AS 1579 ipayipi yensimbiiyipayipi lensimbi elinezinqe elishiselwe i-arc elisetshenziselwa ukuthutha amanzi kanye namanzi angcolile elinobubanzi obungaphandle obungu-≥ 114 mm kanye nezinqwaba zamapayipi ezinomfutho olinganiselwe ongeqile ku-6.8 MPa.

Izinqwaba zamapayipi amalungu esakhiwo esiyindilinga ashayelwa emhlabathini futhi awasetshenziselwa ukulawula ingcindezi yangaphakathi.

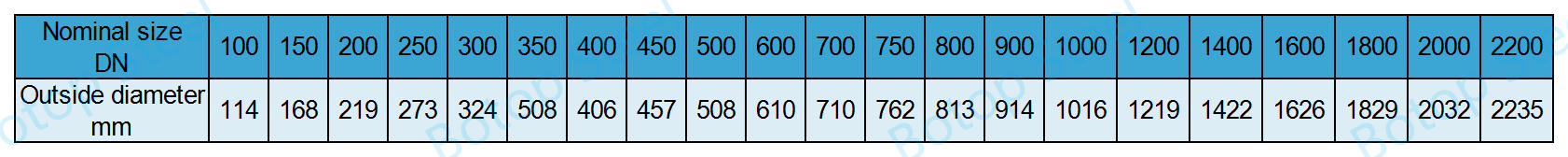

Ubuncane be-diameter obungaphandle bungu-114mm, nakuba kungekho mkhawulo othize ngosayizi wepayipi kodwa osayizi abathandwayo banikezwa.

Izokhiqizwa kusukela kumamaki ahlaziywe noma esakhiwo sensimbi egoqiwe eshisayo ehambisana ne-AS/NZS 1594 noma i-AS/NZS 3678.

Ngokuya ngokusetshenziswa kokugcina kusahlukaniswa ngale ndlela elandelayo:

Amapayipi ahlolwe nge-Hydrostaticizokhiqizwa kusukela ekuhlaziyeni noma ebangeni lesakhiwo sensimbi egoqiwe eshisayo ethobelana ne-AS/NZS 1594 noma i-AS/NZS 3678.

Ama-piles kanye nepayipi elingahloliwe nge-hydrostaticizokwakhiwa kusukela ebangeni lesakhiwo sensimbi ethobelana ne-AS/NZS 1594 noma i-AS/NZS 3678.

Ngaphandle kwalokho,izinqwabaingase yenziwe kusukela ebangeni lokuhlaziya elithobela i-AS/NZS 1594., lapho insimbi izohlolwa ngomshini ngokuvumelana ne-AS 1391 ukuze kuboniswe ukuthi ihlangabezana nezidingo zokuqina ezicaciswe umthengi.

