I-ASTM A335 P11ipayipi lensimbi iyipayipi yensimbi engenamthungo ye-ferritic ephansi ye-alloy yesevisi yezinga lokushisa eliphezulu, ukuqokwa kwe-UNS K11597.

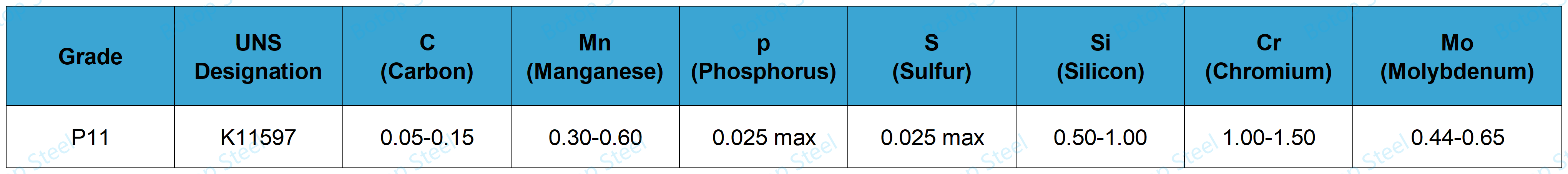

I-P11 ingxubevange ye-chromium-molybdenum enokuqukethwe kwe-chromium okungu-1.00-1.50% kanye nokuqukethwe kwe-molybdenum okungu-0.44-0.65%.

Ivamise ukusetshenziswa kuma-boilers, ama-superheaters, nezishintshisi zokushisa eziteshini zikagesi nasezitshalweni zamakhemikhali.

Izidingo zobuchwepheshe zeI-ASME SA335futhiI-ASTM A335ziyefana, ngakho-ke ukuze kube lula ukwethula, sizosebenzisa i-"ASTM A335" ukubhekisela kulawa mazinga amabili.

Izinto ezibonakalayol: I-ASTM A335 P11 ipayipi yensimbi engenamthungo;

OD: 1/8"- 24";

WT: ngokuvumelana neI-ASME B36.10izidingo;

Isheduli: SCH10, SCH20, SCH30,I-SCH40, SCH60,I-SCH80, SCH100, SCH120, SCH140 kanye ne-SCH160;

Ukuhlonza: STD, XS, XXS;

Ukwenza ngokwezifiso: Amasayizi amapayipi angajwayelekile nawo ayatholakala, osayizi abenziwe ngokwezifiso bayatholakala uma ucelwa;

Ubude: Ubude obuqondile nobungahleliwe;

Isitifiketi se-IBR: Singaxhumana nenhlangano yokuhlola yenkampani yangaphandle ukuze sithole isitifiketi se-IBR ngokwezidingo zakho, izinhlangano zethu zokuhlola ukubambisana yi-BV, SGS, TUV, njll.;

Qeda: Isiphetho esiyisicaba, isiphetho sepayipi esibeveled, noma esiyinhlanganisela;

Ubuso: Ipayipi elikhanyayo, upende, nokunye ukuvikeleka kwesikhashana, ukususwa nokugqwala, uthayela nokufakwa ngepulasitiki, nokunye ukuvikela isikhathi eside;

Ukupakisha: Ikesi lezinkuni, ibhande lensimbi noma ukupakisha ucingo lwensimbi, ipulasitiki noma isivikeli sepayipi lensimbi, njll.

Ngaphandle uma kucaciswe ngenye indlela ku-A335, izinto ezinikezwe ngaphansi kwalokhu kushiwo zizohambisana nezidingo ezisebenzayo zohlelo lwamanje lwe-Specification.I-A999/A999M.

Ipayipi lensimbi le-ASTM A335 kufanele libeengenamthungo.Amashubhu ensimbi angenamthungo anikeza ukwethembeka okukhulu nokufana lapho engaphansi kwengcindezi ephezulu nezimo zokushisa.

