| Igama Lomkhiqizo | Ipayipi Lensimbi Ye-Carbon / Ipayipi Lensimbi Ye-Boiler |

| Okubalulekile | A53 GrB,A36,ST52,ST35,ST42,ST45,X42,X46,X52,X60,X65,X70 |

| Okujwayelekile | I-API 5L,ASTM A106 Gr.B,ASTM A53 Gr.B,ASTMA179/A192,ASTM A335 P9,ASTM A210,ASTM A333 |

| Izitifiketi | I-API 5L, ISO9001,SGS,BV,CCIC |

| Ububanzi bangaphandle | 13.7mm-762mm |

| Ukuqina Kwezindonga | SCH10,SCH20,SCH30,STD,SCH40,SCH60,SCH80,SCH100,SCH120,SCH160,XS,XXS |

| Ubude | 1m, 4m, 6m, 8m, 12m ngokwesicelo somthengi |

| Ukwelashwa Okungaphezulu | upende omnyama, uvanishi, uwoyela, uphethiloli, anti-corrosion coated |

| Ukumaka | Ukumaka okujwayelekile, noma ngokwesicelo sakho.Indlela yokumaka:Fafaza ngopende omhlophe |

| Qeda Ukwelashwa | I-Plain End/Bevelled End/Grooved End/Treaded End With Plastic Caps |

| Icebo | I-Hot Rolled noma I-Cold Rolled ERW |

| Iphakheji | Iphakheji exegayo;Ipakishwe ngezinqwaba(2Ton Max);amapayipi ahlanganisiwe anezihlilingi ekugcineni kokubiliukuze kube lula ukulayisha nokukhipha;okhuniamacala;isikhwama esilukiwe esingangeni manzi |

| Hlola | Ukuhlaziywa Kwengxenye Yamakhemikhali,Izakhiwo Zemishini, Izakhiwo Zobuchwepheshe, Usayizi Wangaphandle Ukuhlolwa, ukuhlolwa kwamanzi, ukuhlolwa kwe-X-ray |

| Isicelo | Ukulethwa koketshezi, ipayipi lesakhiwo, ukwakhiwa, ukuqhekeka kwe-petroleum, ipayipi likawoyela, ipayipi legesi |

I-API 5L X42-X80, PSL1&PSL2 Amafutha NegesiIpayipi Lensimbi Le-Carbon Seamlessisetshenziselwa ukuthutha igesi, amanzi, kanye ne-petroleum yazo zombili izimboni zikawoyela negesi yemvelo.

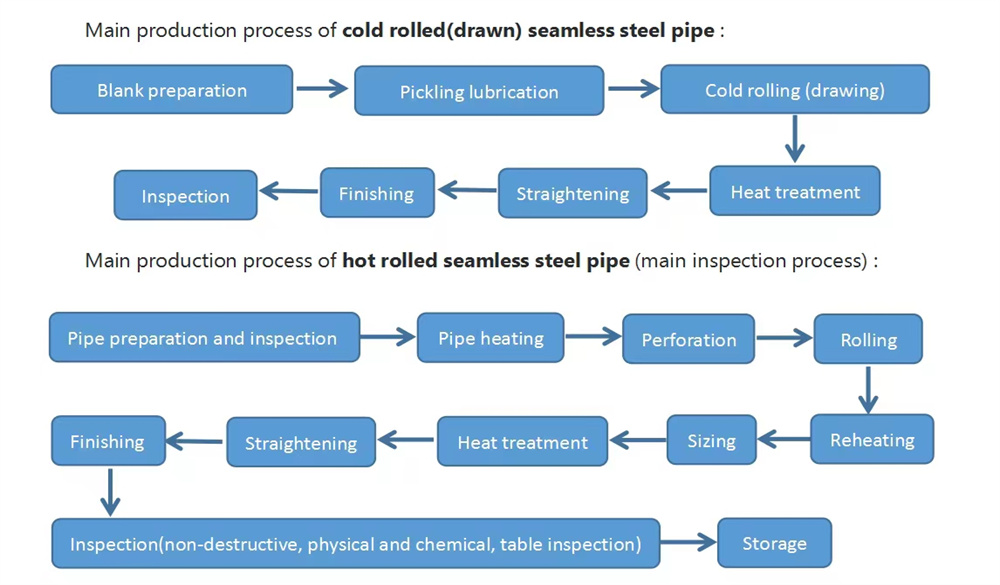

I-API 5L X42-X80, PSL1&PSL2 Amafutha kanye neGas Carbon Seamless Steel Pipe yenziwa ngokudonswa okubandayo noma okugoqwe okushisayo, njengoba kudingwa amakhasimende.

