I-ASTM A335 P91, obeye aziwe njengoI-ASME SA335 P91, iyipayipi yensimbi engenamthungo ye-ferritic alloy yesevisi yezinga lokushisa eliphezulu, i-UNS No. K91560.

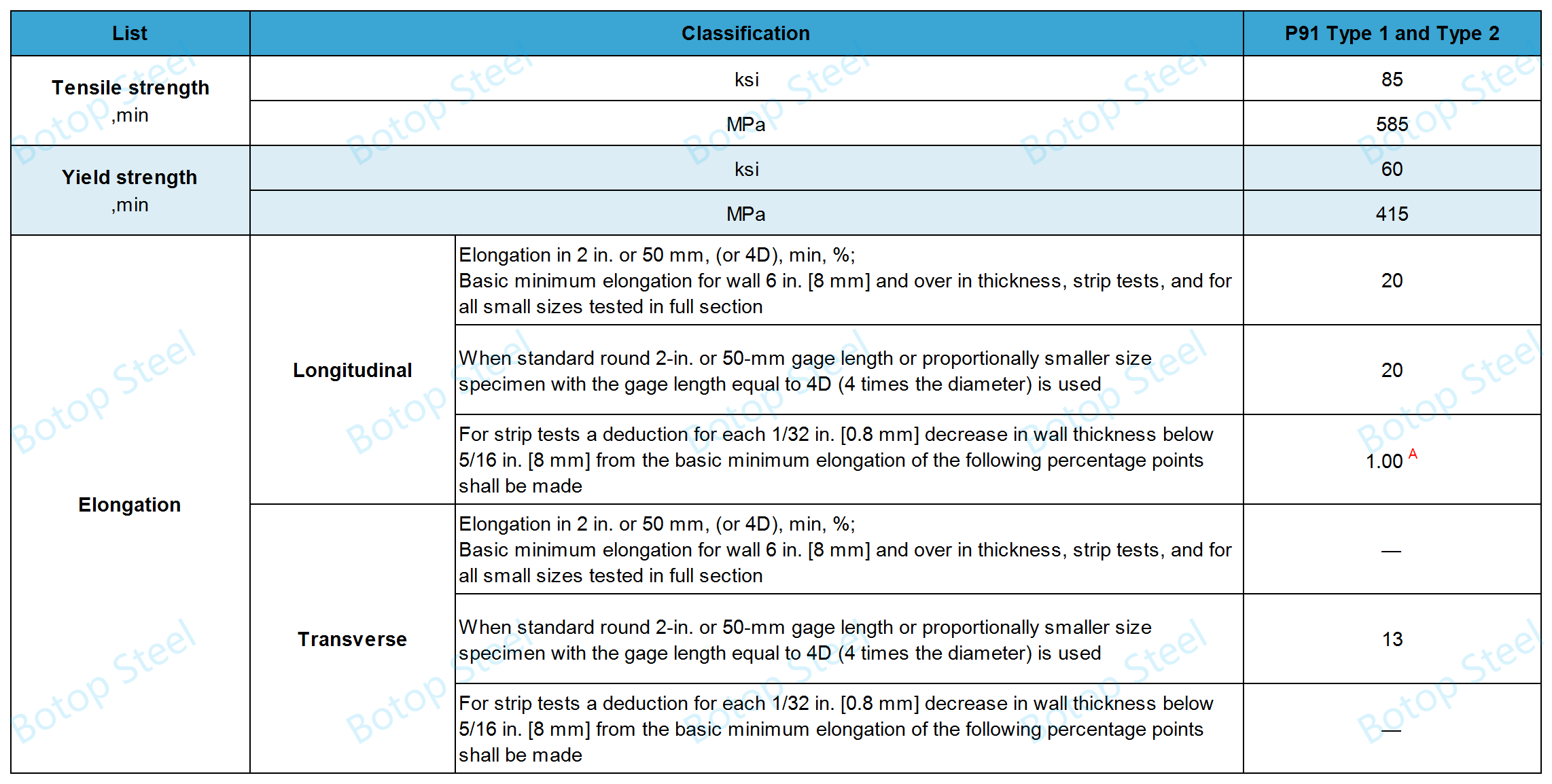

Inobuncaneamandla okudonsa angu-585 MPa(85 ksi) kanye nobuncaneisivuno amandla 415 MPa(60 ksi).