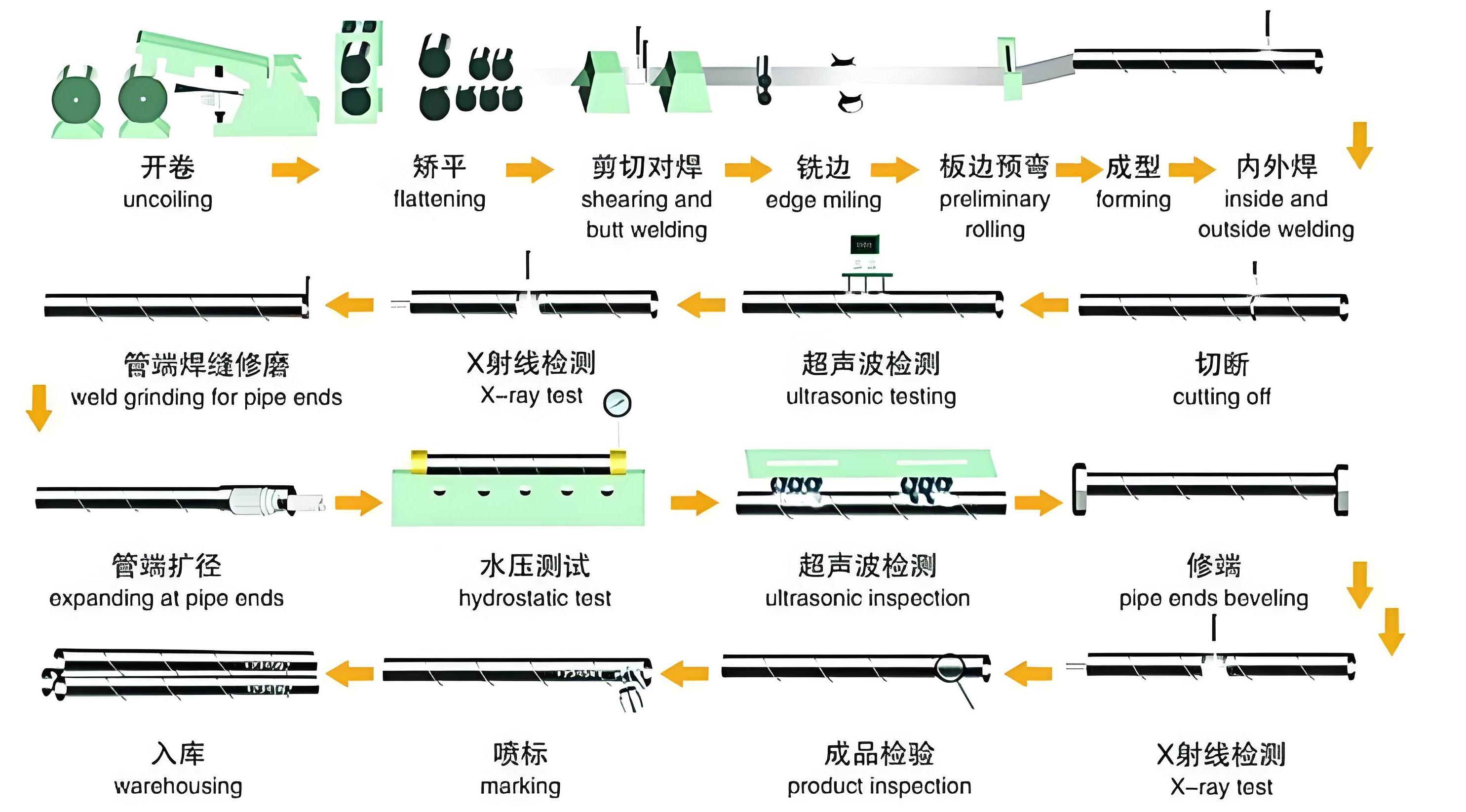

Ipayipi lensimbi le-AS 1579 likhiqizwa kusetshenziswai-arc welding.

Wonke ama-welds azofakwa ngokugcwele ama-butt welds.

Ukushisela i-arc kusebenzisa ukushisa kwe-arc kagesi ukuze kuncibilike izinto zensimbi futhi kwakhiwe ilunga elishiselwe phakathi kwezinsimbi ukuze kwakhe isakhiwo sepayipi lensimbi eliqhubekayo.

Inqubo yokukhiqiza i-arc welding evame ukusetshenziswa yi-SAW (Submerged Arc Welding), eyaziwa nangokuthiI-DSAW, ezingahlukaniswa zibeI-LSAW(SAWL) kanye ne-SSAW (HSAW) ngokuya ngesiqondiso se-butt weld.

Ngaphezu kwe-SAW, kunezinye izinhlobo ze-arc welding ezifana ne-GMAW, GTAW, FCAW, ne-SMAW.Amasu ahlukahlukene we-arc welding anezici zawo kanye nezimo zohlelo lokusebenza, futhi ukukhethwa kwendlela efanelekile yokushisela kuncike ekucacisweni kwepayipi lensimbi elizokwenziwa, isabelomali, kanye nezidingo zekhwalithi.

