I-ASTM A178amashubhu ensimbi angamashubhu kagesi ashiselwe ukumelana (ERW) kainsimbi ye-carbon ne-carbon-manganeseasetshenziswa njengamashubhu obhayela, amapayipi abhayela, amapayipi e-superheater, neziphetho zokuphepha.

Ilungele amashubhu ensimbi anobubanzi obungaphandle obungu-12.7-127mm nogqinsi oluphakathi kuka-0.9-9.1mm.

Amashubhu e-ASTM A178 alungele ukumelana namashubhu ashiselweamadayamitha angaphandle aphakathi kuka-1/2 - 5 kokuthi [12.7 - 127 mm] nogqinsi lwezindonga phakathi kuka-0.035 - 0.360 kokuthi [0.9 - 9.1 mm], nakuba abanye osayizi betholakala njengoba kudingekile, inqobo nje uma la mashubhu ahlangabezana nazo zonke ezinye izidingo zalokhu kucaciswa.

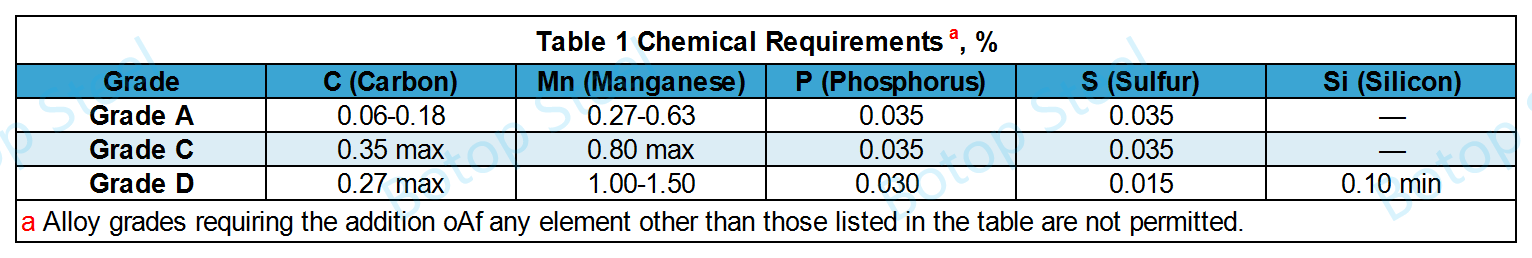

Kunamabanga amathathu okubhekana nezimo ezihlukene zokusebenzisa.

IBanga A, iBanga C, kanye neBanga D.

| Ibanga | Uhlobo Lwensimbi Yekhabhoni |

| Ibanga A | Insimbi Yekhabhoni Ephansi |

| Ibanga C | Medium-Carbon Steel |

| Ibanga D | Insimbi yeCarbon-Manganese |

Izinto ezinikezwe ngaphansi kwalokhu kushiwo zizohambisana nezidingo ezisebenzayo zohlelo lwamanje lwe-Specification A450/A450M.ngaphandle uma kuhlinzekwe ngenye indlela lapha.

Ibanga AfuthiIbanga Cungacacisi insimbi ethile;khetha impahla eluhlaza efanele njengoba kudingeka.

Insimbi yeIbanga Dizobulawa.

Insimbi ebulewe ikhiqizwa ngokwengeza ama-deoxidizer (isb, i-silicon, i-aluminium, i-manganese, njll.) ensimbi encibilikisiwe phakathi nenqubo yokukhiqiza insimbi, ngaleyo ndlela yehlise noma iqede okuqukethwe komoyampilo ensimbi.

Lokhu kwelashwa kuthuthukisa i-homogeneity nokuzinza kwensimbi, kuthuthukisa izakhiwo zayo zemishini, futhi kuthuthukisa ukumelana nokugqwala.

Ngakho-ke izinsimbi ezibulewe zisetshenziswa kabanzi ekusetshenzisweni lapho izinga eliphezulu le-homogeneity kanye nezakhiwo ezinhle kakhulu zemishini zidingeka, njengokwenziwa kwemikhumbi yokucindezela, ama-boilers, nezingxenye ezinkulu zesakhiwo.

Amashubhu ensimbi akhiqizwa kusetshenziswa i-ERWinqubo yokukhiqiza.

I-ERW (I-Electric Resistance Welded)kuyinqubo efaneleke kahle ukukhiqiza ipayipi lensimbi ye-carbon.

