Insimbi ye-ASTM A513iyipayipi yensimbi ye-carbon ne-alloy kanye neshubhu eyenziwe ngensimbi egoqwe ngokushisayo noma ebandayo njengempahla eluhlaza ngenqubo ye-resistance welding (ERW), esetshenziswa kakhulu kuzo zonke izinhlobo zezakhiwo zemishini.

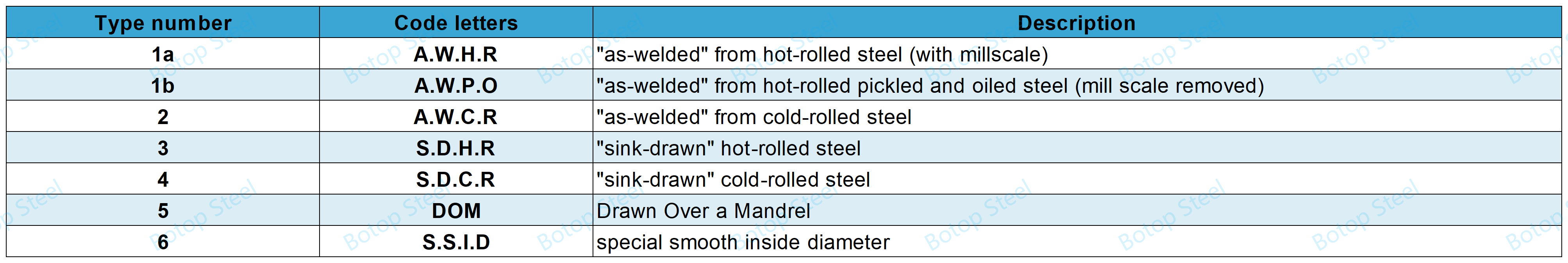

Uhlobo loku-1 lungahlukaniswa lube ngu-1a no-1b.

Uhlobo 1a (AWHR): "njenge-welded" kusuka kunsimbi egoqelwe eshisayo (enesikali sokugaya).

Leli fomu lepayipi lishiselwa ngokuqondile ensimbi egoqwe ngensimbi ene-iron oxide (isikali sokugaya) esakhiwe ngesikhathi sokugoqwa.Lolu hlobo lwepayipi luvame ukusetshenziswa ezinhlelweni lapho ubuqotho bobuso bungabalulekanga ngoba indawo engaphezulu iqukethe isikali sokugaya.

Uhlobo 1b (AWPO): "njenge-welded" kusuka kunsimbi efakwe emanzini anosawoti ashisayo kanye ne-oiled (isikali sokugaya sisusiwe).

Leli fomu lepayipi lishiselwe ngensimbi egoqwe ngokushisayo efakwe emanzini anosawoti futhi igcotshwe ngamafutha futhi ibonakala ngokukhishwa kwesikali sokugaya.Ukwelashwa kokugcotshwa nokugcoba akususi nje kuphela i-oxidation engaphezulu kodwa futhi kunikeza ukuvikeleka kokugqwala nokokugcoba ngesikhathi sokucubungula, okwenza leli payipi lifaneleke kakhulu izinhlelo zokusebenza ezidinga indawo ehlanzekile noma izimo zokucubungula eziqinile kancane.

Izinga lokwenziwa: ASTM A513

Material: Insimbi egoqelwe ngokushisayo noma egoqekile

Inombolo yohlobo:Type1 (1a noma 1b), Type2, Type3, Type4,Uhlobo 5, uhlobo 6.

Ibanga: MT 1010, MT 1015,1006, 1008, 1009 njll.

Ukwelashwa kokushisa: NA, SRA, N.

Usayizi nokuqina kodonga

Umumo wesigaba esingenalutho: Umjikelezo, isikwele, noma ezinye izimo

Ubude

Inani eliphelele

Umjikelezo

Isikwele noma unxande

Ezinye izimo

njengokulandelaniswa, okuyi-hexagonal, i-octagonal, eyindilinga ngaphakathi kanye ne-hexagonal noma i-octagonal ngaphandle, izimbambo ngaphakathi noma ngaphandle, unxantathu, unxande oyindilinga, kanye nokwakheka kuka-D.

I-ASTM A513 I-Round Tubing Type 1 Amabanga ajwayelekile yilawa:

1008,1009,1010,1015,1020,1021,1025,1026,1030,1035,1040,1340,1524,4130,4140.