P91ikakhulukazi iqukethe izakhi ze-alloying njenge-chromium ne-molybdenum, futhi izinhlobonhlobo zezinye izakhi ze-alloying zengezwa, eziyingxenye ye-alloying.high-alloy steel, ngakho-ke inamandla amakhulu nokumelana nokugqwala okuhle kakhulu.

Ngaphezu kwalokho, i-P91 itholakala ngezinhlobo ezimbili,Uhlobo 1futhiUhlobo 2, futhi ivame ukusetshenziswa ezimbonini zikagesi, izindawo zokuhluza, izinsiza zamakhemikhali izinto ezibucayi, kanye namapayipi ezindaweni ezishisa kakhulu nezinomfutho ophezulu.

Ipayipi lensimbi le-P91 lihlukaniswe ngezinhlobo ezimbili, Uhlobo 1 nohlobo 2.

Zombili lezi zinhlobo ziyefana ngokwezakhiwo zemishini nezinye izidingo ezinjengokwelashwa kokushisa,nomehluko omncane ekubunjweni kwamakhemikhali nokugxila kwesicelo esithile.

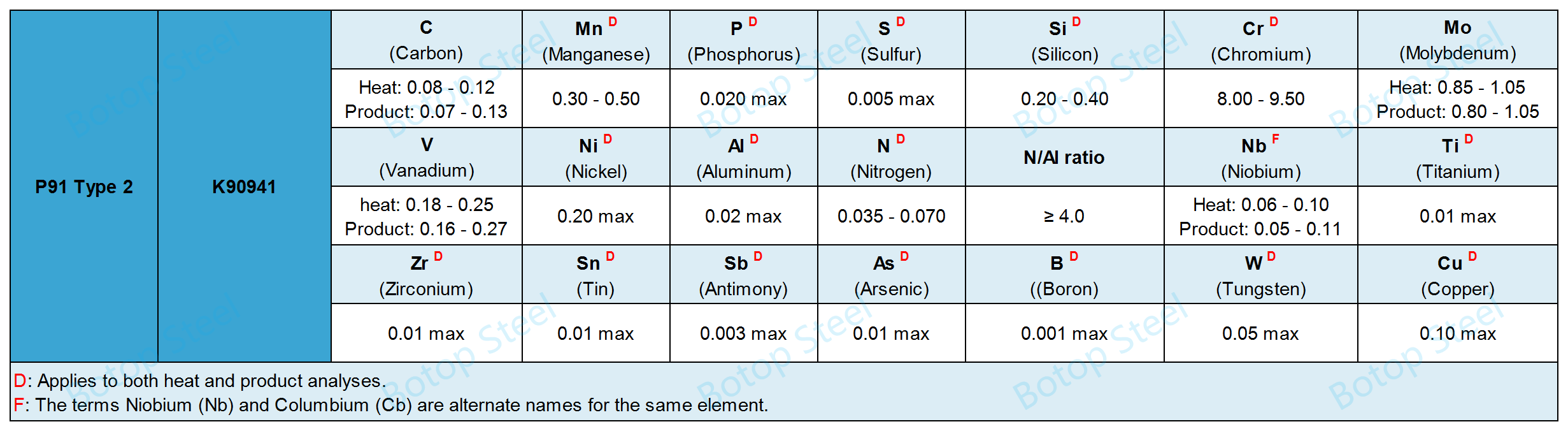

Ukwakheka kwamakhemikhali: Uma kuqhathaniswa noHlobo loku-1, ukwakheka kwamakhemikhali oHlobo 2 kuqine kakhulu futhi kuqukethe izakhi ze-alloying ukuze kunikeze ukumelana nokushisa nokugqwala okungcono.

