I-ASTM A501 Ibanga Biyipayipi lensimbi elakhiwe ngendlela eshisayo elishiselwe futhi elingenamthungo elinamandla amancane angama-448 MPa (65,000 psi) wezinhlelo zokusebenza ezihlukahlukene zesakhiwo.

I-ASTM A501okokwenziwa kanye nokusebenza kwamashubhu ensimbi ekhabhoni ashiselwe akhiwe ngendlela eshisayo angenamthungo ukuze asetshenziswe ngokwesakhiwo.

Lawa mashubhu ensimbi angaba mnyama (angagqunyiwe) noma afakwe uthayela oshisayo, ogcine ekhuphule ukumelana nokugqwala ngokusebenzisa inqubo yokufaka ama-galvanizing, okwenza kube lula ukuhambisana nezimo eziningi zemvelo.

Lawa mapayipi ensimbi asetshenziswa kakhulu kumabhuloho, ezakhiweni, nakwezinye izinhlelo eziningi ezijwayelekile zesakhiwo.

I-ASTM A501 ihlukanisa ipayipi lensimbi ngamabanga amathathu,Ibanga A, ibanga B, kanye nebanga C.

IBanga B yilona elisetshenziswa kakhulu kula mabanga amathathu ngenxa yokuthi lihlinzeka ngezakhiwo ezilinganiselayo ezinhlelweni eziningi zokusebenza kwesakhiwo.

Insimbi izokwenziwa nguisisekelo-oksijini noma inqubo yokwenza insimbi kagesi-arc-isithando somlilo.

Insimbi ingaphonswa ngama-ingots noma i-strand cast.

Lapho izinsimbi zamabanga ahlukene zisakazwa ngokulandelana ngokulandelana, umkhiqizi wensimbi uzohlonza into ewumphumela yoshintsho futhi ayisuse esebenzisa inqubo emisiwe ehlukanisa kahle amabanga.

Ishubhu izokwenziwa ngenye yalezi zinqubo ezilandelayo:engenamthungo; i-welding-butt-welding (i-welding eqhubekayo); i-electric resistance welding (ERW) noma i-submerged arc welding (SAW)okulandelwa ukushisisa kabusha kuso sonke isigaba esiphambene kanye nokwakheka okushisayo ngenqubo yokunciphisa noma yokubumba, noma kokubili.

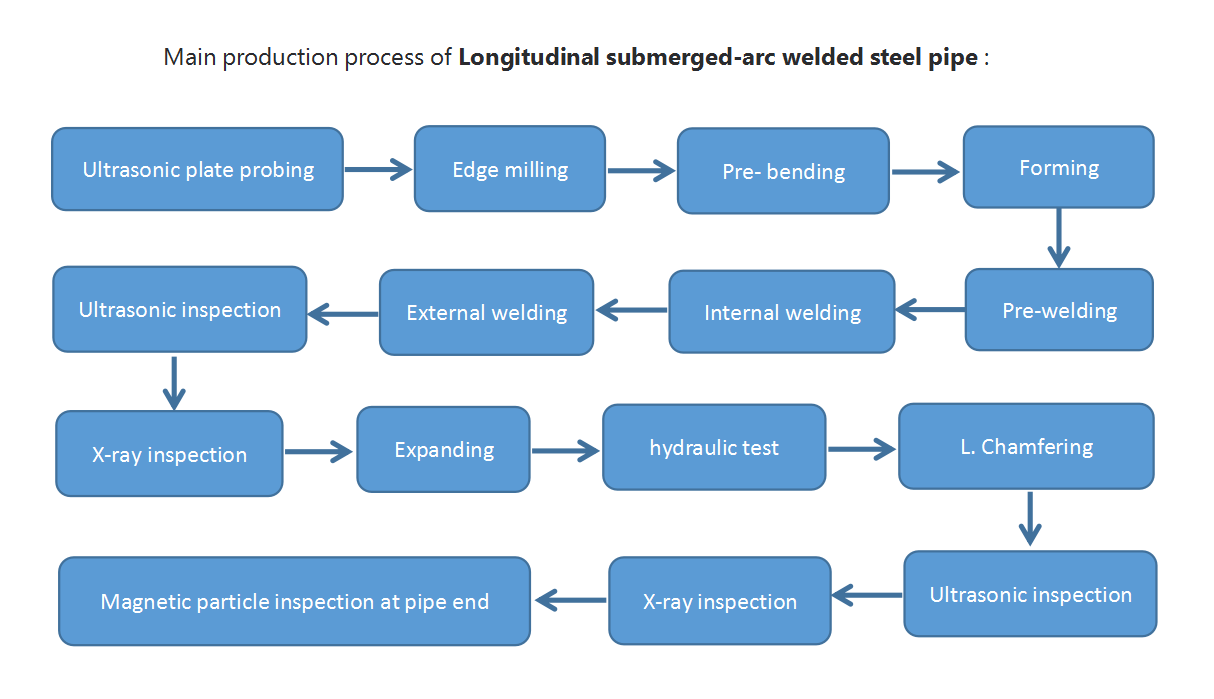

Inqubo ye-welding ye-SAW ihlukaniswe yabaI-LSAW(SAWL) kanye ne-SSAW (HSAW).