Okushisayo

Enkambweni yokukhiqiza, insimbi eshisayo iqala ukushisa emazingeni okushisa aphezulu, okuvumela insimbi ukuba igoqwe esimweni sepulasitiki, okwenza kube lula ukushintsha ukuma nobukhulu bensimbi.Ekupheleni kwenqubo yokugoqa okushisayo, impahla ivamise ukukalwa futhi ikhubazekile.

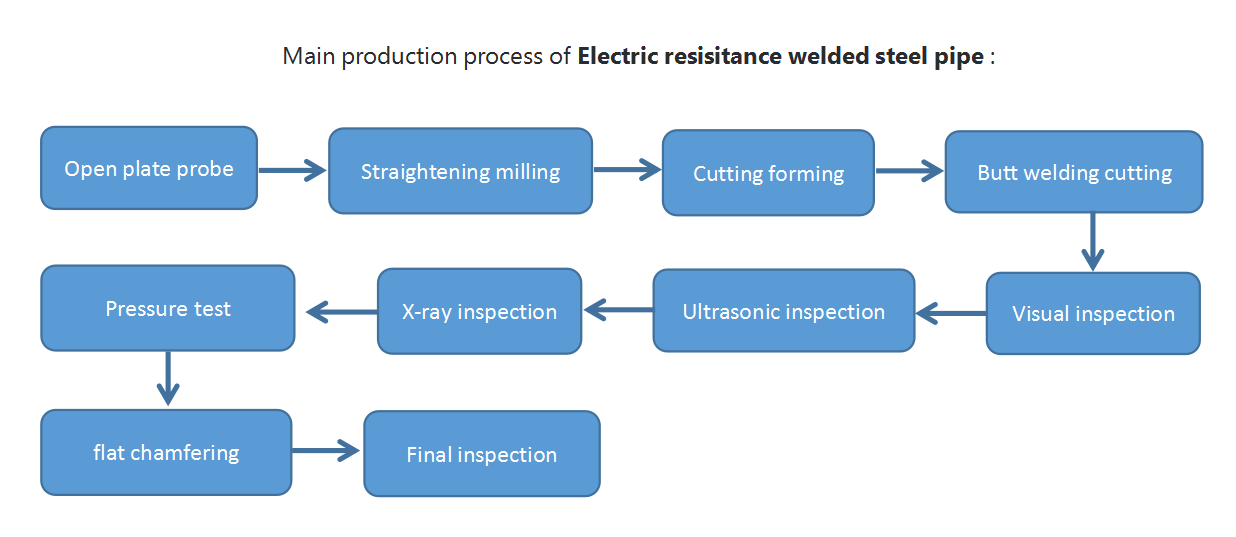

Amashubhu azokwenziwa yi-i-electric-resistance-welded (ERW)inqubo.

Ipayipi le-ERW inqubo yokwenza i-weld ngokugoqa insimbi ibe isilinda futhi ifake ukumelana nokucindezela ngobude bayo.