Izinhlelo zokusebenza: Ngenxa yokwakheka kwamakhemikhali okuthuthukisiwe, Uhlobo 2 lufaneleka kakhulu amazinga okushisa aphakeme kakhulu noma izindawo ezibolayo, noma ezinsizeni lapho kudingeka khona amandla aphezulu nokuqina.

Ipayipi lensimbi le-ASTM A335 kufanele libeengenamthungo.

Inqubo yokukhiqiza engenamthungo ihlukaniswe yabahot finishfuthiukubanda.

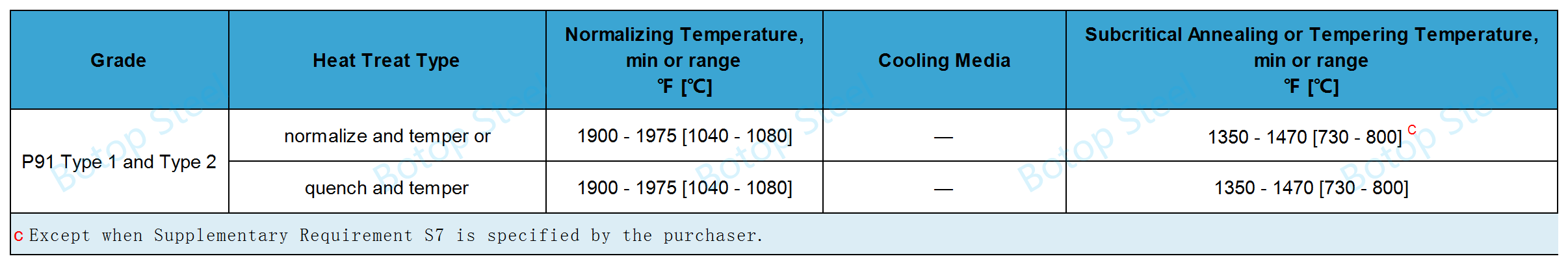

Ngezansi umdwebo wenqubo yokuqeda ukushisa.

Ikakhulukazi, i-P91, ipayipi lensimbi elinengxubevange ephezulu, elivame ukusetshenziswa ezindaweni ezinzima ngaphansi kwamazinga okushisa aphezulu kanye nezingcindezi, ipayipi lensimbi engenamthungo ligcizelelwa ngokufanayo futhi lingenziwa libe yizindonga eziqinile, ngaleyo ndlela kuqinisekiswe ukuphepha okuphezulu nokusebenza kahle kwezindleko. .

I-P91 Wonke amapayipi kufanele aphathwe ngokushisa ukuze kuthuthukiswe i-microstructure yepayipi, ithuthukise izakhiwo zayo zemishini, futhi ithuthukise ukumelana nokushisa okuphezulu nokucindezela.

