I-ASTM A335 P9, eyaziwa nangokuthi i-ASME SA335 P9, iyipayipi yensimbi engenamthungo ye-ferritic alloy yesevisi eshisa kakhuluI-UNS No. K90941.

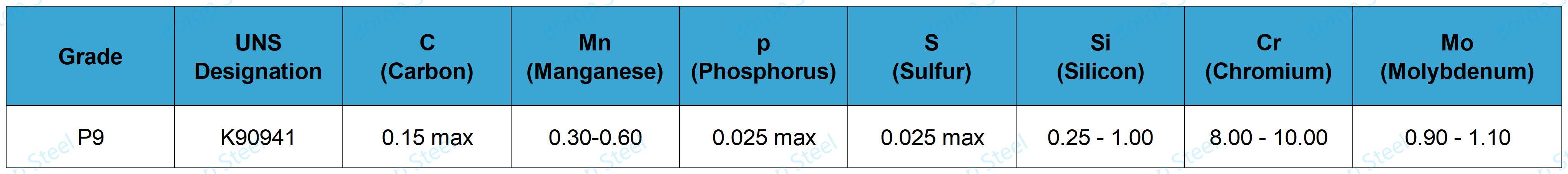

Izakhi ze-alloying ngokuyinhloko ziyi-chromium ne-molybdenum.Okuqukethwe kwe-chromium kusuka ku-8.00 - 10.00%, kuyilapho okuqukethwe kwe-molybdenum kusebangeni lika-0.90% - 1.10%.

P9inamandla amahle kakhulu futhi imelana nokugqwala okuhle ezindaweni ezishisa kakhulu futhi isetshenziswa kakhulu kuma-boilers, imishini ye-petrochemical, kanye neziteshi zikagesi lapho kudingeka khona izinga lokushisa eliphezulu kanye nezindawo ezinengcindezi ephezulu.

⇒ Indaba: ASTM A335 P9 / ASME SA335 P9 engenamthungo ingxubevange yensimbi ipayipi.

⇒Ububanzi bangaphandle: 1/8"-24".

⇒Ukujiya kodonga: Izidingo ze-ASME B36.10.

⇒Isheduli: SCH10, SCH20, SCH30, SCH40, SCH60, SCH80, SCH100, SCH120, SCH140 kanye ne-SCH160.

⇒Ukuhlonza: I-STD (okujwayelekile), i-XS (iqine ngokwedlulele), noma i-XXS (inamandla okuphindwe kabili).

⇒Ubude: Ubude obuqondile noma obungahleliwe.

⇒Ukwenza ngokwezifiso: Ububanzi obungajwayelekile obungaphandle, ukushuba kodonga, ubude, njll ngokuya ngezidingo.

⇒Ukufakwa: Singahlinzeka ngokugoba okufanayo, ama-flange agxiviza, neminye imikhiqizo esekela amapayipi ensimbi.

⇒Isitifiketi se-IBR: Isitifiketi se-IBR singanikezwa uma sidingeka.

⇒Qeda: Isiphetho esingenalutho, isiphetho se-beveled, noma isiphetho sepayipi esiyinhlanganisela.

⇒Ukupakisha: Ikesi lezinkuni, ibhande lensimbi noma ukupakisha ucingo lwensimbi, ipulasitiki noma isivikeli sepayipi lensimbi.

⇒Ezokuthutha: ngezolwandle noma ngezindiza.

Ipayipi lensimbi le-ASTM A335 kumele lingabi namthungo.

Ipayipi lensimbi elingenamthungo liyipayipi lensimbi elingenawo amashisela kulo lonke.

Njengoba ipayipi lensimbi engenamthungo lingenayo imithungo eshiselwe esakhiweni salo, ligwema izingozi zokuphepha ezingase zihlotshaniswe nezindaba zekhwalithi yokushisela.Lesi sici sivumela ipayipi elingenamthungo ukuthi limelane nezingcindezi eziphakeme, futhi isakhiwo sayo sangaphakathi esilinganayo siqinisekisa ubuqotho nokuphepha kwepayipi ezindaweni ezicindezelayo.

Ngaphezu kwalokho, ukuthembeka kweshubhu ye-ASTM A335 kuthuthukiswa ngokungezwa kwezakhi ezithile ze-alloying zezinga lokushisa eliphezulu nezimo zokucindezela okukhulu.