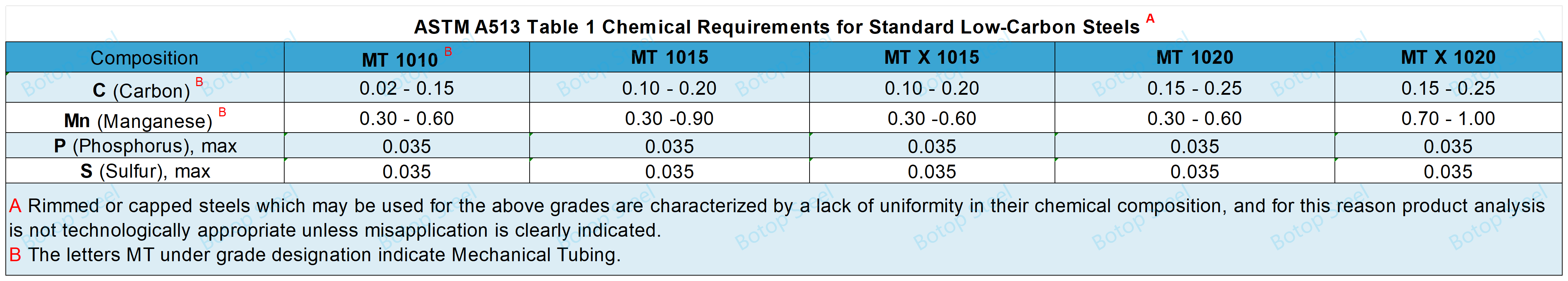

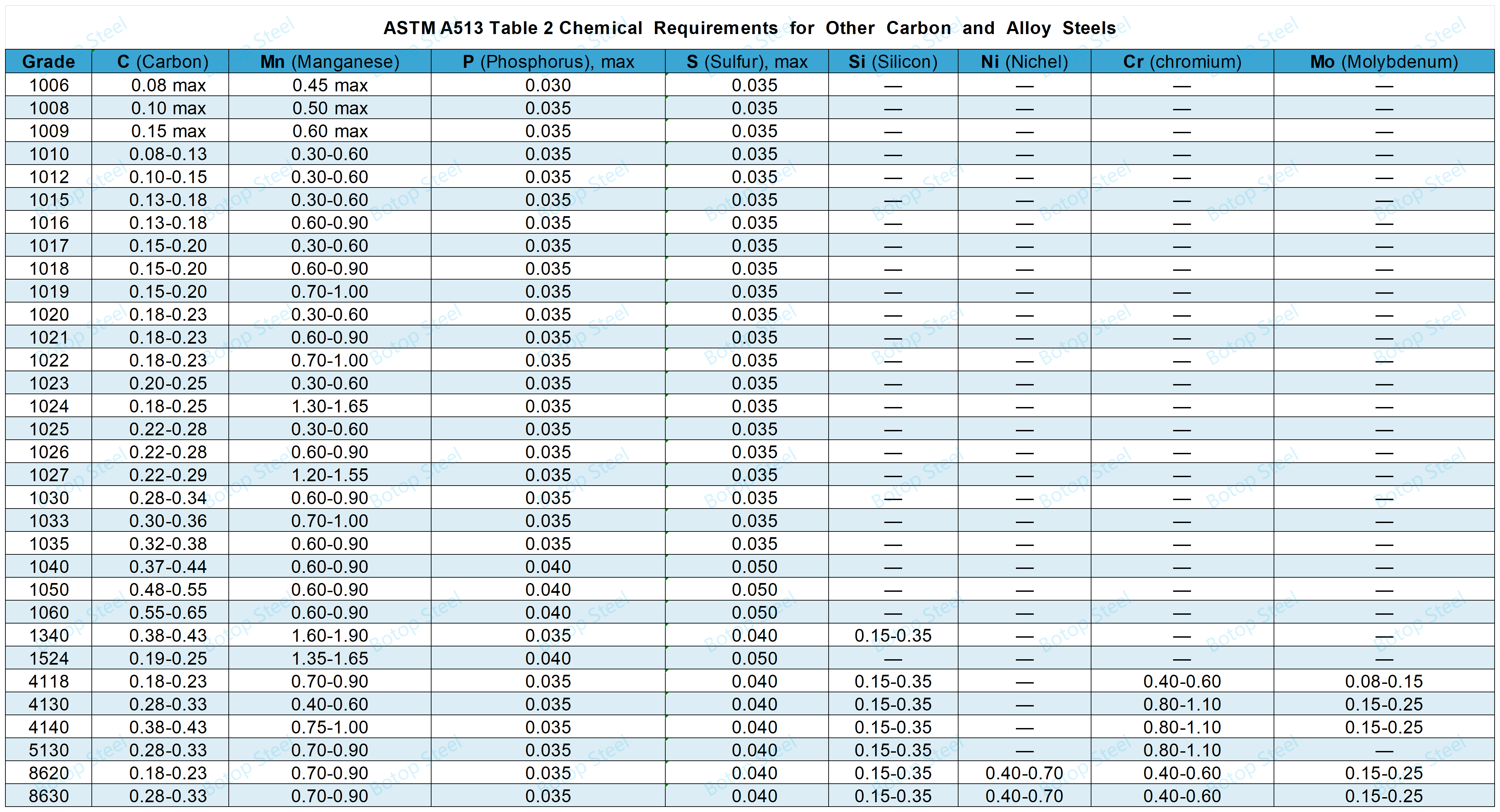

Insimbi kufanele ihambisane nezidingo zokwakheka kwamakhemikhali ezishiwo kuThebula 1 noma Ithebula 2.