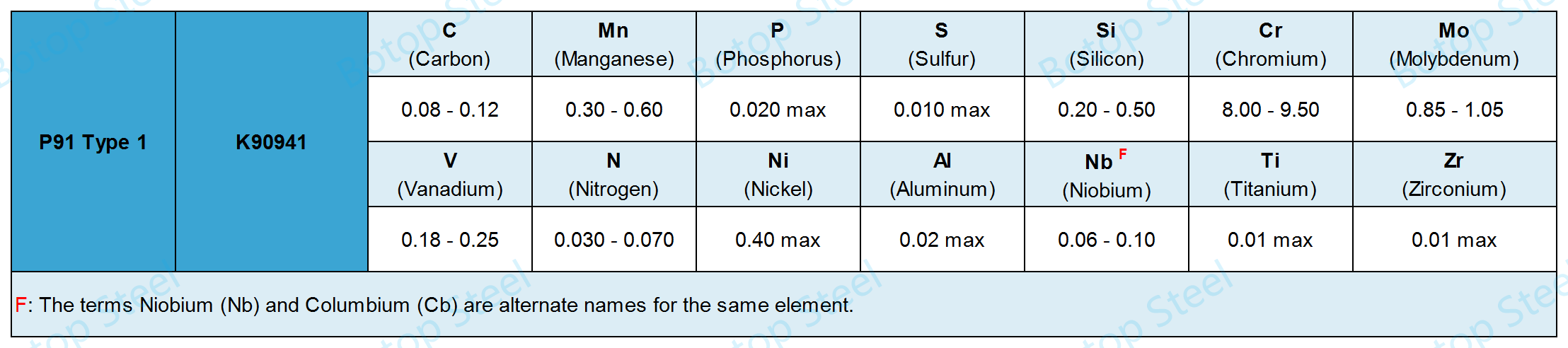

Izingxenye Zamakhemikhali ze-P91

Izingxenye Zamakhemikhali ze-P91 Uhlobo 2

Ngezithombe ezimbili ezingenhla, kulula ukubona umehluko phakathi kwezakhi zamakhemikhali zoHlobo 1 kanye Nohlobo 2 kanye nemikhawulo.

1. Impahla Eqinile

Ukuhlolwa kwe-tensile kuvame ukusetshenziselwa ukukala i-veza amandla, amandla aqinile, futhielongation yohlelo lokuhlola lwamapayipi ensimbi, futhi isetshenziswa kakhulu ezintweni ezibonakalayo zokuhlolwa.