Ngezinzuzo zamandla aphezulu wokushisela, izindawo ezibushelelezi zangaphakathi nangaphandle, isivinini sokukhiqiza esisheshayo, kanye nentengo ephansi, isetshenziswa kabanzi emikhakheni eminingi yezimboni neyokwakha.

I-ASTM A178ipayipi lensimbikumele iphathwe ukushisangesikhathi sokukhiqiza.Isetshenziselwa ukuthuthukisa izakhiwo zemishini kanye nokuzinza kwesakhiwo sepayipi, kanye nokuqeda ukucindezeleka okungenzeka kwethulwe ngesikhathi senqubo yokushisela.

Ngemva kokushisela, wonke amashubhu kufanele ashiswe ezingeni lokushisa elingu-1650°F [900°C] noma ngaphezulu futhi alandelwe ukupholisa emoyeni noma ekamelweni lokupholisa lesithando somoya esilawulwayo.

Amashubhu abandayoizophathwa ngokushisa ngemva kokudlula kokugcina okubandayo ezingeni lokushisa elingu-1200°F [650°C] noma ngaphezulu.

Uma ukuhlaziywa komkhiqizo kwenziwa, imvamisa yokuhlola inqunywa kanje.

| Ukwahlukanisa | Imvamisa Yokuhlola |

| Ububanzi bangaphandle ≤ 3in [76.2mm] | 250 ama-pcs / isikhathi |

| Ububanzi bangaphandle > 3in [76.2mm] | 100 ama-pcs / isikhathi |

| Hlukanisa ngenombolo yokushisa kweshubhu | Ngenombolo yokushisa ngayinye |

Izidingo zezakhiwo zikagesi azisebenzi kumashubhu amancane kuno-1/8 in. [3.2 mm] ngobubanzi bangaphakathi noma 0.015 in. [0.4 mm] ukujiya.

1. Impahla Eqinile

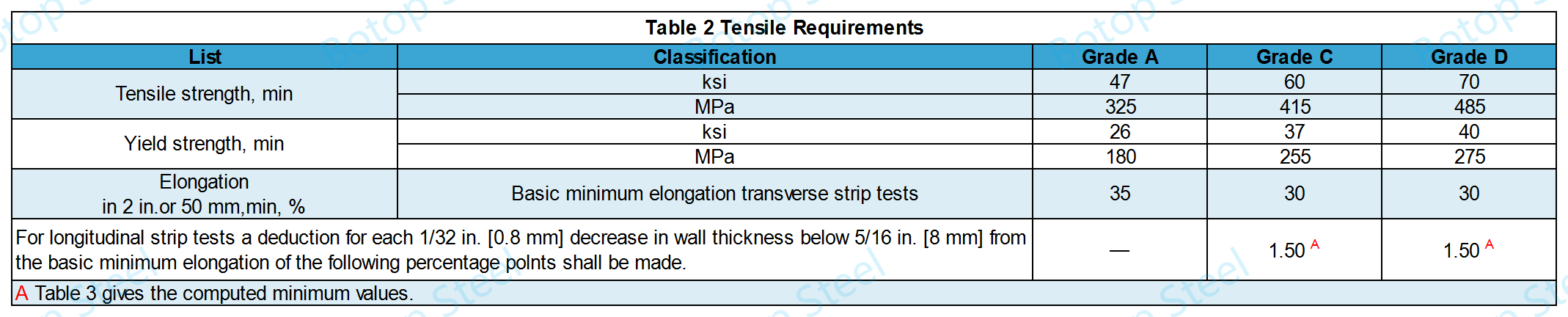

Emakilasini C no-D, ukuhlolwa kwe-tensile kuzokwenziwa kumashubhu amabili endaweni ngayinye.

Kumashubhu eBanga A, ukuhlolwa kwe-tensile ngokuvamile akudingekile.Lokhu kungenxa yokuthi ishubhu yeBanga A isetshenziselwa ikakhulukazi izicelo ezinengcindezi ephansi kanye nezinga lokushisa eliphansi.

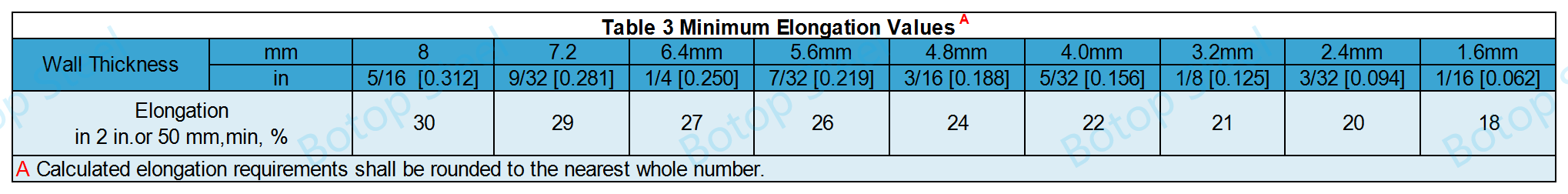

Ithebula lesi-3 linikeza amanani ayisisekelo enziwe ngekhompyutha e-elongation ngayinye engu-1/32 in. [0.8 mm] ukuncipha kokujiya kodonga.