| Ibanga | Yied Amandla ksi[MPa],min | Ultimate Amandla ksi[MPa],min | Ukwelula ku-2 in.(50 mm), min, | RB imiz | RB ubuningi |

| I-As-Welded Tubing | |||||

| 1008 | 30 [205] | 42 [290] | 15 | 50 | - |

| 1009 | 30 [205] | 42 [290] | 15 | 50 | - |

| 1010 | 32 [220] | 45 [310] | 15 | 55 | - |

| 1015 | 35 [240] | 48 [330] | 15 | 58 | - |

| 1020 | 38 [260] | 52 [360] | 12 | 62 | - |

| 1021 | 40 [275] | 54 [370] | 12 | 62 | - |

| 1025 | 40 [275] | 56 [385] | 12 | 65 | - |

| 1026 | 45 [310] | 62 [425] | 12 | 68 | - |

| 1030 | 45 [310] | 62 [425] | 10 | 70 | - |

| 1035 | 50 [345] | 66 [455] | 10 | 75 | - |

| 1040 | 50 [345] | 66 [455] | 10 | 75 | - |

| 1340 | 55 [380] | 72 [495] | 10 | 80 | - |

| 1524 | 50 [345] | 66 [455] | 10 | 75 | - |

| 4130 | 55 [380] | 72 [495] | 10 | 80 | - |

| 4140 | 70 [480] | 90 [620] | 10 | 85 | - |

I-RB ibhekisela ku-Rockwell Hardness B Scale.

Izidingo zobulukhuni ezihambisana namabanga athile zingabukwa kuithebula elingenhla le-RB.

I-1% yawo wonke amashubhu esakhiweni ngasinye futhi angabi ngaphansi kwamashubhu ama-5.

Amashubhu ayindilinga namashubhu akha ezinye izimo lapho eyindilinga ayasebenza.

Wonke amashubhu azonikezwa ukuhlolwa kwe-hydrostatic.

Gcina ingcindezi encane yokuhlolwa kwamanzi ingekho ngaphansi kwama-5s.

Ingcindezi ibalwa njenge:

P=2St/D

P= ubuncane bengcindezi yokuhlolwa kwe-hydrostatic, i-psi noma i-MPa,

S= ukucindezeleka kwe-fiber okuvumelekile kwe-14,000 psi noma i-96.5 MPa,

t= ubukhulu bodonga olucacisiwe, ngaphakathi noma mm,

D= kucaciswe ububanzi bangaphandle, in. noma mm.

Kuyinhloso yalokhu kuhlola ukwenqaba amashubhu aqukethe izici ezilimazayo.

Ishubhu ngalinye lizohlolwa ngokuhlolwa kukagesi okungangonakali ngokuhambisana ne-Practice E213, Practice E273, Practice E309, noma Practice E570.

Ububanzi bangaphandle

Ithebula 4Ukubekezelelwa Kobubanzi Bohlobo I (AWHR) Round Tubing

Ukuqina Kwezindonga

Ithebula 6Ukubekezelela Ukuqina Kwezindonga Zohlobo I (AWHR) Round Tubing (Amayunithi Eyintshi)

Ithebula 7Ukubekezelela Ukuqina Kwezindonga Zohlobo I (AWHR) Round Tubing (Amayunithi we-SI)

Ubude

Ithebula 13Ukubekezelela Ubude bokusika kwe-Lathe-Cut Round Tubing

Ithebula 14Ukubekezelela Ubude BePunch-, Saw-, noma Disc-Cut Round Tubing

Squareness

Ithebula 16Ukubekezelela, Ubukhulu bangaphandle Isikwele kanye namashubhu angunxande

Maka ulwazi olulandelayo ngendlela efanele kudondolo noma inqwaba.

igama lomkhiqizi noma umkhiqizo, usayizi oshiwo, uhlobo, inombolo ye-oda lomthengi, kanye nale nombolo ecacisiwe.

Ibhakhodi iyamukeleka njengendlela yokuhlonza eyengeziwe.

Ishubhu ngeke ingabi nasici futhi izoba nesiphetho esifana nomsebenzi.

Imikhawulo yeshubhu kufanele isikwe kahle futhi ingabi nama-burrs noma imiphetho ebukhali.

I-Rolled Chip (Yohlobo 1a): Thayipha 1a (eqonde ngqo kusuka kunsimbi egoqiwe eshisayo enamashiphu agingqelwe) ngokuvamile inendawo yechip egoqiwe.Lesi simo esingaphezulu siyamukeleka ezinhlelweni ezithile lapho kungadingeki ikhwalithi ephezulu.