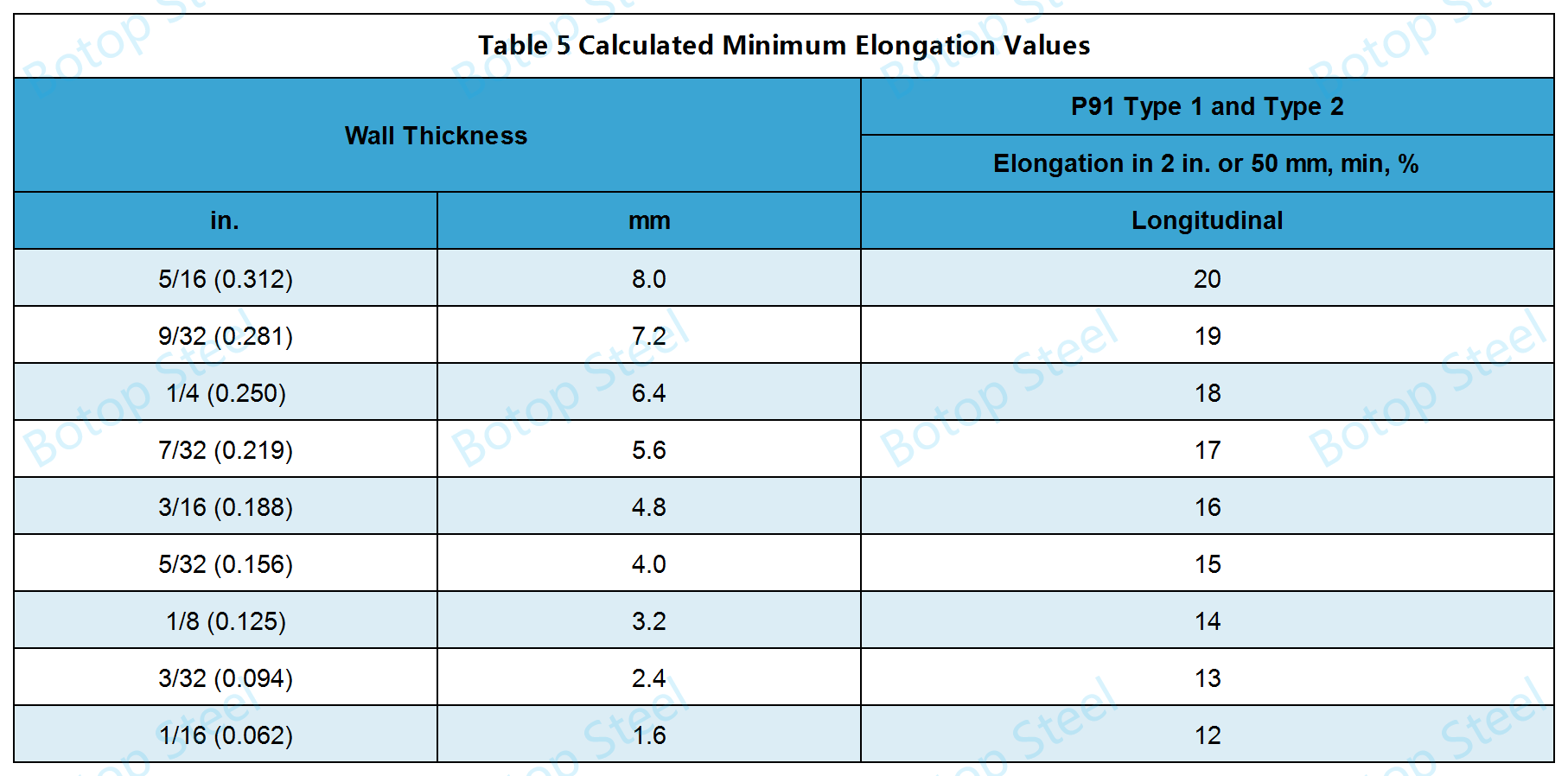

AIthebula lesi-5 linikeza amanani amancane abaliwe.

Lapho ubukhulu bodonga buphakathi kwamanani amabili angenhla, ubuncane bevelu yobude bunqunywa ifomula elandelayo:

I-Longitudinal, P91: E = 32t + 15.00 [E = 1.25t + 15.00]

kuphi:

E = ubude ku-2 in. noma 50 mm, %,

t = ukujiya kwangempela kwezibonelo, ku-. [mm].

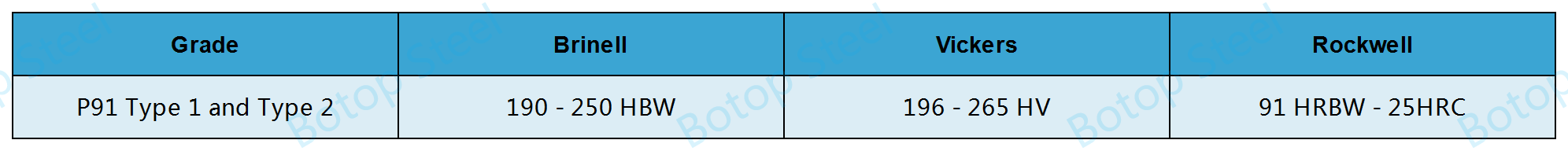

2. Ubulukhuni

Izinhlobonhlobo zezindlela zokuhlola ubulukhuni zingasetshenziswa, okuhlanganisa uVickers, uBrinell, noRockwell.

Ubukhulu bodonga <0.065 in. [1.7 mm]: Akukho ukuhlolwa kokuqina okudingekayo;

0.065 in. [1.7 mm] ≤ ukujiya kodonga <0.200 in. [5.1 mm]: Ukuhlolwa kokuqina kwe-Rockwell kuzosetshenziswa;

Ukuqina kwezindonga ≥ 0.200 in. [5.1 mm]: ukusetshenziswa kokuzithandela kokuhlolwa kokuqina kwe-Brinell noma ukuhlolwa kokuqina kwe-Rockwell.

Ukuhlolwa kokuqina kwe-Vickers kusebenza kuzo zonke izingqimba zamashubhu.Indlela yokuhlola yenziwa ngokuhambisana nezidingo ze-E92.

3. Ukuhlolwa Kokucaba

Ukuhlolwa kuzokwenziwa ngokuhambisana neSigaba 20 sezinga le-ASTM A999.

4. Bend Test

Goba ngo-180 ° ekamelweni lokushisa, akukho mifantu ezovela ngaphandle kwengxenye egobile.