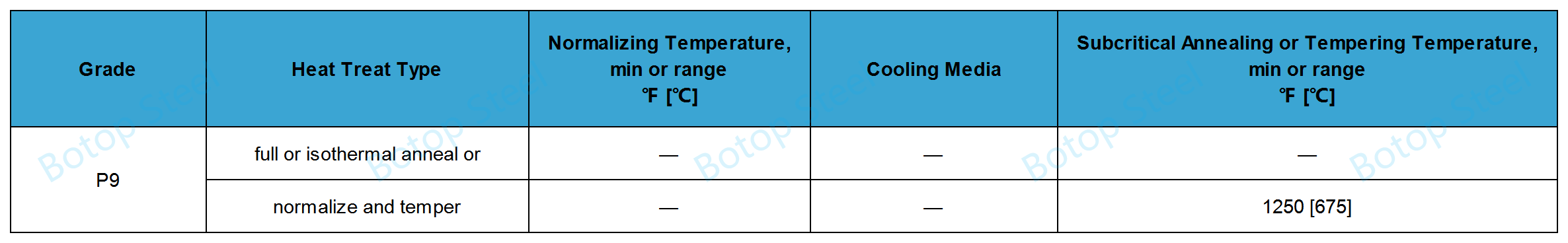

Izinhlobo zokwelapha ukushisa ezitholakalayo zezinto ze-P9 zifaka phakathi ukucwiliswa okugcwele noma kwe-isothermal, kanye nokujwayelekile kanye nokushisa.Inqubo yokwejwayelekile kanye neyokushisa inezinga lokushisa elingu-1250°F [675°C].

Izakhi eziyinhloko ze-alloying ze-P9 ziyiCrfuthiMo, okungama-alloys e-chromium-molybdenum.

I-Cr (Chromium): Njengengxenye eyinhloko ye-alloy, i-Cr inikeza amandla amahle kakhulu okushisa okuphezulu nokumelana ne-oxidation.Yakha ifilimu eqinile ye-chromium oxide ebusweni bensimbi, okwandisa ukuzinza nokumelana nokubola kwepayipi emazingeni okushisa aphezulu.

I-Mo (Molybdenum): Ukwengezwa kwe-Mo kuthuthukisa kakhulu amandla nokuqina kwama-alloys, ikakhulukazi ezindaweni ezinezinga lokushisa eliphezulu.I-Mo iphinde isize ukuthuthukisa amandla okukhasa kwento, okungukuthi ikhono lokumelana nokuguquka ngaphansi kokuchayeka kokushisa isikhathi eside.