I-Seamless ingahlukaniswa ngokuqondile njengokudonswa okubandayo nokushisayo kuqediwe, kuye ngohlelo oluthile nosayizi.

Umdwebo obandayo uvame ukusetshenziselwa amadayimitha amancane noma amashubhu adinga ukunemba okuphezulu kanye nekhwalithi enhle yendawo.Ukuqedwa okushisayo kuvame ukusetshenziselwa ukukhiqiza amapayipi amakhulu ensimbi aqondile nawugqinsi.

Ngezansi ishadi eligelezayo lenqubo yokukhiqiza yamapayipi ensimbi angenamthungo aphelile ngokushisa.

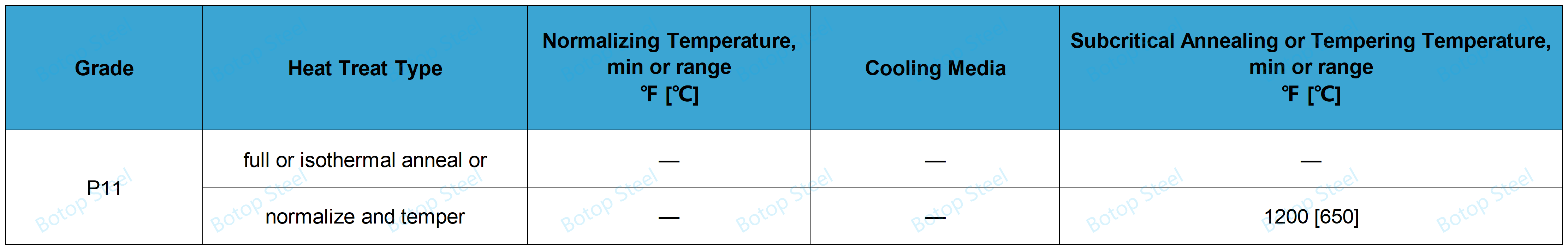

Ukwelashwa kokushisisa kwezinto ze-P11 kungase kugcwale noma kufakwe i-isothermal annealing noma ukushisa ngemva kokujwayelekile, futhi lapho kujwayelekile futhi kushisa, izinga lokushisa lokushisa kufanele okungenani libe ngu-1200 ° F (650 ° C).

Kusukela ekwakhiweni kwamakhemikhali, singakubona kalula lokhoI-P11 iyingxubevange ye-chromium-molybdenum.

Ama-alloys e-Chromium-molybdenum yikilasi lezinsimbi ezine-chromium (Cr) ne-molybdenum (Mo) njengezici eziyinhloko zengxubevange.Ukwengezwa kwalezi zakhi kukhulisa kakhulu amandla, ubulukhuni, ukumelana nokugqoka, nokumelana nokugqwala kwensimbi.Emazingeni okushisa aphezulu, ama-alloys e-Cr-Mo ayakwazi ukugcina izakhiwo ezinhle zemishini kanye nesakhiwo esizinzile.

Cr: ithuthukisa ukumelana ne-oxidation nokumelana nokugqwala kwengxubevange, isiza ukwakha ifilimu ye-oxide enamandla, futhi ivikela izinto ezisetshenziswayo emithonjeni edlayo.

Mo: Ithuthukisa amandla we-alloy, ikakhulukazi emazingeni okushisa aphezulu, ithuthukisa ukumelana ne-creep, futhi ithuthukise amandla okushisa aphezulu wento.

