 110% ti o tumq si àdánù;

L175, L175P, A25, ati A25P irin onipò: 95% ≤ 110% ti o tumq si àdánù.

Iwọn Ode ati Ibiti Sisanra Odi

| Tabili 9-Igbalaaye Ni pato Ita Diamita ati Specific Sisanra Odi | ||

| Pato Ita opin D mm (ninu.) | Pato Odi Sisanra t mm (ninu.) | |

| Special Light titobia | Awọn iwọn deede | |

| 10.3 (0.405) si <13.7 (0.540) | - | 1.7 (0.068) si≤2.4 (0.094) |

| 13.7 (0.540) si <17.1 (0.675) | - | ≥2.2 (0.088) si≤3.0 (0.118) |

| 17.1 (0.675) si <21.3 (0.840) | - | ≥2.3 (0.091) si≤3.2 (0.125 |

| ≥21.3 (0.840) si <26.7 (1.050) | - | ≥2.1 (0.083) si≤7.5 (0.294) |

| ≥26.7 (1.050) si <33.4 (1.315) | - | ≥2.1 (0.083) si≤7.8 (0.308) |

| ≥33.4 (1311}5) si <48.3 (1.900) | - | ≥2.1 (0.083) si≤10.0 (0.394) |

| ≥48.3 (1.900) si <60.3 (2.375) | - | ≥2.1 (0.083) si≤12.5 (0.492) |

| ≥60.3 (2.375) si <73.0 (2.875) | ≥2.1 (0.083) si≤3.6 (0.141) | > 3.6 (0.141) si≤14.2 (0.559) |

| ≥73.0 (2.875) si <88.9 (3.500) | ≥2.1 (0.083) si≤3.6 (0.141) | > 3.6 (0.141) si≤20.0 (0.787) |

| ≥88.9 (3.500) si <101.6 (4.000) | ≥2.1 (0.083) si≤4.0 (0.156) | > 4.0 (0.156) si≤22.0 (0.866) |

| ≥101.6 (4.000) si <168.3 (6.625) | ≥2.1 (0.083) si≤4.0 (0.156) | > 4.0 (0.156) si≤25.0 (0.984) |

| ≥168.3 (6.625) si <219.1 (8.625) | ≥2.1 (0.083) si≤4.0 (0.156 | > 4.0 (0.156) si≤40.0 (1.575) |

| ≥219.1 (8.625) si <273.1 (10.750) | ≥3.2 (0.125) si≤4.0 (0.156 | > 4.0 (0.156) si≤40.0 (1.575 |

| ≥273.1 (10.750) si <323.9 (12.750) | ≥3.6 (0.141) si≤5.2 (0.203) | > 5.2 (0.203) si≤45.0 (1.771) |

| ≥323.9 (12.750) si <355.6 (14.000) | ≥4.0 (0.156) si≤5.6 (0.219) | > 5.6 (0.219) si≤45.0 (1.771 |

| ≥355.6 (14.000) si <457(18.000) | ≥4.5 (0.177) si≤7.1 (0.281) | > 7.1 (0.281) si≤45.0 (1.771 |

| 457 (18.000) si <559 (22.000) | ≥4.8 (0.188) si≤7.1 (0.281) | > 7.1 (0.281) si≤45.0 (1.771) |

| ≥559 (22.000) si <711(28.000) | ≥5.6 (0.219) si≤7.1 (0.281) | > 7.1 (0.281) si≤45.0 (1.771) |

| ≥711 (28.000) si <864(34.000) | ≥5.6 (0.219) si≤7.1 (0.281) | > 7.1 (0.281) si≤52.0 (2.050) |

| ≥864 (34.000) si <965(38.000) | - | ≥5.6 (0.219) si≤52.0 (2.050) |

| 965 (38.000) si <1422 (56.000) | - | ≥6.4 (0.250) si≤52.0 (2.050) |

| 1422 (56.000) si <1829 (72.000) | - | 9.5 (0.375) si≤52.0 (2.050) |

| 1829 (72.000) si <2134(84.000) | - | ≥10.3 (0.406) si≤52.0 (2.050) |

| aPaipu nini apapo ti ita ti ita ati sisanra ogiri ti a sọ ni asọye bi paipu iwọn ina pataki;miiran awọn akojọpọ fun ni yi tabili ti wa ni telẹ bi deede-iwọn paipu. | ||

Opin ati Yika Iyapa

Iyapa Odi

| Table 11-Tolerances fun odi Sisanra | |

| Sisanra Odi t mm (ni) | Awọn ifaradaa mm (ni) |

| SMLS Pipeb | |

| ≤4.0 (0.157) | + 0.6 (0.024) -0.5 (0.020) |

| > 4.0 (0.157) si <25.0 (0.984) | +0.150t -0.125t |

| ≥25.0 (0.984) | + 3.7 (0.146) tabi + 0.1t, eyikeyi ti o tobi -3.0 (0.120) tabi-0.1t, eyikeyi ti o tobi |

| Weld Pipecd | |

| ≤5.0 (0.197) | ±0.5 (0.020) |

| > 5.0 (0.197) si <15.0 (0.591) | ±0.1t |

| 15.0 (0.591) | ± 1.5 (0.060) |

| aTi aṣẹ rira ba ṣalaye ifarada iyokuro fun sisanra ogiri kere ju iye iwulo ti a fun ni tabili yii, ifarada pẹlu sisanra ogiri yoo pọsi nipasẹ iye to lati ṣetọju iwọn ifarada iwulo. bFun paipu pẹlu D2 355.6 mm (14.000 in.) ati 1 2 25.0 mm (0.984 in.), Ifarada sisanra ogiri tibile le kọja ifarada afikun fun sisanra ogiri nipasẹ afikun 0.05t, pese pe afikun ifarada fun ibi- (wo 9.14) ko kọja. cIfarada afikun fun sisanra odi ko kan si agbegbe weld. dWo 9.13.2 fun awọn ihamọ afikun. | |

