I-ASTM A334Ibanga lesi-6ipayipi lensimbi lamandla aphezulu, elisezingeni eliphansi elinekhabhoni ephezulu engu-0.30%, i-manganese engu-0.29-1.06%, amandla amancane okudonsa angu-415Mpa (60ksi), namandla okukhiqiza angu-240Mp (35ksi).

Isetshenziswa kakhulu emkhakheni wezindawo zegesi yemvelo ewuketshezi, ubunjiniyela be-polar, kanye nobuchwepheshe besiqandisi, evumelana nezimo ezisezingeni eliphansi kakhulu lokushisa.

I-ASTM A334kuwukucaciswa okujwayelekile kweshubhu yensimbi engenamthungo neshiselwe kanye nengxubevange yezinhlelo zokusebenza ze-cryogenic.

Kunamabanga amaningana ukuhlangabezana nezidingo ezahlukene.

Grade 1, Grade 3, Grade 6, Grade 7, Grade 8, Grade 9, Grade 11.

Ibanga loku-1kanye neBanga lesi-6 womabili amapayipi ensimbi ye-carbon.

Ipayipi yensimbi ye-ASTM A334 yeBanga lesi-6 ingakhiqizwa ngezinqubo ezingenamthungo noma ezishiselwe.

Izinqubo zokushisela zihlanganisa izindlela ezihlukahlukene ezifanai-electric resistance welding (ERW)futhii-arc welding engaphansi kwamanzi (SAW).

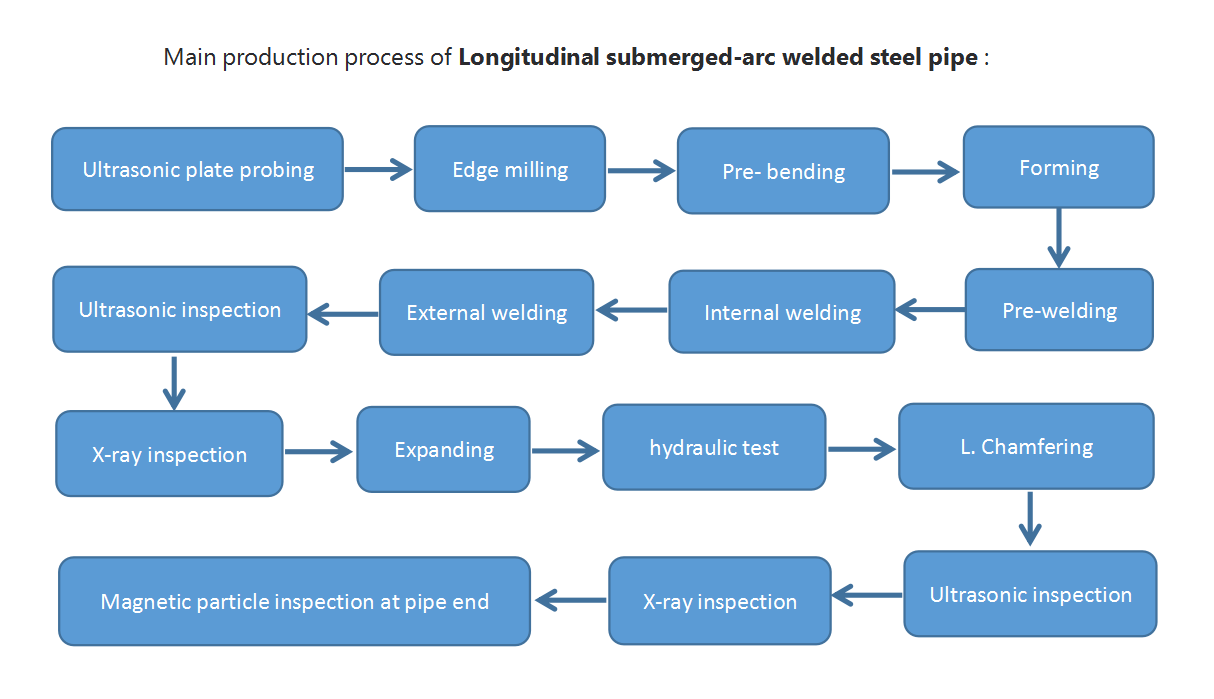

Ngezansi, inqubo yokukhiqiza yeI-Longitudinal Submerged Arc Welding (LSAW).

