I-ASTM A500 iyishubhu yesakhiwo se-carbon steel esakhiwe ngendlela ebandayo esakhiwe ngendlela ebandayo yamabhuloho ashiselwe, acijile, noma abhawudiwe kanye nezakhiwo nezinhloso zesakhiwo esijwayelekile.

Ibanga Biyishubhu lesakhiwo sensimbi ye-carbon epholile elakheke ngezindlela ezihlukahlukene elinamandla angekho ngaphansi kuka-315 MPa [46,000 psi] namandla aqinile angekho ngaphansi kwama-MPa angu-400 [58,000], asetshenziswa ezinhlobonhlobo zezakhiwo nemishini ehlala isikhathi eside ngenxa yokusimama kwayo okuhle nokuhleleka kwayo.

I-ASTM A500 ihlukanisa ipayipi lensimbi ngamabanga amathathu,ibanga B,ibanga C, kanye nebanga D.

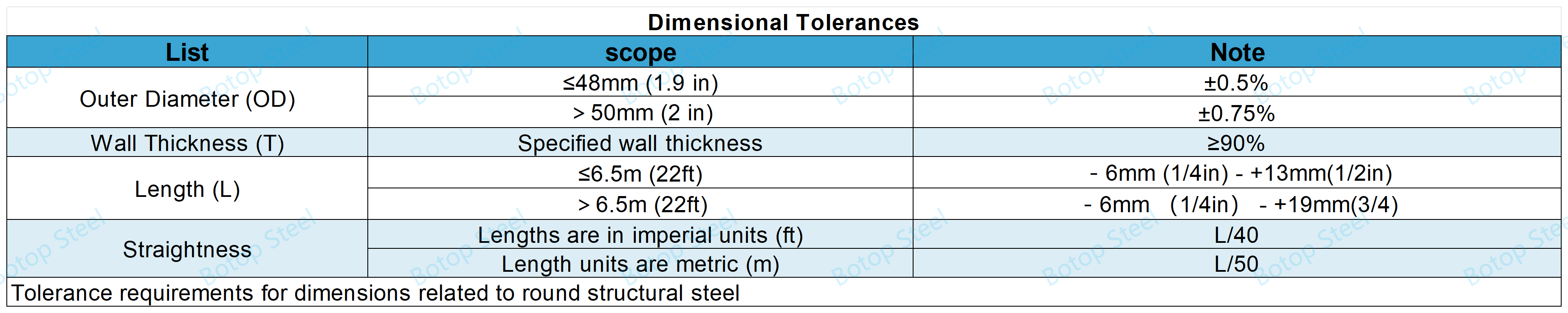

Okwamashubhu aneububanzi obungaphandle ≤ 2235mm [88in]futhiukujiya kodonga ≤ 25.4mm [1in].

Kodwa-ke, uma inqubo yokushisela i-ERW isetshenziswa, amapayipi kuphela anobubanzi obuyi-660 mm nobukhulu bodonga obungu-20 mm angenziwa.

Uma ufuna ukuthenga ipayipi enobukhulu obukhulu bodonga lobubanzi, ungakhetha ukusebenzisa inqubo ye-SAW welding.

I-CHS: Izingxenye eziyindilinga ezingenalutho.

I-RHS: Izingxenye eziyisikwele noma eziwunxande.

I-EHS: Izingxenye eziyizimbotshana eziyi-elliptical.

Insimbi izokwenziwa ngenqubo eyodwa noma ngaphezulu yalezi ezilandelayo:i-oksijeni eyisisekelo noma isithando somlilo sikagesi.

Inqubo Ye-Oxygen Eyisisekelo: Lena indlela yesimanje esheshayo yokukhiqiza insimbi, enciphisa okuqukethwe kwekhabhoni ngokufutha umoya-mpilo ensimbi yengulube encibilikisiwe kuyilapho ikhipha ezinye izakhi ezingadingeki njengesulfure ne-phosphorus. Ifanele ukukhiqizwa okusheshayo kwenani elikhulu lensimbi.

Inqubo yesithando somlilo sikagesi: Inqubo yesithando somlilo sikagesi isebenzisa i-arc kagesi enezinga eliphezulu lokushisa ukuze incibilike izinsalela futhi inciphise ngokuqondile insimbi, futhi iwusizo ngokukhethekile ekukhiqizeni amamaki akhethekile nokulawula ukuqanjwa kwe-alloy, kanye nokukhiqizwa kwenqwaba encane.

Amashubhu azokwenziwa yi-i-electric-resistance-welded (ERW)inqubo.

Ipayipi le-ERW inqubo yokwenza i-weld ngokugoqa insimbi ibe isilinda futhi ifake ukumelana nokucindezela ngobude bayo.

Amashubhu eBanga B angancishiswa noma anciphise ukucindezeleka.