I-API 5L X52 PSL1&PSL2 Oil and Gas Carbon Seamless Steel Pipe yenziwa ngokudonsa okubandayo noma okugoqiwe okushisayo, ngokuvamile osayizi abancane ngokudonswa ngokubanda nosayizi abakhulu ngokugoqwa okushisayo.

Ibanga Nokubunjwa Kwekhemikhali (%)Nge-API 5L PSL1

| Okujwayelekile |

Ibanga | Ukwakheka kwamakhemikhali(%) | |||

| C | Mn | P | S | ||

| I-API 5L | X42 | ≤0.28 | ≤1.30 | ≤0.030 | ≤0.030 |

| X46,X52,X56 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X60,X65 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X70 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

| X52 | ≤0.28 | ≤1.40 | ≤0.030 | ≤0.030 | |

Ibanga Nokubunjwa Kwekhemikhali (%)Nge-API 5L PSL2

| Okujwayelekile |

Ibanga | Ukwakheka kwamakhemikhali(%) | |||

| C | Mn | P | S | ||

| I-API 5L | X42 | ≤0.24 | ≤1.30 | ≤0.025 | ≤0.015 |

| X46,X52,X56 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X60,X65 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X70,X80 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

| X52 | ≤0.24 | ≤1.40 | ≤0.025 | ≤0.015 | |

I-Mechanical Properties ye-API 5L GR.B X42-X80/X52(PSL1):

| Ibanga | Isivuno Amandla(MPa) | Amandla Okuqina(MPa) | Ukwelula A% | ||

|

| psi | I-MPa | psi | I-MPa | Elongation (Min) |

| X42 | 42,000 | 290 | 60,000 | 414 | 21-27 |

| X46 | 46,000 | 317 | 63,000 | 434 | 20~26 |

| X52 | 52,000 | 359 | 66,000 | 455 | 20~24 |

| X56 | 56,000 | 386 | 71,000 | 490 |

|

| X60 | 60,000 | 414 | 75,000 | 517 |

|

| X65 | 65,000 | 448 | 77,000 | 531 |

|

| X70 | 70,000 | 483 | 82,000 | 565 |

|

| X52 | 52,000 | 359 | 66,000 | 455 | 20~24 |

I-Mechanical Properties ye-API 5L/X52I-GR.B Seamless Line Pipe (PSL2):

| Ibanga | Isivuno Amandla(MPa) | Amandla Okuqina(MPa) | Ukwelula A% | Umthelela (J) | ||