Uma ubukhulu bodonga lwepayipi yensimbi akuyona enye yalezi zimpawu zodonga, zingabuye zibalwe ngefomula.

Amayunithi Amayintshi: E = 48t + 15.00nomaAmayunithi e-ISI: E = 1.87t + 15.00

E = ubude ku-2 in. noma 50 mm, %,

t= ukujiya kwesifanekiso sangempela, ngaphakathi. [mm].

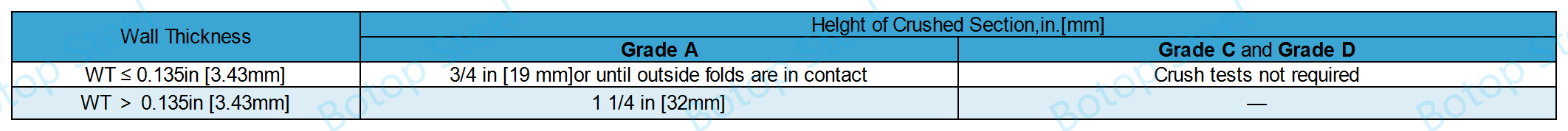

2. Crush Test

Ukuhlolwa kokukhipha kwenziwa ezigabeni zamapayipi ezingama-intshi angu-2 1/2 [amamilimitha angu-63] ubude okufanele zimelane nokukhishwa kwe-longitudinal ngaphandle kokuqhekeka, ukuqhekeka, noma ukuqhekeka kumashisela.

Emashubhuni angaphansi kuka-1 in. [25.4 mm] ububanzi obungaphandle, ubude besampula buzoba ngokuphindwe izikhathi ezingu-2 1/2 kunobubanzi bangaphandle beshubhu.Ukuhlola indawo encane akumele kube isizathu sokwenqatshwa.

3. Ukuhlolwa Kokucaba

Indlela yokuhlola ihambisana nezidingo ezifanele ze-ASTM A450 Isigaba 19.

4. Ukuhlolwa kwe-Flange

Indlela yokuhlola ihambisana nezidingo ezifanele ze-ASTM A450 Isigaba 22.

5. Reverse Flattening Test

Indlela yokuhlola ihambisana nezidingo ezifanele ze-ASTM A450, Isigaba 20.

Ukuhlolwa kukagesi we-Hydrostatic noma okungabhubhisi kwenziwa epayipini ngalinye lensimbi.

Izidingo zihambisana ne-ASTM A450, Isigaba 24 noma 26.

Idatha elandelayo itholakala ku-ASTM A450 futhi ihlangabezana nezidingo ezifanele zamapayipi ensimbi ashiselwe kuphela.

Ukuchezuka Kwesisindo

0 - +10%.

Ukuchezuka Kokuqina Kodonga

0 - +18%.

Ukuchezuka Kwedayamitha Ngaphandle

| Ngaphandle Ububanzi | Izinguquko Ezivumelekile | ||

| in | mm | in | mm |

| OD ≤1 | OD≤ 25.4 | ±0.004 | ±0.1 |

| 1<OD ≤1½ | 25.4<OD ≤38.4 | ±0.006 | ±0.15 |

| 1½<OD<2 | 38.1< OD<50.8 | ±0.008 | ±0.2 |

| 2≤ OD<2½ | 50.8≤ OD<63.5 | ±0.010 | ±0.25 |

| 2½≤ OD<3 | 63.5≤ OD<76.2 | ±0.012 | ±0.30 |

| 3≤ OD ≤4 | 76.2≤ OD ≤101.6 | ±0.015 | ±0.38 |

| 4<OD ≤7½ | 101.6<OD ≤190.5 | -0.025 - +0.015 | -0.64 - +0.038 |

| 7½< OD ≤9 | 190.5< OD ≤228.6 | -0.045 - +0.015 | -1.14 - +0.038 |

Ngemuva kokufakwa kubhayela, ishubhu kufanele ikwazi ukumelana nokunwetshwa nokugoba ngaphandle kokulimala noma ukuqhekeka kuma-welds.