1. Impahla Eqinile

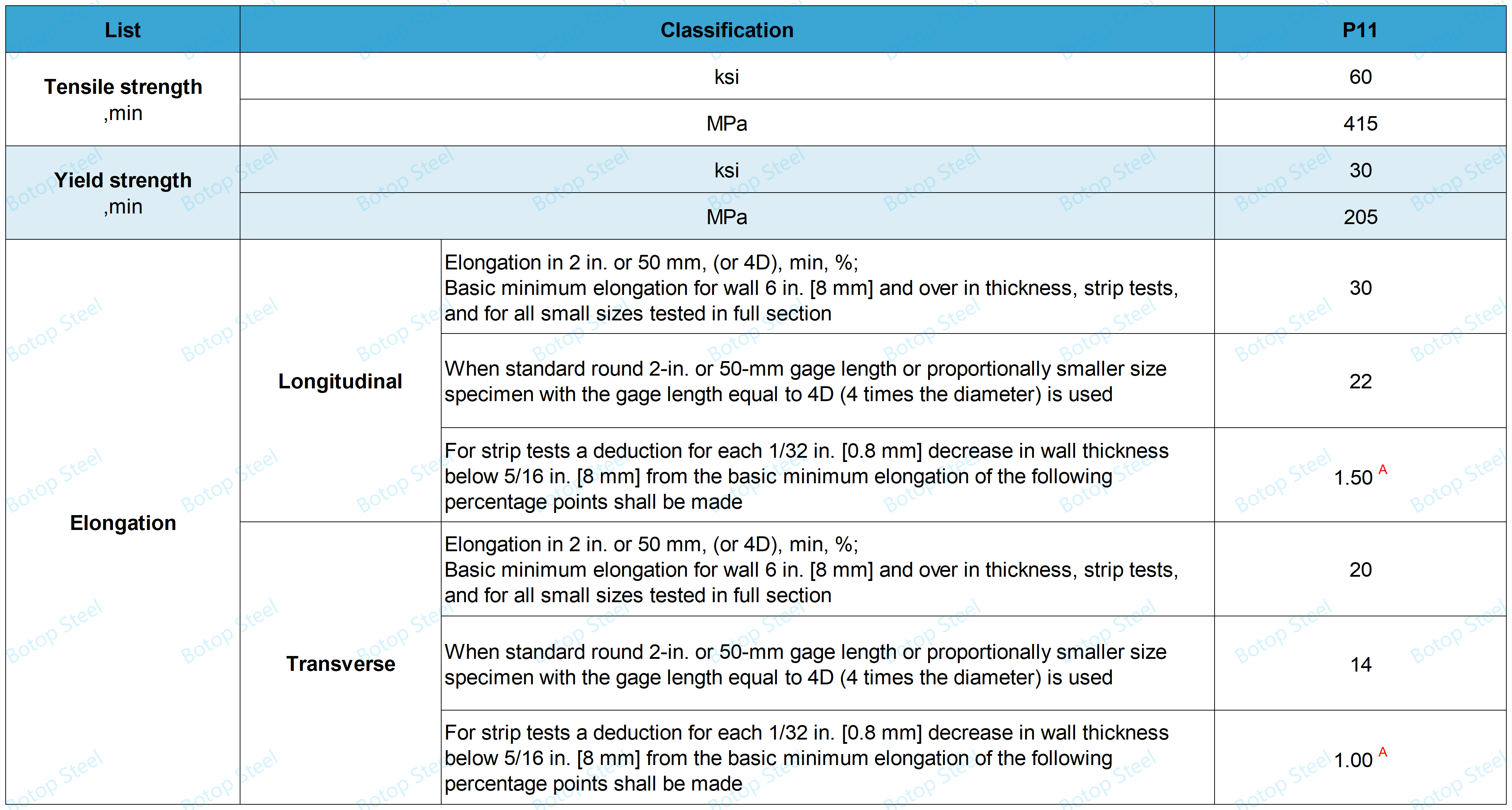

Ukuhlolwa kwe-tensile kuvame ukusetshenziselwa ukukala i-veza amandla, amandla aqinile, futhielongation yohlelo lokuhlola lwamapayipi ensimbi, futhi isetshenziswa kakhulu ezintweni ezibonakalayo zokuhlolwa.