Iyapa Gigun

Awọn ifarada ọpọn iwẹ gigun: Iyapa gigun yẹ ki o jẹ 500 mm (20 inches).

Awọn ifarada paipu gigun laileto:

| Table 12-Tolerances fun ID ipari paipu | |||

| Ipari Laileto Orúkọ m(ft) | Ipari ti o kere julọ m (ft) | Kere Apapọ Gigun Fun kọọkan Bere fun Nkan m (ft) | O pọju Gigun m (ft) |

| Asapo-ati-pọ Pipe | |||

| 6(20) | 4.88 (16.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9(30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 6.71 (22.0) | 10.67 (35.0) | 13.72(45.0 |

| Plain-opin Pipe | |||

| 6(20) | 2.74 (9.0) | 5.33 (17.5) | 6.86 (22.5) |

| 9 (30) | 4.11 (13.5 | 8.00 (26.2) | 10.29 (33.8) |

| 12 (40) | 4.27 (14.0 | 10.67 (35.0) | 13.72 (45.0) |

| 15(50) | 5.33 (17.5) | 13.35 (43.8) | 16.76 (55.0) |

| 18(60) | 6.40 (21.0 | 16.00 (52.5) | 19.81 (65.0) |

| 24(80) | 8.53 (28.0) | 21.34 (70.0) | 25.91 (85.0) |

Iyapa titọ

Lapapọ iyapa lati ila ti o tọ lori gbogbo ipari ti paipu yoo jẹ <0.2% ti ipari pipe;

Iyapa ti agbegbe lati laini titọ yoo jẹ <3.2 mm (0.125 in) lori ipari 1.5 m (5.0 ft) ti opin paipu kọọkan.

Bevel Angle Iyapa

Tube pẹlu t> 3.2 mm (0.125 in) awọn opin alapin yoo jẹ ẹrọ pẹlu bevel weld pẹlu igun bevel ti 30 ° -35 °.

Iwọn ti Dada Gbongbo Ipilẹṣẹ

1.6 mm (0.063 in) pẹlu iyapa ti ± 0.8 mm (0.031 ni).

Ibiti Igun Konu inu (nikan fun paipu irin alailẹgbẹ)

| Table 13-O pọju igun ti abẹnu Taper fun SMLS Pipe | |

| Pato Odi Sisanra t mm (ninu.) | O pọju igun ti Taper awọn iwọn |

| <10.5 (0.413) | 7.0 |

| 10.5 (0.413) si <14.0 (0.551) | 9.5 |

| 14.0 (0.551) si <17.0 (0.669) | 11.0 |

| 17.0 (0.669) | 14.0 |

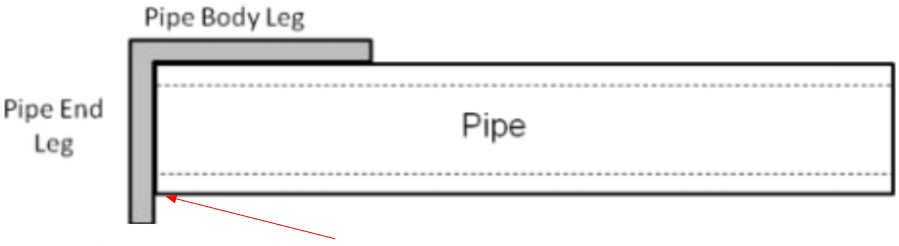

Pipe Ipari Squareness (jade-ti-squareness)

Iwọn ti ita-squareness jẹ aafo laarin opin paipu ati ẹsẹ ipari pipe, eyiti yoo jẹ 1.6 mm (0.063 in.).

Welding Seam Iyapa

Adirẹsi/Iwe Aṣiṣe:

Fun elekitiro-welded (EW) ati lesa-welded (LW) paipu, aiṣedeede ko yẹ ki o ja si sisanra ogiri ti o ku ni weld ti o kere ju sisanra ogiri ti o kere ju laaye.

Fun Submerged Arc Welded (SAW) ati Apapọ Welded (COW), aiṣedeede ko yẹ ki o kọja awọn iye ti o baamu ti a fun ni Tabili 14 ti API 5L.

Burrs (elekitiro-welded (EW) ati lesa-welded (LW) tubes):

Awọn burrs ita ni ao yọkuro si ipo didan pupọ (pẹlu ohun elo ipilẹ).