Usayizi > NPS25 noma D/t ≥ 7.0: Ukuhlolwa kokugoba kufanele kwenziwe ngaphandle kokuhlolwa kokucaba.

5. P91 Izinhlelo Zokulinga Ongazikhethela

Izinto zokuhlola ezilandelayo azizona izinto zokuhlola ezidingekayo, uma kunesidingo zinganqunywa ngokuxoxisana.

S1: Ukuhlaziywa Komkhiqizo

I-S3: Ukuhlolwa Kokucaba

I-S4: Isakhiwo Sensimbi kanye Nokuhlolwa Kwe-Etching

I-S5: Ama-Photomicrographs

I-S6: Ama-Photomicrographs Ezingcezu Ngamunye

I-S7: Okunye Ukwelashwa Kokushisa-Ibanga le-P91 Uhlobo 1 kanye Nohlobo 2

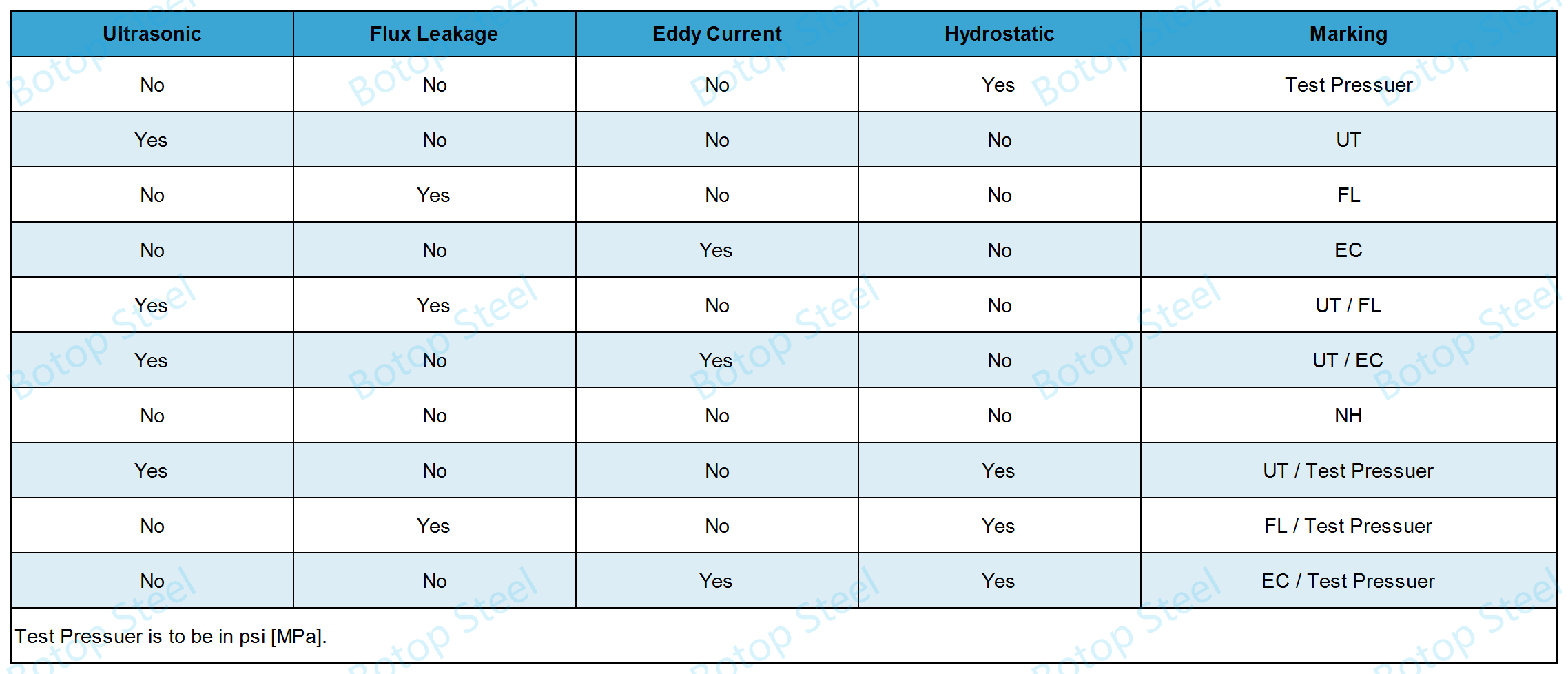

Ukuhlolwa kwamanzi e-P91 kuzohambisana nalezi zidingo ezilandelayo.

I-diameter yangaphandle ~10in.[250mm] nokuqina kodonga ≤ 0.75in.[19mm]: lokhu kufanele kube ukuhlolwa kwe-hydrostatic.

Abanye osayizi bokuhlolwa kukagesi okungangonakali.

Ngensimbi ye-ferritic alloy kanye namashubhu ensimbi engagqwali, udonga lungaphansi kwengcindezi engekho ngaphansiU-60% wamandla esivuno amancane ashiwo.

I-hydro test pressure izogcinwa okungenani 5sngaphandle kokuvuza noma okunye ukukhubazeka.

Umfutho we-hydraulicingabalwa kusetshenziswa ifomula:

P = 2St/D

P= ingcindezi yokuhlola i-hydrostatic ku-psi [MPa];

S = ukucindezelwa kodonga lwamapayipi ku-psi noma [MPa];

t = ukujiya kodonga olucacisiwe, ukujiya kodonga okuzisholo ngokwenombolo yesheduli ye-ANSI eshiwo noma izikhathi ezingu-1.143 ubukhulu obuncane obubekiwe bodonga, in. [mm];