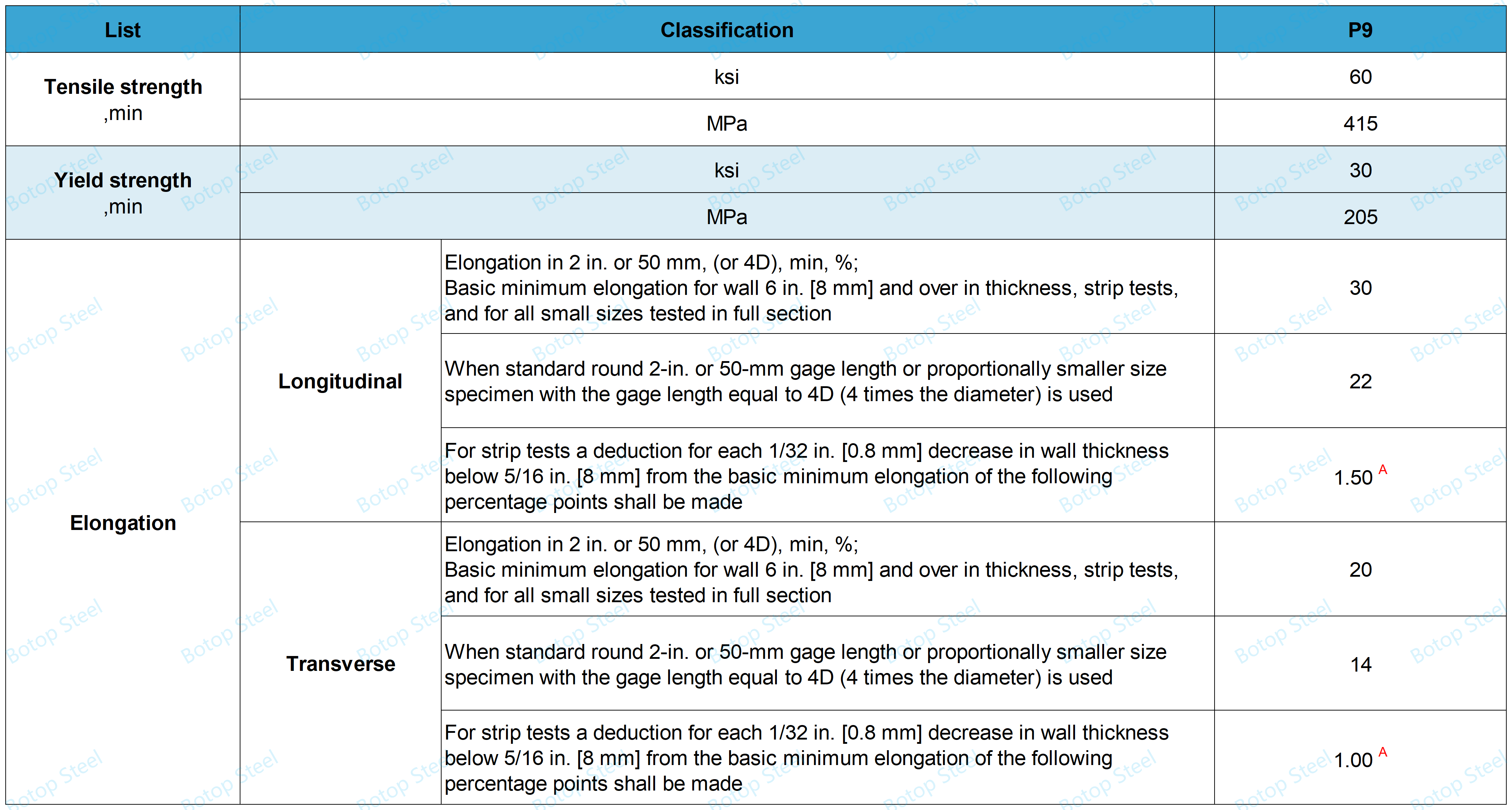

I-Tensile Properties

P5, P5b, P5c, P9,P11, P15, P21, kanye ne-P22: Amandla okuqina kanye nesivuno ayafana.

I-P1, i-P2, i-P5, i-P5b, i-P5c, i-P9, i-P11, i-P12, i-P15, i-P21, ne-P22: Ubude obufanayo.