I-Rolled Chip Ekhishiwe (Yohlobo 1b): Uhlobo 1b (olwenziwe ngensimbi egoqiwe egoqwe ngamafutha nenamafutha afakwe ama-chips asusiwe) inikeza indawo ehlanzekile yezinhlelo zokusebenza ezidinga ukupenda noma ikhwalithi engcono yangaphezulu.

Amashubhu kufanele ambozwe ngefilimu yamafutha ngaphambi kokuthunyelwa ukuze kuvinjwe ukugqwala.

Uma ngabe i-oda lisho ukuthi amashubhu athunyelwe ngaphandleamafutha avimbela ukugqwala, ifilimu yamafutha okungenzeka ukuthi akhiqizwe iyohlala phezulu.

Ingakwazi ukuvimbela ngokuphumelelayo ubuso bepayipi ekuphenduleni ngomswakama nomoya-mpilo emoyeni, ngaleyo ndlela igweme ukugqwala nokugqwala.

Kushibhile: Inqubo yokushisela yensimbi egoqwe eshisayo yenza i-ASTM A513 Type 1 ithengeke kakhulu uma iqhathaniswa nemikhiqizo edonswa abandayo.

Uhlelo olubanzi lwezinhlelo zokusebenza: I-ASTM A513 Uhlobo loku-1 lufanele ukusetshenziswa okuhlukahlukene, okuhlanganisa izingxenye zesakhiwo, amafreyimu, amashelufu, nokuningi.Ukuguquguquka kwayo ezindaweni ezehlukene nemisebenzi kuyenza ibe ukukhetha okudumile ezimbonini ezifana nezezimoto, ezokwakha, nemishini.

I-weldability enhle kakhulu: Ukwakheka kwamakhemikhali e-ASTM A513 Type 1 kuyathandeka ekushiseleni, futhi kungashiselwa kusetshenziswa izindlela ezijwayelekile zokushisela, okuyenza isebenze kakhulu ezindaweni ezahlukahlukene zokukhiqiza.

Amandla amahle nokuqina: Nakuba ingaqinile njengamanye ama-alloy steels noma izinsimbi ezilungisiwe, ihlangabezana nemfuneko yokunikeza amandla anele ezisetshenziswa eziningi zesakhiwo nemishini.Ukucubungula okuqhubekayo, njengokwelashwa kokushisa, kungabuye kuthuthukise izakhiwo zemishini yepayipi ukuze kuhlangabezane nezidingo ezithile.

I-Surface Qeda: Uhlobo 1b lunikeza indawo ehlanzekile, enenzuzo ezinhlelweni zokusebenza lapho kudingeka khona ukuqedwa okuhle kwendawo nalapho kudingeka khona ukudweba noma ukulungiswa okwengeziwe kwendawo.

I-ASTM A513 Type 1 inikeza ibhalansi enhle yezindleko, ukusebenza, kanye nokuguquguquka, iyenze ifanelekele izinhlelo eziningi zokusebenza zemishini nesakhiwo lapho kudingeka khona amashubhu angabizi kakhulu anezici ezinhle zokuwumshini.

Isetshenziswa ekwakheni njengezakhiwo ezisekelayo njengemishayo namakholomu.

Isetshenziswa ekukhiqizeni izingxenye zesakhiwo semishini ehlukahlukene, njengama-bearings namashafts.

Uhlaka kanye nezinhlaka zokusekela emishinini yezolimo.

Isetshenziselwa ukwakha amashelufu ensimbi kanye nezinhlelo zokugcina ezindaweni zokugcina izimpahla nezitolo.

Singomunye wabaphambili abashiselwe ipayipi lensimbi elishiselwe kanye nabakhiqizi nabahlinzeki bepayipi lensimbi engenamthungo abavela eChina, abanohlu olubanzi lwamapayipi ensimbi ekhwalithi ephezulu esitokweni, sizimisele ukukunikeza uhla olugcwele lwezixazululo zamapayipi ensimbi.

Ukuze uthole imininingwane eyengeziwe yomkhiqizo, sicela ukhululeke ukuxhumana nathi, sibheke phambili ekusizeni ukuthi uthole izinketho ezingcono kakhulu zamapayipi ensimbi ngezidingo zakho!