Ukubunjwa kokugcina komumo kuzokwenziwa ngenqubo yokubumba eshisayo.

Kuzovunyelwa ukwengeza ukwelashwa okushisa okujwayelekile kwamashubhu anogqinsi olungaphezulu kuka-13mm [1/2 in].

| Izidingo zamakhemikhali ze-ASTM A501 zeBanga B,% | |||

| Ukwakheka | Ibanga B | ||

| Ukuhlaziywa Kokushisa | Ukuhlaziywa Komkhiqizo | ||

| C (Ikhabhoni)B | ubuningi | 0.22 | 0.26 |

| Mn (Manganese)B | ubuningi | 1.40 | 1.45 |

| I-P (Phosphorus) | ubuningi | 0.030 | 0.040 |

| I-S(Sulfur) | ubuningi | 0.020 | 0.030 |

| I-Cu(Copper)B (lapho kucaciswa insimbi yethusi) | imiz | 0.20 | 0.18 |

| BEkuncishisweni ngakunye kwephuzu lephesenti elingu-0.01 ngaphansi kwesilinganiso esiphezulu esishiwo sekhabhoni, kuvunyelwe ukunyuka ngamaphesenti angu-0.06 ngaphezu komkhawulo oshiwo we-manganese, kuze kufike ku-1.60 % ngokuhlaziywa kokushisa kanye no-1.65 % ngokuhlaziywa komkhiqizo. | |||

Ukuhlaziywa komkhiqizo kuzokwenziwa kusetshenziswa izibonelo zokuhlola ezithathwe ebudeni obubili beshubhu endaweni ngayinye enobude obungama-500, noma ingxenyenamba yayo, noma izingcezu ezimbili zesitoko esigoqelwe phansi esitokisini ngasinye senani elihambisanayo lesitoko esigoqelwe phansi.

Izibonelo ze-Tensile zizothobela izimfuneko ezisebenzayo ze-Test Methods and Definitions A370, Appendix A2.

| Izidingo ze-ASTM A501 Grade B Tensile | |||

| Uhlu | Ukuqina Kwezindonga mm [ku] | Ibanga B | |

| Amandla aqinile, min, psi[MPa] | Konke | 65000 [448] | |

| Amandla esivuno, min, psi[MPa] | ≤25 [1] | 46,000 [315] | |

| >25 [1] kanye ≤ 50 [2] | 45,000 [310] | ||

| >50 [2] kanye ≤ 76 [3] | 42,500 [290] | ||

| >76 [3] kanye ≤ 100 [4] | 40,000 [280] | ||

| Ukwelula, iminithi, % | - | 24 | |

| Amandla Anomthelela | iminithi,isilinganiso, ft/Ibf [J] | - | 20 [27] |

| iminithi,ongashadile, ft/Ibf [J] | - | 14 [19] | |

Izibonelo zokuhlolwa kwe-tension zizoba izifanekiso zokuhlola ezinosayizi ogcwele we-longitudinal noma ama-specimens okuhlola ama-longitudinal strip.

Okwamashubhu ashiselwe, noma yiziphi izibonelo zokuhlolwa kwe-longitudinal strip zizothathwa endaweni okungenani engu-90° lapho okushisela khona futhi zizolungiswa ngaphandle kokucaba kubude begeji.

Ukuhlolwa kwe-longitudinal stripama-specimens azokhishwa wonke ama-burrs.

Izibonelo zokuhlolwa kwe-tension akufanele ziqukathe ukungapheleli okungaphezulu okungaphazamisa ukunqunywa okufanele kwezici eziqinile.