Awọn burrs ti inu ko ni fa 1.5 mm (0.060 ni) ni ikọja elegbegbe ti tube, ati sisanra ogiri ni aaye ti yiyọ Burr ko ni kere ju sisanra ogiri ti o kere julọ ti a gba laaye.

Weld Giga(Submerged Arc Welding (SAW) ati Apapo Alurinmorin (COW) paipu):

Yọ awọn ti o ku iga ti awọn ti abẹnu weld laarin o kere 100 mm (4.0 in) ti opin paipu ni kọọkan opin paipu, ki o si lọ awọn weld ki o ko ba dide siwaju sii ju 0.5 mm (0.020 in) loke awọn dada. ti paipu ti o wa nitosi.

API 5L Igbeyewo Awọn ohun

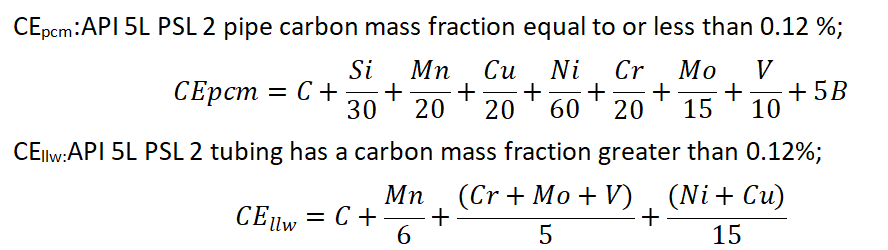

Kemikali Tiwqn

Ọna Idanwo: Tọkasi ISO 9769 tabi ASTM A751.

Ipilẹ kemikali ti API 5L PSL1 ati API 5L PSL2 paipu irin t> 25.0 mm (0.984 in) ni a gbọdọ pinnu nipasẹ idunadura ti o da lori awọn akojọpọ kemikali ninu awọn tabili ti o baamu.

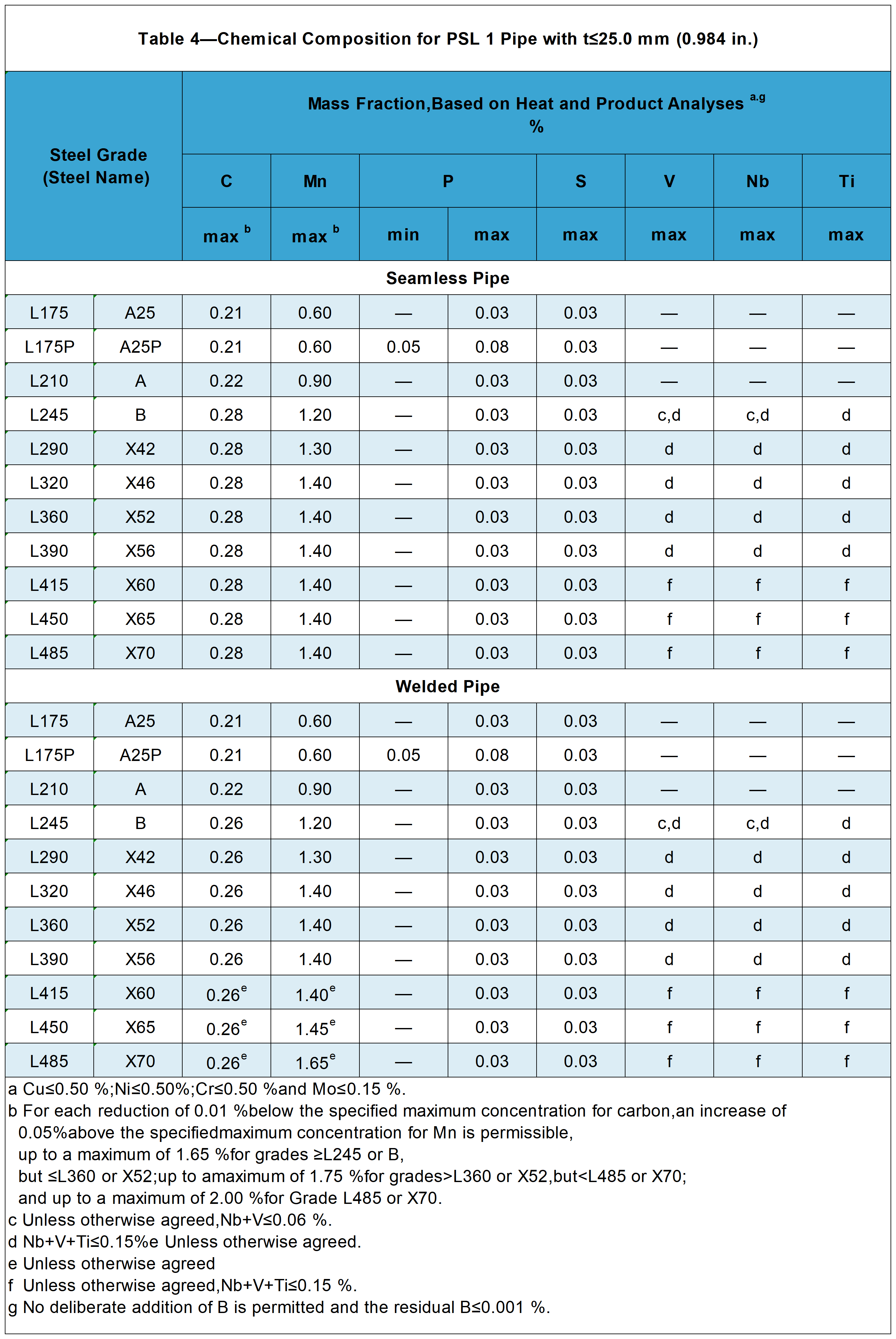

Iṣakojọpọ Kemikali fun PSL 1 Pipe pẹlu t≤25.0 mm (0.984 in.)