Amazinga ngokwawo awakucacisi ngokuqondile ukwakheka kwamakhemikhali athile kanye nezakhiwo zemishini, njengoba lokhu kuvame ukuncika kumazinga athile ensimbi afana ne-AS/NZS 1594 noma i-AS/NZS 3678, echaza kabanzi ngezidingo zamakhemikhali nezomshini zensimbi esetshenziselwa ukwenza lezi. amashubhu.

I-AS 1579 icacisa kuphela okulingana nekhabhoni.

I-carbon equivalent (CE) yensimbi akufanele idlule i-0.40.

CE=Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

I-CE iyipharamitha ebalulekile esetshenziselwa ukuhlola ukushisela kwensimbi.Kuyasiza ukubikezela ukuqina okungase kwenzeke ensimbi ngemva kokushisela futhi ngaleyo ndlela kuhlolwe ukushisela kwayo.

Ukuhlolwa kwengcindezi ye-Hydrostatic kuyadingeka kuwo wonke amanzi noma ipayipi lensimbi lamanzi angcolile elisetshenziselwa ukuthutha.

Izinqwaba zamapayipi ngokuvamile azidingeki ukuthi zihlolwe nge-hydrostatically ngoba ngokuyinhloko zisetshenziselwa ukuthwala imithwalo yesakhiwo kunokucindezela kwangaphakathi.

Izimiso Zokuhlola

Ipayipi livalwe ekugcineni ngakunye futhi licindezelwa nge-hydrostatically.

Ihlolwe amandla ngengcindezi emele ingcindezi yokuklama yepayipi.Ihlolelwa ukucinana kokuvuza ngengcindezi elinganiselwe yepayipi.

Izingcindezi Zokuhlola

Ukucindezela okukhulu okulinganiselwe kwepayipi yensimbi yi-6.8 MPa.Lokhu kuphezulu kunqunywa umkhawulo wemishini yokuhlola ingcindezi engu-8.5 MPa.

Pr= 0.72×(2×SMYS×t)/OD noma i-Pr= 0.72×(2×NMYS×t)/OD

Pr: Ingcindezi elinganiselwe, ku-MPa;

I-SMYS: Amandla esivuno esincane esibaluliwe, ku-MPa;

I-NMYS: Amandla esivuno esincane esilinganiselwe, ku-MPa;

t: Ukujiya kodonga, ngo-mm;

OD: Ububanzi bangaphandle, ngo-mm.

Ezimweni eziphuthumayo, ukucindezela kwesikhashana kungase kuholele ekwandeni kokucindezeleka kwamapayipi.Ngaphansi kwalezi zimo, ubuningi bokucindezeleka obuhlanganisiwe obuvunyelwe buyonqunywa umklami, kodwa akumele budlule u-0.90 x SMYS.

Pt= 1.25Pr

Ngemva kokuhlolwa kwamandla, ngeke kube nokugqashuka noma ukuvuza epayipini lokuhlola.

Amaphesenti angama-90 wamandla ashiwo ubuncane besivuno (SMYS) noma amandla okuvunwa amancane okuzisholo (NMYS) noma angu-8.5 MPa, kuye ngokuthi yikuphi okuncane.

Pl=Pr

Ukuhlolwa kokuvuza kuzokwenziwa epayipini.

Lapho kuhlolwa ukuvuza, akumele kube khona ukuvuza okubonakalayo endaweni yepayipi.

Wonke amapayipi okuhlola angewona awe-hydrostatic azoba nogqinsi olungekho ngaphansi kuka-8.0 mm.

Ipayipiizoba no-100% wamashisela ayo ahlolwe ngendlela engonakalisi ngezindlela ze-ultrasonic noma ze-radiographic ngokuhambisana ne-AS 1554.1 Isigaba se-SP futhi ahambisane nemibandela yokwamukela eshiwo.

Ukuhlolwa okungonakalisi kokushisela kwenqwaba okuyingxenyengezinqwaba zamapayipi.Imiphumela yokuhlolwa izohambisana nezidingo ze-AS/NZS 1554.1 Class SP.Uma ukuhlola kuveza ukungahambisani nokulebula, yonke insimbi yokushisela kuleyo nqwaba yamapayipi izohlolwa.