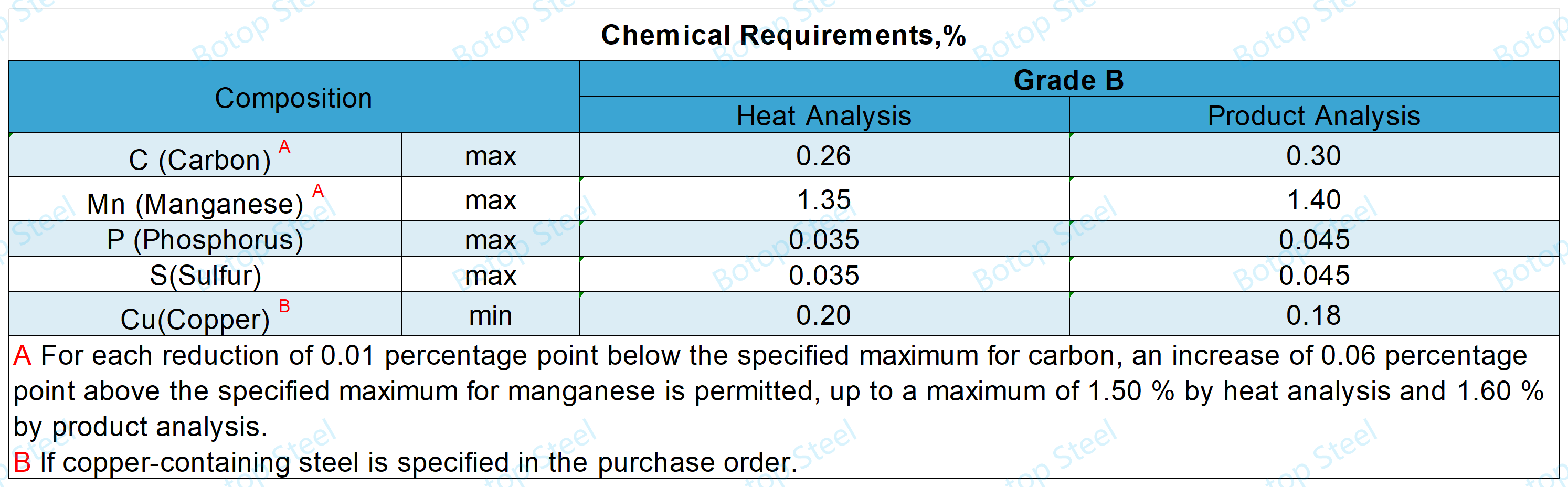

Ukwakheka kwamakhemikhali ensimbi ye-ASTM A500 yeBanga B kufaka phakathi amanani amaphakathi ekhabhoni ne-manganese ukuze kuqinisekiswe izakhiwo ezinhle zemishini kanye nokushisela. Ngesikhathi esifanayo, amazinga e-phosphorus nesulfure alawulwa ngokuqinile ukuze agweme i-embrittlement, futhi izengezo zethusi ezilinganiselwe zithuthukisa ukumelana nokugqwala.

Lezi zakhiwo zifaneleka kahle ukusetshenziswa kwesakhiwo, ikakhulukazi ezindaweni lapho kudingeka khona ukushisela okuhle nokuqina.

Izifanekiso zizohlangabezana nezidingo ezisebenzayo ze-ASTM A370, iSithasiselo A2.

| Uhlu | Ibanga B | |

| Amandla aqinile, imiz | psi | 58,000 |

| I-MPa | 400 | |

| Amandla okukhiqiza, imiz | psi | 46,000 |

| I-MPa | 315 | |

| Ubude ngokungu-2 in. (50 mm), min,C | % | 23A |

| AIsebenza ebugqilini obucacisiwe bodonga (t ) obulingana noma obukhulu kuno-0.180 in. [4.57mm]. Ngokuqina kodonga olucacisiwe olulula, amanani amancane obude azobalwa ngefomula: iphesenti lobude ngamayintshi angu-2. [50 mm] = 61t+ 12, azungezwe kumaphesenti aseduze. Ku-A500M sebenzisa ifomula elandelayo: 2.4t+ 12, ifinyezwe kumaphesenti aseduze. CAmanani amancane okunweba ashiwo asebenza kuphela ezivivinyweni ezenziwa ngaphambi kokuthunyelwa kweshubhu. | ||

Welddusizotest: Usebenzisa isampula okungenani ama-intshi angu-4 (100 mm) ubude, yenza isifanekiso sibe sicaba nge-weld ku-90 ° ukuya lapho kulayishwa khona kuze kube yilapho ibanga phakathi kwamapuleti lingaphansi kuka-2/3 we-diameter yangaphandle yepayipi. isifanekiso akufanele siqhekeke noma siphuke endaweni yangaphakathi noma yangaphandle phakathi nale nqubo.