|

| psi | I-MPa | psi | I-MPa | Elongation (Min) | Okuncane |

| X42 | 290 | 496 | 414 | 758 | 21-27 | 41(27) |

| X46 | 317 | 524 | 434 | 758 | 20~26 | 41(27) |

| X52 | 359 | 531 | 455 | 758 | 20~24 | 41(27) |

| X56 | 386 | 544 | 490 | 758 |

|

|

| X60 | 414 | 565 | 517 | 758 |

|

|

| X65 | 448 | 600 | 531 | 758 |

|

|

| X70 | 483 | 621 | 565 | 758 |

|

|

| X80 | 552 | 690 | 621 | 827 |

| |

| X52 | 359 | 531 | 455 | 758 | 20~24 | 41(27) |

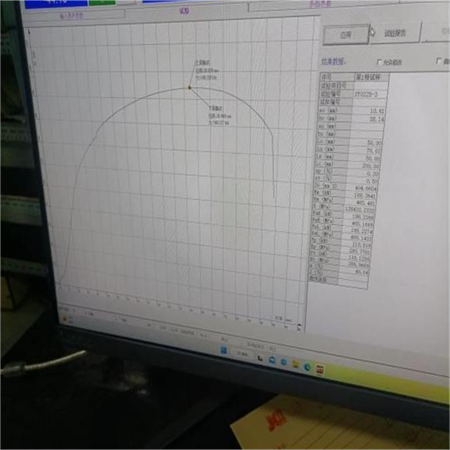

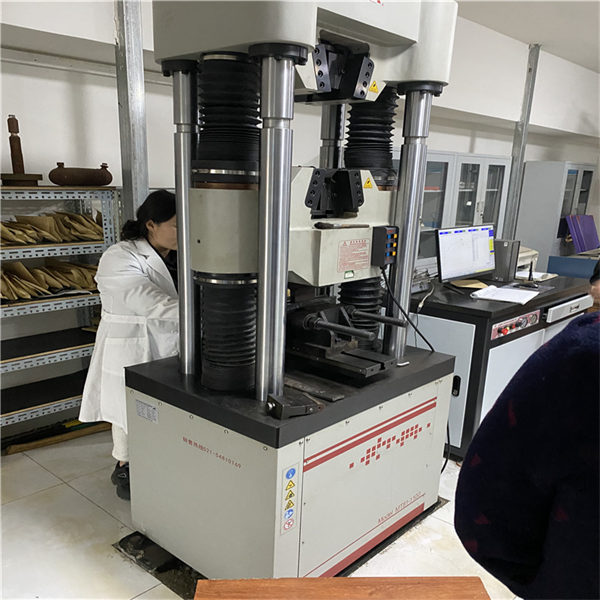

Ukuhlolwa Komshini

Ukuhlola Ukuqina

Bend Testing

Ukuhlolwa kokuqina komzimba wepayipi—Ukuhlolwa kwe-tensile kufanele kwenziwe ngokuhambisana ne-ISO6892 noma i-ASTM A370. Amasampula e-Longitudinal kufanele asetshenziswe. Kabili ngeyunithi ngayinye yokuhlola yepayipi enesilinganiso esifanayo sokwandisa ukubanda abd

Ukuhlolwa kokucaba—Ukuhlolwa okukodwa kokucaba kuzokwenziwa kuma-specimens avela ekugcineni kwamashubhu amabili akhethwe endaweni ngayinye.

Ukuhlolwa komthelela we-CVN—Ukuhlolwa kwe-Charpy kufanele kwenziwe ngokuhambisana ne-ASTM A370. Kabili ngeyunithi ngayinye yokuhlola yobude bepayipi obungengaphezu kuka-100 enesilinganiso esifanayo sokwanda okubandayo kwe-abd

Ukuhlolwa Kokuqina - Lapho izindawo okusolakala ukuthi ziqinile zitholwa ngokuhlolwa okubonakalayo, ukuhlolwa kokuqina kuzokwenziwa ngokuya nge-ISO 6506, ISO 6507, ISO 6508 noma ASTM A 370 kusetshenziswa imishini yokuhlola ubulukhuni obuphathekayo nezindlela ezihambisana ne-ASTM A 956, ASTM A 1038 noma i-ASTM E 110 ngokuya ngendlela eyi-U.

Ukuhlolwa kwe-Hydro-static—Ishubhu ngalinye lizohlolwa ngomfutho we-hydro-static

Ukuhlola Ukugoba— ubude obanele bepayipi buzoma bubanda bufinyelele ku-90° buzungeze i-cylindrical mandrel.

Ukuhlolwa kwe-X-ray okungu-100% komthungo we-weld

Ukuhlolwa kwe-ultrasonic

Ukuhlolwa kwamanje kwe-eddy

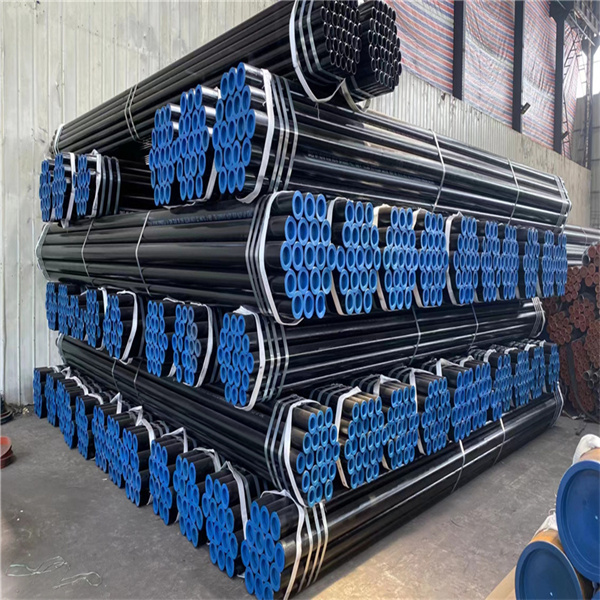

Ipayipi elingenalutho noma i-Black / Varnish coating (ngokwezidingo zekhasimende);

6" nangaphansi zibe izinyanda ezinezihlilingi ezimbili zikakotini;

Zombili ziphela ngabavikeli bokugcina;

Isiphetho esingenalutho, i-bevel end(2" nangaphezulu eneziphetho ze-bevel, idigri: 30~35°), intambo futhi yahlanganiswa;

Ukumaka.

| Usayizi | Ukubekezela (ngokuhlonishwat to ecaciswe ngaphandleububanzi) |

| <2 3/8 | + 0.016 in., - 0.031 in. (+ 0.41 mm, - 0.79 mm) |

| > 2 3/8 kanye ≤4 1/2, ashiselwe okuqhubekayo | ±1.00% |

| > 2 3/8 kanye <20 | ±0.75% |

| > 20. engenamthungo | ± 1.00% |

| >20 kanye <36, ashiselwe | + 0.75%.-0.25% |

| > 36, ezishiselwe | + 1/4 ku-.. - 1/8 in. (+ 6.35 mm, -3.20 mm) |

Esimeni sepayipi elihlolwe nge-hydro-statically ukuze libe nezingcindezi ezidlula izingcindezi ezijwayelekile zokuhlola, okunye ukubekezelela kungase kuvunyelwane ngakho phakathi komkhiqizi nomthengi.