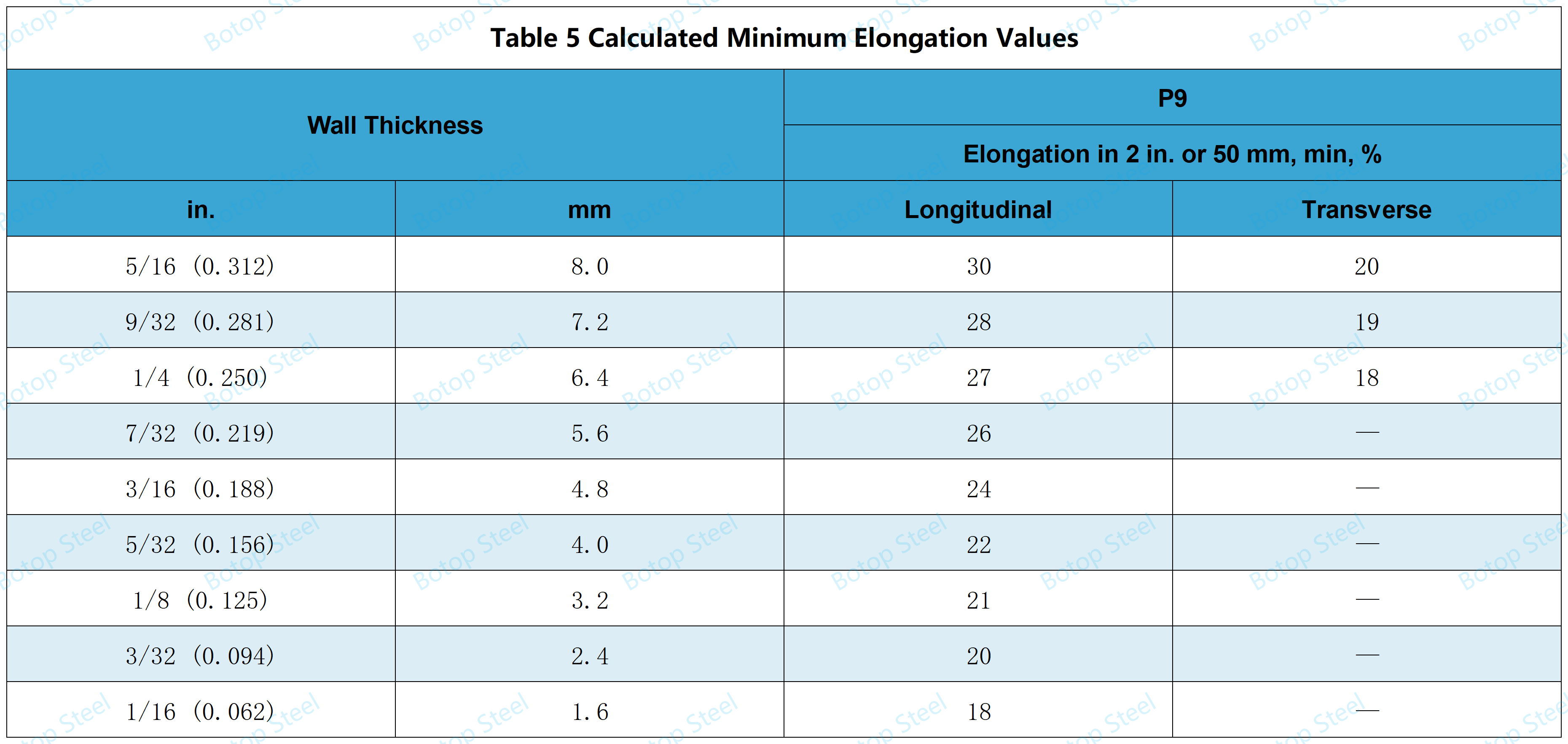

AIthebula lesi-5 linikeza amanani amancane abaliwe.

Lapho ubukhulu bodonga buphakathi kwamanani amabili angenhla, ubuncane bevelu yobude bunqunywa ifomula elandelayo:

I-Longitudinal, P9: E = 48t + 15.00 [E = 1.87t + 15.00]

Phenduka, P9: E = 32t + 15.00 [E = 1.25t + 15.00]

kuphi:

E = ubude ku-2 in. noma 50 mm, %,

t = ukujiya kwangempela kwezibonelo, ku-. [mm].

Ukuqina

I-P9 ayidingi ukuhlolwa kokuqina.

I-P1, i-P2, i-P5, i-P5b, i-P5c, i-P9, i-P11, i-P12, i-P15, i-P21, i-P22, ne-P921: Akukho ukuhlolwa kokuqina okudingekayo.

Lapho ububanzi bangaphandle > ama-intshi angu-10. [250 mm] nokuqina kodonga ≤ 0.75 in. [19 mm], konke kuzohlolwa nge-hydrostatically.

Ingcindezi yokuhlola ingabalwa kusetshenziswa isibalo esilandelayo.

P = 2St/D

P= ingcindezi yokuhlola i-hydrostatic ku-psi [MPa];

S= ukucindezelwa kodonga lwamapayipi ku-psi noma [MPa];

t= ukujiya kodonga olucacisiwe, ukujiya kodonga okulinganiselwe ngokwenombolo yesheduli ye-ANSI eshiwo noma izikhathi ezingu-1.143 ubukhulu obuncane obubekiwe bodonga, ngo. [mm];

D= kucaciswe ububanzi obungaphandle, ububanzi obungaphandle obuhambisana nosayizi wepayipi le-ANSI elishiwo, noma ububanzi bangaphandle obalwe ngokwengeza u-2t (njengoba kuchazwe ngenhla) kububanzi obushiwo bangaphakathi, ku-. [mm].

Isikhathi sokuhlola: gcina okungenani ama-5, akukho ukuvuza.