D = eshiwo ububanzi obungaphandle, ububanzi obungaphandle obuhambisana nosayizi wepayipi le-ANSI elishiwo, noma ububanzi bangaphandle obalwe ngokwengeza u-2t (njengoba kuchazwe ngenhla) kububanzi obushiwo bangaphakathi, ku-. [mm].

Ipayipi le-P91 lihlolwa ngendlela yokuhlola i-E213.Izinga le-E213 liphathelene ngokuyinhloko nokuhlolwa kwe-ultrasonic (UT).

Uma icaciswe ku-oda, ingabuye ihlolwe ngokwendlela yokuhlola i-E309 noma i-E570.

Izinga le-E309 livamise ukubhekana nokuhlolwa kwe-electromagnetic (eddy current), kuyilapho i-E570 iyindlela yokuhlola ehlanganisa ama-eddy array amanje.

Ukwehluka Okuvumelekile Kububanzi

Ukuze ipayipi oda ukubaububanzi bangaphakathi, ububanzi bangaphakathi akufanele buhluke ngaphezu kuka-±1% ukusuka kububanzi obushiwo bangaphakathi.

Izinguquko Ezivumelekile Ebugqileni Bodonga

Izilinganiso zobukhulu bodonga zizokwenziwa kusetshenziswa ama-caliper asebenza ngomshini noma amathuluzi okuhlola alinganiswe ngokufanelekile anonemba okufanele.Esimeni sengxabano, ukulinganisa okunqunywe kusetshenziswa ama-caliper mechanical kuzosebenza.

Ubukhulu obuncane bodonga kanye nedayamitha yangaphandle ukuze kuhlolwe ukuthobela le mfuneko yepayipi eli-odwe yi-NPS [DN] kanye nenombolo yeshejuli kubonisiweI-ASME B36.10M.

Amaphutha

Ukungapheleli kobuso kuthathwa njengokungamaphutha uma kweqa u-12.5% wogqinsi oluncane lodonga noma kweqa ukujiya kodonga oluyisisekelo.

Ukungapheleli

Izimpawu zemishini, imihuzuko, nemigodi, noma yikuphi ukungapheleli kwakho kujule kuno-1/16 in. [1.6 mm].