Njengomkhiqizi wamashubhu ensimbi ashiselwe, siyakwazi ukuhlangabezana nezidingo ezithile zamakhasimende ethu ahlukahlukene, sinikeza izinhlobonhlobo zezinketho zomkhiqizo ukuze siqinisekise ukusebenza okuhle kakhulu kanye nekhwalithi yalo lonke uhlelo lokusebenza.

I-weld yocezu olulodwa lweshubhu ye-LSAW ithuthukisa kakhulu amandla eshubhu, ivumela ukuthi imelane nezingcindezi eziphezulu.

Ngaphezu kwalokho, ifaneleka ngokufanelekile ukukhiqizwa kwepayipi lensimbi elinobubanzi obukhulu nelinodonga oluwugqinsi elihlangabezana nezidingo ze-ASTM A334 Grade 6 ezinhlelweni ezinkulu zokulethwa kwezimboni namandla, njengokwakhiwa kwegesi enkulu yemvelo enoketshezi (liquefied nature). LNG) izinsiza.

Ngesikhathi esifanayo, ukulawula okunembayo kwe-dimensional kuqinisekisa amadayimitha amapayipi angaguquki kanye nokuqina kodonga ukuze kuthuthukiswe ukwethembeka kokuxhumeka nokuvimbela ukuvuza ezinhlelweni zamapayipi.

Zijwayeze ngokufudumeza izinga lokushisa elifanayo elingekho ngaphansi kuka-1550 °F [845 °C] futhi uphole emoyeni noma ekamelweni lokupholisa lesithando somlilo esilawulwa umoya.

Uma ukuthukuthela kuyadingeka, kuzodinga ukuxoxisana.

Ukwakheka kwamakhemikhali epayipi lensimbi le-ASTM A334 Grade 6 yakhelwe ukuqinisekisa izakhiwo ezinhle zemishini emazingeni okushisa aphansi kanye nokuqina okwanele kwesevisi ethembekile ngaphansi kwezimo ezimbi kakhulu.

| Ibanga | C (Ikhabhoni) | Mn (Manganese) | P (Phosphorus) | S (Isibabule) | Si (I-silicon) |

| Ibanga lesi-6 | ubuningi 0.30 | 0.29-1.06 | ubuningi 0.025 | ubuningi 0.025 | iminithi 0.10 |

| Ekunciphiseni ngakunye kwekhabhoni ngo-0.01% ngaphansi kuka-0.30 %, ukwenyuka kwe-manganese ngo-0.05 % ngaphezu kuka-1.06 % kuzovunyelwa ukuba kufinyelele ku-1.35% wemanganese. | |||||

Ezinsimbi zeBanga 1 noma zeBanga lesi-6, akuvunyelwe ukunikeza amamaki e-alloying kunoma yiziphi izici ngaphandle kwalezo ezidingekayo ngokucacile.Nokho, kuvunyelwe ukwengeza izakhi ezidingekayo ukuze i-deoxidation yensimbi.