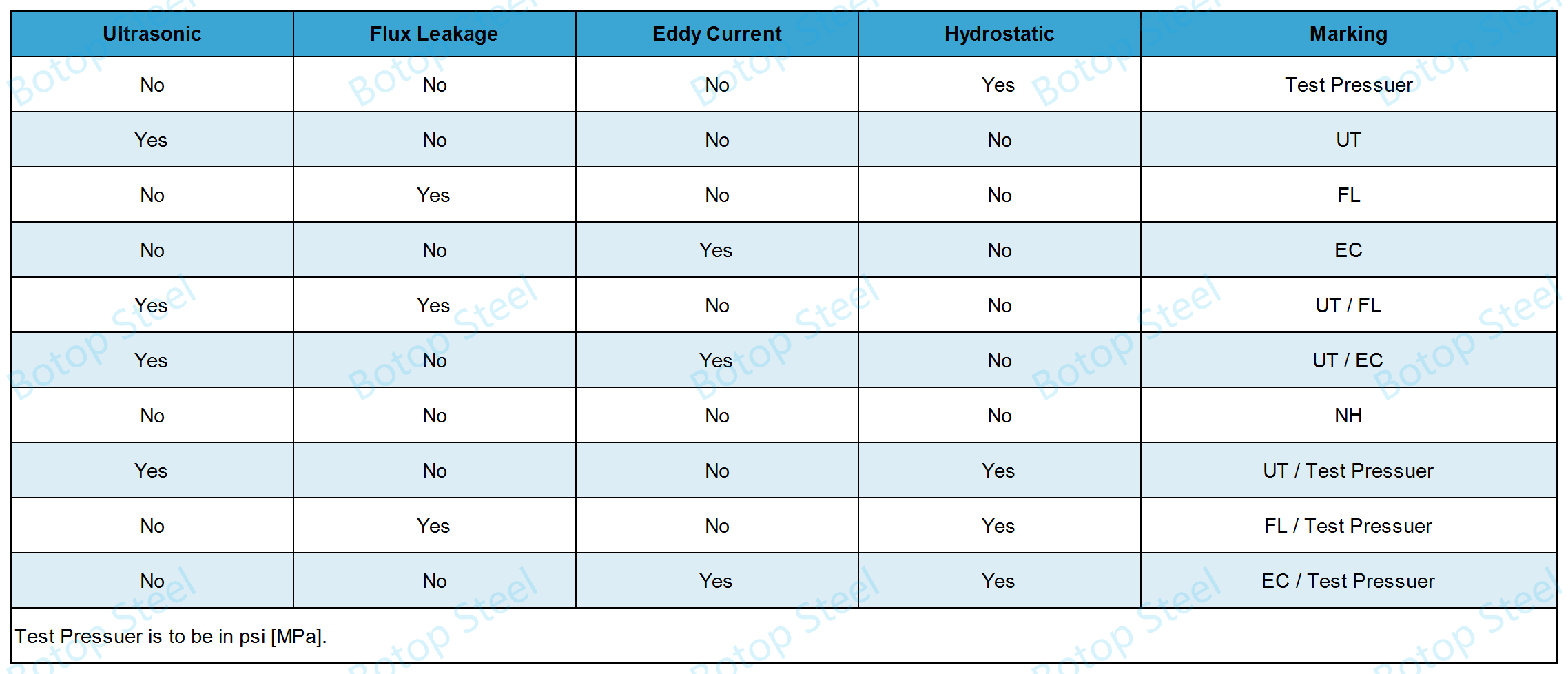

Uma ipayipi akufanele lihlolwe ngamanzi, ukuhlolwa okungabhubhisi kuzokwenziwa epayipini ngalinye ukuze kutholwe amaphutha.

Ukuhlolwa okungabhubhisi kwempahla ye-P9 kufanele kwenziwe ngenye yezindlelaE213, E309 or E570.

E213: Prakthiza Ukuhlolwa kwe-Ultrasonic ye-Metal Pipe kanye ne-Tubing;

E309: Zijwayeze Ukuhlolwa Kwamanje kwe-Eddy Kwemikhiqizo Yensimbi Yeshubhu Ukusebenzisa Ukugcwala Kwezibuthe;

E570: Prakthiza Ukuhlolwa Kwe-Flux Ukuvuza Kwemikhiqizo Ye-Ferromagnetic Steel Tubular;

Ukwehluka Okuvumelekile Kububanzi

Ukuchezuka kodayamitha kungahlukaniswa ngokuya ku-1. ngokusekelwe kububanzi obungaphakathi noma 2. ngokusekelwe kububanzi obujwayelekile noma obungaphandle.