Amamaki nama-abrasions achazwa ngokuthi ama-cable mark, ama-dinges, ama-guide mark, ama-roll mark, ama-ball scratches, amaphuzu, ama-die marks, nokunye okunjalo.

Lungisa

Amaphutha angase asuswe ngokugaya, inqobo nje uma ukujiya kodonga olusele abukho ngaphansi kobukhulu obuncane bodonga.

Ukulungisa kungenziwa futhi ngokushisela kodwa kufanele kuhambisane nezidingo ezifanele ze-A999.

Zonke izinsimbi zokulungisa ku-P91 zizokwenziwa ngenye yezinqubo zokushisela ezilandelayo nezinto ezisetshenziswayo: SMAW, A5.5/A5.5M E90XX-B9:SAW, A5.23/A5.23M EB9 + i-neutral flux;I-GTAW, A5.28/A5.28M ER90S-B9;kanye ne-FCAW A5.29/A5.29M E91TI-B9.Ukwengeza, isamba sokuqukethwe kwe-Ni+Mn kwazo zonke izinto ezisetshenziswayo zokushisela ezisetshenziselwa ukushisela ukulungiswa kwe-P91 Uhlobo 1 noHlobo lwe-2 ngeke lidlule u-1.0%.

Ipayipi le-P91 kufanele liphathwe ngokushisisa ku-1350-1470 °F [730-800°C] ngemva kokulungiswa kokushisela.

Indawo yangaphandle yepayipi yensimbi ehloliwe kufanele ibe nezinto ezilandelayo:

Igama lomkhiqizi noma uphawu lokuhweba;inombolo ejwayelekile;ibanga;ubude nophawu olwengeziwe "S".

Izimpawu zokucindezela kwe-hydrostatic kanye nokuhlola okungabhubhisi kuthebula elingezansi kufanele nakho kufakwe.

Uma ipayipi lilungiswa ngokushisela, lizomakwa "WR".

p91 Uhlobo (Uhlobo 1 noma Uhlobo 2) kufanele lukhonjiswe.

I-EN 10216-2: X10CrMoVNb9-1 noma 1.4903;

I-JIS G 3462: STPA 28;

I-GB/T 5310: 10Cr9Mo1VNb;

Lokhu okulingana kusondele kakhulu ekwakhiweni kwamakhemikhali nasezimpahleni zokuwumshini ku-ASTM A335 P91.

Izinto ezibonakalayol: I-ASTM A335 P91 ipayipi yensimbi engenamthungo;

OD: 1/8"- 24";

WT: ngokuvumelana neI-ASME B36.10izidingo;

Isheduli: SCH10, SCH20, SCH30,I-SCH40, SCH60,I-SCH80, SCH100, SCH120, SCH140 kanye ne-SCH160;

Ukuhlonza:I-STD (ejwayelekile), i-XS (iqine ngokwedlulele), noma i-XXS (i-double extra-strong);

Ukwenza ngokwezifiso: Amasayizi amapayipi angajwayelekile nawo ayatholakala, osayizi abenziwe ngokwezifiso bayatholakala uma ucelwa;

Ubude: Ubude obuqondile nobungahleliwe;

Isitifiketi se-IBR: Singaxhumana nenhlangano yokuhlola yenkampani yangaphandle ukuze sithole isitifiketi se-IBR ngokwezidingo zakho, izinhlangano zethu zokuhlola ukubambisana yi-BV, SGS, TUV, njll.;

Qeda: Isiphetho esiyisicaba, isiphetho sepayipi esibeveled, noma esiyinhlanganisela;

Ubuso: Ipayipi elikhanyayo, upende, nokunye ukuvikeleka kwesikhashana, ukususwa nokugqwala, uthayela nokufakwa ngepulasitiki, nokunye ukuvikela isikhathi eside;

Ukupakisha: Ikesi lezinkuni, ibhande lensimbi noma ukupakisha ucingo lwensimbi, ipulasitiki noma isivikeli sepayipi lensimbi, njll.