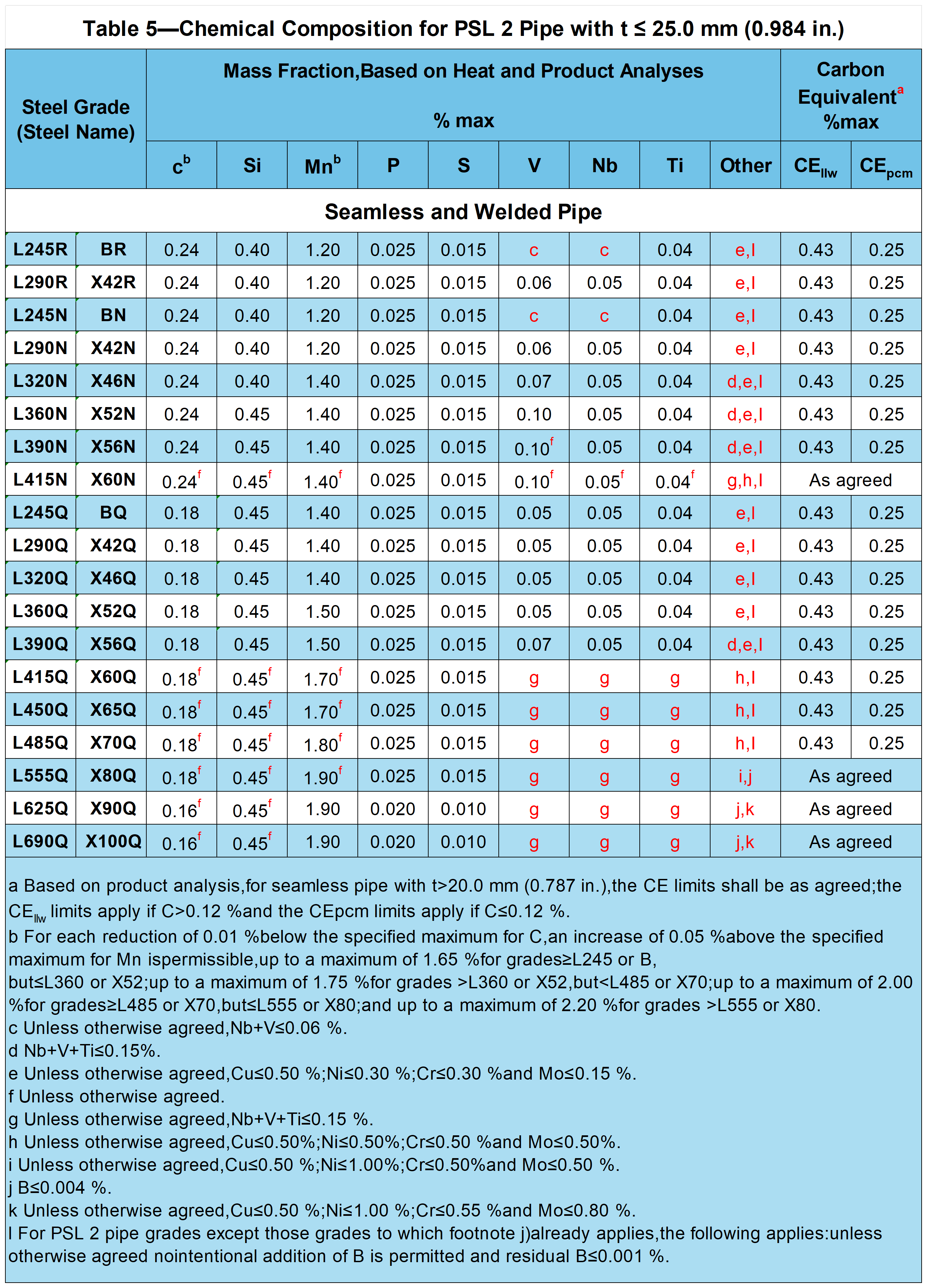

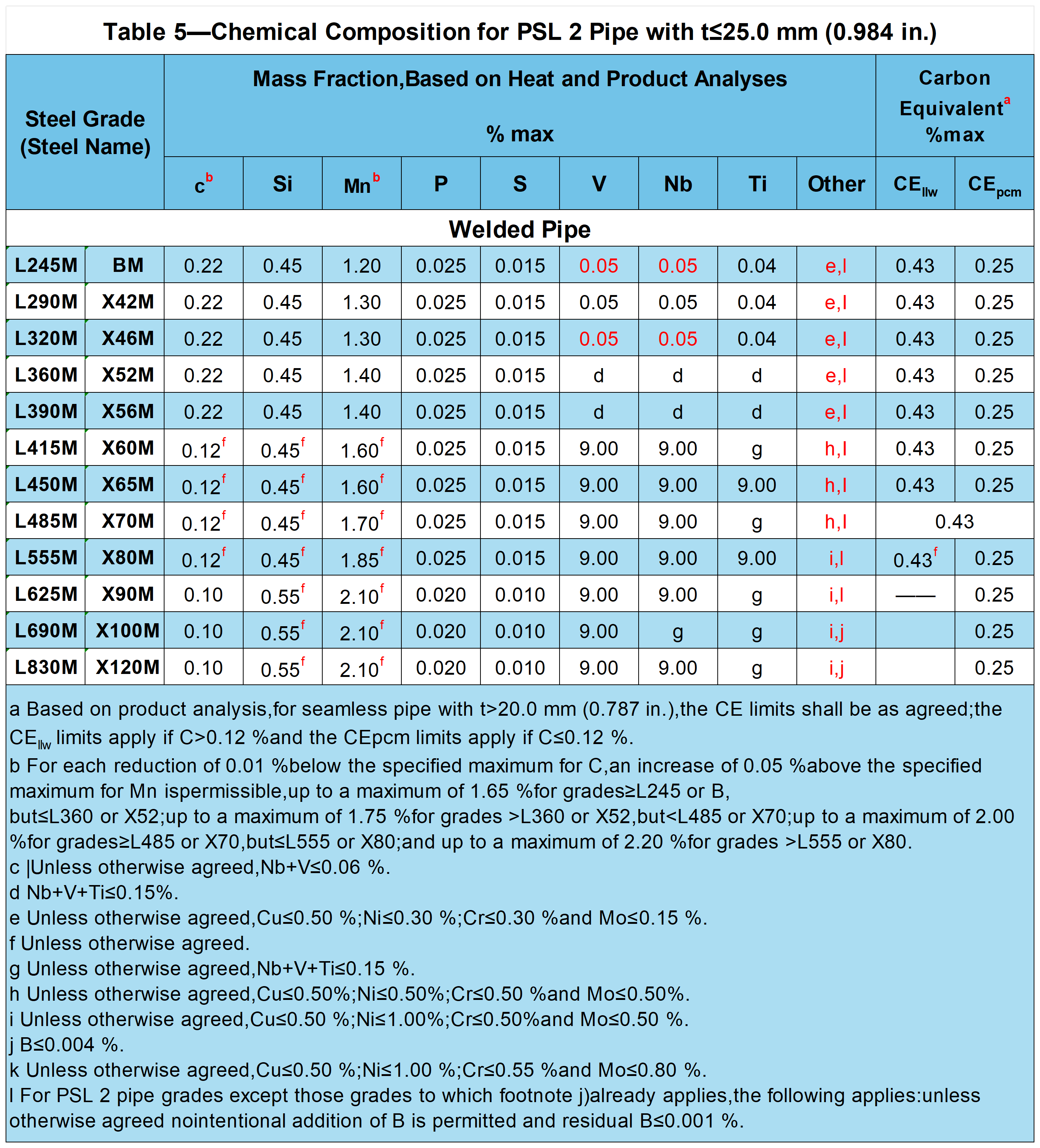

Iṣakojọpọ Kemikali fun PSL 2 Pipe pẹlu t≤25.0 mm (0.984 in.)

Awọn ohun-ini fifẹ

Awọn ọna Idanwo: Yoo ṣee ṣe ni ibamu pẹlu ISO 6892-1 tabi ASTM A370.

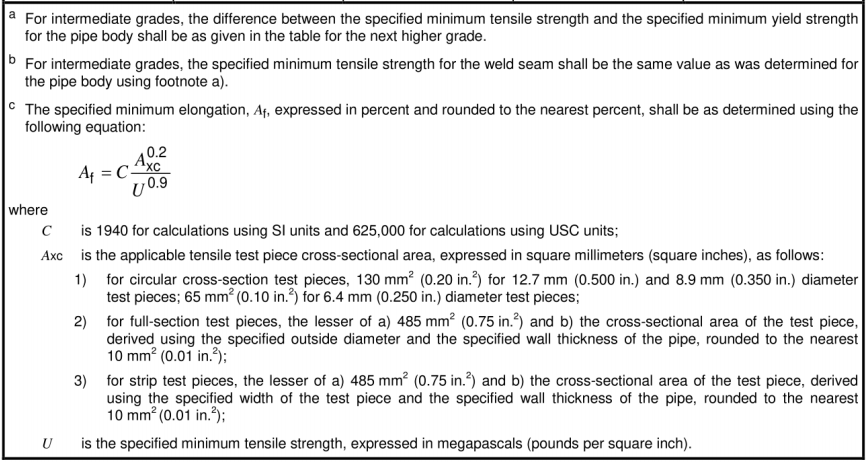

Awọn ibeere fun Awọn abajade ti Awọn Idanwo Fifẹ fun PSL 1 Pipe

| Tabili 6-Awọn ibeere fun Awọn abajade ti Awọn Idanwo Afẹfẹ fun PSL 1 Pipe | ||||

| Pipe ite | Paipu Ara ti Seamless ati Welded Pipe | Weld Seam ti EW, LW, SAW, ati paipu Maalu | ||