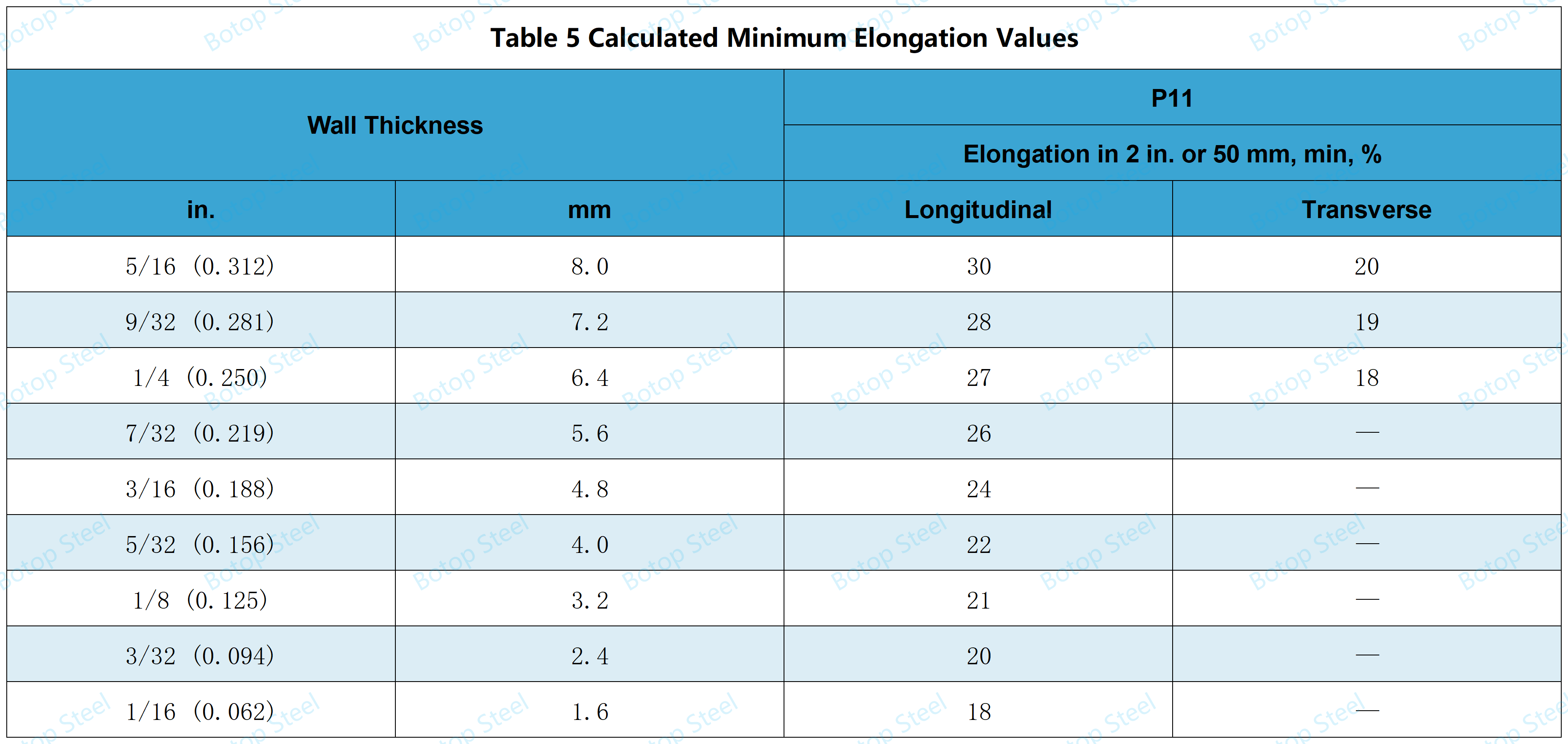

AIthebula lesi-5 linikeza amanani amancane abaliwe.