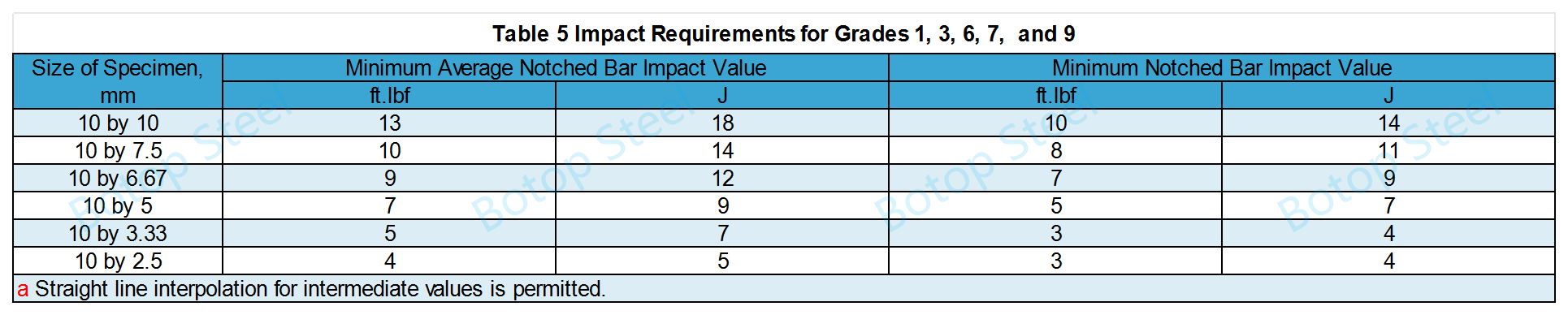

Ukuhlolwa komthelela kumapayipi ensimbi eBanga lesi-6 kwenziwa ku--45°C [-50°F] njengendlela yokuqinisekisa ukuqina nomthelela wokumelana kwezinto endaweni enezinga lokushisa eliphansi kakhulu.

Ukuhlolwa kwenziwa ngokukhetha amandla omthelela afanele ngokusekelwe ekugqineni kodonga lwepayipi lensimbi.

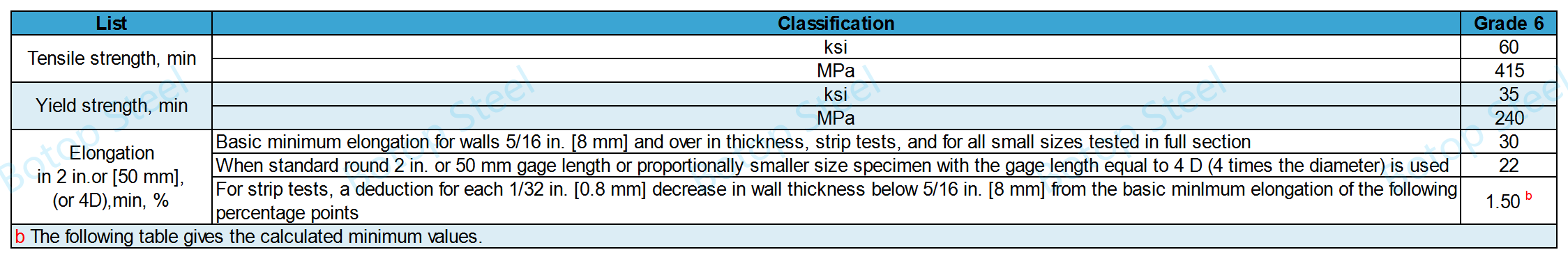

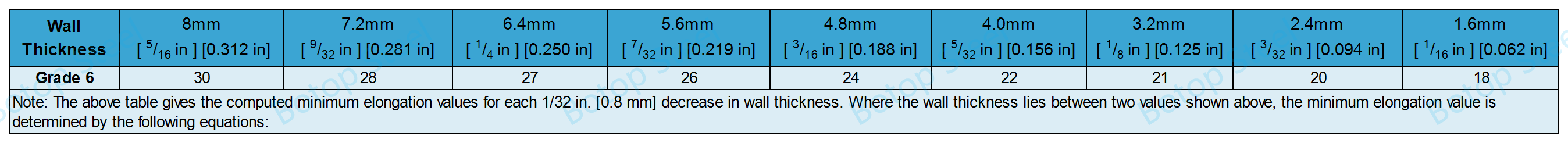

Amanani e-elongation amancane abaliwe ku-1/32 in ngayinye.[0.80 mm] ukuncipha kokujiya kodonga.

| Ibanga | Rockwell | Brinell |

| I-ASTM A334 Ibanga lesi-6 | B90 | 190 |

Ipayipi ngalinye kufanele lihlolwe ngendlela engonakalisi ngogesi noma nge-hydrostatic ngokuvumelana ne-Specification A1016/A1016M.

Ngaphandle kwalapho kucaciswe ngenye indlela ku-oda lokuthenga, uhlobo lokuhlola oluzosetshenziswa luzoba ngokokuzikhethela komkhiqizi.

Ukuhlola Ukucaba

Ukuhlolwa kwe-Flare (Amashubhu Angenamthungo)

Ukuhlolwa kwe-Flange (Amashubhu ashiselwe)

Reverse Flattening Test

1. Izinsiza ze-Liquefied Natural Gas (LNG).: Ngenxa yezindawo zayo zokushisa eziphansi kakhulu, ipayipi yensimbi yeBanga lesi-6 isetshenziswa kabanzi ekukhiqizeni i-LNG, isitoreji kanye nezindawo zokuthutha.Lezi zakhiwo zidinga izinto ezigcina amandla aphezulu kanye nokuqina okuhle emazingeni okushisa aphansi kakhulu.