Ipayipi ductility test: qhubeka wenze isifanekiso sibe isicaba kuze kube yilapho ibanga phakathi kwamapuleti lingaphansi kwe-1/2 yobubanzi obungaphandle bepayipi. ngalesi sikhathi, ipayipi akufanele libe nemifantu noma ukuphuka endaweni yangaphakathi nangaphandle.

Ubuqothotest: Qhubeka wenze isifanekiso sibe sicaba kuze kube yilapho kuvela ukuphuka noma kuze kube yilapho izimfuneko zokuqina kodonga sezihlangatshezwana nazo. Uma ubufakazi bokucwecwa kwe-ply, impahla engazinzile, noma ukushisela okungaphelele kutholakala ngesikhathi sokuhlolwa kokucaba, isifanekiso sizothathwa njengokungagculisi.

Ukuhlolwa kokuvutha kuyatholakala kumashubhu ayindilinga ≤ 254 mm (10 in) ububanzi, kodwa akuphoqelekile.

Wonke amashubhu ngeke angabi nasici futhi azoba nesiphetho esinjengomsebenzi.

Ukungapheleli kobuso kuzobhekwa njengamaphutha lapho ukujula kwakho kunciphisa ukujiya kodonga olusele lube ngaphansi kuka-90 % wogqinsi olucacisiwe.

Amaphutha afika ku-33% ogqinsi olucacisiwe odongeni ekujuleni angaqedwa ngokuphelele ngokusika noma ukugaya ukuze kuqedelwe insimbi.

Uma kusetshenziswa i-filler welding, inqubo ye-welding emanzi izosetshenziswa futhi insimbi ephumayo ye-weld izosuswa ukuze kugcinwe indawo ebushelelezi.

Ukulimala okungaphezulu, okufana nezimpawu zokubamba, isikhunta esincane noma izimpawu zokugoqa, noma imigodi engashoni, akubhekwa njengeziphambeko inqobo nje uma zingasuswa phakathi kogqinsi olucacisiwe lodonga.

Ulwazi olulandelayo kufanele lufakwe:

Igama lomkhiqizi: Lokhu kungaba igama eliphelele lomkhiqizi noma isifinyezo.

Ibhrendi noma uphawu lokuhweba: Igama lomkhiqizo noma uphawu lokuhweba olusetshenziswa umenzi ukuhlukanisa imikhiqizo yakhe.

Ukucaciswa komklami: I-ASTM A500, engadingi ukufaka unyaka wokushicilelwa.

Incwadi Yebanga: Ibanga B, C noma D.

Kumashubhu esakhiwo ≤ 100mm (4in) ububanzi, amalebula angasetshenziswa ukumaka ulwazi lokuhlonza ngokucacile.

Ngokuyinhloko isetshenziselwa izinjongo zesakhiwo, inikeza amandla adingekayo wemishini kanye nokushisela ukusekela ukuklama nokwakhiwa kwezakhiwo zezakhiwo nezobunjiniyela.

Leli payipi lensimbi lisetshenziswa kabanzi ekwakheni amafreyimu, amabhuloho, izikhungo zezimboni, kanye nezinhlobonhlobo zezinye izingxenye zesakhiwo ezidinga amandla nokuqina.

I-ASTM A370: Izindlela Zokuhlola Nezincazelo Zokuhlolwa Komshini Kwemikhiqizo Yensimbi.

I-ASTM A700: Umhlahlandlela Wokupakisha, Ukumaka, kanye Nezindlela Zokulayisha Zemikhiqizo Yensimbi Yokuthunyelwa.

I-ASTM A751: Izindlela Zokuhlola Nezinqubo Zokuhlaziya Amakhemikhali Emikhiqizo Yensimbi.

Amagama e-ASTM A941 Ahlobene Nensimbi, Insimbi Engagqwali, Ama-alloys Ahlobene, kanye nama-Ferroalloys.

Ngokwezidingo zamakhasimende, ukwelashwa okunqanda ukugqwala kwezindawo zamapayipi ensimbi kungenziwa ngezindlela eziningi ezihlukene ukuze kuthuthukiswe ukumelana nokugqwala nokunweba impilo yayo yokusebenza.

Kubandakanya ukuvenisha, upende, i-galvanization, i-3PE, i-FBE, nezinye izindlela.

Singabakhiqizi nabahlinzeki bepayipi lensimbi yensimbi esezingeni eliphezulu abavela eChina, futhi siphinde sibe nesitoko sepayipi sensimbi esingenamthungo, sikunikeza izixazululo eziningi zamapayipi ensimbi!

Uma ufuna ukwazi ulwazi oluthe xaxa mayelana nemikhiqizo yamapayipi ensimbi, ungaxhumana nathi!