Lapho ubukhulu bodonga buphakathi kwamanani amabili angenhla, ubuncane bevelu yobude bunqunywa ifomula elandelayo:

I-Longitudinal, P11: E = 48t + 15.00 [E = 1.87t + 15.00]

Phenduka, P11: E = 32t + 15.00 [E = 1.25t + 15.00]

kuphi:

E = ubude ku-2 in. noma 50 mm, %,

t = ukujiya kwangempela kwezibonelo, ku-. [mm].

2. Ubulukhuni

Ipayipi leBanga le-P11 alidingi ukuhlolwa kokuqina.

Inani lobulukhuni bereferensi linikezwe ngezansi.

Isimo esifakiwe:

Ukuqina ngokuvamile kuphakathi kuka-150 no-200 HB.

Isimo esijwayelekile nesithambile:

Ukuqina busuka cishe ku-170 kuya ku-220 HB.

Isimo esiqinile nesithambile:

Ukuqina bungafinyelela ku-250 kuya ku-300 HB noma ngaphezulu, kuye ngezinga lokushisa elipholile nesikhathi.

3. Izinhlelo Zokulinga Ongazikhethela

Izinto zokuhlola ezilandelayo azizona izinto zokuhlola ezidingekayo, uma kunesidingo zinganqunywa ngokuxoxisana.

Ukuhlaziywa Komkhiqizo

Ukuhlola Ukucaba

Bend Test

Isakhiwo Sensimbi kanye Nokuhlolwa Kwe-Etching

Ama-Photomicrographs

Ama-photomicrographs wezingcezu ngazinye

I-P11 hydrotest izothobela lezi zidingo ezilandelayo.

I-diameter yangaphandle ~10in.[250mm] nokuqina kodonga ≤ 0.75in.[19mm]: lokhu kufanele kube ukuhlolwa kwe-hydrostatic.

Abanye osayizi bokuhlolwa kukagesi okungangonakali.

Izidingo ezilandelayo zokuhlolwa kwe-hydrostatic zihlanganiswa kusukela kuzidingo ze-ASTM A999:

Ngensimbi ye-ferritic alloy kanye namashubhu ensimbi engagqwali, udonga lungaphansi kwengcindezi engekho ngaphansiU-60% wamandla esivuno amancane ashiwo.

I-hydro test pressure izogcinwa okungenani 5sngaphandle kokuvuza noma okunye ukukhubazeka.

Umfutho we-hydraulicingabalwa kusetshenziswa ifomula:

P = 2St/D

P= ingcindezi yokuhlola i-hydrostatic ku-psi [MPa];

S = ukucindezelwa kodonga lwamapayipi ku-psi noma [MPa];

t = ukujiya kodonga olucacisiwe, ukujiya kodonga okuzisholo ngokwenombolo yesheduli ye-ANSI eshiwo noma izikhathi ezingu-1.143 ubukhulu obuncane obubekiwe bodonga, in. [mm];

D = eshiwo ububanzi obungaphandle, ububanzi obungaphandle obuhambisana nosayizi wepayipi le-ANSI elishiwo, noma ububanzi bangaphandle obalwe ngokwengeza u-2t (njengoba kuchazwe ngenhla) kububanzi obushiwo bangaphakathi, ku-. [mm].

Ipayipi ngalinye kufanele lihlolwe ngendlela yokuhlola engacekeli phansi ngokuhambisana ne-PracticeE213, ZijwayezeE309, noma ZijwayezeE570.

Ukwehluka Okuvumelekile Kububanzi

Ukuze ipayipi oda ukubaububanzi bangaphakathi, ububanzi bangaphakathi akufanele buhluke ngaphezu kuka-±1% ukusuka kububanzi obushiwo bangaphakathi.