| Agbara Ikorea Rsi.5 MPa(psi) | Agbara fifẹa Rm MPa(psi) | Ilọsiwaju (lori 50 mm tabi 2 in.) Af % | Agbara fifẹb Rm MPa(psi) | |

| min | min | min | min | |

| L175 tabi A25 | 175 (25,400) | 310(45,000) | c | 310(45,000) |

| L175P tabi A25P | 175 (25,400) | 310(45,000) | c | 310 (45,000) |

| L210 tabi A | 210 (30,500) | 335(48,600) | c | 335(48,600) |

| L245 tabi B | 245 (35,500) | 415(60,200) | c | 415(60,200) |

| L290 tabi X42 | 290 (42,100) | 415(60,200) | c | 415 (60,200) |

| L320 tabi X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| L360 tabi X52 | 360 (52,200) | 460 (66,700) | c | 460 (66,700) |

| L390 tabi X56 | 390 (56,600) | 490 (71,100) | c | 490 (71,100) |

| L415 tabi X60 | 415 (60,200) | 520 (75,400) | c | 520 (75,400) |

| L450 tabi X65 | 450 (65,300) | 535(77,600) | c | 535(77,600) |

| L485 tabi X70 | 485 (70,300) | 570 (82,700) | c | 570 (82,700) |

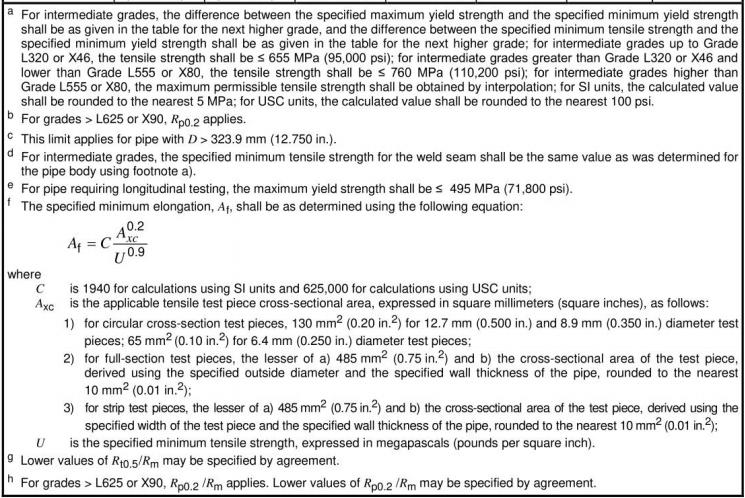

Awọn ibeere fun Awọn abajade ti Awọn Idanwo Fifẹ fun PSL 2 Pipe

| Tabili 7-Awọn ibeere fun Awọn abajade ti Awọn Idanwo Itọju fun PSL 2 Pipe | |||||||

| Pipe ite | Paipu Ara ti Seamless ati Welded Pipe | Weld Seam ti HFW SAW ati CoW Pipe | |||||

| Agbara Ikorea Rto.5 MPa(psi) | Agbara fifẹa Rm MPa (psi) | Ipinac Rt0.5/Rm | Ilọsiwaju (lori 50 mm tabi 2 in.) Af % | Fifẹ Agbarad Rm MPa (psi) | |||

| min | o pọju | min | o pọju | o pọju | min | min | |

| L245R tabi BR L245N tabi BN L245Q tabi BQ L245M tabi BM | 245 (35.500) | 450 (65.300)e | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L290R tabi X42R L290N tabi X42N L290Q tabi X42Q L290M tabi X42M | 290 (42.100) | 495 (71.800) | 415 (60.200) | 655 (95.000) | 0.93 | f | 415 (60.200) |

| L320N tabi X46N L320Q tabi X46Q L320M tabi X46M | 320 (46.400) | 525 (76.100) | 435 (63.100) | 655 (95.000) | 0.93 | f | 435 (63.100) |

| L360N tabi X52N L360Q tabi X52Q L360M tabi X52M | 360 (52.200) | 530 (76.900) | 460 (66.700) | 760 (110.200) | 0.93 | f | 460 (66.700) |

| L390N tabi X56N L390Q tabi X56Q L390M tabi X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L390N tabi X56N L390Q tabi X56Q L390M tabi X56M | 390 (56.600) | 545 (79.000) | 490 (71.100) | 760 (110.200) | 0.93 | f | 490 (71.100) |

| L415N tabi X60N L415Q tabi X60Q L415M tabi X60M | 415 (60.200) | 565 (81.900) | 520 (75.400) | 760 (110.200 | 0.93 | f | 520 (75.400) |

| L450Q tabi X65Q L450M tabi X65M | 450 (65.300) | 600 (87.000) | 535 (77.600) | 760 (110.200) | 0.93 | f | 535 (77.600) |

| L485Q tabi X70Q L485M tabi X70M | 485 (70.300) | 635 (92.100) | 570 (82.700) | 760 (110.200) | 0.93 | f | 570 (82.700) |

| L555Q tabi X80Q L555M tabi X80M | 555 (80.500) | 705 (102.300) | 625 (90.600) | 825 (119.700) | 0.93 | f | 625 (90.600) |

| L625M tabi X90M | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.95 | f | 695 (100.800) |

| L625Q tabi X90Q | 625 (90.600) | 775 (112.400) | 695 (100.800) | 915 (132.700) | 0.97g | f | - |

| L690M tabi X100M | 690 (100.000)b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | 760 (110.200) |

| L690Q tabi X100Q | 690 (100.000) b | 840 (121.800)b | 760 (110.200) | 990 (143.600) | 0.97h | f | - |

| L830M tabi X120M | 830 (120.400)b | 1050 (152.300)b | 915 (132.700) | 1145 (166.100) | 0.97h | f | 915 (132.700) |

Ilọsiwaju ogorun ni isinmi yoo jẹ ijabọ fun awọn apẹẹrẹ pẹlu ipari wọn ti 50 mm (2 in).