Amashubhu okushisa aphezulu azokwazi ukumelana nayo yonke imisebenzi edingekayo yokubumba, ukushisela, kanye nokugoba ngaphandle kokulimala.

Isetshenziswa kakhulu kumashubhu obhayela, amaflue abhayela, ama-superheater flues, neziphetho eziphephile.

I-ASTM A178 Ibanga Aokuqukethwe kwekhabhoni ephansi ye-tubing kuyinikeza ukushisela okuhle kanye nokuqina okuphezulu kwezinhlelo zokusebenza ezingekho ngaphansi kwengcindezi ephezulu.

Isetshenziselwa ikakhulukazi izinhlelo zokusebenza ezinomfutho ophansi kanye nezinga lokushisa eliphakathi njengamabhoyela anengcindezi ephansi (isb., amabhoyela asekhaya, amabhilidi amancane amahhovisi, noma ama-boilers asefekthri) nezinye izishintshisi zokushisa ezindaweni ezinezinga lokushisa eliphansi.

I-ASTM A178 Ibanga Cinokuqukethwe okuphezulu kwekhabhoni ne-manganese okunikeza leli shubhu amandla angcono nokumelana nokushisa kwezimo zokusebenza ezinzima kakhulu.

Ifanele ukusetshenziswa komfutho ophakathi nendawo nezinga lokushisa eliphakathi njengamabhoyili ezimbonini namanzi ashisayo, ngokuvamile adinga izingcindezi namazinga okushisa aphezulu kunamabhayela asekhaya.

I-ASTM A178 Ibanga Damashubhu anokuqukethwe okuphezulu kwe-manganese kanye nokuqukethwe kwe-silicon efanelekile ukunikeza amandla amahle kakhulu nokumelana nokushisa, okuwenza azinze ezindaweni ezishisa kakhulu nezinomfutho ophezulu futhi afanele ukumelana nezimo zokusebenza ezimbi kakhulu.

Ivamise ukusetshenziswa ezindaweni ezinomfutho ophezulu kanye nezinga lokushisa eliphezulu, njengamabhoyili esiteshi samandla kanye nama-superheaters ezimbonini.

1. I-ASTM A179 / ASME SA179: Isishintshi sokushisa sensimbi engenamthungo kanye namashubhu e-condenser wesevisi ye-cryogenic.Isetshenziswa kakhulu ezindaweni ezinengcindezi ephansi, ifana nezakhiwo zamakhemikhali nezomshini ku-ASTM A178.

2. I-ASTM A192 / ASME SA192: Amashubhu e-boiler ensimbi engenamthungo asenkonzweni yokucindezela okuphezulu.Isetshenziswa ngokuyinhloko ekwenzeni izindonga zamanzi, i-economizers nezinye izingxenye zokucindezela kuma-boilers we-ultra-high.

3. ASTM A210 / ASME SA210: Imboza ibhoyela yensimbi engenamthungo ne-alloy steel kanye namashubhu okushisa aphezulu okushisa okuphezulu kanye nezinhlelo zokubhayela ezinomfutho ophakathi.

4. Idatha ye-DIN 17175: Amashubhu ensimbi angenamthungo namapayipi okusetshenziselwa ukucindezela okuphezulu kanye nezindawo zokushisa eziphezulu.Ikakhulukazi esetshenziswa ekwakhiweni kwamapayipi e-steam ama-boilers nemikhumbi yokucindezela.

5. I-EN 10216-2: Ichaza izimo zobuchwepheshe zamashubhu angenamthungo namapayipi wezinsimbi ezingezona i-alloy ne-alloy ezinezakhiwo ezishiwo zokushisa okuphezulu ezisetshenziswayo ngaphansi kwengcindezi.

6. I-JIS G3461: Imboza amashubhu ensimbi ekhabhoni ama-boilers kanye nezishintshisi zokushisa.Ifanele izimo zokushintshanisa ukushisa okujwayelekile okuphansi nokuphakathi.

Singabakhiqizi nabahlinzeki bepayipi lensimbi yensimbi esezingeni eliphezulu abavela eChina, futhi siphinde sibe nesitoko sepayipi sensimbi esingenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi!

Nganoma yimiphi imibuzo noma ukuze ufunde kabanzi mayelana neminikelo yethu, ungangabazi ukusithinta.Izixazululo zakho zepayipi lensimbi ezilungile ziwumlayezo nje!