Amapayipi nokufakwa okusetshenziselwa ukuthuthwa kwamanzi kanye nendle kuzovikelwa ekugqwaleni ngokukhetha i-coating efanelekile.

Endabeni yamanzi aphuzwayo, kufanele ahambisane ne-AS/NZS 4020. Inhloso ukuqinisekisa ukuthi le mikhiqizo, lapho ithinta uhlelo lokuhlinzeka ngamanzi, ayilithinti kabi izinga lamanzi, njengokungcoliswa kwamakhemikhali, i-microbiological. ukungcola, noma ukuguqulwa kokunambitheka nokubukeka kwamanzi.

Ingaphandle leshubhu, elingengaphezu kuka-150 mm ukusuka ekugcineni, lizophawulwa ngokucacile nangokuphelele ngolwazi olulandelayo:

a) Inombolo ye-serial ehlukile, okungukuthi inombolo yeshubhu;

b) Indawo yokukhiqiza;

c) Ubukhulu bangaphandle nokuqina kodonga;

d) Inombolo ejwayelekile, okungukuthi AS 1579;

e) Igama lomkhiqizi noma uphawu lokuhweba;

f) Isilinganiso somfutho wepayipi lokuhlola i-Hydrostatic (kuphela ipayipi lensimbi elihlolwa nge-hydrostatic);

g) Ukumakwa kokuhlola okungabhubhisi (NDT) (kuphela kwepayipi lensimbi elihlolwe ngokungalimazi).

Umkhiqizi uzohlinzeka Umthengi isitifiketi esisayiniwe esisho ukuthi ipayipi lakhiwe ngokuvumelana nezimfuneko zoMthengi kanye naleli Zinga.

I-ASTM A252: Idizayinelwe izinqwaba zamapayipi ensimbi futhi iqukethe izici zemishini ezinemininingwane kanye nokucaciswa kokwakheka kwamakhemikhali kwamakilasi amathathu okusebenza.

I-EN 10219: kuhlobene namashubhu ensimbi akhiwe abandayo ashiselwe ukuze asetshenziswe ngokwesakhiwo okuhlanganisa nezinqwaba zamapayipi.

ISO 3183: Ipayipi likalayini wensimbi embonini kawoyela negesi, elinezidingo zekhwalithi namandla ezenza lifaneleke nokuthwala izinqwaba zamapayipi.

I-API 5L: Ikakhulukazi isetshenziselwa amapayipi okuthutha embonini kawoyela negesi, amazinga aphezulu futhi ayenza ifaneleke ukwenza izinqwaba ezingaphansi kwemithwalo ephezulu.

I-CSA Z245.1: Icacisa amapayipi ensimbi kanye nokufakwa kokuthuthwa kwamafutha negesi, okubuye kufane nezinqwaba zamapayipi.

I-ASTM A690: Idizayinelwe izinqwaba zamapayipi ensimbi asetshenziswa ezindaweni zasolwandle nezifanayo, igcizelela ukumelana nokugqwala.

I-JIS A 5525: Ipayipi lensimbi elivamile laseJapane elimboza izinqwaba zamapayipi, okuhlanganisa impahla, ukwakhiwa, izidingo zobukhulu kanye nokusebenza.

I-GOST 10704-91: Eshiselwe ngogesi ipayipi lensimbi eliqondile elisetshenziselwa ukwakha kanye nezakhiwo zobunjiniyela, kuhlanganise nezinqwaba zamapayipi.

I-GOST 20295-85: Imininingwane yamapayipi ensimbi ashiselwe ngogesi okuthuthwa kukawoyela negesi, abonisa ukusebenza kwawo ngaphansi kwengcindezi ephezulu nasezindaweni ezinzima, esebenza ezinqwaba zamapayipi.

Kusukela yasungulwa ngo-2014, i-Botop Steel isiphenduke umhlinzeki oholayo wepayipi lensimbi eNyakatho neChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezisombululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.