Fun awọn apẹẹrẹ pẹlu ipari wiwọn ti o kere ju 50 mm (2 in), elongation ni isinmi yoo yipada si elongation ni 50 mm (2 in) ni ibamu pẹlu ISO 2566-1 tabi ASTM A370.

Hydrostatic Ipa Idanwo

Ọna idanwo: API 5L 10.2.6.

Gbogbo awọn titobi pipe (SMLS) paipu ati paipu welded pẹlu D ≤ 457 mm (18.000 in) yoo ni akoko imuduro ti ko kere ju awọn aaya 5.paipu welded pẹlu D> 457 mm (18.000 in) yoo ni akoko imuduro ti ko din ju awọn aaya 10.

Tẹ Idanwo

Awọn ọna Idanwo: Idanwo atunse yoo ni ibamu si awọn ibeere ti ISO 8491 tabi ASTM A370.

Ko si apakan ti apẹrẹ ti yoo ya ati weld kii yoo ya.

Ipele L175P/A25P jẹ irin ti a mu dara si irawọ owurọ ti o funni ni iṣẹ ṣiṣe okun to dara ju L175/A25 irin ṣugbọn o nira pupọ lati tẹ.

Idanwo fifẹ

Awọn ọna Idanwo: Idanwo funmorawon yoo ni ibamu si awọn ibeere ti ISO 8492 tabi ASTM A370.

Awọn aaye laarin awọn meji farahan yoo jẹ iru awọn ti ko si wo inu ti awọn weld yoo ṣẹlẹ titi awọn pàtó kan ijinna ti a ami.

Idanwo Titẹ Itọsọna

Awọn ọna Idanwo: Idanwo itọka itọsọna yoo ni ibamu si awọn ibeere ti ISO 5173 tabi ASTM A370.

Idanwo Lile

Ọna idanwo: Idanwo lile ni ibamu si ISO 6506, ISO 6507, ISO 6508, tabi ASTM A370.

Nigbati a ba rii awọn lumps lile ifura ni ayewo irisi, o yẹ ki o lo oluyẹwo lile lile to ṣee gbe fun idanwo lile.

Idanwo Ikolu CVN fun API 5L PSL2 Irin Pipe

Awọn ọna Idanwo: Idanwo ikolu charpy yoo pade awọn ibeere ti ASTM A370.

DWT igbeyewo fun API 5L PSL2 Welded Pipe

Ọna idanwo: Idanwo DWT yoo wa ni ibamu pẹlu API5L3.

Ayẹwo Makiro-ati Idanwo Metallographic

Inu ati ita weld iyapa ti submerged arc welded (SAW) ati combi-welded (COW) paipu yoo wa ni ẹnikeji nipasẹ macroscopic se ayewo.

Fun awọn tubes to nilo itọju igbona weld, idanwo irin-irin yoo ṣee ṣe lati rii daju pe gbogbo HAZ ti ni itọju ooru daradara ni itọsọna sisanra ogiri kikun.

Fun awọn tubes ti ko nilo itọju igbona weld, idanwo metallographic yoo ṣee ṣe lati rii daju pe ko si igbanu ti ko ni itutu.

Idanwo ti kii ṣe iparun (nikan fun idi pataki mẹta API 5L PSL2 paipu)

Ọna idanwo: API 5L Annex E.

Paipu Siṣamisi ati Location

Awọn eroja isamisi ti o wọpọ fun awọn tube irin:

Orukọ olupese paipu tabi siṣamisi;

Siṣamisi "API Spec 5L".(Gbogbogbo abbreviated to API 5L.) Awọn ọja ti o ni ibamu si diẹ ẹ sii ju ẹyọkan ibaramu le jẹ samisi pẹlu orukọ boṣewa kọọkan.

Pato Ita opin

Pato odi sisanra

Ipele paipu (orukọ irin)

Iru paipu

Gigun (gigun paipu ni m si 0.01 m ti o sunmọ julọ (ni ft si idamẹwa ẹsẹ to sunmọ))

Ipo ti irin paipu markings

D ≤ 48.3 mm (1.900 in) paipu irin: Awọn taabu ti a ṣe ni igbagbogbo ni gigun ti paipu irin tabi ti o le ni ifipamo si lapapo irin paipu.

Paipu pẹlu D> 48.3 mm (1.900 ni):

Ide ita: Bibẹrẹ ni aaye kan ni ita ita paipu laarin 450 mm ati 760 mm (1.5 ft ati 2.5 ft) lati opin kan ti paipu naa.