1. Ububanzi bangaphakathi: ±1%.

2. I-NPS [DN] noma i-diameter yangaphandle: Lokhu kuvumelana nokuchezuka okuvumelekile kuthebula elingezansi.

Izinguquko Ezivumelekile Ebugqileni Bodonga

Ubukhulu bodonga lwamapayipi kunoma iyiphi indawo akumele budlule ukubekezelelana okucacisiwe.

Ubukhulu obuncane bodonga kanye nedayamitha yangaphandle ukuze kuhlolwe ukuhambisana nale mfuneko yepayipi eli-odwe yi-NPS [DN] kanye nenombolo yeshejuli ibonisiweI-ASME B36.10M.

Okuqukethwe kokumaka: Igama lomkhiqizi noma uphawu lokuhweba;inombolo ejwayelekile;ibanga;ubude nophawu olwengeziwe "S".

Izimpawu zokucindezela kwe-hydrostatic kanye nokuhlola okungabhubhisi kuthebula elingezansi kufanele nakho kufakwe.

Ukumaka indawo: Ukumaka kufanele kuqale cishe amayintshi angu-12 (300 mm) ukusuka ekugcineni kwepayipi.

Kumapayipi afika ku-NPS 2 noma ngaphansi kuka-3 ft (1 m) ubude, ukumaka ulwazi kungase kunamathiselwe kuthegi.

Ipayipi lensimbi le-ASTM A335 P9 lisetshenziswa kabanzi kuma-boilers, eziteshini zamandla kagesi we-petrochemical, njll., adinga ukumelana nokushisa okuphezulu nokucindezela okukhulu ngenxa yokushisa kwawo okuphezulu nokumelana nokucindezela okuphezulu.

Ama-boilers: Ikakhulukazi ekufakweni kwepayipi lesitimu okuyinhloko kanye nokufaka kabusha kwamapayipi amabhoyela abaluleke kakhulu kanye namazinga okushisa aphezulu kakhulu nezingcindezi.

Imishini ye-Petrochemical: Okufana namapayipi e-cracker kanye namapayipi asezingeni eliphezulu, aphatha izihwamuko ezishisa kakhulu namakhemikhali, adinga izinto ezinokushisa okuhle kakhulu nokumelana nokugqwala.

Iziteshi zikagesi: Okwamapayipi amakhulu esitimu kanye nezifudumezi ezinomfutho ophezulu, kanye namapayipi ka-turbine angaphakathi ukuze abhekane nezikhathi ezinde zokushisa okuphezulu nokucindezela.

I-P9 Materials inamabanga azo ajwayelekile ezinhlelweni ezijwayelekile zikazwelonke.

I-EN 10216-2: 10CrMo9-10;

I-GB/T 5310: 12Cr2Mo;

I-JIS G3462: STBA 26;

ISO 9329: 12CrMo195;

I-GOST 550: 12ChM;

Ngaphambi kokukhetha noma iyiphi into efanayo, kunconywa ukuthi ukuqhathanisa okunemininingwane yokusebenza nokuhlolwa kwenziwe ukuze kuqinisekiswe ukuthi okunye okubalulekile kuzohlangabezana nezidingo zomklamo wokuqala.

Kusukela yasungulwa ngo-2014,Insimbi ye-Botopisibe ngumphakeli ohamba phambili wepayipi lensimbi ye-carbon eNyakatho yeChina, elaziwa ngomsebenzi omuhle kakhulu, imikhiqizo yekhwalithi ephezulu, nezixazululo ezibanzi.

Le nkampani inikeza izinhlobonhlobo zamapayipi ensimbi ye-carbon nemikhiqizo ehlobene, okuhlanganisa ipayipi lensimbi engenamthungo, i-ERW, i-LSAW, ne-SSAW, kanye nohlu oluphelele lokufakwa kwamapayipi nama-flange.Imikhiqizo yayo ekhethekile ihlanganisa ama-alloys asezingeni eliphezulu kanye nezinsimbi ezingenasici ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene wamapayipi.

Sicela uzizwe ukhululekile ukusithinta uma unezidingo noma imibuzo mayelana namashubhu ensimbi.Sibheke ngabomvu ukuthola ulwazi lwakho futhi sibheke ngabomvu ukukusiza.