| Ngaphandle Kwe-Roundness | |||||

| Usayizi | Minus Tolerance | Plus Ukubekezelelana | Ukubekezelelana Kokuphela-kuya-Ekupheleni | Ububanzi, Ukubekezelelana kwe-Axis (Iphesenti Le-OD Ecacisiwe) | Umehluko Omkhulu Phakathi Kobubanzi Obuncane Nobukhulu (Kusebenza Kuphela Epayipini Elino-D/t≤75) |

| ≤10 3/4 l&V4 | 1/64(0.40mm) | 1/16(1.59mm) | - | - | |

| >10 3/4 kanye ≤20 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | - | - | - |

| > 20 kanye ≤ 42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | <0.500 in. (12,7 mm) |

| >42 | 1/32 (0.79 mm) | 3/32 (2.38 mm) | b | ± 1% | £ Q625 in. (15.9 mm) |

Ukubekezelela okungaphandle kwendingilizi kusebenza kumadiayamitha aphezulu kanye nobuncane njengoba kukalwa ngegeji yebha, i-caliper, noma idivayisi ekala ubukhulu bangempela nobuncane bamadiayamitha.

Isilinganiso sobubanzi (njengoba silinganiswa ngetheyiphu yodayamitha) yesinye isiphetho sepayipi akufanele sihluke ngokungaphezu kuka-3/32 in. (2.38 mm) kusukela kolunye uhlangothi.

| Usayizi | Uhlobo Lwepayipi | Ukubekezelela1 (Iphesenti Lokuqina Kwezindonga Ezishiwo} | |

| IBanga B noma Eliphansi | Ibanga X42 noma ngaphezulu | ||

| <2 7/8 | Konke | +20.- 12,5 | + 15.0.-12.5 |

| > 2 7/8 kanye <20 | Konke | + 15,0,-12,5 | + 15-I2.5 |

| >20 | Kushiselwe | + 17.5.-12.5 | + 19.5.-8.0 |

| >20 | Ayinamthungo | + 15.0.-12.5 | + 17.5.-10,0 |

Lapho ukubekezelela okunegethivu kuncane kunalokhu okubaluliwe kucaciswa umthengi, ukubekezelela okuhle kuzokhushulwa kububanzi obusebenzayo obuphelele bokubekezelelana ngamaphesenti ngaphansi kobukhulu bodonga obunegethivu bokubekezelela.

| Ubuningi | Toi-lerance (amaphesenti) |

| Ubude obubodwa, ipayipi eliyisipesheli elikhethekile noma ipayipi elingu-A25Ubude obubodwa, elinye ipayipiCarloads.GradeA25,40,000lb(18 144kg)noma ngaphezuluUkulayishwa kwezimoto, ngaphandle kweBanga A25,40.0001b (18 144 kg) noma ngaphezuluUkulayishwa kwezimoto, wonke amabanga angaphansi kuka-40000 lb (18 144 kg) Oda izinto. Ibanga A25. 40.000 lb (18 144 kg) noma ngaphezulu Oda izinto, ngaphandle kweBanga A25,40,000 lb (18 144 kg) noma ngaphezulu Oda izinto, wonke amabanga, ngaphansi kuka-40.000 lb (18 144 kg) | + 10.-5.0 + 10,-35 -2.5 -1.75 -15 -3.5 -1.75 -3.5 |

Amanothi:

1.Ukubekezelelwa kwesisindo kusebenza ezisindweni ezibaliwe zepayipi elinentambo-futhi-ahlanganiswe kanye nezisindo ezifakwe kuthebula noma ezibaliwe zepayipi elingaphethe lutho. Lapho ukubekezelela ukuqina kodonga okunegethivu kuncane kunalokhu okubalulwe ngenhla kwethebula elichazwe umthengi, ukubekezelelwa kwesisindo okuhlanganisiwe kobude obubodwa kuzokwenyuswa kube ngamaphesenti angama-22.5 okungaphansi kokubekezelela okunegethivu.

2.Ngomthwalo wezimoto owenziwe ngepayipi ovela ezintweni ezi-oda ezingaphezu kweyodwa, ukubekezelelwa komthwalo wemoto kufanele kusetshenziswe kusisekelo sento ye-oda yomuntu ngamunye.

3. Ukubekezelelwa kwezinto ze-oda kusebenza enanini lilonke lamapayipi athunyelwe entweni ye-oda.