Inu inu: Bẹrẹ siṣamisi lori inu inu paipu o kere ju 150 mm (6.0 in) lati opin paipu kan.

Iwọn deede

Paipu kariaye ati agbegbe ati awọn iṣedede tube fun eyiti API 5L jẹ deede tabi, ni awọn ipo kan, aṣayan yiyan, bakanna bi nọmba awọn iṣedede ohun elo kan pato:

International ati agbegbe awọn ajohunše

1. ISO 3183 - Iwọn opo gigun ti agbaye fun ile-iṣẹ epo ati gaasi ti a tẹjade nipasẹ International Organisation for Standardization ati ni ibatan pẹkipẹki si API 5L.

2. EN 10208 - European Standard fun awọn paipu irin fun gbigbe awọn gaasi epo ati awọn olomi.

3. GB / T 9711 - Iwọn orilẹ-ede Kannada fun awọn ọna gbigbe ti opo gigun ti epo ni ile-iṣẹ epo ati gaasi.

4. CSA Z245.1 - Canadian Standard ibora ila paipu fun awọn gbigbe ti epo ati gaasi.

5. GOST 20295 - Russian Standard fun irin laini paipu fun gbigbe ti epo ati epo awọn ọja.

6. IPS (Iranian Petroleum Standards) - Iranian Petroleum Standards fun laini paipu fun epo ati gaasi ile ise.

7. JIS G3454, G3455, G3456 - Japanese Industrial Standards fun gbigbe oniho ti o yatọ si awọn kilasi titẹ.

8. DIN EN ISO 3183 - German Industrial Standard da lori ISO 3183 fun paipu laini.

9. AS 2885 - Australian Standard fun awọn ọna paipu laini fun gbigbe ti epo ati gaasi.

Ohun elo Specific Standards

1. API 5CT - American Petroleum Institute bošewa fun epo daradara casing ati tubing, eyi ti, biotilejepe nipataki lo ninu epo kanga, jẹ tun pataki ninu awọn epo ati gaasi ile ise.

2. ASTM A106 - Awujọ Amẹrika fun Idanwo ati Awọn ohun elo ti o ṣe deede fun paipu erogba erogba ati irin pipe fun iṣẹ iwọn otutu giga.

3. ASTM A53 - National Institute for Testing and Materials standard for aless and welded carbon steel pipe, ti a lo fun gbigbe omi ni iwọn otutu yara tabi awọn iwọn otutu kekere.

4. ISO 3834 - International Organisation for Standardization Standard fun awọn ibeere didara, idojukọ lori awọn eto idaniloju didara fun awọn irin welded.

5. dnv-os-f101 - Awujọ iyasọtọ ti ara ilu Nowejiani fun awọn eto fifin inu omi inu omi fun epo ti ilu okeere ati awọn opo gigun ti gaasi.

6. MSS SP-75 - Awọn olupilẹṣẹ Standards Society boṣewa ti o fojusi lori agbara giga, iwọn ila opin nla ti o ni iyipo welded irin pipe paipu.

Isakoso Didara ati Awọn Ilana Ibaramu Ayika

1. NACE MR0175 / ISO 15156 - Awọn ibeere fun awọn ohun elo ti a lo ninu epo ati isediwon gaasi ni awọn agbegbe hydrocarbon ti sulfur ti o ni sulfur, eyiti, lakoko ti o jẹ pataki pẹlu yiyan ohun elo, jẹ pataki fun aridaju idena ipata ti awọn ohun elo ti a lo ninu ile-iṣẹ epo ati gaasi.

Awọn ọja ibatan wa

API 5L PSL1&PSL2 GR.B Gigun Irẹlẹ-aaki Welded Pipe

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Erogba Irin Pipe

API 5L GR.B Odi Giru Dirapa Tii Irin Ailopin fun Ṣiṣeto ẹrọ

API 5L Gr.X52N PSL 2 Irin Pipe ACC.Si IPS-M-PI-190(3) & NACE MR-01-75 fun iṣẹ ekan

API 5L X42-X80/ API 5L X52 / PSL1&PSL2 Epo ati Gaasi Erogba Irin Pipe

API 5L GR.B Alailowaya Line Pipe fun Ipa ati Igbekale

API 5L/ASTM A106/ASTM A53 Gr.B Alailẹgbẹ Erogba Irin Pipe

BotopSteel jẹ Ọjọgbọn Ilu ChinaWelded Erogba Irin Pipes Olupese&IpeseJu ọdun 16 lọ pẹlu awọn toonu 8000+ ti Laini Laini Ailopin ni Iṣura Ni oṣu kọọkan.A ti ṣetan lati fesi si ọ laarin awọn wakati 24 ni kete lẹhin ti o ti gba ibeere kan ati tun lati ṣe agbekalẹ awọn anfani ti ko ni opin ati agbari ni ayika agbara.

awọn afi: API 56 46th, Awọn Iyapa Onisẹpo, PSL1, PSL2,awọn olupese, awọn aṣelọpọ, awọn ile-iṣelọpọ, awọn onijaja, awọn ile-iṣẹ, osunwon, ra, idiyele, asọye, pupọ, fun tita, idiyele.

Akoko ifiweranṣẹ: Mar-22-2024