Izinguquko Ezivumelekile Ebugqileni Bodonga

Izilinganiso zobukhulu bodonga zizokwenziwa kusetshenziswa ama-caliper asebenza ngomshini noma amathuluzi okuhlola alinganiswe ngokufanelekile anonemba okufanele.Esimeni sengxabano, ukulinganisa okunqunywe kusetshenziswa ama-caliper mechanical kuzosebenza.

Ubukhulu obuncane bodonga kanye nedayamitha yangaphandle ukuze kuhlolwe ukuthobela le mfuneko yepayipi eli-odwe yi-NPS [DN] kanye nenombolo yeshejuli kubonisiweI-ASME B36.10M.

Ivamise ukusetshenziswa kuma-boilers, ama-superheaters, nezishintshisi zokushisa eziteshini zikagesi nasezitshalweni zamakhemikhali.

Ama-boilers: I-P11 isetshenziswa kabanzi ekwakhiweni kwama-boilers ngenxa yokumelana nokushisa okuphezulu nezingcindezi, ikakhulukazi ezigabeni ezingaphansi kokushisa okukhulu nezingcindezi.

I-Superheater: Isetshenziselwa ukukhulisa izinga lokushisa lesitimu ukuze kuthuthukiswe ukusebenza kahle kokushisa.i-p11 iqinisekisa ukuthi amandla nokuqina kwento kugcinwa ngisho nasemazingeni okushisa aphezulu.

Izishintshi zokushisa: I-P11 ithuthukisa ukugqwala nokumelana nezinga lokushisa eliphezulu kwezishintshisi zokushisa, ngaleyo ndlela ithuthukise ukwethembeka nokuphepha kwezinto zokusebenza.

Amapayipi amapayipi: Amasistimu wamapayipi ezitshalweni zamakhemikhali ngokuvamile adinga ukuthutha uketshezi olunezinga lokushisa eliphezulu noma isitimu.amandla aphezulu okushisa kanye nezakhiwo ezinhle zemishini ye-P11 ziyenza ilungele lezi zinhlelo zokusebenza.

a) Ilingana nani i-ASTM A335 P11?

GB/T 5310: 12CrMo;

I-DIN 17175: 10CrMo9-10 (1.7380);

I-EN 10216-2: 10CrMo9-10;

I-BS 3604: 10CrMo9-10;

I-JIS G3462: STPA23;

I-GOST 550-75: 12Kh1MF.

b)Ingabe i-P11 iyinsimbi ene-alloy ephansi?

Yebo, i-P11 iyinsimbi ephansi ye-alloy.

Insimbi yengxubevange ephansi iyingxubevange ye-iron-carbon okufakwe kuyo i-elementi eyodwa noma ngaphezulu ye-alloying (isb., i-chromium, i-molybdenum, i-nickel, njll.) enengqikithi yokuqukethwe kwe-alloying element ngokuvamile esukela ku-1 kuya ku-5 %.

c)Ayini amandla aqinile we-ASTM A335 P11?

Amandla amancane okudonsa angu-415 MPa [60 ksi].

d)Ayini amandla okukhiqiza we-ASTM A335 P11?

Amandla amancane okudonsa angu-205 MPa [30 ksi].

e) Uyini umkhawulo wezinga lokushisa we-ASTM A335 P11?

Ezindaweni ezine-oxidizing: Amazinga aphezulu okushisa esevisi ngokuvamile angaba ngu-593°C (1100°F).

Ezindaweni ezingenayo i-oxidizing: amazinga okushisa aphezulu esevisi acishe abe ngu-650°C (1200°F) angafinyelelwa.

f)Ingabe i-A335 P11 kazibuthe?

Inguzibuthe ezingeni lokushisa lekamelo.Lesi sakhiwo singase sibe usizo kwezinye izinhlelo zokusebenza, njengalapho impahla idingeka ukuze ihambisane nemishini yokuthola kazibuthe.

g)Iyini intengo ye-ASTM A335 P11?

Izintengo ziyahlukahluka ngemakethe, xhumana nathi ukuze uthole isilinganiso esinembile.