Ukuqina kwezindonga ≤ 6.3mm [0.25in] akudingi ukuhlolwa komthelela.

| I-ASTM A501 Dimensional Tolerances | ||

| Uhlu | ububanzi | Qaphela |

| Ububanzi Bangaphandle (OD) | ≤48mm (1.9 in) | ±0.5mm [1/48 in] |

| >50mm (2 in) | ± 1% | |

| Ukuqina Kwebonda (T) | Ukuqina kodonga olucacisiwe | ≥90% |

| Isisindo | isisindo esishiwo | 96.5%-110% |

| Ubude (L) | ≤7m (22 ft) | -6mm (1/4in) - +13mm (1/2in) |

| 7-14m (22-44 ft) | -6mm (1/4in) - +19mm (3/4) | |

| Ukuqondile | Ubude bungamayunithi wasebukhosini (ft) | L/40 |

| Amayunithi obude ayimethrikhi (m) | L/50 | |

Amashubhu esakhiwo ngeke angabi nasici futhi azoba nesiphetho esibushelelezi ngenxa yenqubo yokukhiqiza eginqikayo.

Lapho ukujula kweziphambeko ebusweni bepayipi kudlula u-10% wobukhulu bodonga oluvamile, lezi ziphambeko zizobhekwa njengezingavumelani. Ukulungisa ngokushisela kuzovunyelwa kuphela uma kuvunyelwene phakathi komthengi nomkhiqizi. Ngaphambi kokulungiswa ngokushisela, amaphutha okufanele alungiswe kufanele asuswe ngokuphelele ngokusika noma izindlela zokugaya.

Ukuze ipayipi lesakhiwo libe i-galvanized dip, lokhu kunamathela kufanele kuhambisane nezidingo ezifanele ze-Specification.I-ASTM A53.

Ubude obunye beshubhu yesakhiwo kufanele buphawulwe ngendlela efanelekile, njengokugingqika, ukunyathela, ukunyathela, noma ukudweba.

Ukumaka kwe-ASTM A501 kufanele kube nolwazi olulandelayo njengobuncane:

Igama lomkhiqizi

Ibhrendi noma uphawu lokuhweba

Usayizi

Igama lezinga (unyaka wokushicilelwa awudingeki)

Ibanga

Kumashubhu esakhiwo <50 mm [2 in] OD, kuvunyelwe ukumaka ulwazi lwensimbi kulebula enamathiselwe kunqwaba ngayinye.

Insimbi ye-ASTM A501 yeBanga B ihlanganisa amandla kanye ne-ductility nenqubo yokukhiqiza eshisayo, iyenze ifaneleke ezihlukahlukene zezinhlelo zokusebenza zesakhiwo.

Ukwakha nokwakha: Ivamise ukusetshenziswa ekwakhiweni nasekusetshenzisweni kwezakhiwo lapho kudingeka amandla aphezulu nokuqina kwezinto eziqinile. Lokhu kuhlanganisa izakhiwo, izinkundla zemidlalo, amabhuloho, nezinye izakhiwo.

Izinsiza zezimboni: Ngenxa yamandla ayo aphezulu, ifanele ukusetshenziswa ezindaweni zezimboni ezifana nezimboni nezindawo zokugcina izimpahla lapho ubuqotho besakhiwo bubaluleke kakhulu.

Ingqalasizinda yezokuthutha: leli banga lisetshenziselwa ukwakhiwa kwengqalasizinda yezokuthutha, okuhlanganisa iziteshi zezitimela, izikhumulo zezindiza, nezindawo ezidlula umgwaqo onguthelawayeka.

Izingxenye Zesakhiwo: Ibuye isetshenziswe ngokuvamile ekwenzeni izingxenye zesakhiwo njengamakholomu, imishayo, nama-trusses, okwenza uhlaka lwezakhiwo ezihlukahlukene.

Ukwenziwa kwemishini: Ekukhiqizweni kwemishini esindayo nemishini, ingasetshenziselwa izingxenye ezidinga izingxenye zesakhiwo esinamandla amakhulu.

Umkhiqizi uzonikeza umthengi isitifiketi sokuthobelana esisho ukuthi umkhiqizo wathathwa isampula, wahlolwa, futhi wahlolwa ngokuhambisana nalesi simiso kanye nanoma yiziphi ezinye izidingo ezicaciswe ku-oda lokuthenga noma inkontileka nokuthi zonke lezi zidingo zahlangatshezwana nazo. Isitifiketi sokuthobela umthetho sizobandakanya inombolo ethile kanye nonyaka wokukhishwa.

I-Botop Steel ingumkhiqizi wekhwalithi ephezulu we-Welded Carbon Steel Pipe kanye nabahlinzeki abavela e-China, futhi isitokwe samapayipi ensimbi esingenamthungo.

I-Botop Steel izinikele ngokuqinile kwikhwalithi futhi isebenzisa izilawuli eziqinile nokuhlolaqinisekisa ukwethembeka komkhiqizo. Ithimba layo elinolwazi lihlinzeka ngezixazululo eziqondene nawe kanye nokwesekwa kochwepheshe, ngokugxila ekwanelisekeni kwamakhasimende. Sibheke ngabomvu ukusebenza nawe.