2. Izinhlelo zokuthutha uwoyela negesi: esetshenziselwa ukuthutha ama-hydrocarbon awuketshezi noma amagesi, njenge-liquefied petroleum gas (LPG) nolunye uketshezi olunezinga lokushisa eliphansi endaweni enezinga lokushisa eliphansi.

3. Ubuchwepheshe beziqandisi kanye nezindawo zokugcina ezibandayo: Lokhu kusebenza nakwezinye izindawo zobuchwepheshe beziqandisi, njengeziqandisi kanye nezinhlelo zokugcina ezibandayo ekucutshungulweni kokudla nezinye izinqubo zamakhemikhali ezidinga ukusebenza kwezinga lokushisa eliphansi.

4. Ubunjiniyela be-polar: Kumaphrojekthi wobunjiniyela ezifundeni ezipholile, njengeziteshi zocwaningo lwesayensi e-Arctic noma e-Antarctica, asetshenziselwa ukwakha amasistimu okuthutha aqinile futhi athembekile nezakhiwo okumele zikwazi ukumelana namazinga okushisa abandayo nezimo zemvelo ezinzima.

5. Ama-air-conditioning nama-heaters: Futhi evame ukusetshenziswa ezinhlelweni ezinkulu ze-air-conditioning kanye nezishintshi zokushisa, okudingeka zisebenze ngokuphumelelayo emazingeni okushisa aphansi ukuze kuqinisekiswe ukusebenza kahle kwesistimu nokuphepha.

6. Ubunjiniyela bamandla kanye neziteshi zikagesi: Kumaphrojekthi akhethekile wobunjiniyela bamandla, njengezinhlobo ezithile zeziteshi zikagesi, amashubhu ensimbi eBanga lesi-6 angasetshenziswa ukuphatha uketshezi noma amagesi emazingeni okushisa aphansi ukuze kuqinisekiswe ukusebenza okuphephile nokusebenza kahle kwesistimu.

I-EN 10216-4:P265NL: Isetshenziselwa ikakhulukazi imikhumbi yokucindezela i-cryogenic kanye nezinhlelo zamapayipi e-cryogenic, inokuqina okuhle namandla futhi ifanele ukusetshenziswa ezindaweni ze-cryogenic.

I-DIN 17173:TTSt41N: Idizayinelwe izinhlelo zokusebenza ezisezingeni lokushisa eliphansi, inikeza ukusebenza okuhle kakhulu kwezinga lokushisa eliphansi futhi ivamise ukusetshenziswa kumishini namapayipi adinga izindawo zokusebenza ezinezinga lokushisa eliphansi kakhulu.

I-JIS G3460:STPL46: Isetshenziselwa amasistimu okuthutha amapayipi ezindaweni ezinezinga lokushisa eliphansi, elikwazi ukumelana nemithelela ethile yezinga lokushisa eliphansi nezingcindezi.

I-GB/T 18984:09Mn2V: Le nto ikhethekile ekwenziweni kwamashubhu ensimbi angenamthungo ukuze asetshenziswe ezindaweni ezinezinga lokushisa eliphansi, ezinokuqina okuhle kwezinga lokushisa eliphansi kanye nokumelana nokuqhekeka.

Lapho kukhethwa lezi zinto ezifanayo, kubalulekile ukuqinisekisa ukuthi ukwakheka kwamakhemikhali abo kanye nezakhiwo zemishini kuhlangabezana nezidingo ezidingekayo zokufaka isicelo kanye nezidingo zokusebenza.

Le mingcele kufanele iqhathaniswe ngokuningiliziwe futhi izinqubo zokuhlola ezengeziwe nezitifiketi zingadingeka ukuze kuqinisekiswe ukufaneleka nokusebenza kwento.

Selokhu yasungulwa ngo-2014, iBotop Steel isibe ngumphakeli ohamba phambili wecarbon steel pipeeNyakatho neChina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezixazululo ezibanzi.Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.